Complex metal part forming method adopting combination of electric arc additive and laser additive

A laser additive and additive forming technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., to reduce the number of cracks and pores, reduce processing costs, and shorten the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

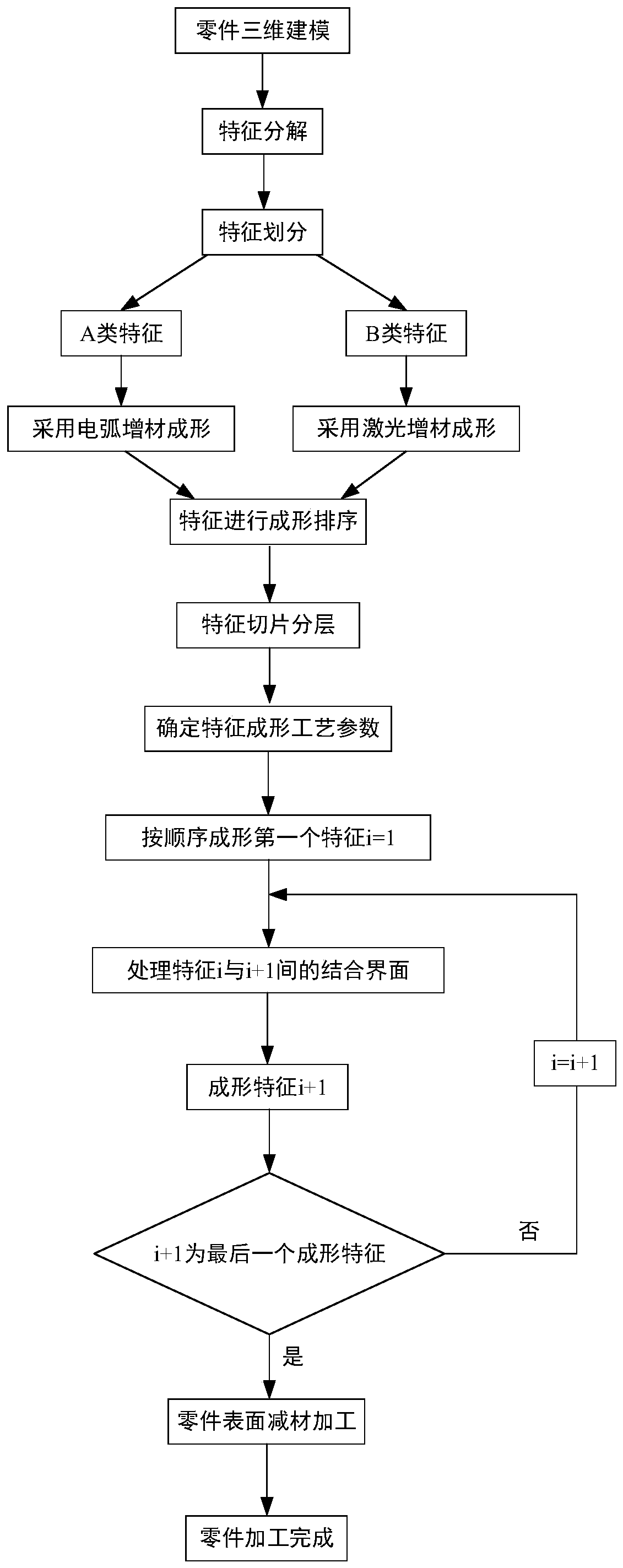

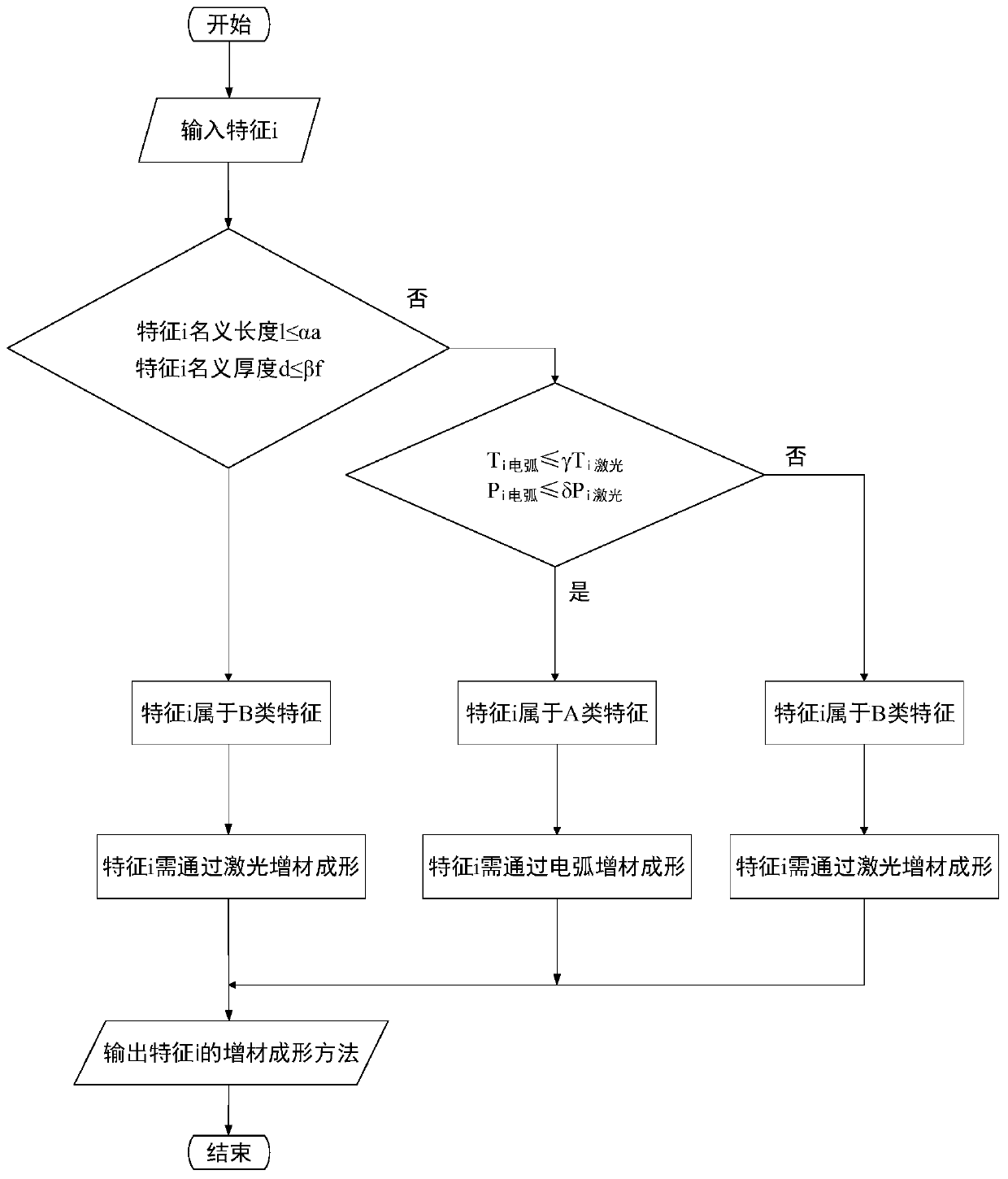

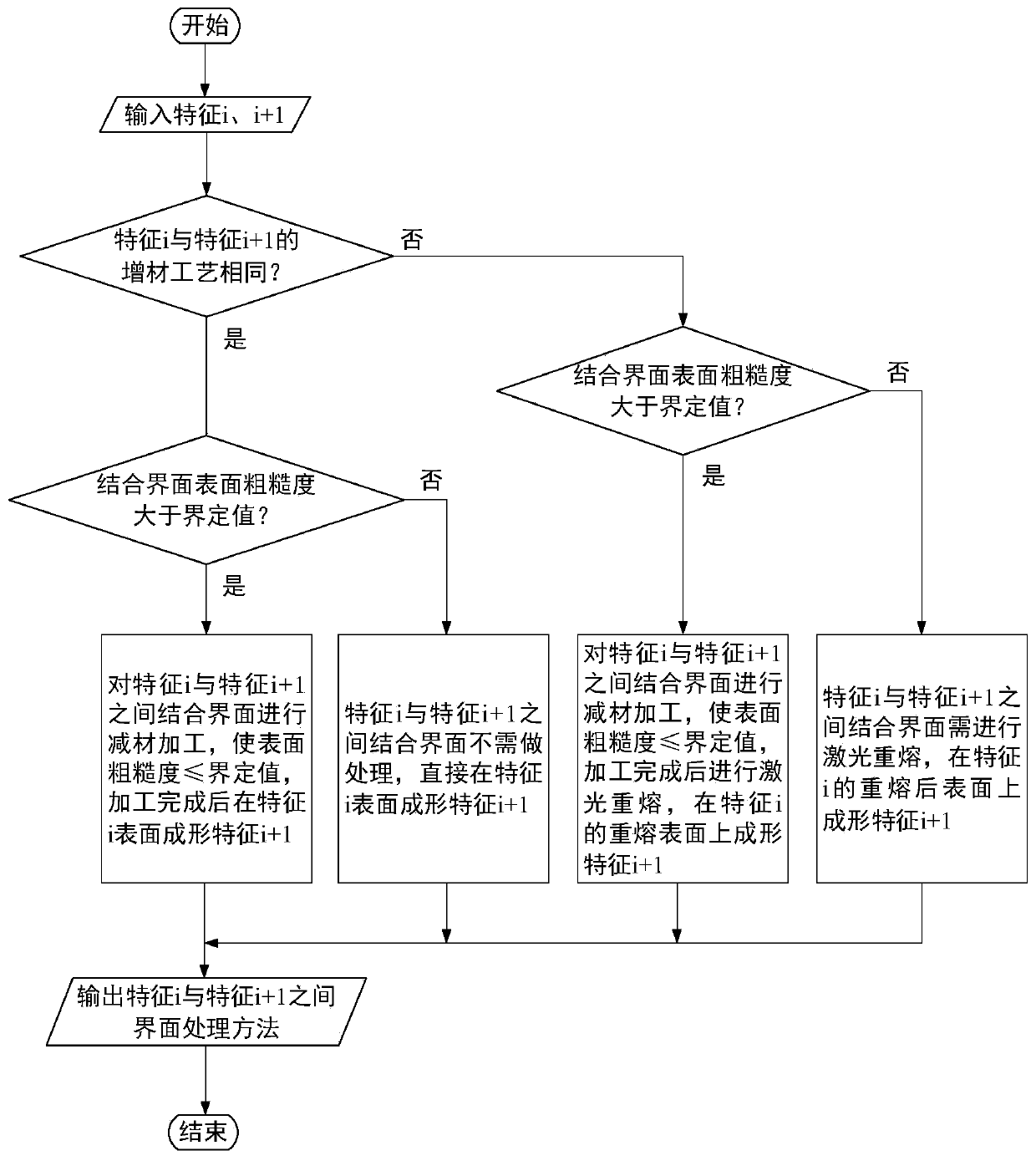

[0054] see Figure 5 and Figure 6 , taking a structural part with complex and difficult-to-form features as an example to describe the present invention in detail, the wire-feeding additive adopts the MIG forming process, and the diameter of the wire is 0.6mm to 2.5mm, and the powder-feeding additive adopts the LMD forming process. During laser cladding deposition, the type of powder material used can be the same as that of wire material, the size of the powder is 100 μm to 500 μm, and the limit value of the combined interface surface roughness is Ra6.3. The parts in the embodiment contain complex features such as variable diameter rotation and local convexity, so it is difficult to be directly formed by forging, so the forming process is re-planned in this embodiment. In this embodiment, firstly, the three-dimensional modeling of the part is carried out to generate the blank model of additive forming, and the feature decomposition of the model is carried out to obtain six f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com