Dispensing equipment and method for preparing high thermal conducting interface material by adopting dispensing equipment

A kind of equipment and glue dispensing technology, which is applied in the field of preparing high thermal conductivity interface materials, can solve the problems of difficult cutting of flexible materials, difficult and large size of products, etc., and achieve the effect of excellent thermal conductivity, low cost and optimized process parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

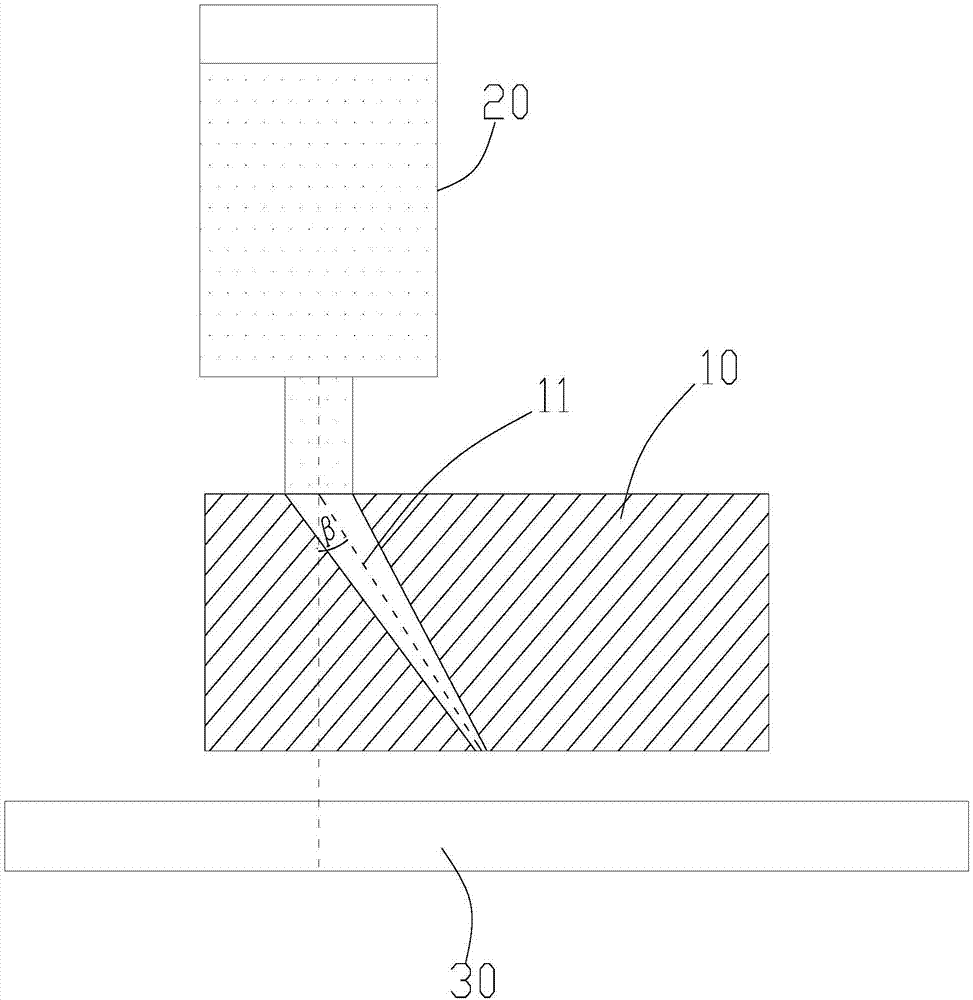

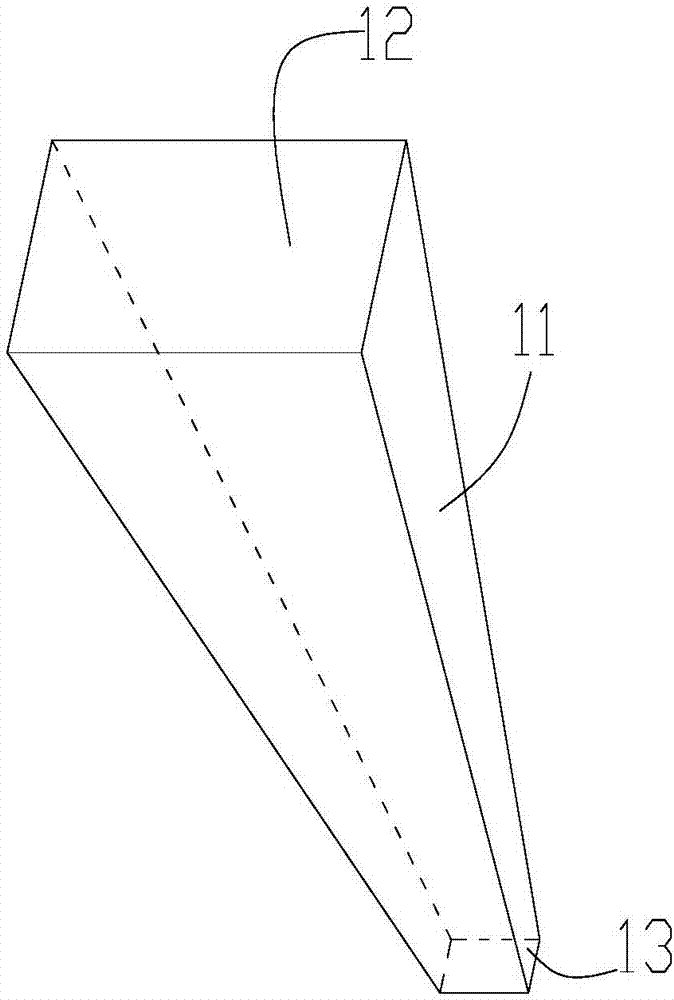

[0047] refer to Figure 1-3, a dispensing device, comprising a dispensing mold 10; the dispensing mold 10 is provided with a glue extrusion channel 11; the glue extrusion channel 11 includes a glue extrusion channel inlet 12 and a through dispensing Outlet 13 of the extrusion channel on the bottom surface of the mold, the cross-sectional area of the extrusion channel gradually decreases from top to bottom; an angle β is formed between the central axis of the extrusion channel and a vertical line, and β is 45°.

[0048] Glue dispensing equipment also comprises the glue barrel 20 that is arranged on the glue dispensing mold 10 tops, and the discharge port of described glue barrel 20 is connected with described extrusion channel inlet, and their cross-sectional area is identical; The cross-section of described glue barrel The area is A1, the cross-sectional area A2 of the inlet of the dispensing mold, and the cross-sectional area A3 of the outlet of the dispensing mold, A1:A2=4...

Embodiment 2

