Vanadium-containing carbidic austempered ductile iron and preparation method thereof

A nodular cast iron and carbide technology, applied in the field of metallurgical casting, can solve the problems of low toughness, narrow application range, easy fracture, etc., achieve uniform structure distribution, improve comprehensive mechanical properties, suppress and avoid the formation of network carbides Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

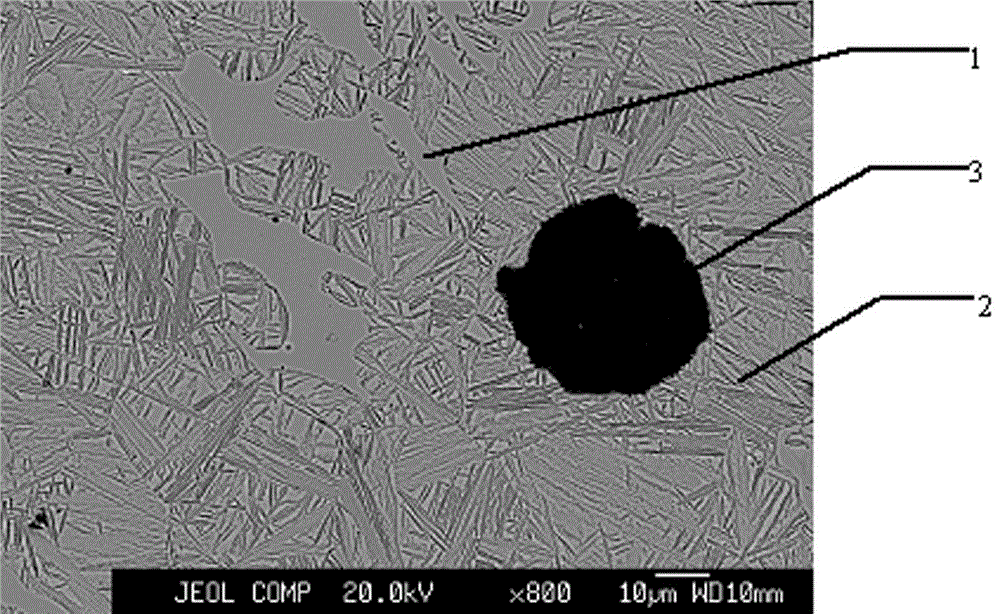

[0030] Composition and mass percentage: C: 3.23; Si: 3.01; Mn: 0.56; P: 0.037; S: 0.006; Ce: 0.035; Mg: 0.023; Cr: 1.15; V: 0.28; the balance is iron.

[0031] (1) Melting: Put the configured pig iron, scrap steel, ferromanganese, ferrovanadium and other alloy charge into an intermediate frequency induction electric furnace, heat and melt into molten iron of ductile iron alloy, test and adjust the composition before the furnace, and the furnace temperature is about 1510℃.

[0032] (2) Spheroidizing and inoculating treatment of molten iron: using the spheroidizing inoculation method of rushing into the bag, placing 1.8% of the raw material mass of VNCR-80 rare earth magnesium spheroidizing agent in the bottom groove of the bag, and placing the VI- of 0.8% of the raw material mass on it. 70RE inoculant; before pouring, put 0.03% cerium oxide of the raw material quality in the cavity, then pouring alloy iron liquid, pouring temperature 1416℃, pouring time 24 seconds, after cooling to g...

