Orientation heat transfer hexagonal boron nitride/cordierite textured ceramic and preparation method thereof

A technology of hexagonal boron nitride and cordierite, which is applied in the field of textured ceramics and its preparation, can solve the problems of low thermal conductivity and poor heat protection effect, and achieves improved directional heat transfer, simple process and obvious directional heat transfer characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

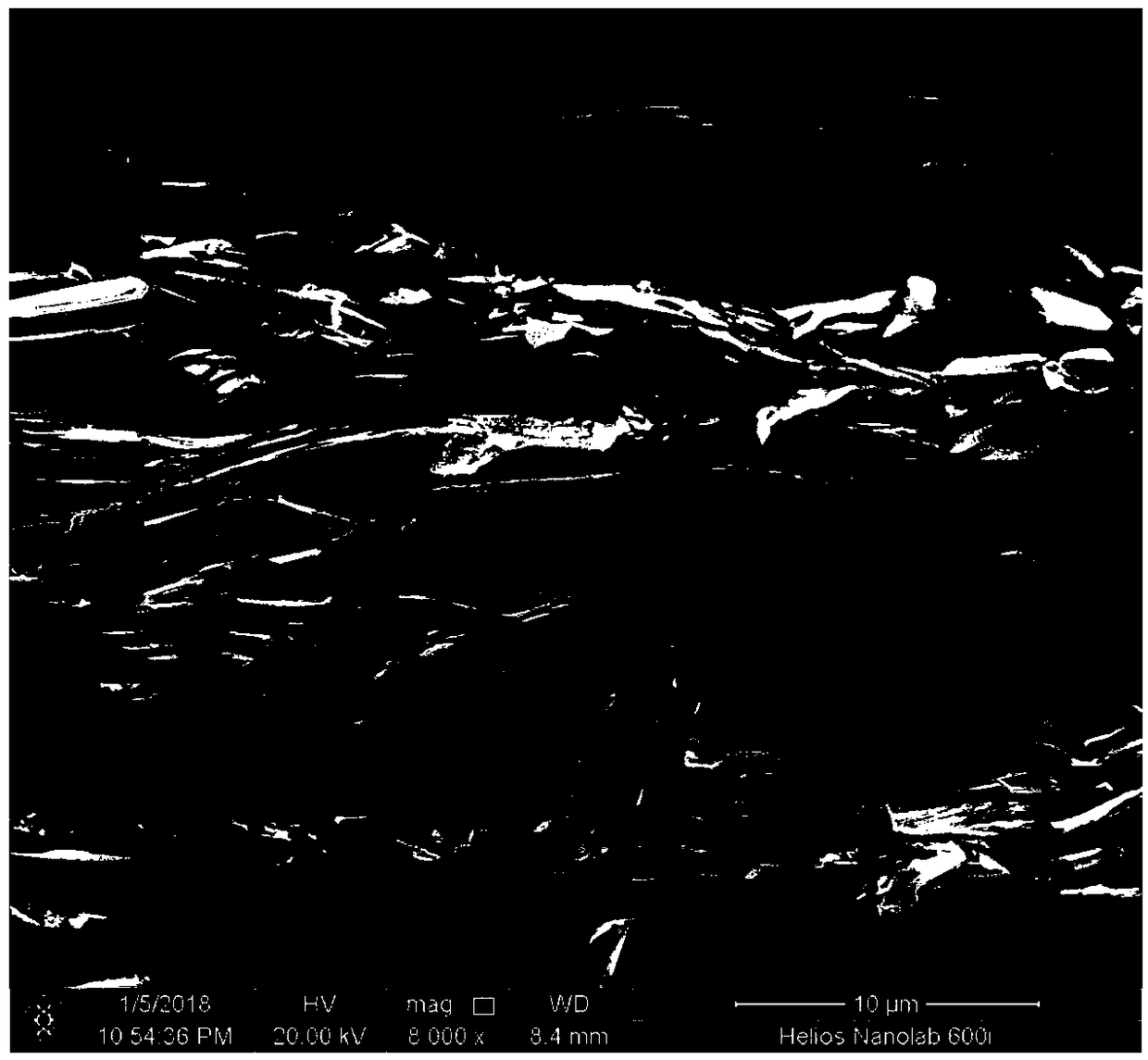

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: In this embodiment, the directional heat transfer hexagonal boron nitride / cordierite textured ceramic consists of 60-90% h-BN powder, 1.38-5.52% MgO powder, 3.49-13.96% Nano-Al 2 o 3 powder and the rest of the fused silica powder.

[0026] The principles and beneficial effects of this embodiment are:

[0027] In order to overcome the problem that the directional heat transfer characteristics of h-BN ceramic matrix composite materials for high temperature are not obvious, this embodiment adds MgO powder, Al 2 o 3 Hexagonal boron nitride / cordierite textured ceramics with texture characteristics are prepared by hot-pressing sintering technology, which can improve the degree of h-BN grain orientation, so that h-BN ceramics can conduct heat in a directional manner, and then Improves its heat resistance.

[0028] 1. In this embodiment, MgO powder and Al are added to h-BN powder 2 o 3 powder and fused silica powder, through MgO, Al 2 o 3 In si...

specific Embodiment approach 2

[0032] Specific embodiment 2: The preparation method of directional heat transfer hexagonal boron nitride / cordierite textured ceramics in this embodiment is carried out according to the following steps:

[0033] 1. Weigh 60-90% of h-BN powder, 1.38-5.52% of MgO powder, and 3.49-13.96% of nano-Al according to mass fraction 2 o 3 The powder and the rest of the fused silica powder are used as raw materials; the raw materials are mixed and then dried by rotary evaporation and sieved to obtain a mixed powder;

[0034] 2. Put the mixed powder into the graphite mold, place the graphite mold on the press for pre-pressing treatment, and obtain the green body;

[0035] 3. Put the pre-pressed green body and the graphite mold together in a hot-press furnace for hot-press sintering, and the process is completed.

[0036] The principles and beneficial effects of this embodiment are:

[0037] In order to overcome the problem that the directional heat transfer characteristics of h-BN ceram...

specific Embodiment approach 3

[0042] Embodiment 3: This embodiment differs from Embodiment 2 in that: the sieve used in step 1 is larger than 80 mesh. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com