A kind of preparation method of nb-si base super high temperature alloy turbine blade

An ultra-high temperature alloy and turbine blade technology, applied in turbines, mechanical equipment, energy efficiency improvement and other directions, can solve the problems of uneven melt temperature, cumbersome process, affecting alloy properties, etc., to achieve fast melting and accumulation, and avoid alloy pollution. , the effect of high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Example 1: Rapid preparation of Nb-18Si-24Ti-2Cr-2Al-2Hf (at.%, atomic percent) ultra-high temperature alloy turbine blade.

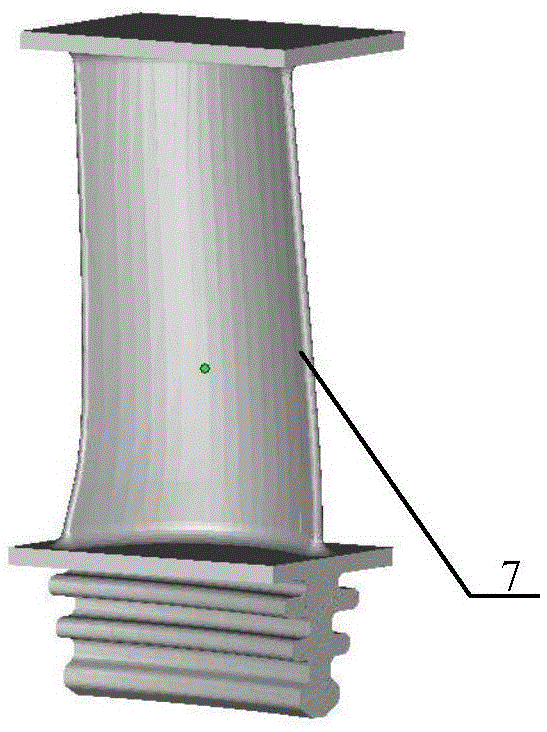

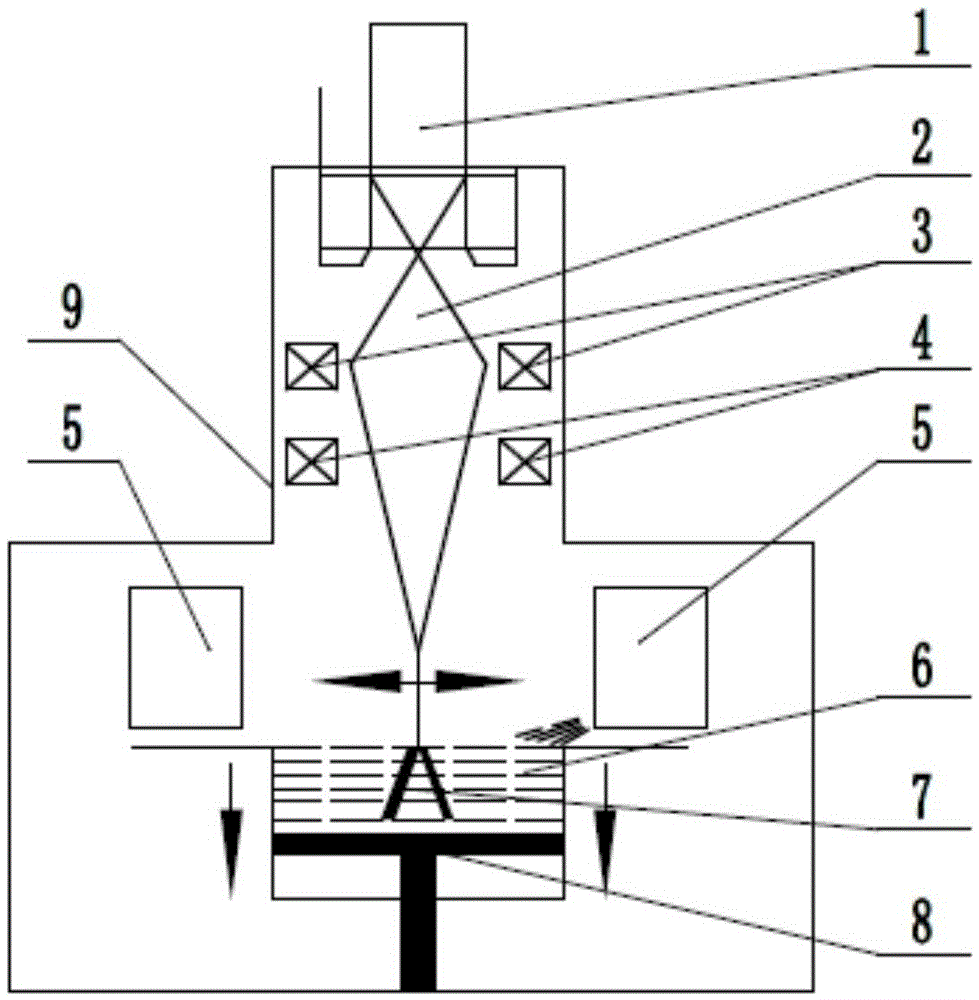

[0046] 1. First utilize CAD three-dimensional drawing software (such as Magics etc.) to set up the three-dimensional STL file of Nb-18Si-24Ti-2Cr-2Al-2Hf alloy turbine blade (7); Then utilize layered software (such as EBMassembler etc.) to STL file in Layered slice processing is carried out in the height direction, and evenly divided into slices with a thickness of 0.05mm. The slice contains the cross-sectional information of the blade (7) and the scanning processing path; use the layering software to save the slice as an ABF file, and import it into the electron beam selection area In the rapid prototyping equipment (9);

[0047] 2. Put the Nb-18Si-24Ti-2Cr-2Al-2Hf powder (6) with an argon atomization size between 50 and 150 μm into the powder spreading mechanism (5). Equipment (9) is evacuated to 10 -3 ~10 -2 After Pa, the electron gun (1) e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com