Embodiment 2

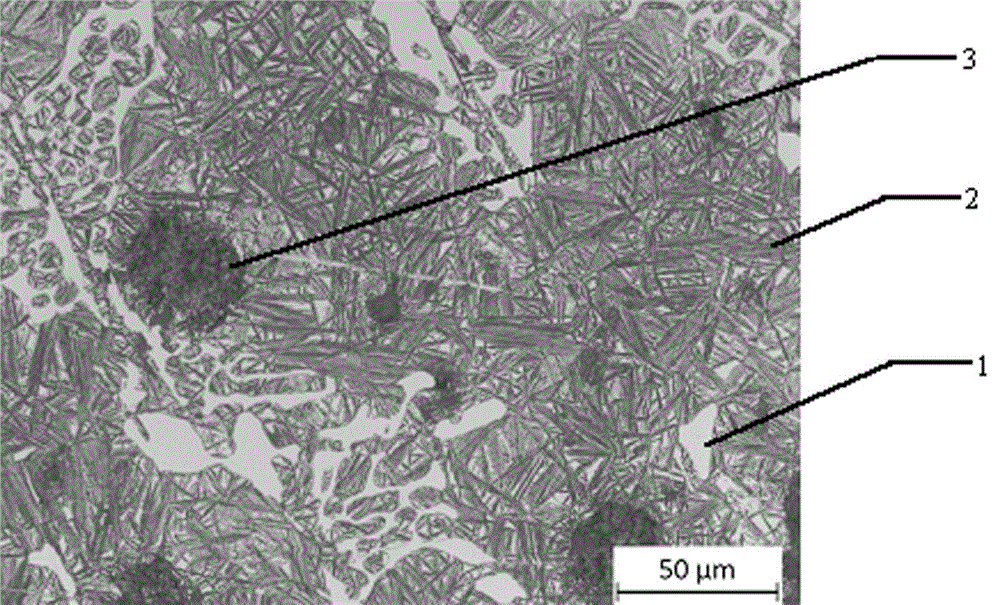

[0035] Composition and mass percentage: C: 3.35; Si: 2.81; Mn: 0.57; P: 0.038; S: 0.006; Ce: 0.023; Mg: 0.013; Cr: 1.15; V: 0.50; the balance is iron.

[0036] (1) Melting: the same as in Example 1. The furnace temperature is 1530℃.

[0037] (2) Spheroidization and inoculation treatment of molten iron: same as in Example 1. The pouring temperature is 1425℃, the pouring time is 18 seconds, and the ductile iron is obtained after cooling.

[0038] (3) Salt bath austempering heat treatment: same as Example 1. The performance is shown in Table 1.

Embodiment 3

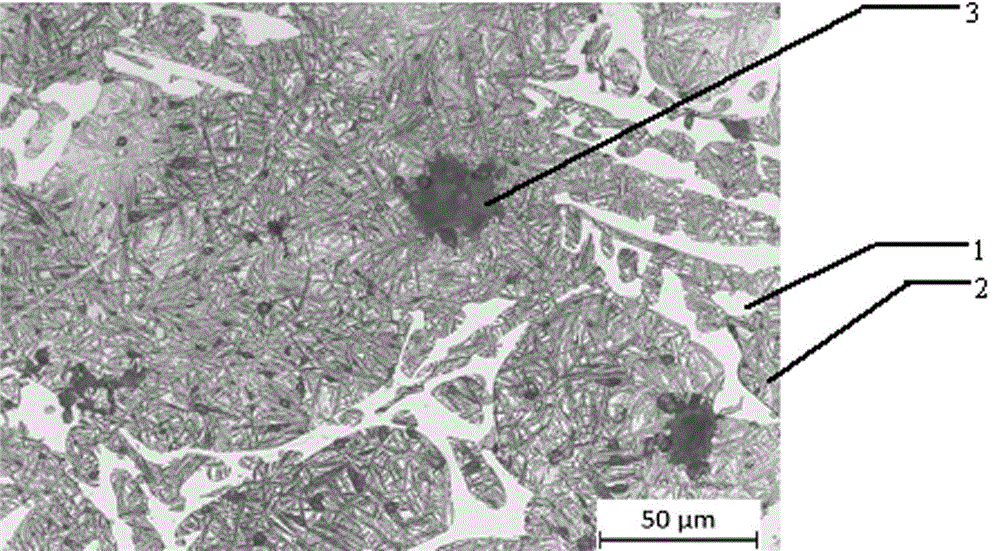

[0040] Composition and mass percentage: C: 3.37; Si: 2.79; Mn: 0.58; P: 0.038; S: 0.006; Ce: 0.019; Mg: 0.012; Cr: 1.15; V: 0.68; the balance is iron.

[0041] (1) Melting: the same as in Example 1. The furnace temperature is 1525℃.

[0042] (2) Spheroidization and inoculation treatment of molten iron: same as in Example 1. The pouring temperature is 1425℃, the pouring time is 18 seconds, and the ductile iron is obtained after cooling.

[0043] (3) Salt bath austempering heat treatment: same as Example 1. The performance is shown in Table 1.

[0044] Table 1 The performance of the vanadium-containing carbide austenitic ductile iron of the present invention

[0045]

[0046] Note: The abrasion test data is tested under the same working conditions, with a pressure of 1 kg and a time of 30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com