Preparing method of TiAl alloy turbine blade

A technology for turbine blades and alloys, which is applied in the field of preparation of TiAl alloy turbine blades. It can solve the problems of reducing the comprehensive performance of TiAl alloys, high brittleness of TiAl alloys at room temperature, and restrictions on the application of TiAl alloys, so as to achieve good interlayer bonding and avoid deformation and fracture. Phenomenon, the effect of reducing internal thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment includes the following steps:

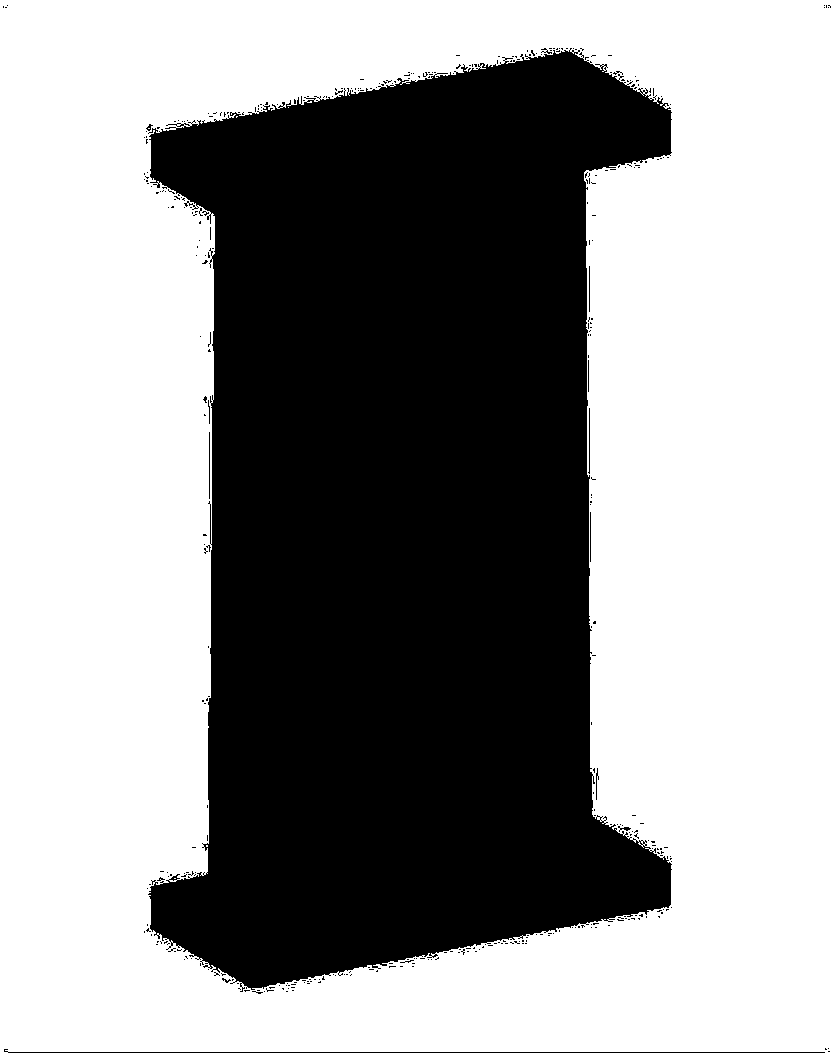

[0033] Step 1, at first utilize CAD three-dimensional drawing software to set up the three-dimensional model of turbine blade, as figure 1 As shown, then use the Build Assembler layering software to slice the three-dimensional model of the turbine blade along the height direction to obtain slice data, and then import the slice data into the electron beam selection rapid prototyping equipment; each of the slice processes The thickness of the layer slice is 150 μm;

