Grid cutting equipment

A technology for cutting equipment and grids, applied in shearing machine equipment, metal processing equipment, devices for cutting with nibbling action, etc., can solve problems such as environmental pollution, increase energy consumption, and increase production costs, and solve uneven distribution. , Improve the distribution effect, improve the effect of retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

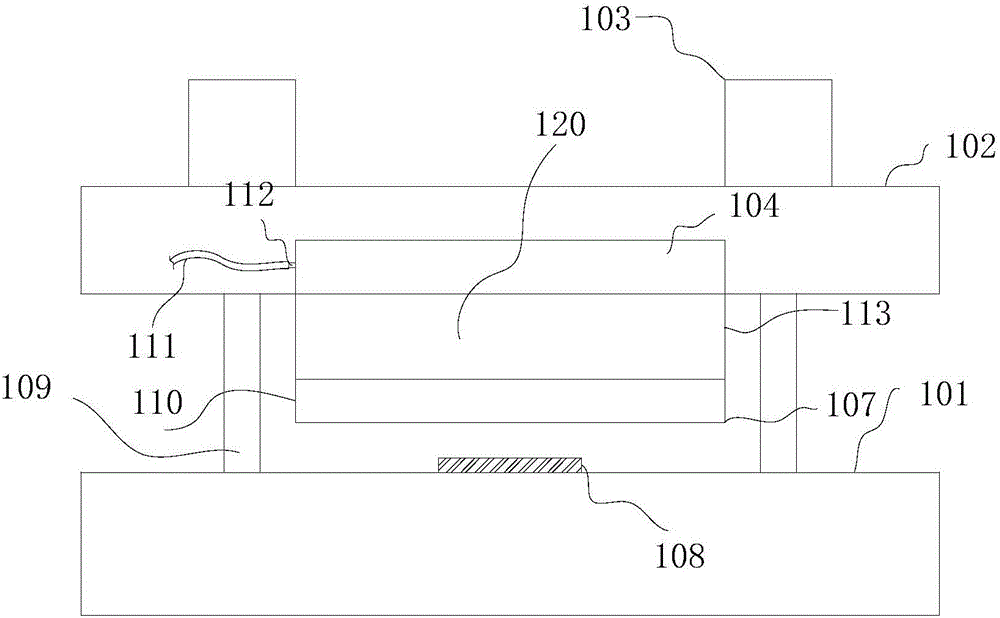

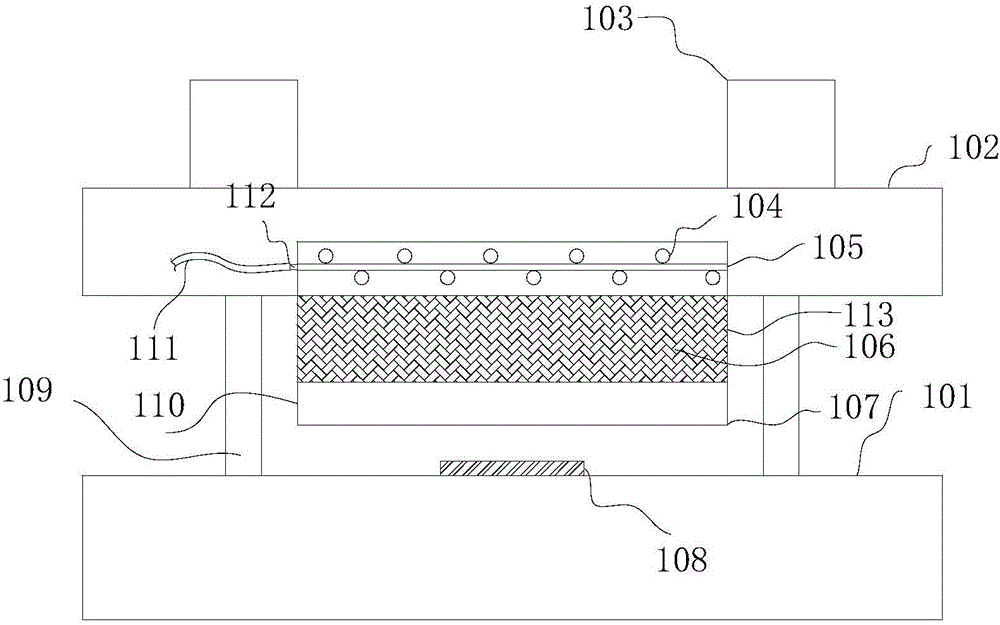

[0035] like Figure 1~3 As shown, a grid cutting equipment includes a frame 101 provided with a grid conveyor belt and a knife frame 102 mounted on the frame 101 and capable of moving relative to the frame 101. The tool frame 102 is provided with a hydraulic cylinder 103. The piston rod 109 of the hydraulic cylinder 103 is fixed to the frame 101, and the hydraulic cylinder 103 is provided with two groups.

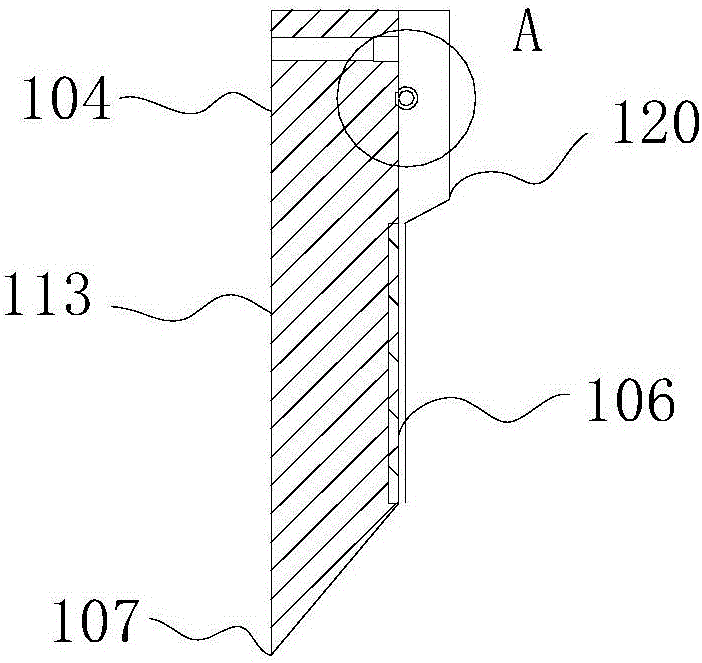

[0036] A cutter 110 for cutting the grid 108 is installed on the knife rest 102, and a dust cover 120 wrapping the tail portion 104 and the cutter body 113 is installed on the cutter 110. The frame 101 is divided into successively: the tail portion 104 for fixing with the knife rest 102, the cutter body 113 protruding from the knife rest 102 and the blade portion 107 for interacting with the grid 108; The cooling pipeline of the heat exchange m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com