Surface modified SiC reinforced aluminum-based composite material and preparation method thereof

A technology of surface modification and composite materials, which is applied in the field of surface modified SiC reinforced aluminum matrix composite materials and its preparation, which can solve the problems of low wear resistance, performance difference, and low strength of composite materials, and achieve uniform distribution of structures and forming good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

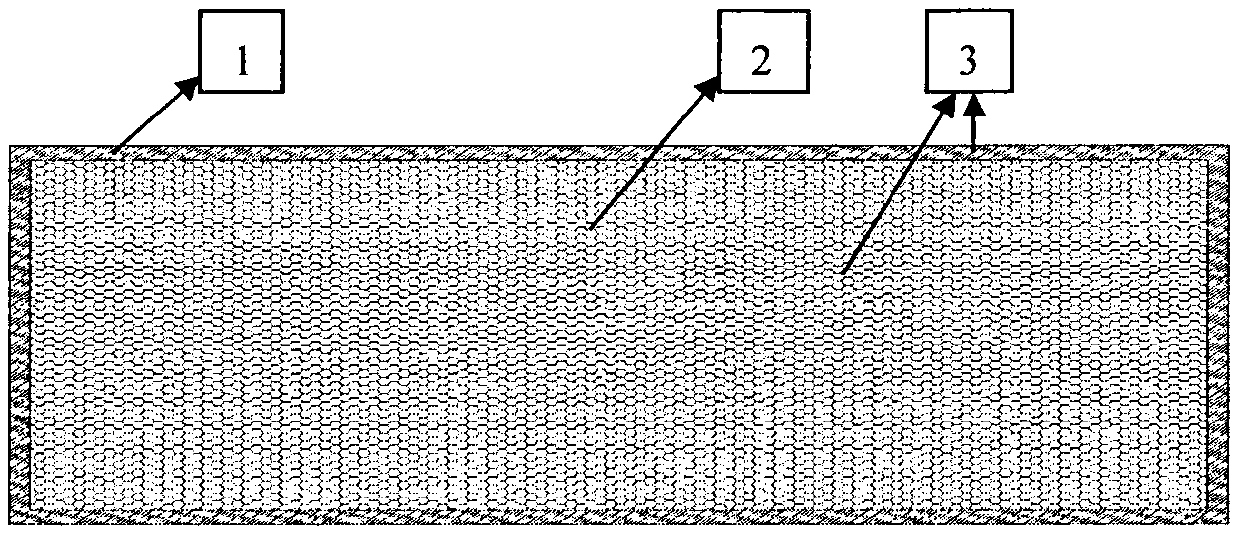

Image

Examples

Embodiment 1

[0023] (1) Clean the porous carbon foam ultrasonically for 30 minutes, and dry it in an oven at 100° C. for 5 hours before use;

[0024] (2) Place the porous carbon foam in (1) in the main temperature zone of the CVI tube furnace, raise it to 1100 °C at 10 °C / min, press CH 3 SiCl 3 :H 2 : Ar is (1:10:9) ratio into Ar, H 2 、CH 3 SiCl 3 , keep the pressure in the tube furnace at 500Pa, deposit for 13h, and finally cool down to room temperature at a rate of 5°C / min to obtain a carbon foam-supported SiC preform;

[0025] (3) Put the SiC prefabricated body supported by carbon foam into a muffle furnace, keep it warm at 650°C for 6 hours, and remove the carbon foam skeleton by oxidation to obtain a SiC porous ceramic body;

[0026] (4) Precursor impregnation and pyrolysis (PIP) of the SiC porous ceramic body: the impregnation solution is polycarbosilane (PCS) xylene solution, the vacuum degree of the impregnation tank is 10Pa, pressurized to 1.8MPa, and maintained at high press...

Embodiment 2

[0031] (1) Clean the porous carbon foam ultrasonically for 30 minutes, and dry it in an oven at 100° C. for 5 hours before use;

[0032] (2) Place the porous carbon foam in (1) in the main temperature zone of the CVI tube furnace, raise it to 1200 °C at 5 °C / min, press CH 3 SiCl 3 :H 2 : Ar is the ratio of (1:10:10) into Ar, H in sequence 2 、CH 3 SiCl 3 , keep the pressure in the tube furnace at 300Pa, deposit for 12h, and finally cool down to room temperature at a rate of 3°C / min to obtain a carbon foam-supported SiC preform;

[0033] (3) Put the SiC prefabricated body supported by carbon foam into a muffle furnace, keep it warm at 700°C for 6 hours, and remove the carbon foam skeleton by oxidation to obtain a SiC porous ceramic body;

[0034] (4) Precursor impregnation and pyrolysis (PIP) of the SiC porous ceramic body: the impregnation solution is polycarbosilane (PCS) xylene solution, the vacuum degree of the impregnation tank is 6Pa, pressurized to 1.5MPa, and mainta...

Embodiment 3

[0039] (1) Clean the porous carbon foam ultrasonically for 30 minutes, and dry it in an oven at 100° C. for 5 hours before use;

[0040] (2) Place the porous carbon foam in (1) in the main temperature zone of the CVI tube furnace, raise it to 1050 °C at 6 °C / min, press CH 3 SiCl 3 :H 2 : Ar is (1:10:9) ratio into Ar, H 2 、CH 3 SiCl 3 , keep the pressure in the tube furnace at 320Pa, deposit for 14h, and finally cool down to room temperature at a rate of 4°C / min to obtain a carbon foam-supported SiC preform;

[0041] (3) Put the SiC prefabricated body supported by carbon foam into a muffle furnace, keep it warm at 620°C for 6 hours, and remove the carbon foam skeleton by oxidation to obtain a SiC porous ceramic body;

[0042] (4) Precursor impregnation and pyrolysis (PIP) of the SiC porous ceramic body: the impregnation solution is polycarbosilane (PCS) xylene solution, the vacuum degree of the impregnation tank is 6Pa, pressurized to 2MPa, and maintains the high pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com