Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

A technology of hybrid welding and high nitrogen steel, applied in the field of hybrid welding of laser and MIG, to achieve the effect of small deformation of workpiece, uniform distribution and fast welding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

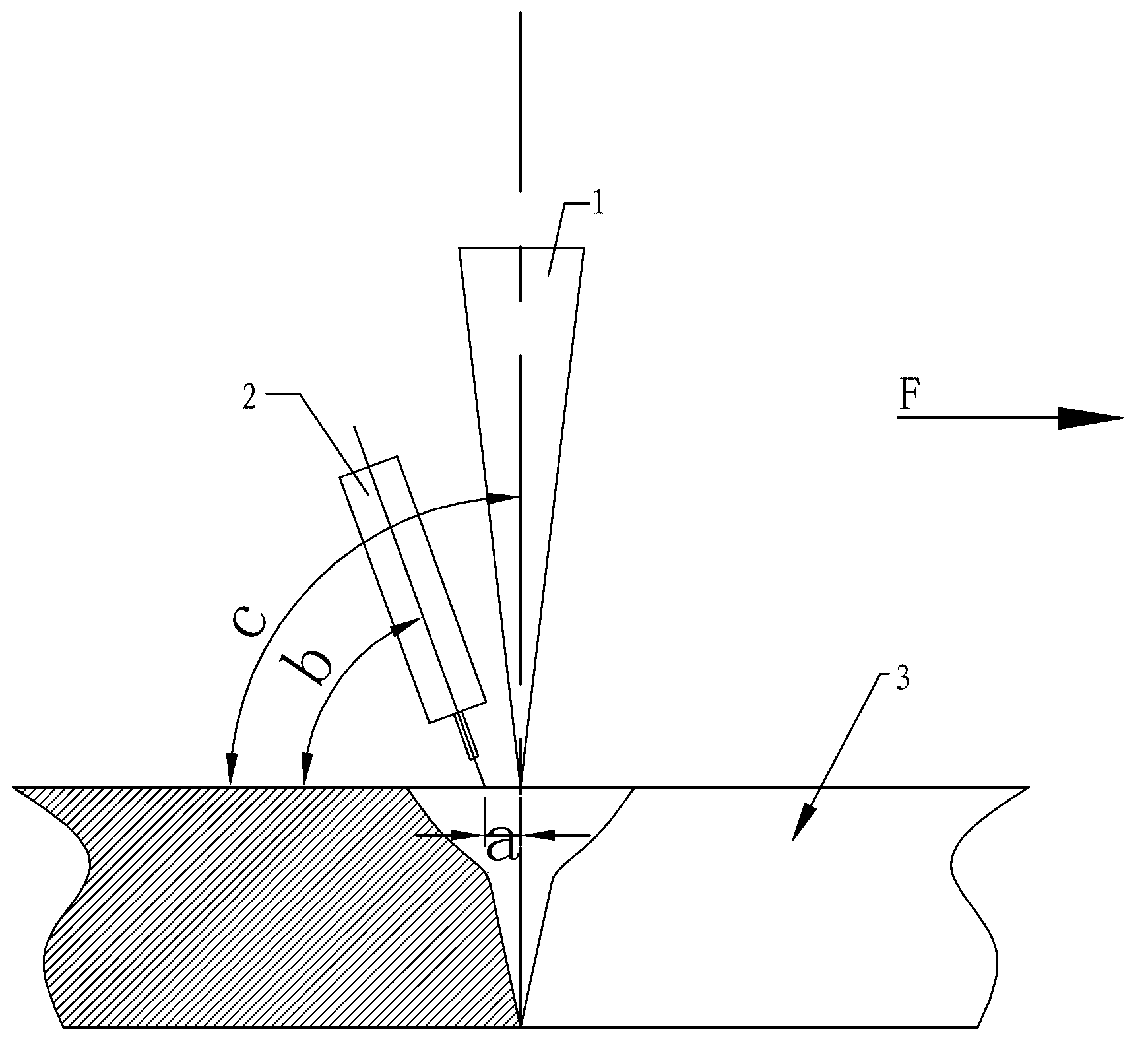

[0035] Example 1, such as figure 1 As shown, the installation requirements of laser beam 1, MIG welding torch 2 and welding test plate 3 are arranged, and F is the welding direction. Where b is the angle between the MIG welding torch 2 and the welding test plate 3, c is the angle between the laser welding torch and the welding test plate 3, and a is the distance between heat sources.

[0036] The laser-MIG arc hybrid welding process of medium-thickness high-nitrogen steel containing 0.6% nitrogen in this embodiment is a single-sided welding and double-sided forming process, and the thickness of the welded high-nitrogen steel plate is 8 mm. It includes the following steps: (1) Design the joint form And the welding method, using single-sided welding without groove, the butt gap between the two welding test plates is 0mm; (2) Set the laser-MIG arc composite welding composite method as laser beam in front, MIG arc in the back, the distance between the two composite heat sources (...

