Ceramic bond grinding tool for oriented arrangement of abrasives and preparation method thereof

A ceramic bond and directional arrangement technology, which is applied in the direction of abrasive materials, grinding/polishing equipment, grinding devices, etc., can solve the problem of low orientation rate of abrasive materials, improve the quality of the grinding surface and improve the effective grinding edge Quantity, the effect of improving the grinding ability of abrasive tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The vitrified bond superabrasive tool with directional arrangement of abrasives in this embodiment is a superhard grinding wheel, which is prepared by a method comprising the following steps:

[0043] 1) Take 100g of CBN abrasive with a particle size of 325 / 400, 30g of vitrified bond powder, 10g of sodium polyacrylate, and 100g of deionized water, mix and stir evenly, adjust the pH to 9 with ammonia water, and ultrasonically disperse for 30 minutes to obtain a slurry;

[0044] The vitrified bond is composed of the following mass percentage components: SiO 2 60%, Al 2 o 3 12%, B 2 o 3 13%, Na 2 O 15%;

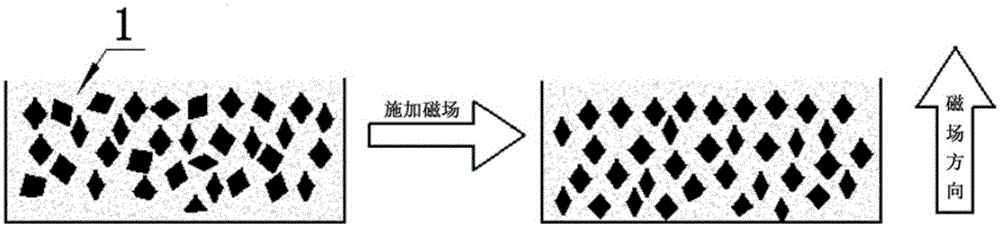

[0045] 2) inject the slurry obtained in step 1) into a plastic mold (grinding wheel forming mold), then place it statically in a strong magnetic field generator, and magnetize it for 20 hours under the condition of a magnetic field strength of 10T to obtain a magnetized slurry;

[0046] Magnetization orientation process such as figure 1 As shown, the slurry 1 is...

Embodiment 2

[0051] The vitrified bond superabrasive tool with directional arrangement of abrasives in this embodiment is a superhard grinding wheel, which is prepared by a method comprising the following steps:

[0052] 1) Take 100g of CBN abrasive with a particle size of W20, 20g of vitrified bond powder, 12g of sodium citrate, and 100g of deionized water, mix and stir evenly, adjust the pH to 10 with ammonia water, and ultrasonically disperse for 60 minutes to obtain a slurry;

[0053] The vitrified bond is composed of the following mass percentage components: SiO 2 70%, Al 2 o 3 5%, B 2 o 3 15%, Na 2 O10%;

[0054] 2) Inject the slurry obtained in step 1) into a plastic mold (grinding wheel forming mold), then place it statically in a strong magnetic field generator, and magnetize it under the condition of a magnetic field strength of 8T for 15 hours to obtain a magnetized slurry; magnetization orientation process With embodiment 1;

[0055] 3) The magnetized slurry obtained ...

Embodiment 3

[0058] The vitrified bond superabrasive tool with directional arrangement of abrasives in this embodiment is a superhard grinding wheel, which is prepared by a method comprising the following steps:

[0059] 1) Take 100g of diamond abrasive with a particle size of W40, 20g of vitrified bond powder, 20g of sodium tripolyphosphate, and 100g of deionized water, mix and stir evenly, adjust the pH to 8 with ammonia water, and ultrasonically disperse for 60 minutes to obtain a slurry;

[0060] The vitrified bond is composed of the following mass percentage components: SiO 2 58%, Al 2 o 3 18.5%, Na 2 O 10.5%, Li 2 O 8%, ZnO 5%;

[0061] 2) Inject the slurry obtained in step 1) into a plastic mold (grinding wheel forming mold), then place it statically in a strong magnetic field generator, and magnetize it for 20 hours under the condition of a magnetic field strength of 12T to obtain a magnetized slurry; magnetization orientation process With embodiment 1;

[0062] 3) The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com