[0054] A dispensing device, comprising a dispensing mold; the dispensing mold is provided with a glue extrusion channel; the glue extrusion channel includes a glue extrusion channel inlet that runs through the top surface of the glue dispensing mold and a glue extrusion channel that runs through the bottom surface of the glue dispensing mold At the outlet, the cross-sectional area of the extruding channel gradually decreases from top to bottom; the central axis of the extruding channel forms an angle β with a vertical line, and β is 30°.

[0055] The dispensing equipment also includes a glue barrel arranged above the glue dispensing mold, the discharge port of the glue barrel is connected with the entrance of the extrusion channel, and their cross-sectional area is the same; the cross-sectional area of the glue barrel is A1 , the cross-sectional area A2 of the inlet of the dispensing mold, the cross-sectional area A3 of the outlet of the dispensing mold, A1:A2=5:1; A2:A3=8:...

Embodiment 3

[0061] A dispensing device, comprising a dispensing mold; the dispensing mold is provided with a glue extrusion channel; the glue extrusion channel includes a glue extrusion channel inlet that runs through the top surface of the glue dispensing mold and a glue extrusion channel that runs through the bottom surface of the glue dispensing mold At the outlet, the cross-sectional area of the extrusion channel gradually decreases from top to bottom; the central axis of the extrusion channel forms an angle β with a vertical line, and β is 60°.

[0062] The dispensing equipment also includes a glue barrel arranged above the glue dispensing mold, the discharge port of the glue barrel is connected with the entrance of the extrusion channel, and their cross-sectional area is the same; the cross-sectional area of the glue barrel is A1 , the cross-sectional area A2 of the inlet of the dispensing mold, the cross-sectional area A3 of the outlet of the dispensing mold, A1:A2=6:1; A2:A3=16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com