Patents

Literature

99results about How to "Reduce the number of pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low dielectric comsumption CaCu3Ti4O12 ceramic preparing method

InactiveCN101070245AExcellent dielectric propertiesCompact bodyPiezoelectric/electrostrictive/magnetostrictive devicesDielectricPolyvinyl alcohol

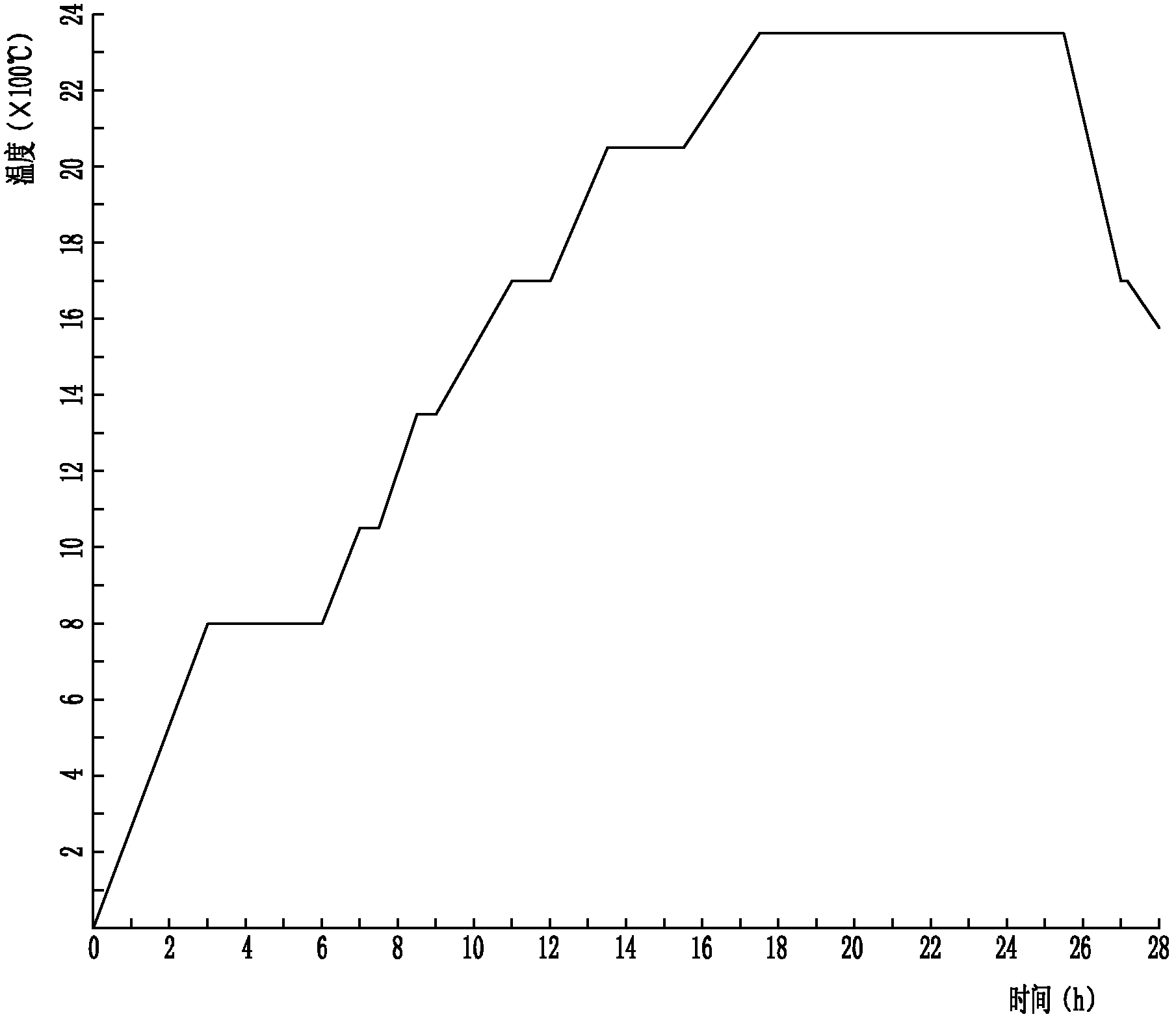

This invention relates to preparation method of a low electric loss CaCu3Ti4O12 ceramic.Firstly mix the raw material calcium carbonate, titanium dioxide and cupric oxide according to molar ratio of 1:4:3, wet method ball mill to gain mixture powder. Drythe mixture powder, then preburn at 850 to 1000deg. Ball mill the mixture powder after preburning, past at least 80 orders screen mesh, dry, add polyvinyl alcohol and grind, corning, dry pressing and moulding, then cold equal steady pressure for shaping, sintering the body, then furnace cool.

