A coating for coating the surface of metal materials and its preparation method

A technology for metal materials and coatings, applied in coatings and other directions, can solve the problems of poor wear resistance of coatings, reduced product qualification rate, insufficient shielding, etc., to improve wear resistance, improve shielding performance, and enhance solvent release. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

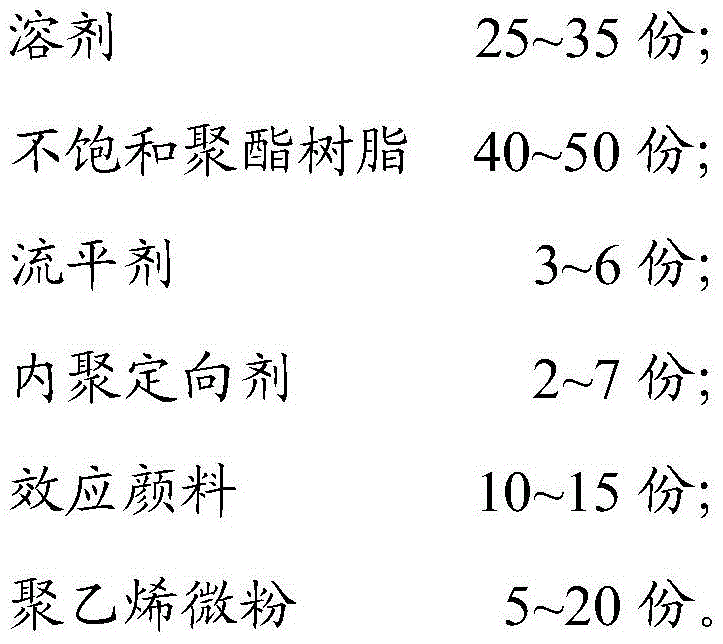

[0030] A coating for coating the surface of metal materials, comprising the following components proportioned in parts by weight:

[0031]

[0032] The above-mentioned coating for coating the surface of metal materials is prepared by the following method:

[0033] (1) Grind and disperse 15 parts of butyl acetate, 40 parts of acrylic resin, and 5 parts of polyethylene micropowder in proportion to make the particle size less than 5 μm;

[0034] (2) After step (1) is completed, add 5 parts of cellulose acetate butyrate CAB381 while stirring, and disperse with a disperser;

[0035] (3) After step (2) is completed, add 5 parts of byk 310 leveling agent while stirring, and disperse with a disperser;

[0036] (4) After step (3) is completed, add 10 parts of aluminum-silver paste while stirring, and disperse with a disperser;

[0037] (5) After the step (4) is completed, add the remaining 15 parts of butyl acetate while stirring, and disperse with a disperser to obtain a coating ...

Embodiment 2

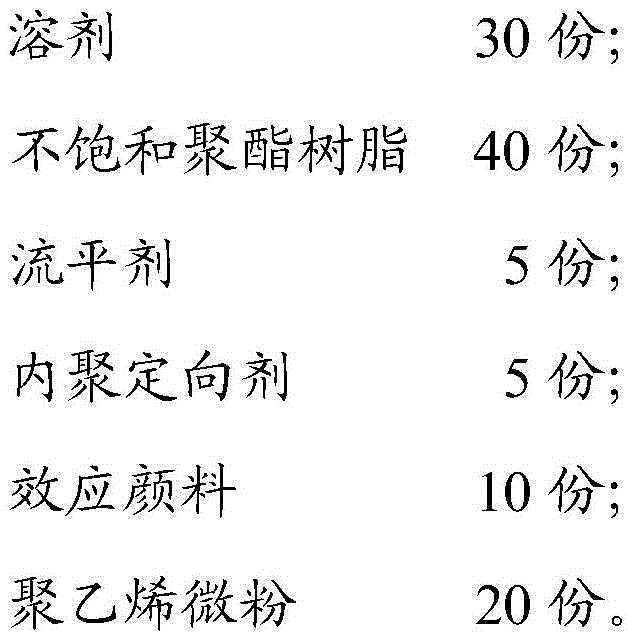

[0040] A coating for coating the surface of metal materials, comprising the following components proportioned in parts by weight:

[0041]

[0042]

[0043] Embodiment 2 preparation method is identical with embodiment 1

Embodiment 3

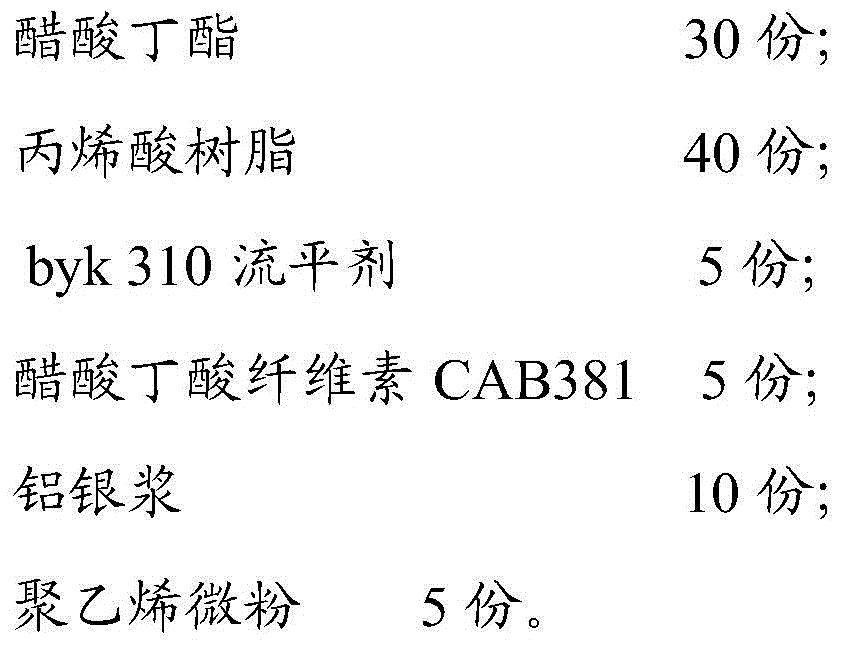

[0045] A coating for coating the surface of metal materials, comprising the following components proportioned in parts by weight:

[0046]

[0047] The preparation method of embodiment 3 is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com