Flame-retarding low-melting-point polyester fiber and preparation method thereof

A low-melting point polyester and flame-retardant polyester technology, which is applied in fiber processing, conjugated synthetic polymer artificial filament, filament/thread forming, etc., can solve problems such as slow melting speed, high melting point, and single variety , to achieve the effect of fast melting speed, lower melting point and low melting point temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

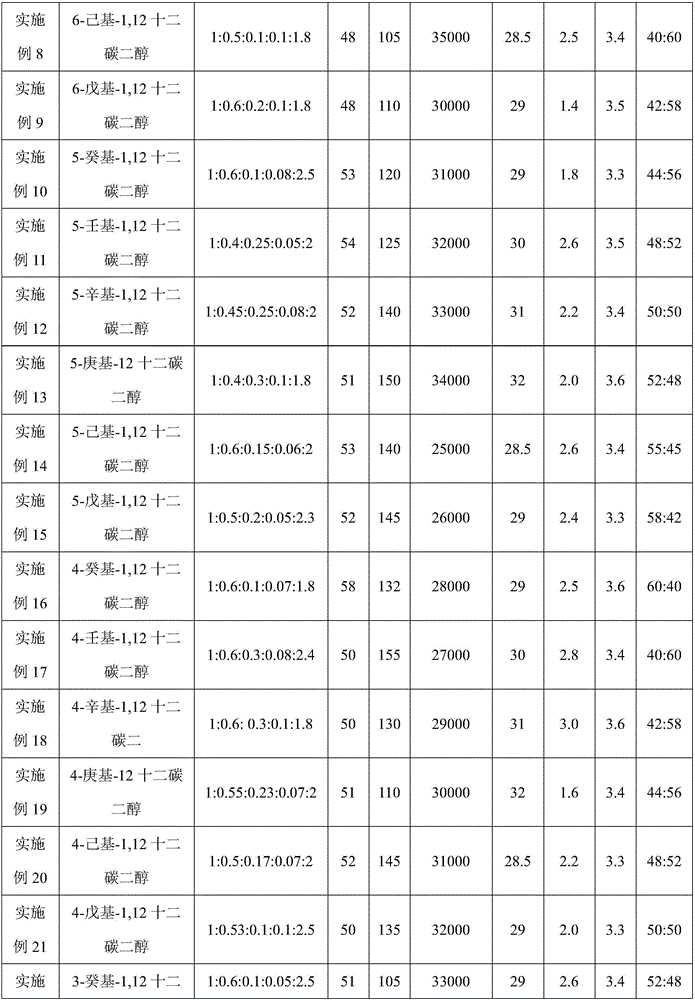

Embodiment 1

[0047] A preparation method of flame-retardant low-melting polyester fiber:

[0048] The preparation steps of low melting point polyester:

[0049] (1) Esterification reaction;

[0050] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol and 2-pentyl-1,12 dodecanediol into a slurry, carry out esterification reaction, pressurized reaction under nitrogen atmosphere, The pressurized pressure is normal pressure and the temperature is 230°C. When the distilled amount of water in the esterification reaction reaches more than 90% of the theoretical value, it is the end point of the esterification reaction, and the esterification product is obtained; among them, terephthalic acid, m- The molar ratio of phthalic acid, diethylene glycol, 2-pentyl-1,12 dodecanediol and ethylene glycol is 1:0.4:0.1:0.05:1.8;

[0051] (2) polycondensation reaction;

[0052] Then, under the action of catalyst and stabilizer, the polycondensation reaction in the low vac...

Embodiment 2

[0067] A preparation method of flame-retardant low-melting polyester fiber:

[0068] Low melting point polyester polymerization steps:

[0069] (1) Esterification reaction;

[0070] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol and 2-hexyl-1,12 dodecanediol into slurry, carry out esterification reaction, pressurize reaction under nitrogen atmosphere, add The pressure is 0.3 MPa, the temperature is 250 ° C, when the distilled amount of water in the esterification reaction reaches more than 90% of the theoretical value, it is the end point of the esterification reaction, and the esterification product is obtained; among them, terephthalic acid, m-benzene The molar ratio of dicarboxylic acid, diethylene glycol, 2-hexyl-1,12 dodecanediol and ethylene glycol is 1:0.6:0.3:0.1:2.5;

[0071] (2) polycondensation reaction;

[0072] Then, under the action of catalyst and stabilizer, the polycondensation reaction in the low vacuum stage starts...

Embodiment 3

[0087]A preparation method of flame-retardant low-melting polyester fiber:

[0088] Low melting point polyester polymerization steps:

[0089] (1) Esterification reaction;

[0090] After preparing terephthalic acid, isophthalic acid, ethylene glycol, diethylene glycol, p-ethylbenzoic acid and 2-heptyl-12 dodecanediol into a slurry, carry out esterification reaction, in a nitrogen atmosphere Under pressurized reaction, the pressurized pressure is 0.1MPa, and the temperature is 240°C. When the distilled amount of water in the esterification reaction reaches more than 90% of the theoretical value, it is the end point of the esterification reaction, and the esterification product is obtained; wherein, for The molar ratio of phthalic acid, isophthalic acid, diethylene glycol, 2-heptyl-12 dodecanediol, and ethylene glycol is 1:0.5:0.2:0.07:2; the amount of p-ethylbenzoic acid added 0.1% of the moles of phthalic acid.

[0091] (2) polycondensation reaction;

[0092] Then, under t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com