Cu-W-Ni copper matrix composite used for liner, electroforming method and electroforming solution thereof

A copper-based composite material and composite material technology, applied in the field of Cu-W-Ni copper-based composite material and its electroforming method and electroforming solution, can solve the problem of patent application and Authorization, no public literature reports, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Electroforming solution preparation: according to the volume of the electroforming tank, multiply the volume by NiSO 4 ·7H 2 O; Na 2 WO 4 2H 2 O; CuSO 4 ·5H 2 O; CuCl 2 2H 2 O; Na 3 C 6 h 5 o 7 ·H 2 O; C 12 h 25 SO 4 Na; saccharin; 1,4-butynediol concentrations to obtain the required drug weight and volume respectively, and then add the required deionized water to the electroforming tank and heat to 50-70°C. Na first 2 WO 4 2H 2 O was dissolved in deionized water, followed by the addition of Na 3 C 6 h 5 o 7 ·H 2 O; C 12 h 25 SO 4 Na, and stirred for a while, and then added NiSO 4 ·7H 2 O, CuSO 4 ·5H 2 O and CuCl 2 2H 2 O. Finally, saccharin and 1,4-butynediol were respectively added into the electroforming tank, and the temperature was kept constant and fully stirred.

[0024] Pretreatment of cathode and anode materials: the cathode mandrel used is aluminum mandrel, polished with sandpaper before use, rinsed with deionized water, put in...

Embodiment 2

[0028] Prepare the electroforming liquid for preparing Cu-W-Ni copper-based composite material in the electroforming tank, and its composition is:

[0029] NiSO 4 ·7H 2 O: 210g / L; Na 2 WO 4 2H 2 O: 80g / L; CuSO 4 ·5H 2 O: 6g / L; CuCl 2 2H 2 O: 1.5g / L; Na 3 C 6 h 5 o 7 ·H 2 O: 290g / L; C 12 h 25 SO 4 Na: 0.4g / L; Saccharin: 1.0-1.5g / L; 1,4-Butynediol: 0.25-1mL / L.

[0030]The anode material is domestic phosphor copper plate (Cu is 99.9%, P is 0.02-0.06%), and a metal copper plate with a thickness of 1mm is used as the cathode;

[0031] The process conditions are: pH=6.0; temperature 55°C; current density=15A / dm 2 ; Stirring method: mechanical stirring; electroforming time: 2-4h.

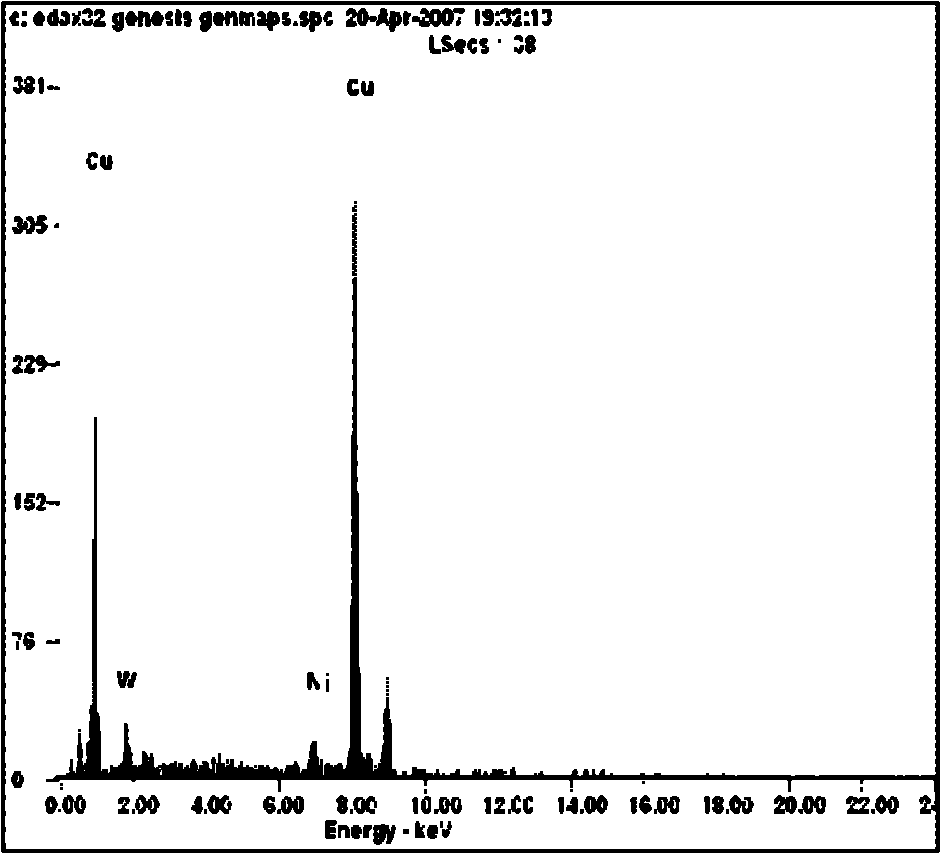

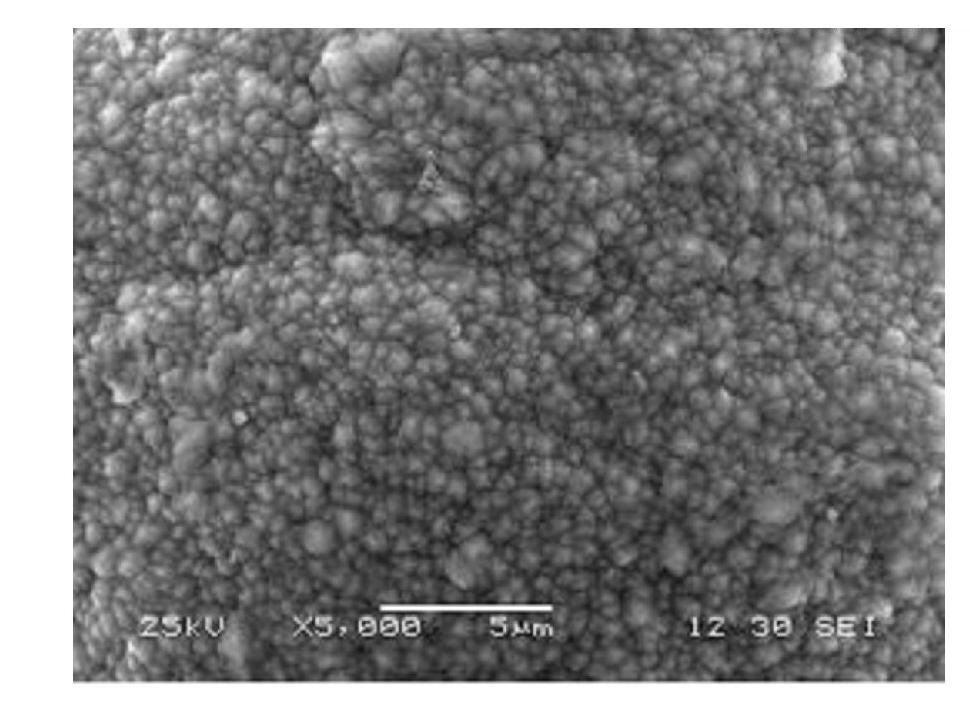

[0032] In the obtained Cu-W-Ni copper-based composite material, the copper content is 85.6% (percentage by weight), the nickel content is 8.4%, and the tungsten content is 6%, and the material structure is evenly distributed, and the crystal grains are ultrafine. See figure 1 and figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com