Preparation method of NiAlIr alloy

A technology of alloy and alloy liquid, which is applied in the field of NiAlIr alloy preparation, can solve the problems of difficult metal wire, brittleness, and inability to be popularized and applied, and achieve the effect of good surface quality, uniform structure distribution, and internal compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

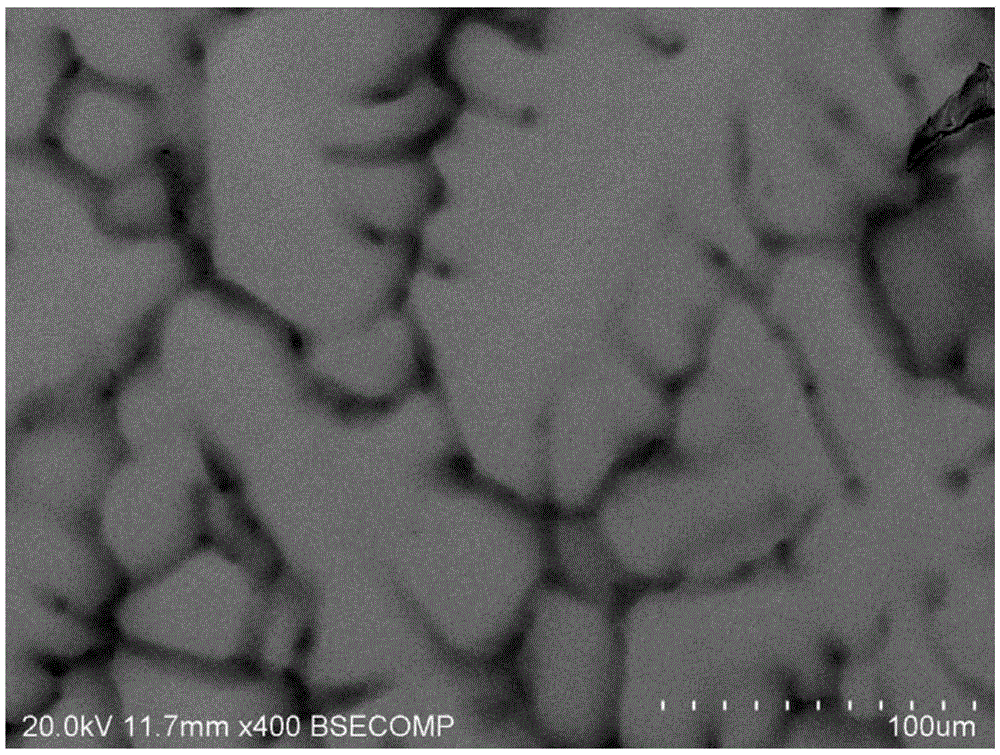

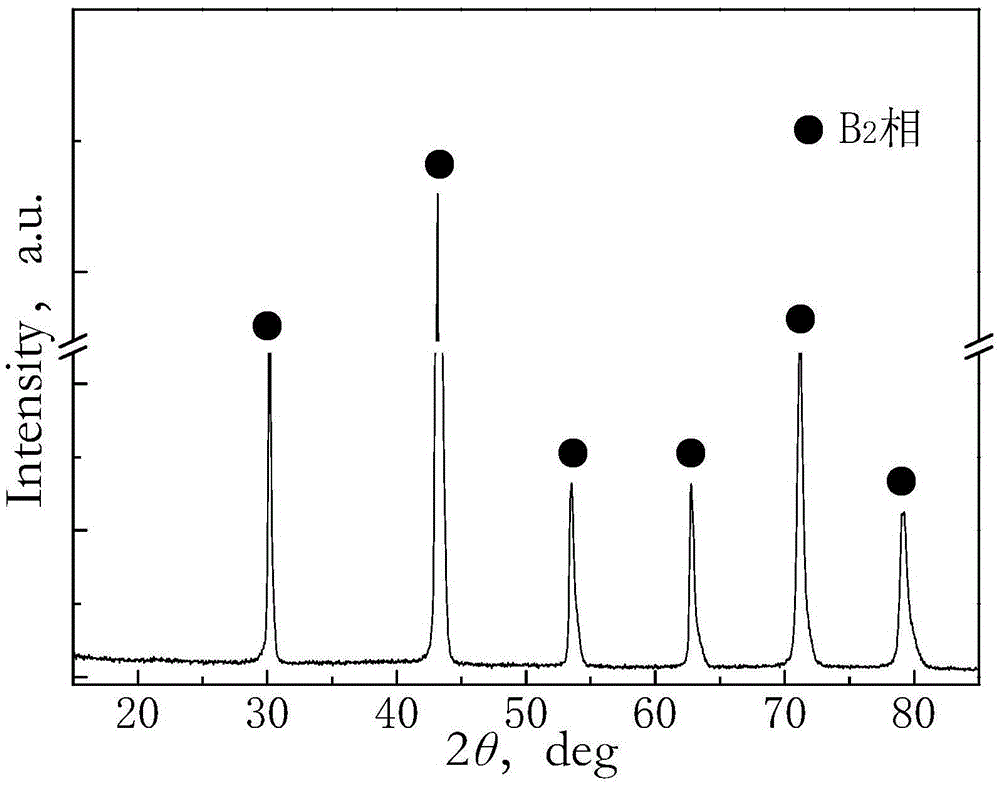

[0050] Taking the preparation of a NiAlIr alloy with a component content (atomic percentage) of 20% nickel, 50% aluminum, and 30% iridium as an example, the following steps are included:

[0051] (1) Mold installation: Assemble a graphite mold with a cavity diameter of 0.8 mm and a length of 5 mm in the negative pressure suction casting system in the vacuum arc furnace;

[0052] (2) Load samples: turn on the vacuum arc furnace, and put high-purity Ni, Al and Ir with a nominal composition of 50Al-20Ni-30Ir (> 99.9wt.%) placed in the crucible of the vacuum arc furnace;

[0053] (3) Vacuum: Open the vacuum valve and pump to a vacuum of 1.0×10 -3 MPa, then tighten the vacuum valve;

[0054] (4) Inflation: Flush argon gas into the sample chamber of the vacuum arc furnace to a vacuum degree of 0.7MPa;

[0055] (5) Repeat steps 3 to 4;

[0056] (6) The vacuum arc furnace is energized to start the arc to melt Ni, Al and Ir, and continue to heat until the metal is melted and then continue to heat...

Embodiment 2

