Paraffin wax melting and heat insulating device capable of automatically controlling temperature

A heat preservation device and paraffin wax technology, applied in mixers with rotating stirring devices, chemical instruments and methods, chemical/physical/physicochemical fixed reactors, etc., can solve the problems of reducing on-site processing efficiency and low safety factor, Achieve the effect of satisfying melting and heat preservation performance, reducing human labor, and high heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

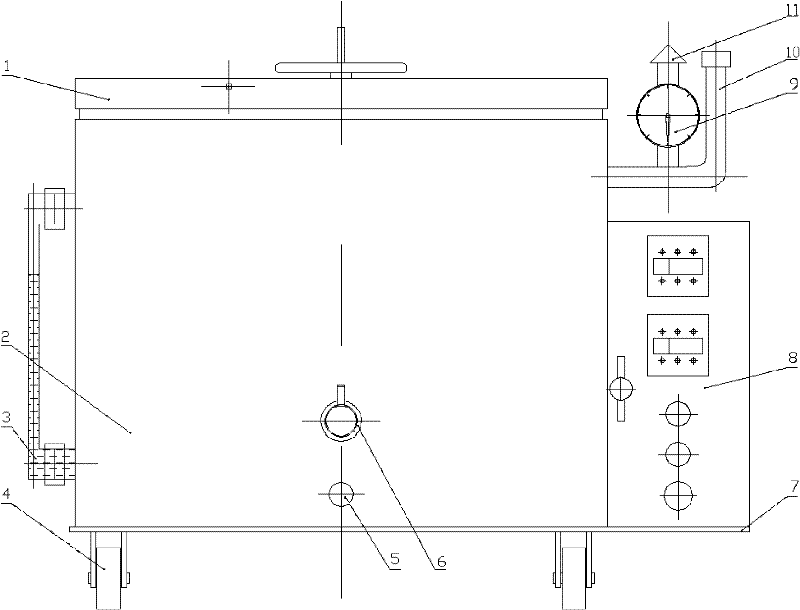

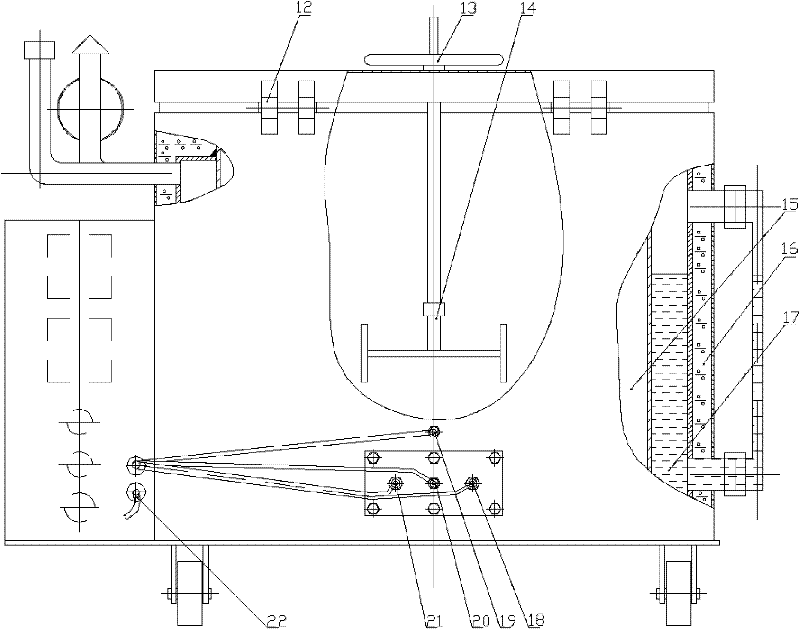

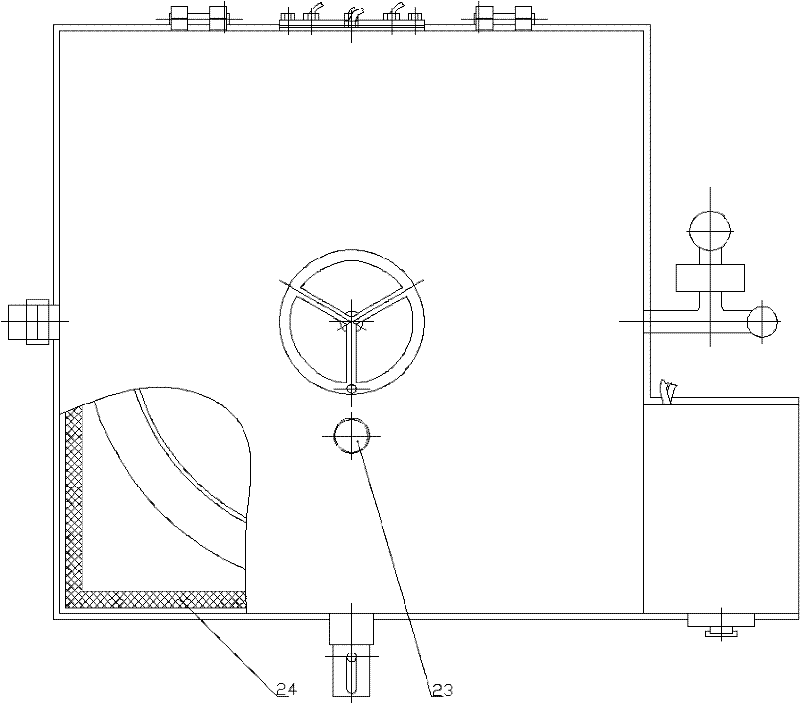

[0017] The automatic temperature-controlled paraffin melting and heat preservation device of the present invention is as follows: figure 1 , figure 2 and image 3 As shown, it mainly includes a bottom frame 7, a box body 2, a paraffin container 15, a heating system and a stirring mechanism. The box body 2 is installed on the bottom frame 7, and the upper end of the box body 2 is installed with the box body cover 1 through the hinge 12 (see figure 2 ), the box cover 1 has a vacuum layer insulation structure, and a viewing window 23 is provided on it to observe the melting of the paraffin. Casters 4 are installed at the bottom of the bottom frame 7, so that the whole device can be moved, so as to meet the paraffin filling work of aviation thin-walled parts on multiple machine tools. A paraffin container 15 is arranged in the box body 2, and a heating layer 17 and a thermal insulation layer 16 are arranged between the paraffin wax container 15 and the box body 2. Layer 16 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com