Directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method

A technology of chopped carbon fiber and thermoplastic resin, which is applied in the field of composite material preparation, can solve the problems of difficult uniform distribution of fiber filaments, high melt viscosity of resin, and limited fiber content, etc., and achieve the effect of solving orientation difficulties, saving energy, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

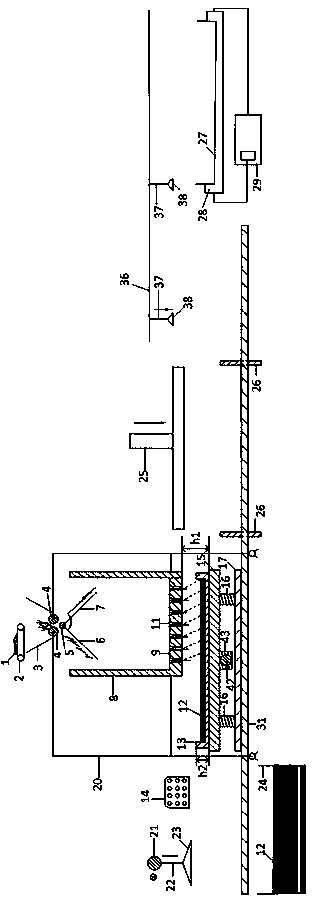

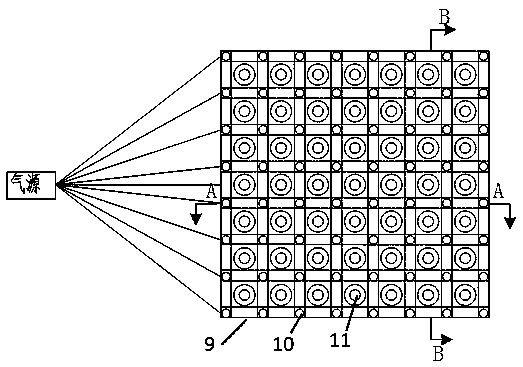

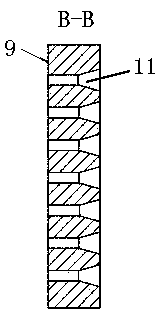

[0025] Such as figure 1 As shown, from left to right, the device for preparing directional cloth chopped carbon fiber thermoplastic resin-based prepreg of the present invention is the first grabbing and transporting unit, the directional laying unit, the compression molding unit, the second grabbing and transporting unit, and the cooling unit.

[0026] Wherein, the first grab transport unit is composed of a first suction cup guide rail 21 , a first telescopic rod 22 , a first vacuum suction cup 23 , an infrared heater 14 , and a raw material box 24 . The first sucker guide rail 21 is placed horizontally front and back, and the raw material box 24 is placed directly under the first sucker guide rail 21 , and the resin film 12 is placed in the raw material box 24 . The infrared heater 14 is disposed on the right side of the first suction cup rail 21 . The first telescopic rod 22 is arranged vertically up and down, and its length can be stretched up and down. The upper end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com