Owner:XIAMEN UNIV

Black-bottomed Zijin oil droplet ceramic product and preparation process thereof

ActiveCN108129129ALess deformation and bubble defectsGood vitrification effectClaywaresPotassium feldsparOil droplet

The invention discloses a black-bottomed Zijin oil droplet ceramic product and a preparation process thereof. The ceramic product comprises a green body and a glaze, wherein the green body is preparedfrom the following components in parts by weight: 5 to 7 parts of yellow clay soil, 3 to 4 parts of high clay and 2 to 3 parts of black soil; the glaze is prepared from the following components in parts by weight: 100 parts of red glaze ores, 48 to 52 parts of water, 10 to 12 parts of ash, 12 to 15 parts of a potassium feldspar powder, 8 to 10 parts of a quartz powder, 6 to 8 parts of a talcum powder, 3 to 5 parts of iron red and 1 to 2 parts of zinc oxide. According to the black-bottomed Zijin oil droplet ceramic product and the preparation process thereof, the green body and the glaze are prepared from crude ores and other natural materials; as burnt at high temperature, the green body has a small deformation and little blister defects; the burnt ceramic product comprises a relatively small number of pores in a glaze surface, is good in vitrification effect, and has a black and bright glaze surface; moreover, Zijin glossy crystal spots are irregularly spread on the glaze surface, sothat crystallization is natural; oil droplet stripes are natural in density; the stripes have strong three-dimensional and layering effects. Therefore, the black-bottomed Zijin oil droplet ceramic product is extremely high in artistic aesthetic feeling.

