Steel material for CT80 level coiled tubing and manufacturing method thereof

A manufacturing method and oil pipe technology, applied in the field of oil pipe steel manufacturing, can solve the problems of increasing heat treatment process, increasing cost, etc., and achieve the effect of grain refinement, increase of fineness, and inhibition of grain growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

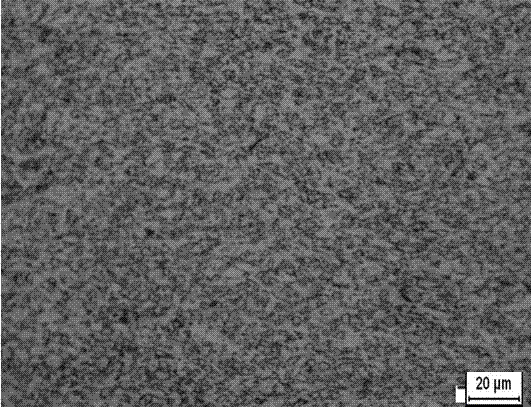

Image

Examples

Embodiment 1

[0024] The specific gravity is 0.11% carbon, 0.30% silicon, 0.70% manganese, 0.50% chromium, 0.25% nickel, 0.13% molybdenum, 0.30% copper and 0.02% niobium for steelmaking. Converter melting, casting into 80mm thick billet. In the smelting process, solid metal calcium cored wire is used for final deoxidation, and controlled rolling and controlled cold rolling are carried out after forming ingots. After 9 passes of controlled rolling and controlled cooling, the starting temperature of the first three passes of rough rolling is 1050 ° C, and the subsequent The six-pass finish rolling start temperature is 900°C, the final rolling temperature is 830°C, the cooling rate is 16°C / s, the final cooling temperature is 550°C, and the steel strip with a thickness of 80mm is finally rolled to a steel strip of 4.5mm. Among the impurities in the steel strip, nitrogen≤0.004%, phosphorus≤0.015%, sulfur≤0.005%, the yield strength is 565MPa, the tensile strength is 685MPa, and the elongation is ...

Embodiment 2

[0026] The specific gravity is 0.12% carbon, 0.35% silicon, 0.80% manganese, 0.55% chromium, 0.18% nickel, 0.14% molybdenum, 0.35% copper and 0.025% niobium for steelmaking. Converter melting, casting into 80mm thick billet. In the smelting process, solid metal calcium cored wire is used for final deoxidation, and controlled rolling and controlled cold rolling are carried out after forming ingots. After 9 passes of controlled rolling and controlled cooling, the starting temperature of the first three passes of rough rolling is 1100 °C, and the subsequent The six-pass finish rolling temperature is 950°C, the final rolling temperature is 850°C, the cooling rate is 17°C / s, the final cooling temperature is 570°C, and the steel strip with a thickness of 80mm is finally rolled to a steel strip of 4.5mm. Among the impurities in the steel strip, nitrogen≤0.004%, phosphorus≤0.015%, sulfur≤0.005%, the yield strength is 565MPa, the tensile strength is 685MPa, and the elongation is 32%. ...

Embodiment 3

[0028] The specific gravity is 0.13% carbon, 0.40% silicon, 0.90% manganese, 0.60% chromium, 0.10% nickel, 0.15% molybdenum, 0.40% copper and 0.04% niobium for steelmaking. Converter melting, casting into 80mm thick billet. In the smelting process, solid metal calcium cored wire is used for final deoxidation, and controlled rolling and controlled cold rolling are carried out after forming ingots. After 9 passes of controlled rolling and controlled cooling, the initial rolling temperature of the first three passes is 1150 ° C, and the subsequent The six-pass finish rolling temperature is 920°C, the final rolling temperature is 880°C, the cooling rate is 18°C / s, and the final cooling temperature is 600°C, and the steel strip with a thickness of 80mm is finally rolled to a steel strip of 4.5mm. Among the impurities in the steel strip, nitrogen≤0.004%, phosphorus≤0.015%, sulfur≤0.005%, the yield strength is 565MPa, the tensile strength is 685MPa, and the elongation is 32%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com