Black pigment special for automobile glass and preparation method thereof

A technology of automotive glass and melanin, which is applied in the field of special melanin for automotive glass and its preparation, can solve the problems of masking and corrosion resistance limitations, high energy consumption at firing temperature, etc., and achieve reduced energy consumption, good hiding power, and shielding properties. and good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

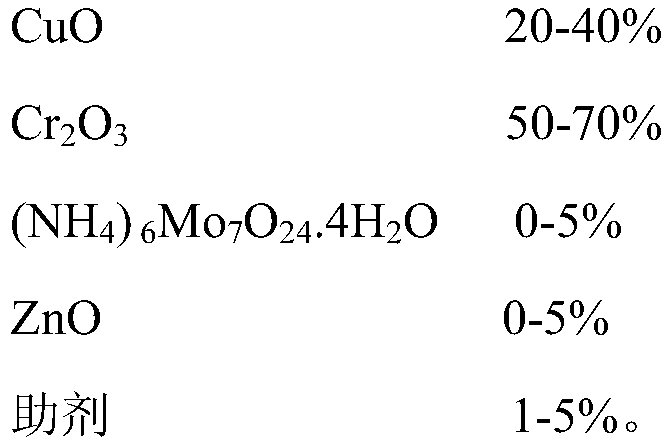

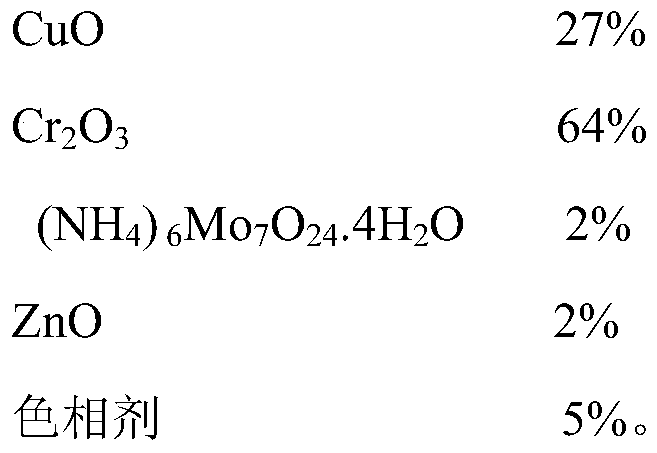

[0028] The special melanin for automobile glass of the present invention, by weight percentage, raw material composition is as follows:

[0029]

[0030] in:

[0031] Hue agent is Fe 2 o 3 .

[0032] The preparation method of special melanin for automobile glass of the present invention comprises the following steps:

[0033] (1) 27% CuO, 64% Cr 2 o 3 , 2% (NH 4 ) 6 Mo 7 o 24 4H 2 O, 2% ZnO, 5% Fe 2 o 3 After mixing evenly, put it into a ball mill and grind it until the particle size is ≤60μm, of which 90% of the particle size is less than 60μm, and then dry it at a temperature of 60°C for 12 hours. After drying, put it into a sagger and put it in a kiln High temperature firing;

[0034] (2) Add the black material fired at a certain temperature obtained in step (1) into a ball mill for secondary grinding until the particle size is 5 μm, wherein 90% of the particle size is 5 μm, and pulverized into powder to obtain the special melanin for automobile glass.

[0...

Embodiment 2

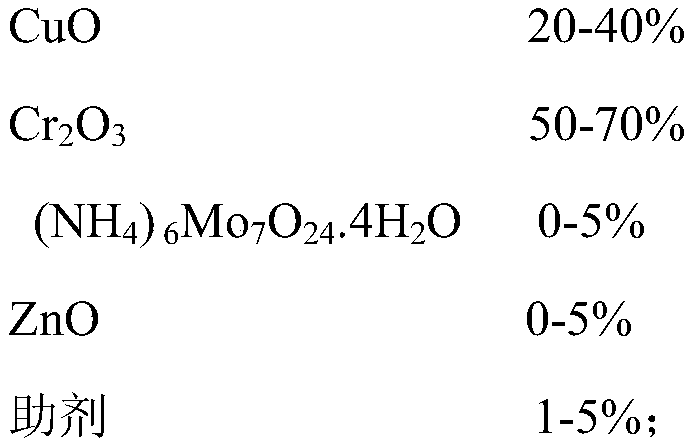

[0038] The special melanin for automobile glass of the present invention, by weight percentage, raw material composition is as follows:

[0039]

[0040]

[0041] in:

[0042] Mineralizer is H 3 BO 3 .

[0043] The preparation method of special melanin for automobile glass of the present invention comprises the following steps:

[0044] (1) 31% CuO, 60% Cr 2 o 3 , 3% (NH 4 ) 6 Mo 7 o 24 4H 2 O, 3% ZnO, 3% H 3 BO 3 After mixing evenly, put it into a ball mill to grind until the particle size is ≤60μm, of which 93% of the particle size is less than 60μm, and then dry it at a temperature of 90°C for 9 hours. After drying, put it into a sagger and place it in a kiln at a high temperature firing;

[0045] (2) Add the black material calcined at a certain temperature obtained in step (1) into a ball mill for secondary grinding until the particle size is 5 μm, wherein 95% of the particle size is less than 5 μm, and pulverized into powder to obtain the special melani...

Embodiment 3

[0049] The special melanin for automobile glass of the present invention, by weight percentage, raw material composition is as follows:

[0050]

[0051] in:

[0052] The masking agent is V 2 o 5 .

[0053] The preparation method of special melanin for automobile glass of the present invention comprises the following steps:

[0054] (1) 31% CuO, 62% Cr 2 o 3 , 3.5% V 2 o 5 Mix evenly with 3.5% ZnO, add to a ball mill and grind until the particle size is ≤60μm, of which the particle size is less than 60μm, accounting for 92%, and then dry at a temperature of 120°C for 6 hours. After drying, put it into a sagger fired in a kiln at high temperature;

[0055] (2) Add the black material fired at a certain temperature obtained in step (1) into a ball mill for secondary grinding to a particle size of 5 μm, wherein 5 μm accounts for 93%, and pulverize it into powder to obtain the special melanin for automotive glass.

[0056] The high-temperature firing described in step (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com