[0062] The difference between this embodiment and embodiment 1 is that the composition (atomic percentage) of NiAlIr alloy is 10% nickel, 50% aluminum, and 40% iridium. In step 3, the vacuum degree is 1.5×10. -3 MPa, suction casting NiAlIr alloy wire, the heating temperature in step 6 is 2600℃, the heat preservation in step 7 is 1 min, and the output current of magnetic stirring is 30A. Due to the large diameter and length of NiAlIr alloy wire, argon is filled in step 8 to a vacuum of 0.85MPa , To increase the casting pressure of alloy wire.

[0063] The structure and phase analysis of the NiAlIr alloy prepared in this example are consistent with the results of Example 1, and will not be repeated here.

Embodiment 3

[0065] The difference between this embodiment and embodiment 1 is that the composition (atomic percentage) of the NiAlIr alloy is 15% nickel, 50% aluminum, and 35% iridium. In step 3, the vacuum degree is 1.2×10. -3 MPa, suction casting NiAlIr alloy wire, the heating temperature in step 6 is 2580 ℃, the holding time in step 7 is 0.8 min, and the output current of magnetic stirring is 25A. Because the diameter and length of the alloy wire are centered, argon is filled in step 8 to a vacuum of 0.80 MPa .

[0066] The structure and phase analysis of the NiAlIr alloy prepared in this example are consistent with the results of Example 1, and will not be repeated here.

[0067] In summary, the NiAlIr alloy wire prepared by the invention has uniform composition, compact microstructure, regular size and shape, reduces the amount of precious metal iridium in the spark plug electrode sheet, and reduces the production cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com