Double-column rotary corrosive-wear testing machine

A rotating, double-column technology, used in weather resistance/light resistance/corrosion resistance, wear resistance testing, measuring devices, etc., can solve the problems of uneven medium, limited medium composition, large particle size, etc., to ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

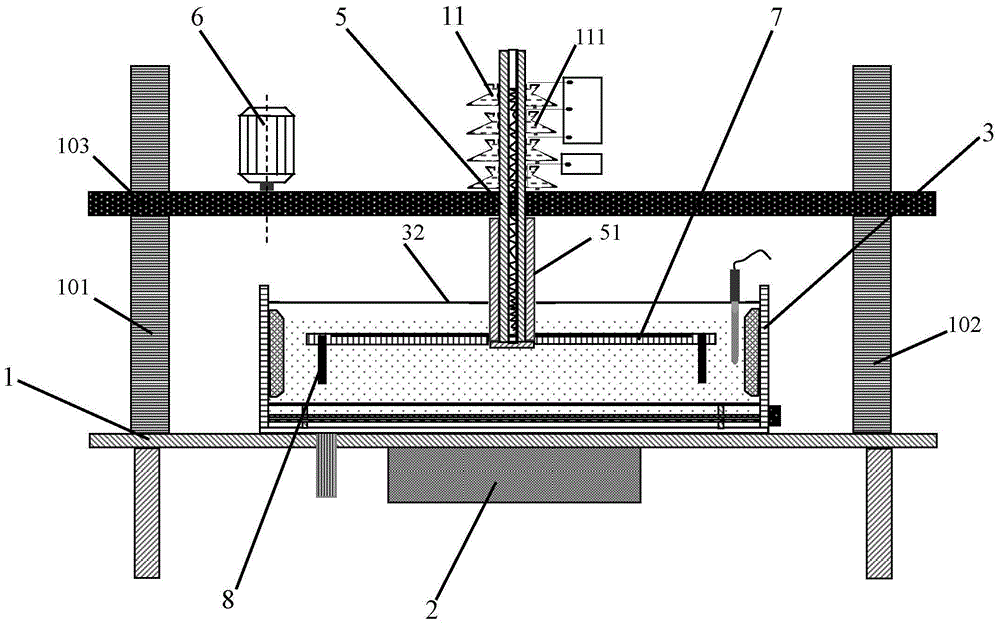

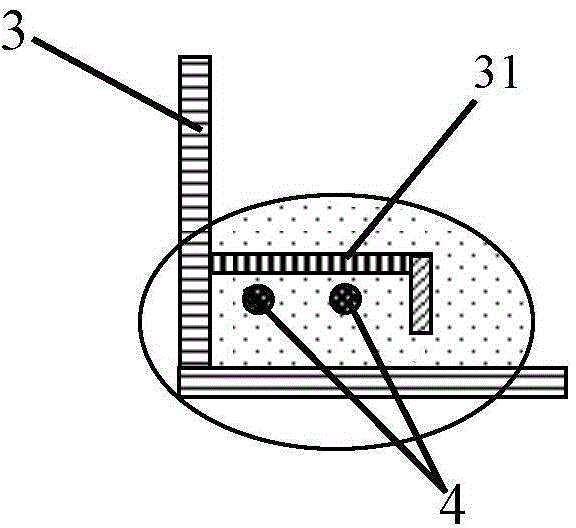

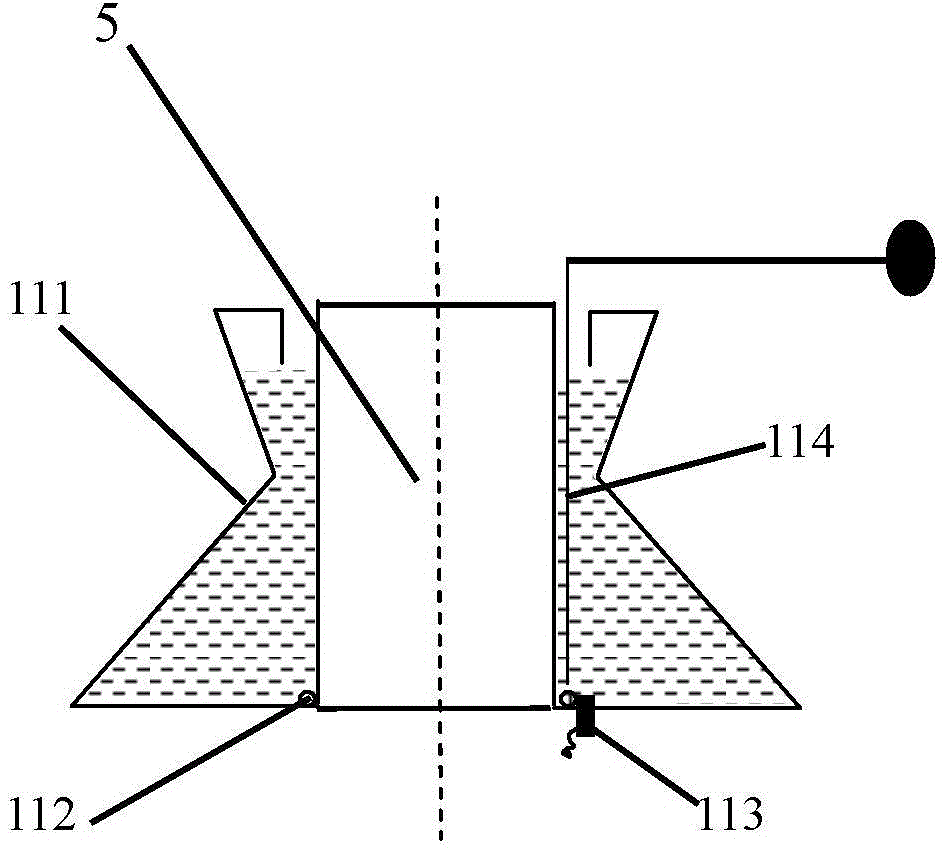

[0050] see Figure 1 to Figure 6 , the double-column rotary abrasion testing machine of the present invention, it comprises, test bench 1, two upright columns 101,102 are set on both sides of the upper end surface, a beam 103 is set on the top of the upright column, and a through hole is set in the center of the beam 103; the beam lifting drive mechanism 2, Set on the test bench 1, connect the crossbeam 103, the crossbeam 103 moves up and down along the columns 101, 102; the test tube 3 is set in the center of the upper end surface of the test bench 1, and the inner and lower part of the test tube 3 is provided with an annular temperature control pipe 4. A pipe cover plate 31 connected to the inner wall of the test cylinder 3 is provided above the temperature control pipeline 4; a cover plate 32 with a central hole is provided at the upper end of the test cylinder 3; the transmission shaft 5 is vertically installed on the test bench 1 In the central through hole of the crossbe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com