Preparation method of piezoelectric ferroelectric ceramic material based on 3D printing technology

A ferroelectric ceramic and 3D printing technology, applied in the direction of additive processing, can solve the problems of complicated operation and cumbersome preparation process, and achieve the effect of short production cycle, optimized performance and improved texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] refer to figure 1 , a method for preparing a piezoelectric ferroelectric ceramic material based on 3D printing technology, comprising the following steps:

[0041] Step 1. Prepare lead-based or lead-free piezoelectric ferroelectric ceramic pre-fired powder. The lead-based or lead-free piezoelectric ferroelectric ceramic pre-fired powder is potassium sodium niobate or lead magnesium niobate-lead titanate pre-fired powder one of the body. The particle size of the lead magnesium niobate-lead titanate or potassium sodium niobate calcined powder is 300-600nm.

[0042] Step 2, making the lead-based or lead-free piezoelectric ferroelectric ceramic pre-fired powder into a 3D printing piezoelectric ferroelectric ceramic slurry;

[0043]Specifically, the lead-based or lead-free piezoelectric ferroelectric ceramic pre-fired powder is mixed with photosensitive resin, photoinitiator and dispersant to obtain 3D printing piezoelectric ferroelectric ceramic slurry: 3D printing piezoe...

Embodiment 1

[0058] A method for preparing a piezoelectric ferroelectric ceramic material based on 3D printing technology provided by the present invention specifically includes the following steps:

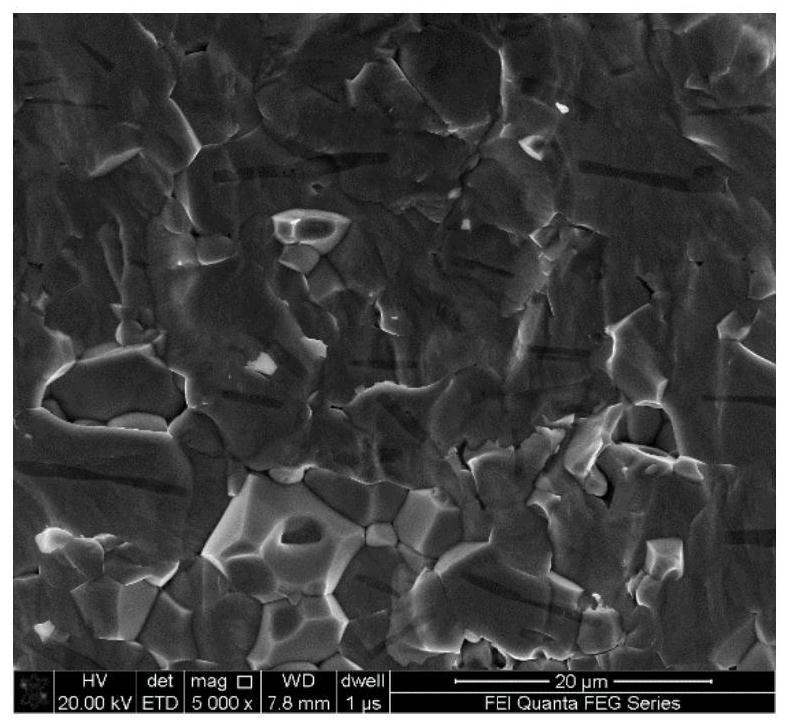

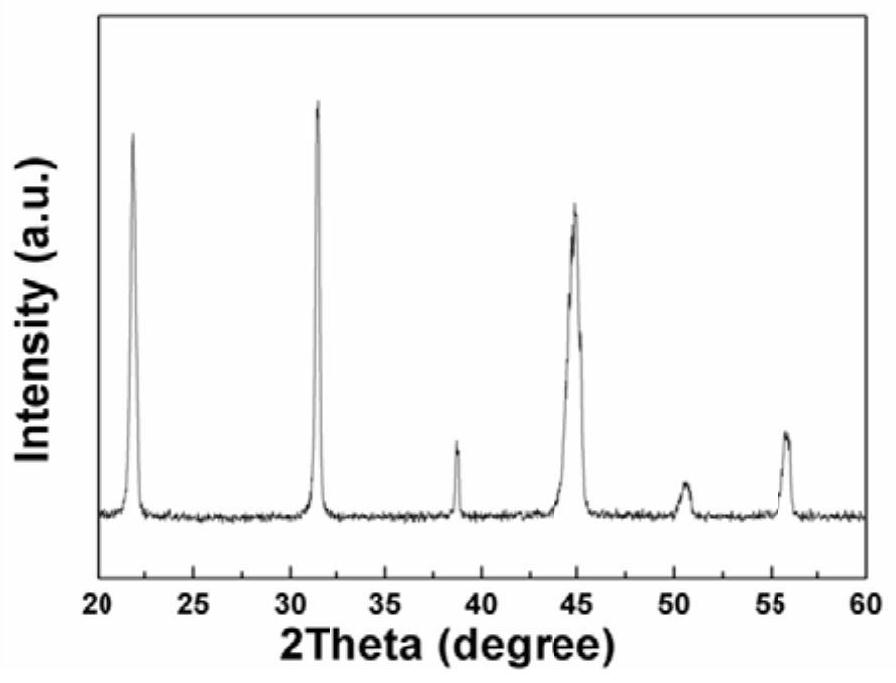

[0059] Step 1, preparing lead magnesium niobate-lead titanate ceramic calcined powder, the particle size of the prepared lead magnesium niobate-lead titanate ceramic calcined powder is 300nm;

[0060] Step 2, the lead magnesium niobate-lead titanate ceramic pre-fired powder is made into a 3D printing piezoelectric ferroelectric ceramic slurry;

[0061] Specifically, (1) weighing according to the weight percentages of piezoelectric ceramic pre-fired powder, photosensitive resin, and dispersant of 70.8wt%, 27wt%, and 1.5wt%, using a ball mill to mix for 4 hours, the speed of the ball mill is 160 rpm, Obtain premix slurry; (2) weigh 1wt% and 0.7wt% template and photoinitiator according to weight percentage, add in premix slurry, adopt ball mill to mix 1h, ball mill speed is 80 rev / min, obtain 3D...

Embodiment 2

[0072] A method for preparing a piezoelectric ferroelectric ceramic material based on 3D printing technology provided by the present invention specifically includes the following steps:

[0073] Step 1, preparing potassium-sodium niobate-based ceramic calcined powder, the particle size of the prepared potassium-sodium niobate-based ceramic calcined powder is 400nm;

[0074] Step 2, making the potassium-sodium niobate-based ceramic pre-fired powder into a 3D printing piezoelectric ferroelectric ceramic slurry;

[0075] Specifically, the potassium sodium niobate-based ceramic calcined powder, photosensitive resin and dispersant are weighed according to the weight percentages of piezoelectric ceramic calcined powder, photosensitive resin and dispersant of 77wt%, 22wt%, and 0.5wt%, Ball milling and mixing to obtain 3D printing piezoelectric ferroelectric ceramic slurry, adding 3wt% sodium niobate template and 0.5wt% photoinitiator.

[0076] Step 3. Prepare a 3D printed piezoelect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com