Once surface heat regenerator

A regenerator and subsurface technology, which is applied in the cooling of turbine/propulsion device, engine components, and engine cooling, etc., can solve the problems of reducing the volume of the regenerator without greatly improving the heat exchange performance, etc. The effect of improved heat exchange efficiency, compact structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

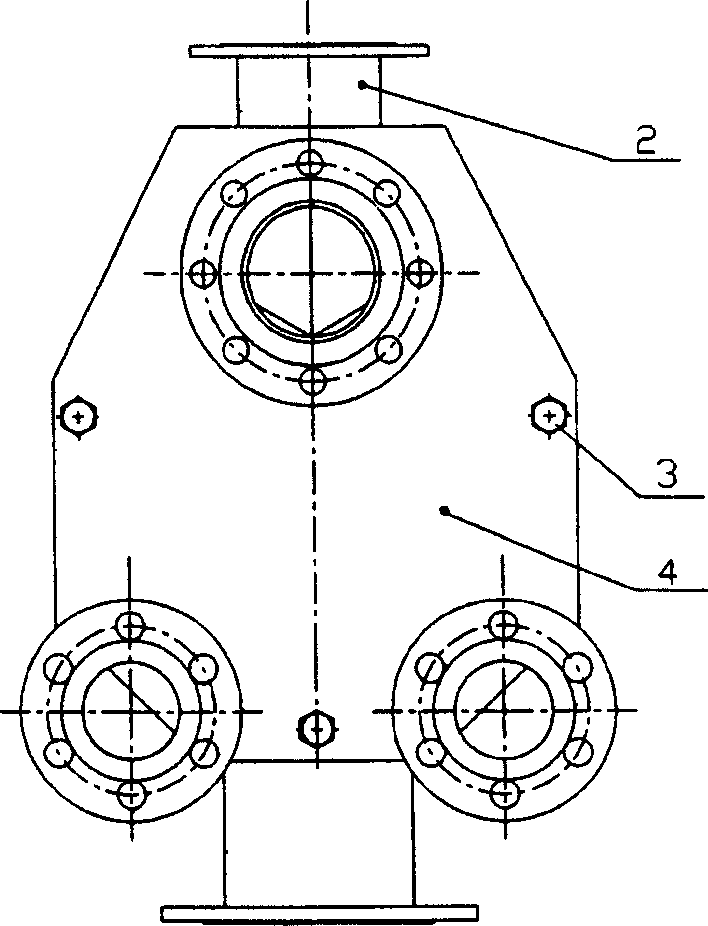

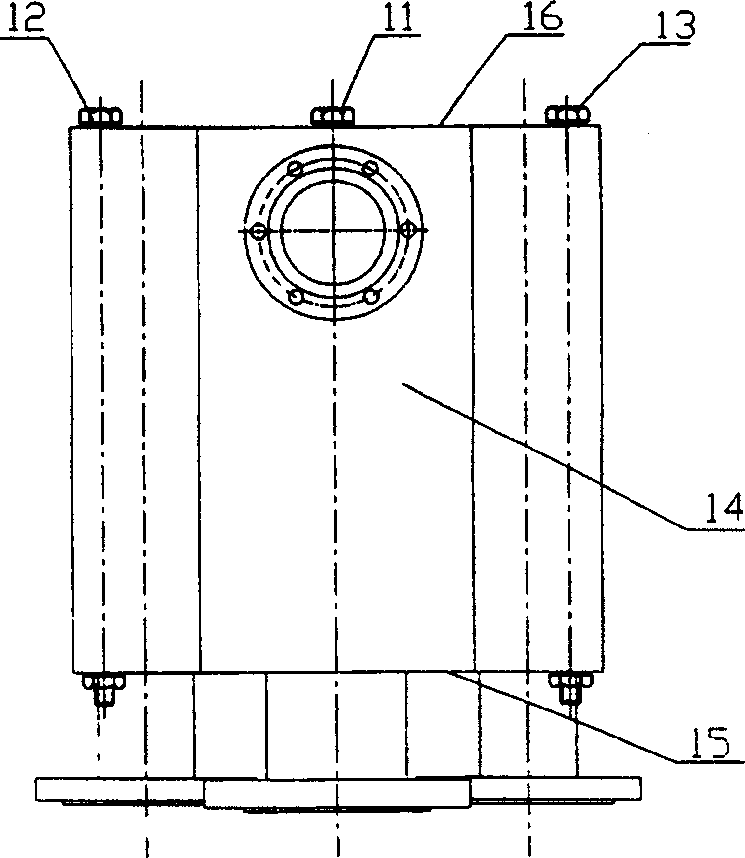

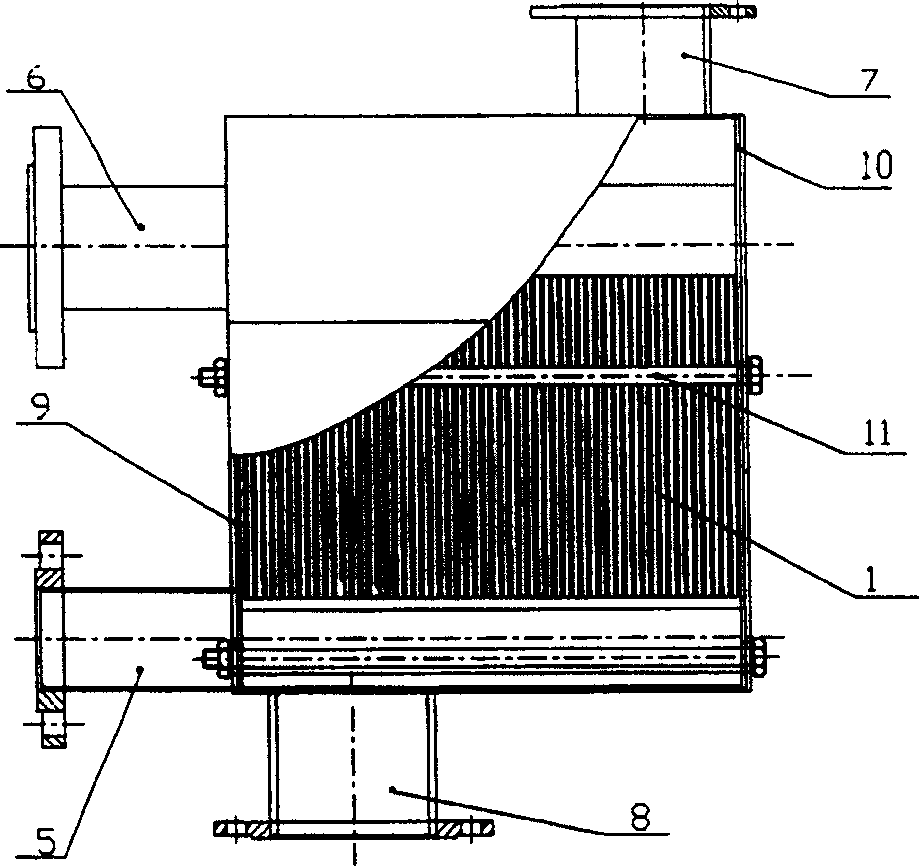

[0024] Such as figure 1 one Figure 12 As shown, the present invention includes: a core body 1 , an inlet and outlet pipeline 2 , a connecting rod pressure balance member 3 and a casing 4 . The core 1 is located in the inner center of the regenerator, the pressure balance member 3 is located at the front and rear ends of the core 1, the inlet and outlet pipelines 2 are located at the upper and lower ends of the core 1 and the upper and lower surfaces of the shell 4, and the shell 4 is The outer package of the regenerator, the core 1 is composed of a plurality of air chambers 17 and the outdoor side strips 20, the air chamber 17 is composed of corrugated plates 19 and indoor side strips 18, and the corrugated plates 19 are composed of corrugated areas 21 and flat areas 22 The corrugated area 21 is located in the center of the corrugated plate 19, and the plane area 22 is around the corrugated area 21. From the longitudinal section, the plane area 22 is located on the mid-plane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com