Testing device for external characteristics of high-temperature molten salt pump

A test device, high-temperature molten salt technology, applied in pump testing, liquid variable-capacity machinery, machines/engines, etc., can solve the problems of less research, impact on measurement accuracy, and difficulty in performance testing, and achieve high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

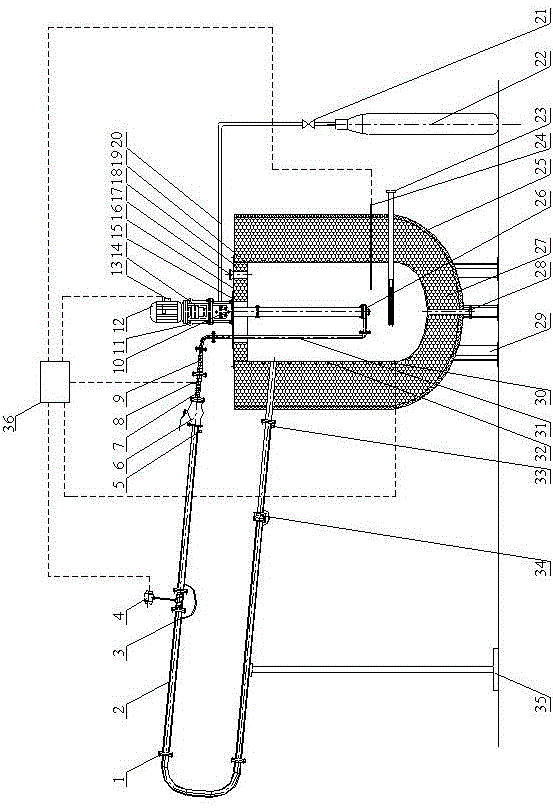

[0094] exist figure 1 Among them, the device of the present invention includes six systems, which are power transmission system, hydraulic system, gas system, heating system, heat preservation and heat tracing system, and data acquisition and analysis system.

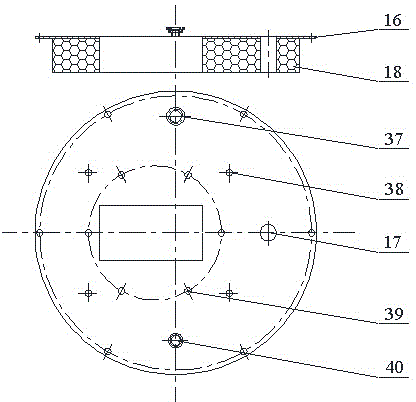

[0095] The power transmission system of the present invention comprises a motor (12), a shaft coupling (14), a motor support (11), and a transmission shaft (10). Motor (12) is installed on the molten salt pump fixed plate (15) by motor support (11), and molten salt pump fixed plate (15) is fixed on molten salt tank cover plate (16) top by bolt. The motor (12) and the transmission shaft (10) are connected through a coupling (14) to realize power transmission.

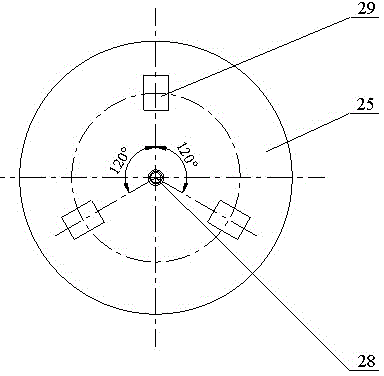

[0096] exist figure 1 Among them, the liquid circuit system of the present invention includes molten salt tank (19), molten salt pump (26), molten salt pump outlet pipe (31), valve (6), expansion joint (34), reducing pipe (9), U-shaped jacketed pipe (2). The g...

Embodiment 2

[0103] The main steps of molten salt pump performance test are:

[0104] 1) Remove the sundries in the molten salt tank (19), especially without leaving organic matter and combustibles. The three components of molten salt are all strong oxidizers, which are easy to decompose to release oxygen and heat. It is not flammable itself, but it can cause Combustibles burn and are sensitive to friction and thermal shock.

[0105] 2) Connect the motor (12) to the pump shaft, remove the impeller of the molten salt pump (26), adjust the frequency converter to adjust the motor (12) to the test speed, and record the no-load torque of the pump.

[0106] 3) Install the entire power transmission system on the molten salt tank cover (16).

[0107] 4) Check whether all instruments and equipment are working normally.

[0108] 5) Add molten salt powder into the molten salt tank (19).

[0109] 6) Turn on the steam tracing circuit and the electric heating belt (7) of the jacketed pipe (2), prehea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com