Method for preparing high silicon steel strip by powder tape casting and high-temperature diffusion sintering

A technology of tape casting and high temperature diffusion, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of unsatisfactory scale and output, harsh working environment and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

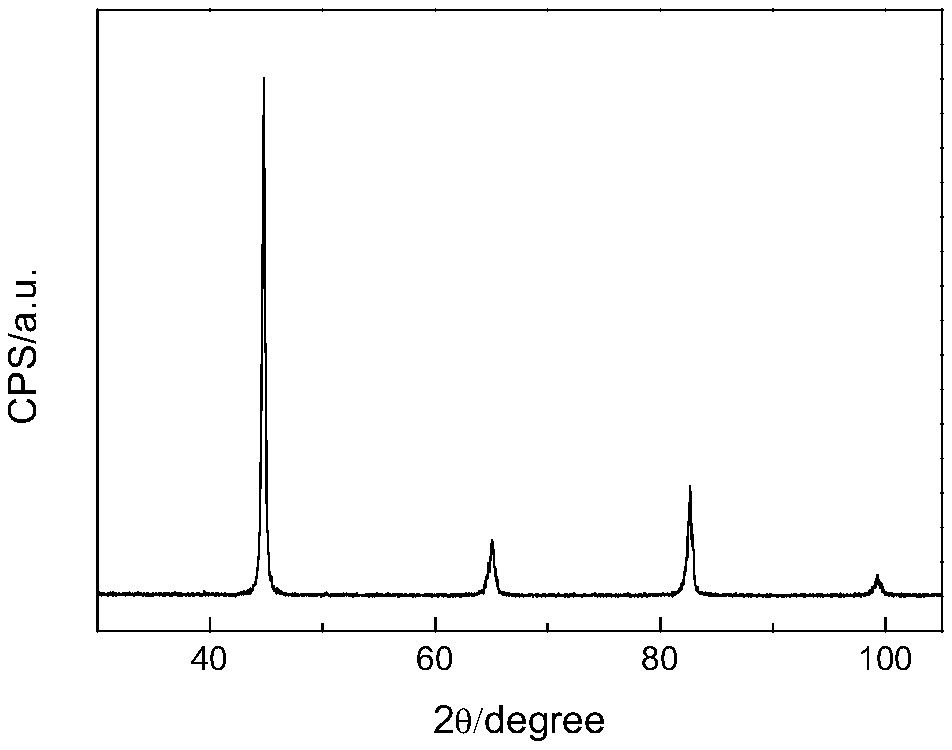

[0050] Mix -100 mesh water atomized Fe powder with Fe-70% Si high-purity powder with particle size ≤ 6 μm according to the ratio of 90.43:9.57 to form Fe-6.7% Si mixed powder. Mix phosphoric acid and absolute ethanol at a ratio of 0.8:100 to prepare a passivation solution. Mix the passivation solution and the weighed metal powder raw material according to the ratio of 0.4:1, stir with a mixer for 0.5h, put it into the oven for passivation, the baking temperature is 40°C, and the passivation time is 4h to obtain passivation powder .

[0051] A 10:1.0 mixture of methyl ethyl ketone and absolute ethanol is used as a mixed solvent, epoxy resin is used as a binder, polyethylene glycol is used as a plasticizer, and triethanolamine is used as a dispersant. The volume ratio of the epoxy resin to the polyethylene glycol is 1:1, the added amount of the mixed solvent is 60%, and the added amount of the dispersant is 0.1%, to form a slurry organic solution. Mix the passivation powder an...

Embodiment 2

[0058] Mix -100 mesh water atomized Fe powder with Fe-50% Si high-purity powder with a particle size of ≤10 μm in a ratio of 91:9 to form a Fe-4.5% Si mixed powder. Mix phosphoric acid and absolute ethanol at a ratio of 2.0:100 to prepare a passivation solution. Mix the passivation solution and the weighed metal powder raw material according to the ratio of 0.6:1, stir with a mixer for 2 hours, then put it into an oven for passivation, the baking temperature is 42°C, and the passivation time is 6 hours to obtain passivation powder.

[0059]A 10:1.0 mixture of methyl ethyl ketone and absolute ethanol is used as a mixed solvent, epoxy resin is used as a binder, polyethylene glycol is used as a plasticizer, and triethanolamine is used as a dispersant. The volume ratio of the epoxy resin to the polyethylene glycol is 1:1, the added amount of the mixed solvent is 60%, and the added amount of the dispersant is 0.1%, to form a slurry organic solution. Mix passivation powder and orga...

Embodiment 3

[0067] Mix -100 mesh water atomized Fe powder with Fe-60% Si high-purity powder with particle size ≤ 6 μm according to the ratio of 89.17:10.83 to form Fe-6.5% Si mixed powder. Mix phosphoric acid and absolute ethanol at a ratio of 1.0:100 to prepare a passivation solution. Mix the passivation solution and the weighed metal powder raw material according to the ratio of 0.5:1, stir with a mixer for 1 hour, then put it into an oven for passivation, the baking temperature is 40°C, and the passivation time is 5 hours to obtain passivation powder.

[0068] A 10:1.0 mixture of methyl ethyl ketone and absolute ethanol is used as a mixed solvent, epoxy resin is used as a binder, polyethylene glycol is used as a plasticizer, and triethanolamine is used as a dispersant. The volume ratio of the epoxy resin to the polyethylene glycol is 1:1, the added amount of the mixed solvent is 60%, and the added amount of the dispersant is 0.1%, to form a slurry organic solution. Mix passivation pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com