Boron magnesium co-doped VO2 powder, preparation method and application thereof

A VO2 and co-doping technology, which is applied in chemical instruments and methods, nanotechnology, color-changing fluorescent materials, etc., can solve the problem of not being able to obtain VO2 materials with both low phase transition temperature and high visible light transmittance, and reach the phase transition temperature The effect of low, uniform tissue distribution and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

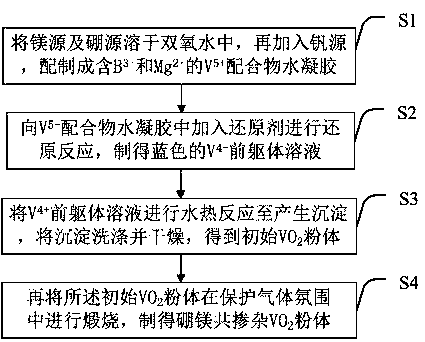

[0048] Follow V 0.93 B 0.02 Mg 0.05 o 2 The composition ratio weighs the corresponding amount of 0.546gV 2 o 5 Powder, 0.0186g H 3 BO 3 Powder, 0.0121g MgCO 3 powder; at 80°C, the H 3 BO 3 Powder and MgCO 3 The powder was dissolved in 60ml of 15% H 2 o 2 , stir for 10 minutes until completely dissolved, then add VO while stirring 2 Powder, containing B after violent reaction 3+ and Mg 2+ V 5+ complex hydrogel;

[0049] Weigh 1.1345g H 2 C 2 o 2 2H 2 O, add to the complex hydrosol obtained above, stir well until the blue V is formed 4+ Precursor solution, and continue to react at 80°C for 30 minutes;

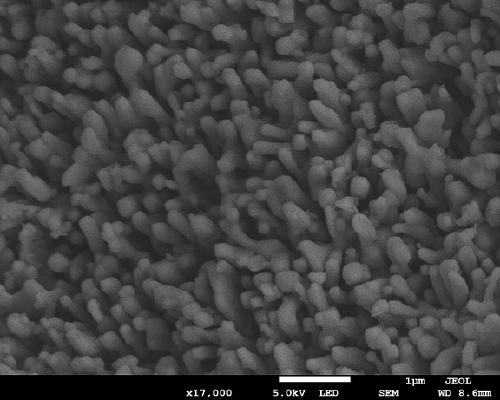

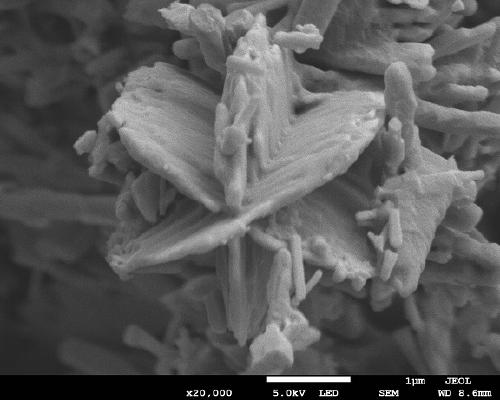

[0050] The blue precursor obtained above was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 200°C for 72 hours. After the reaction was completed, a blue-black precipitate was obtained, which was washed repeatedly by centrifugation, deionized water and absolute ethanol, and heated at 80°C. Vacuum drying to obtain a blue-black pow...

Embodiment 2

[0055] Follow V 0.91 B 0.04 Mg 0.05 o 2 The composition ratio weighs the corresponding amount of 0.546g V 2 o 5 Powder, 0.0372g H 3 BO 3 Powder, 0.0121g MgCO 3 powder; at 80°C, the H 3 BO 3 Powder and MgCO 3 The powder was dissolved in 60ml of 15% H 2 o 2 In the medium, stir for 10 minutes until completely dissolved, then add V while stirring 2 o 5 Powder, containing B after violent reaction 3+ and Mg 2+ V 5+ complex hydrogel;

[0056] Weigh 1.1345g H 2 C 2 o 2 2H 2 O, add to the complex hydrosol obtained above, stir well until the blue V is formed 4+ Precursor solution, and continue to react at 80°C for 30 minutes;

[0057] The blue precursor obtained above was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 200°C for 72 hours. After the reaction was completed, a blue-black precipitate was obtained, which was washed repeatedly by centrifugation, deionized water and absolute ethanol, and heated at 80°C. Vacuum drying to obtai...

Embodiment 3

[0062] Follow V 0.89 B 0.06 Mg 0.05 o 2 The composition ratio weighs the corresponding amount of 0.546g V 2 o 5 Powder, 0.0558g H 3 BO 3 Powder, 0.0121g MgCO 3 powder; at 80°C, the H 3 BO 3 Powder and MgCO 3 The powder was dissolved in 60ml of 15% H 2 o 2 In the medium, stir for 10 minutes until completely dissolved, then add V while stirring 2 o 5 Powder, containing B after violent reaction 3+ and Mg 2+ V 5+ complex hydrogel;

[0063] Weigh 1.1345g H 2 C 2 o 2 2H 2 O, add to the complex hydrosol obtained above, stir well until the blue V is formed 4+ Precursor solution, and continue to react at 80°C for 30 minutes;

[0064] The blue precursor obtained above was transferred to a hydrothermal reaction kettle, and hydrothermally reacted at 200°C for 72 hours. After the reaction was completed, a blue-black precipitate was obtained, which was washed repeatedly by centrifugation, deionized water and absolute ethanol, and heated at 80°C. Vacuum drying to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com