Heat-conducting anisotropic polyamide-imide composite material and preparation method thereof

A technology of polyamide-imide and composite materials, which is applied in the field of thermally conductive anisotropic polyamide-imide composite materials and its preparation, can solve problems such as unsatisfactory mechanical properties, ensure processing performance and mechanical properties, and reduce additives Quantity, the effect of not easy to reunite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

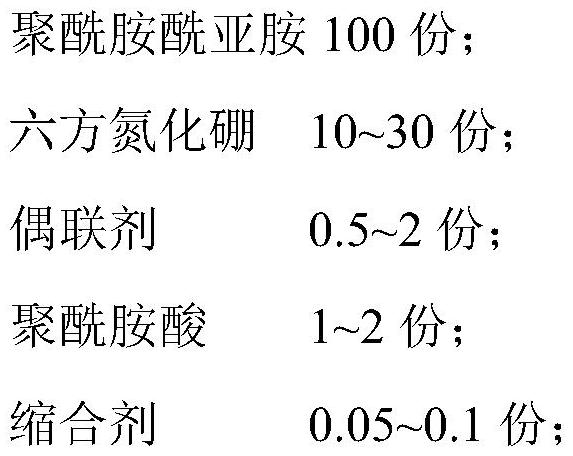

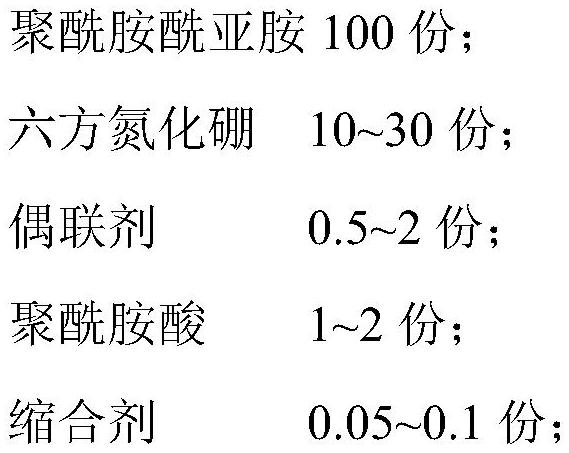

Method used

Image

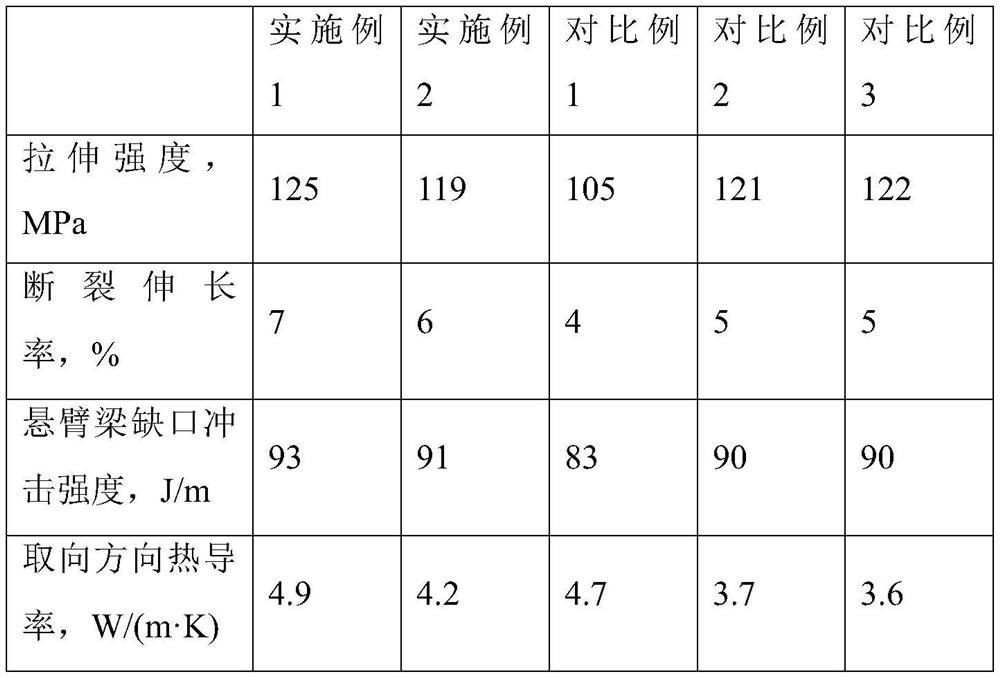

Examples

Embodiment 1

[0052] A preparation method of a thermally conductive anisotropic polyamide-imide composite material, comprising the following steps:

[0053] (1) Dissolve the polyamideimide powder in DMF, the mass ratio is polyamideimide:DMF=1:4, stir and disperse evenly, then ultrasonically vibrate for 1h, and after all the materials are dissolved, polyamideimide is obtained Amine powder solution.

[0054] The h-BN micro-nano powder is treated with mixed acid, wherein the hexagonal boron nitride micro-nano powder is obtained by high-speed mixing of hexagonal boron nitride powder with an average particle size of 50 μm and 30 nm, the mass ratio is 10:3, and the mixed acid is The mixed acid of concentrated nitric acid and concentrated sulfuric acid, the volume ratio is concentrated nitric acid: concentrated sulfuric acid = 1:1, the mass ratio is hexagonal boron nitride: mixed acid = 1:25, after stirring and ultrasonic dispersion at room temperature for 1 hour, in a water bath of 80 ° C The re...

Embodiment 2

[0062] The raw materials used in this example are exactly the same as those in Example 1. The difference is that in this example, a composite material with thermal conductivity anisotropy is obtained by extrusion molding, wherein the thickness of the extrusion die is 1 mm and the width is 50 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com