Automatic turning device for thrust ball bearing ferrule

A thrust ball bearing, automatic technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of reduced production efficiency, energy waste, increased production costs, etc., to avoid scrap, avoid unequal grinding, and improve production. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

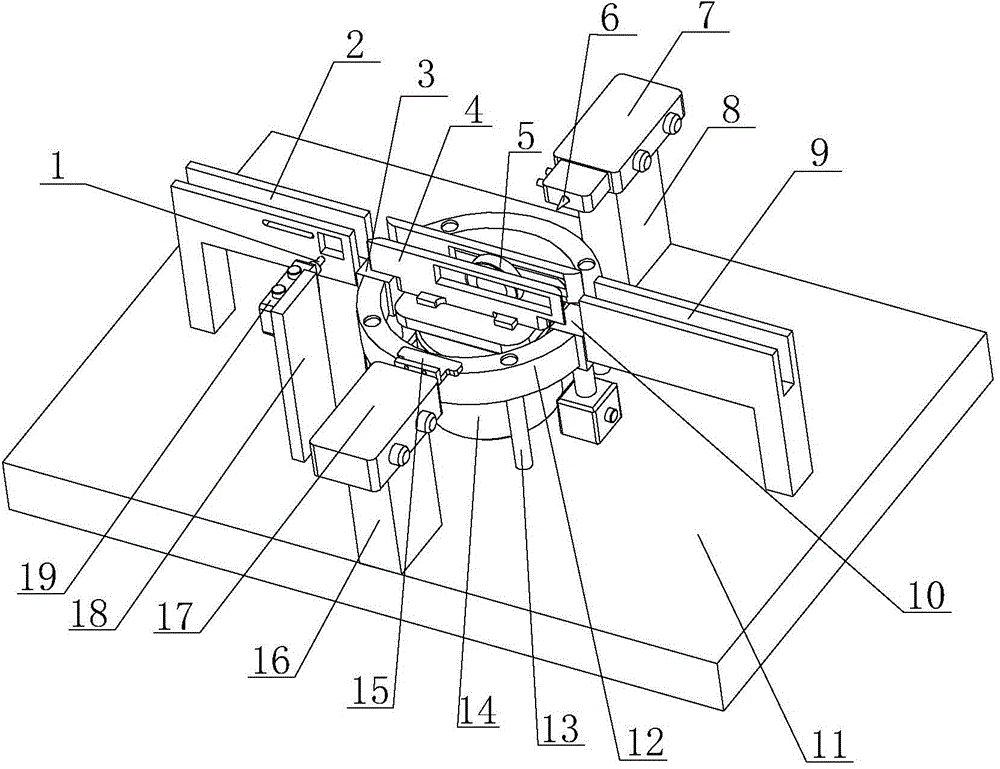

[0014] Such as figure 1 As shown, the present invention comprises base 11, feed channel 2, quantification mechanism, automatic surface turning mechanism, positioning mechanism, detection mechanism, discharge channel 9 and control system, and described automatic surface turning mechanism comprises motor 14, and section becomes U-shaped The positioning feedway and the circular retaining ring 12 that wraps the positioning feedway in the center, the circular retaining ring 12 is supported and fixedly installed on the base 11 by the support rod 13, and the top surface of the circular retaining ring 12 is higher than that of the positioning feedway The bottom surface prevents the workpiece 5 positioned in the positioning feedway from falling out of the positioning feedway when the positioning feedway is rotating. The circular stop ring 12 offers two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com