Owner:江春华

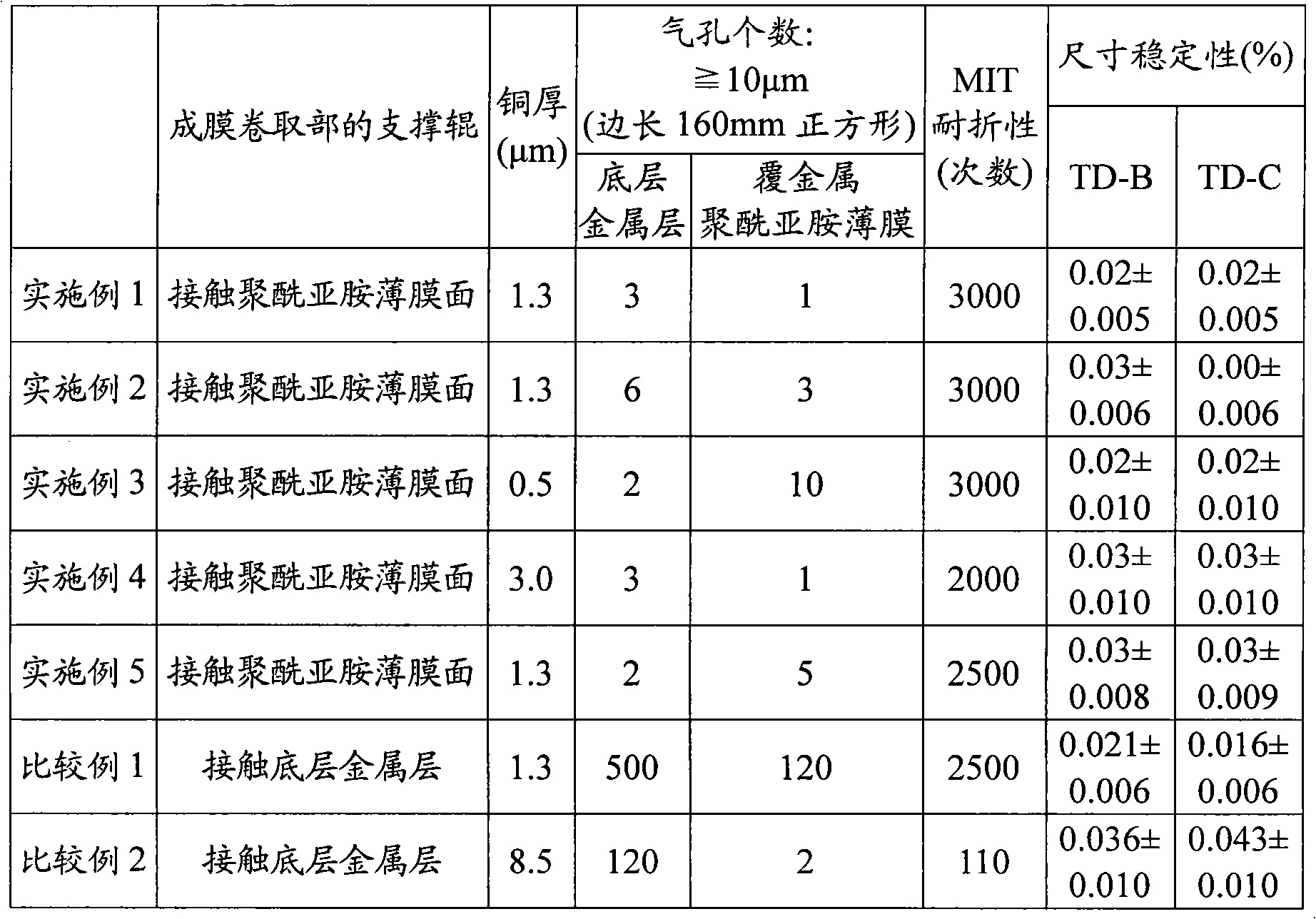

Metal-coated polyimide film and process for producing the same

ActiveCN101996891AReduce the number of poresImprove folding resistanceSemiconductor/solid-state device detailsSolid-state devicesCopperElectroplating

The present invention relates to a metal-coated polyimide film and a process for producing the same. The objective of the invention is to provide the metal-coated polyimide film and the process for producing the same, having high folding resistance and excellent dimension stability corresponding to fine space between and less air hole number of an electronic circuit. To this end, the surface of the polyimide film is provided with a base metal layer composed of a nickel-chromium alloy layer and a copper layer by a dry-type electroplating method in a continuous coiling manner, when the surface of the polyimide film is provided with a copper electroplating layer, during a period from setting the nickel-chromium alloy layer on the surface of the polyimide film to coil the polyimide film provided with the base metal layer to a roller, a part contacted with a conveying device for conveying is only used as the surface of the polyimide film.

Owner:SUMITOMO METAL MINING CO LTD

Method for preparing rare-earth-doped manganese-zinc ferrite material

InactiveCN109553408AChanging grain boundary compositionChange ionic valencePolyvinyl alcoholRare earth

The invention relates to the technical field of magnetic materials, and discloses a method for preparing a rare-earth-doped manganese-zinc ferrite material, comprising the steps of adding manganese oxide, zinc oxide and iron oxide as main components to a ball mill and conducting ball milling to obtain a mixture A; pre-firing the mixture A, and then conducting cooling to room temperature to obtaina pre-fired material; adding the pre-sintered material, vanadium oxide, niobium oxide, bismuth trioxide, molybdenum oxide, phosphorus pentoxide, copper oxide and a composite rare earth additive into aball mill, and conducting secondary ball milling and drying to obtain a mixture B, wherein the composite rare earth additive is composed of cerium oxide, yttrium oxide and lanthanum oxide; adding a polyvinyl alcohol solution to the mixture B, conducting mixing and granulation, and then conducting sieving by a sieve of 40-80 mesh, so as to obtain pellets; adding the pellets into a molding machinefor pressing, so as to obtain a blank; and sintering the blank and conducting cooling. The rare-earth-doped manganese-zinc ferrite material prepared by the method of the invention has high initial magnetic conductivity and saturation magnetic flux density.