Embodiment 2

[0037] Embodiment 2, the laser-MIG arc hybrid welding process of medium-thickness high-nitrogen steel containing 0.6% nitrogen in this embodiment is a double-sided welding process, and the thickness of the welded high-nitrogen steel plate is 16mm. It includes the following steps: (1) Design joints For the form and welding method, double-sided welding without groove is adopted, and the butt gap between the two welding test plates is 0mm; (2) The laser-MIG hybrid welding method is set to be the laser beam in front and the MIG arc behind, and the distance between the two composite heat sources (3) Set the MIG welding shielding gas, obtain the mixed gas of helium, nitrogen and argon with a volume ratio of 2:3 through the gas mixing valve, and set the welding shielding gas flow rate of the MIG welding machine to 25L / min ; (4) Set the MIG welding process specification, the welding current range is 230A, and the dry elongation of the welding wire is 14mm; (5) Set the laser welding pow...

Embodiment 3

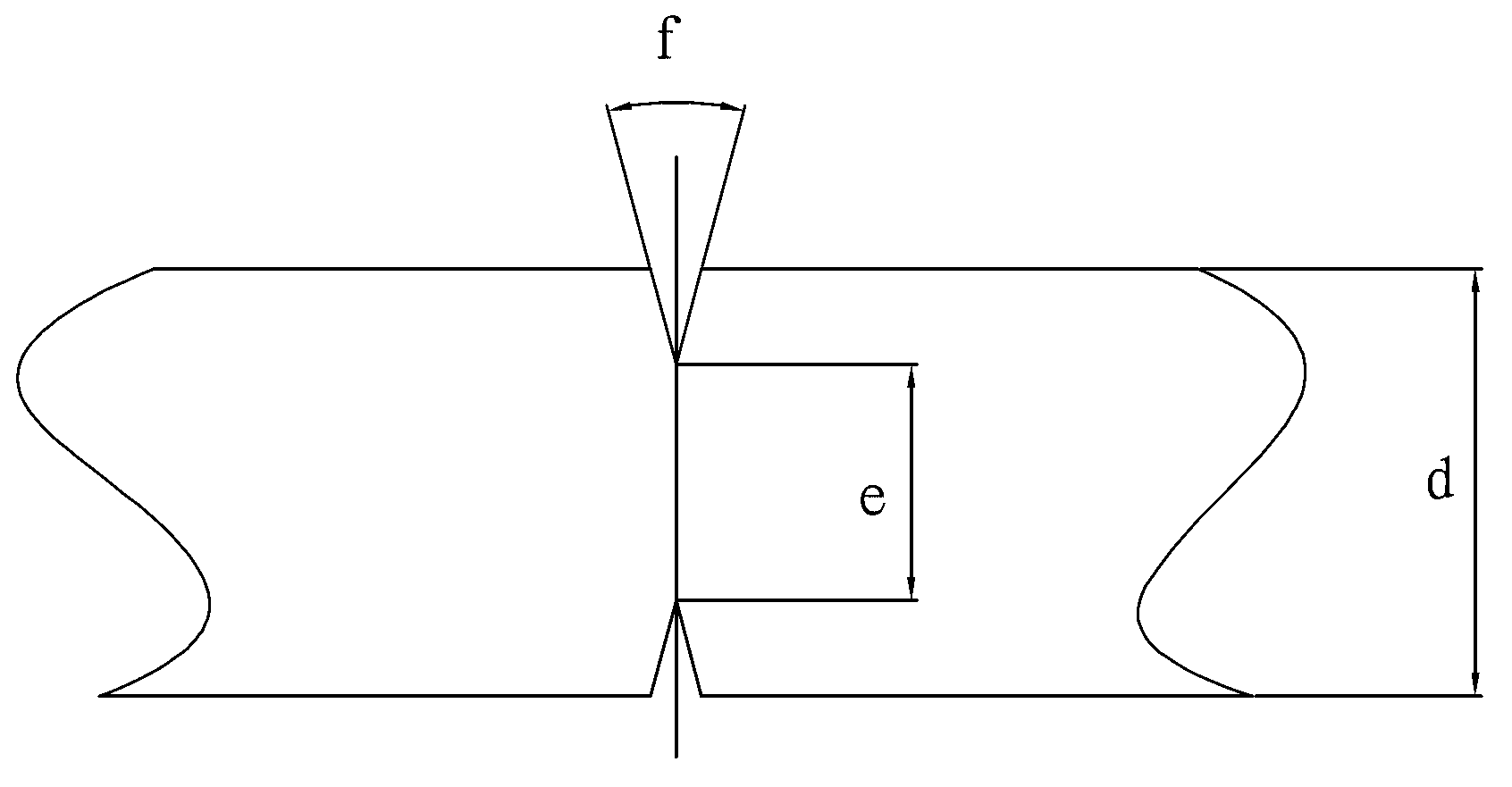

[0038] Example 3, combined with figure 2 As shown, where f is the angle of the break, e is the blunt edge, and d is the thickness of the high nitrogen steel. The laser-MIG composite welding process of the medium-thickness high-nitrogen steel containing 0.6% nitrogen in this embodiment is a double-sided welding process, and the thickness of the welded high-nitrogen steel plate is 20mm. It includes the following steps: (1) Design the joint form and welding method, Attached figure 2 Design the groove of the joint, and adopt double-sided welding, and the butt gap is 0mm; (2) Set the composite mode of laser-MIG hybrid welding as laser beam in front, MIG arc behind, and the distance between the two composite heat sources is 3mm; (3) Set Set the MIG welding shielding gas, obtain the mixed gas of helium, nitrogen and argon with a volume ratio of 2:3 through the gas mixing valve, and set the welding shielding gas flow rate of the MIG welding machine to 30L / min; (4) Set the MIG Weld...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com