Magnetic field induced arrangement carbon fiber heat conduction material and preparation method thereof

A heat-conducting material and carbon fiber technology, applied in the field of thermal management, can solve the problems of high axial thermal conductivity of carbon fibers, disorderly arrangement of carbon fibers, and inability to give full play to the excellent performance of high axial thermal conductivity of carbon fibers, etc. The preparation method is simple, convenient and easy The effect of promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

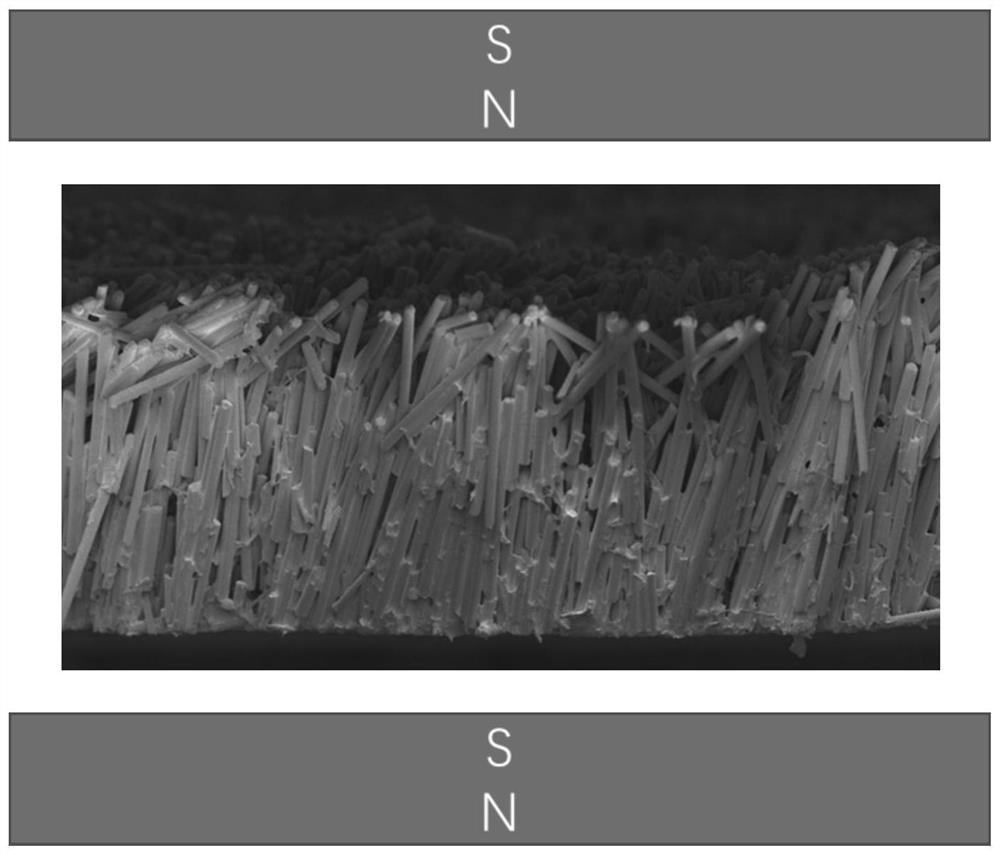

[0025] The preparation process of the aligned carbon fiber heat conducting material is as follows:

[0026] a. Add 60% carbon fiber and 5% to 15% film-forming agent into the polyvinyl alcohol solution, perform mechanical stirring, and ultrasonically disperse;

[0027] b. Transfer the mixture to a glass or other non-magnetic container;

[0028] c. The container and the mixture are transferred to the magnetic field, a certain surface of the container is perpendicular to the direction of the magnetic field, the mixture changes from liquid to solid, and moves out of the magnetic field;

[0029] d. Transfer the solid mixture to an electric constant temperature blast drying oven for further heating and curing.

[0030] e. The thermal conductivity of highly oriented carbon fiber thermal conductive material reaches 65W / (m·K).

Embodiment 1

[0033] A heat-conducting material with aligned carbon fibers, including 10% carbon fibers, 84% vinyl silicone oil, 5% curing agent, and 1% catalyst. The carbon fiber has a diameter of 10 μm and a length of 25 μm.

Embodiment 2

[0035] A thermally conductive material with aligned carbon fibers, comprising 5% carbon fibers, 85% polyvinyl alcohol, and 10% film-forming agent. The fiber has a diameter of 5 μm and a length of 200 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com