Owner:ZHONGDE ELECTRONICS

Manufacturing process for die-casting saggars with refractory materials

InactiveCN104175389ALow costReduce the number of poresDischarging arrangementCeramic shaping mandrelsRefractoryDie casting

The invention discloses a manufacturing process for die-casting saggars with refractory materials. A method that a mold is die-cast by a press is adopted. The mold comprises an upper mold core, wherein the upper mold core is provided with a cooling water channel and an exhaust pipeline, a lower mold core matched with the upper mold core is arranged below, and the lower mold core adopts a floating structure. During mold opening, the lower mold core rises to the highest position, and the refractory materials are evenly placed onto the floating mold core of a lower mold; a switch of the press is pressed to press the upper mold core downwards, when the upper mold core is pressed downwards to the floating mold core of the lower mold, the floating mold core of the lower mold drops along with the upper mold core, the bottom surface of the floating mold core of the lower mold is stopped from dropping when being pressed downwards to a working table surface of the press, the upper mold core drops continuously at the moment, the refractory materials distributed on the lower mold core are compacted, after compaction, the upper mold core rises, and the floating mold core of the lower mold returns to the initial position. The manufacturing process is convenient in blanking and can solve problems that a lot of air holes exist in the pressed saggars and the saggars are uneven in thickness.