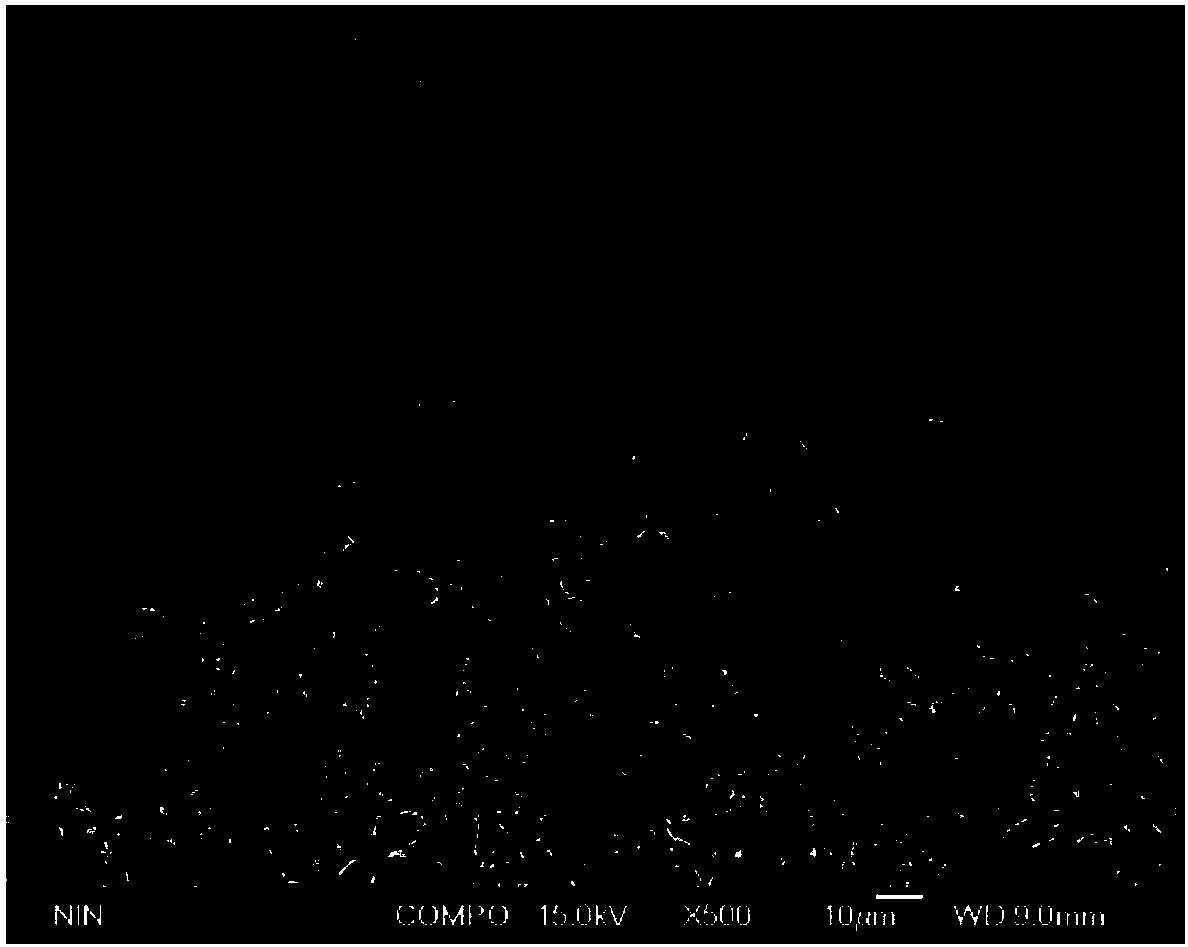

[0034] Step 2: Put the Ti-48Al-2Cr-2Nb alloy powder into the powder bin of the electron beam selective rapid prototyping equipment, and then vacuumize the forming cavity of the electron beam selective rapid prototyping equipment to a vacuum degree of 5×10 -2 Pa, the forming substrate in the forming cavity is preheated to 1000°C by electron beam; the Ti-48Al-2Cr-2Nb alloy powder is prepared by the gas atomization method, and the Ti-48Al obtained by the gas atomi...

Embodiment 2

[0043] Step 1. First, use Pro / Engineer software to build a three-dimensional model of the turbine blade, and then use the BuildAssembler layering software to slice the three-dimensional model of the turbine blade along the height direction to obtain slice data, and then import the slice data into the electron beam In the area-selected rapid prototyping equipment; the thickness of each layer of slices in the slicing process is 100 μm;

[0044] Step 2: Put the Ti-48Al-2Cr-2Nb alloy powder into the powder bin of the electron beam selective rapid prototyping equipment, and then vacuumize the forming chamber of the electron beam selective rapid prototyping equipment to a vacuum degree of 4.8×10 -2 Pa, using electron beams to preheat the forming substrate in the forming cavity to 1100°C; the TiAl alloy powder is prepared by the gas atomization method, and the TiAl alloy powder prepared by the gas atomization method is spherical and has a particle size smaller than 120 μm; the scanni...

Embodiment 3

[0051] Step 1. First, use the CAD 3D drawing software to establish a 3D model of the turbine blade, and then use the BuildAssembler layering software to slice the 3D model of the turbine blade along the height direction to obtain slice data, and then import the slice data into the electron beam In the area-selected rapid prototyping equipment; the thickness of each layer of slices in the slicing process is 50 μm;

[0052] Step 2: Put the Ti-48Al-2Cr-2Nb alloy powder into the powder chamber of the electron beam selective rapid prototyping equipment, and then vacuumize the forming chamber of the electron beam selective rapid prototyping equipment to a vacuum degree of 4.5×10 -2 Pa, the forming substrate in the forming cavity is preheated to 1050°C by electron beam; the TiAl alloy powder is prepared by the gas atomization method, and the TiAl alloy powder prepared by the gas atomization method is nearly spherical, with a particle size of less than 80 μm; the scanning speed of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com