Unleaded brazing filler metal

A lead-free solder, mass percentage technology, applied in the direction of welding/cutting media/materials, welding media, metal processing equipment, etc., can solve the problems of high melting point, poor wettability, unsatisfactory physical properties, etc., and achieve tissue distribution Uniform, wettability-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

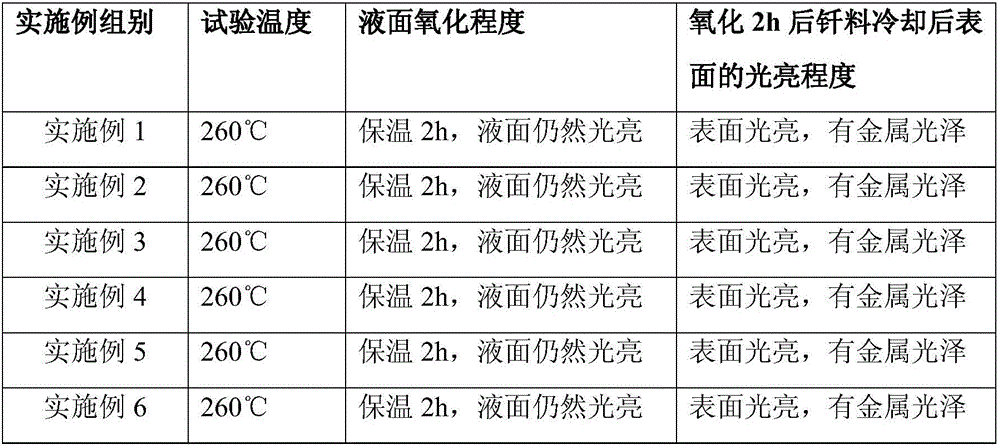

Examples

Embodiment 1

[0053] In terms of mass percentage, the lead-free solder provided by this embodiment consists of the following components:

[0054] 0.7% Cu;

[0055] 0.05%Ni;

[0056] 0.025% Ge;

[0057] 1.2% Bi;

[0058] 1.0% Zn;

[0059] 0.2% Ce;

[0060] 0.1% Er;

[0061] The balance is Sn.

Embodiment 2

[0063] In terms of mass percentage, the lead-free solder provided by this embodiment consists of the following components:

[0064] 0.5% Cu;

[0065] 0.07%Ni;

[0066] 0.02% Ge;

[0067] 0.5% Bi;

[0068] 0.5% Zn;

[0069] 0.1% Ce;

[0070] 0.07 Er;

[0071] The balance is Sn.

Embodiment 3

[0073] In terms of mass percentage, the lead-free solder provided by this embodiment consists of the following components:

[0074] 0.8% Cu;

[0075] 0.08%Ni;

[0076] 0.01% Ge;

[0077] 0.15% Bi;

[0078] 1.5% Zn;

[0079] 0.03% Ce;

[0080] 0.03% Er;

[0081] The balance is Sn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com