Owner:浙江立鑫高温耐火材料有限公司

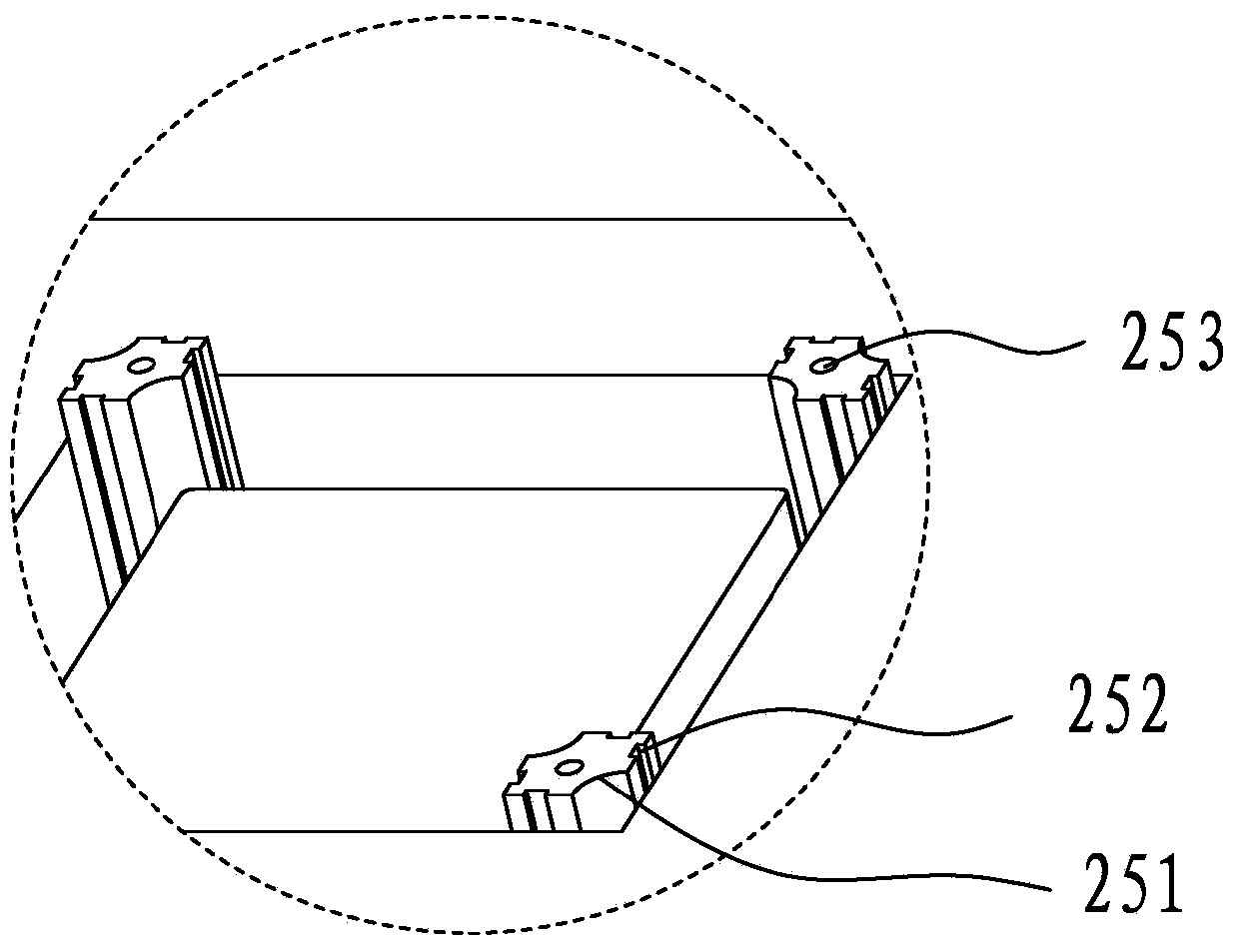

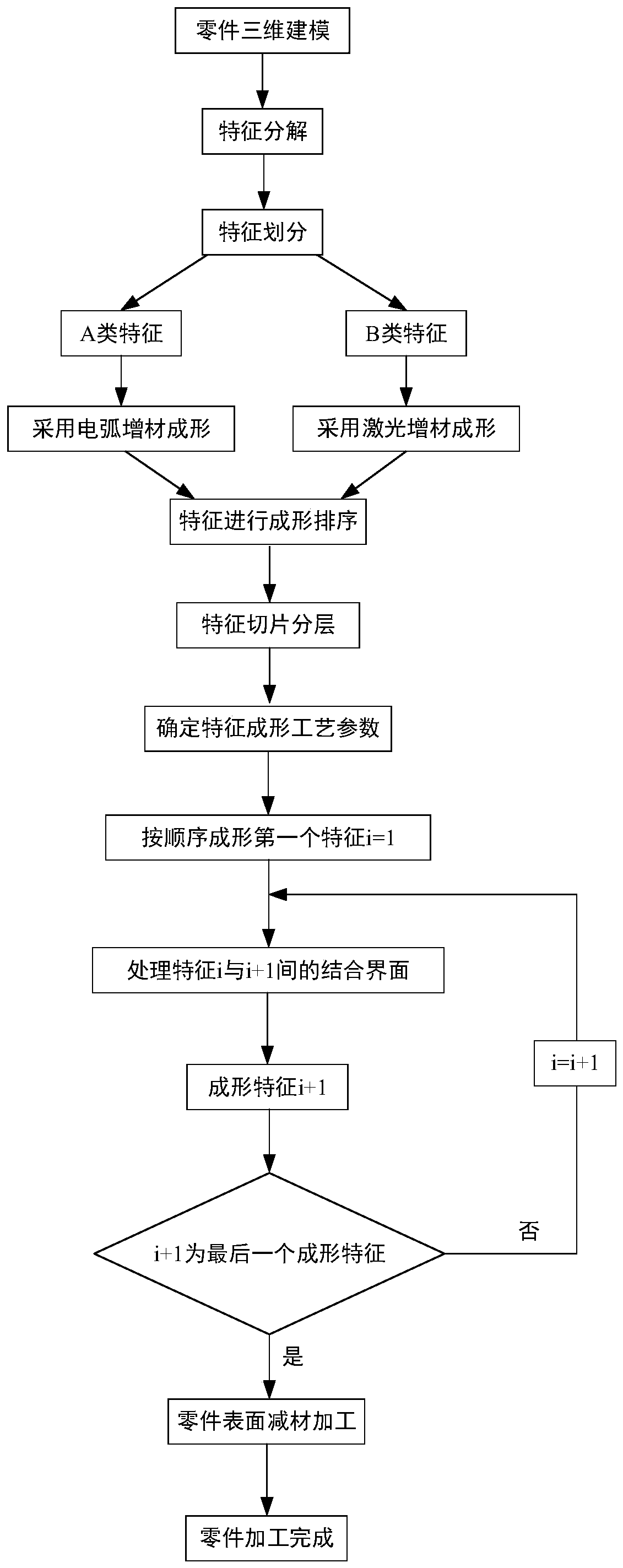

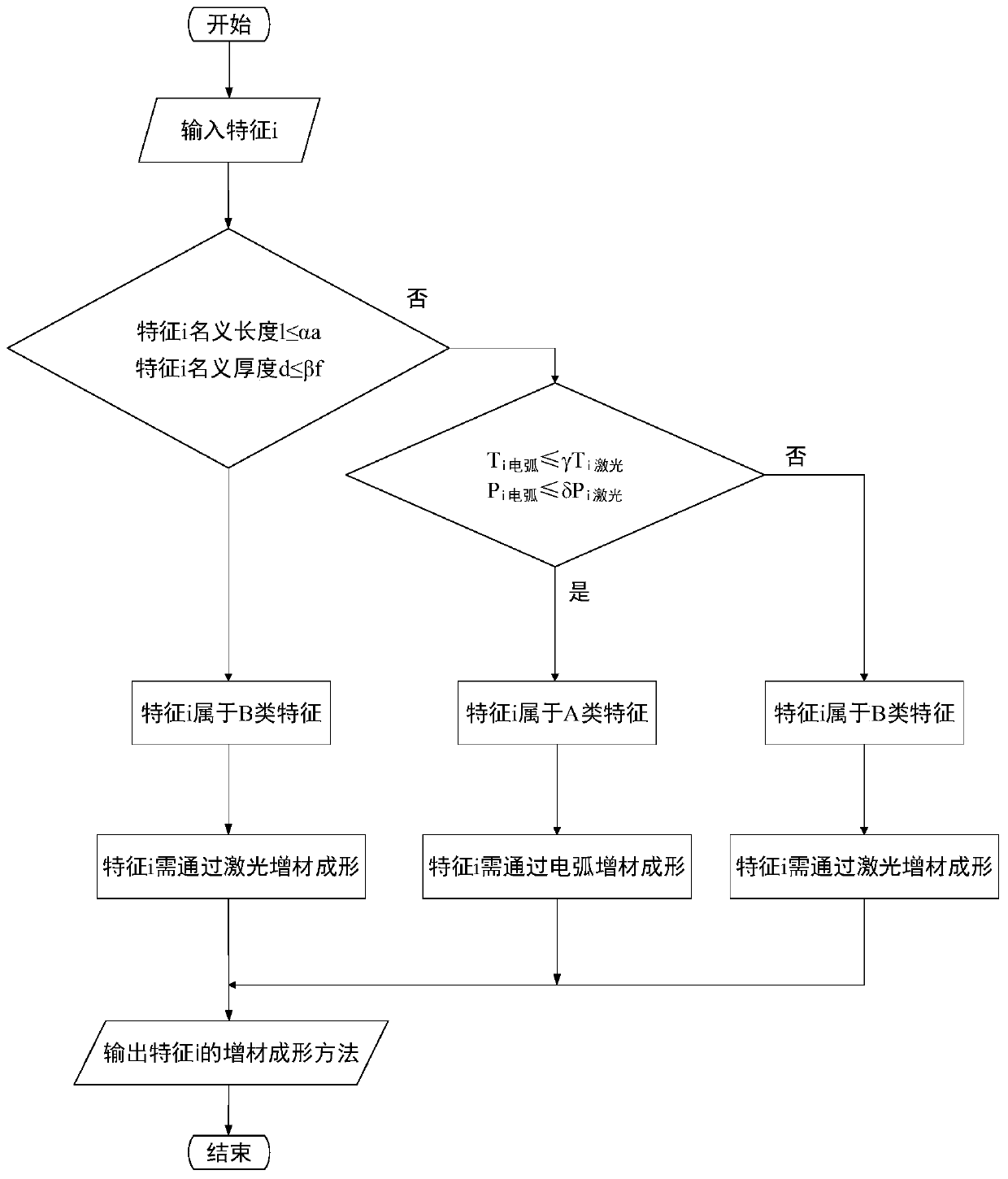

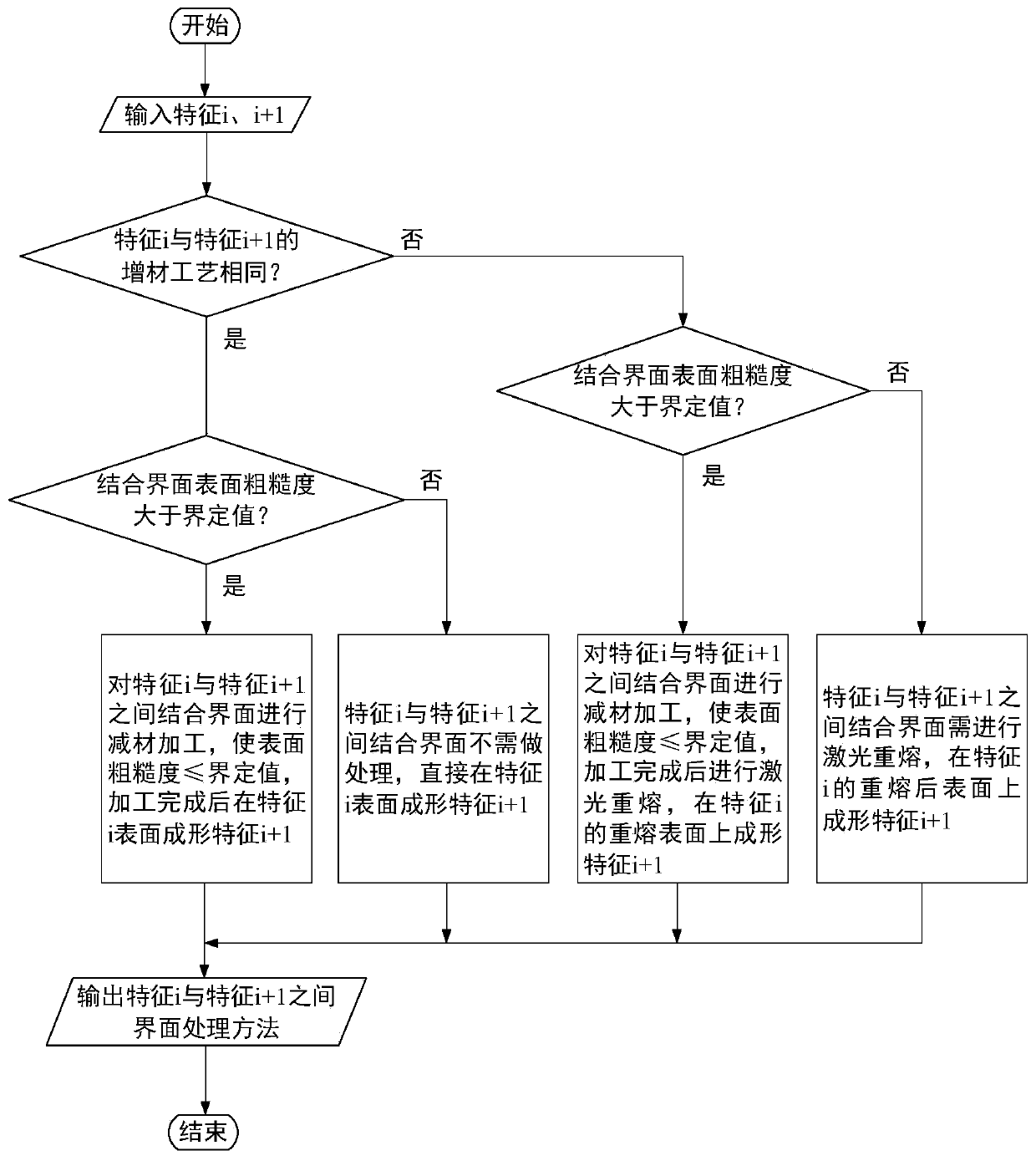

Complex metal part forming method adopting combination of electric arc additive and laser additive

ActiveCN111545915AGuaranteed forming effectImprove mechanical propertiesLaser beam welding apparatusLaser additive manufacturingMachining

The invention discloses a complex metal part forming method adopting combination of an electric arc additive and a laser additive. The complex metal part forming method comprises the steps that three-dimensional modeling is conducted on a part entity, geometric feature decomposition is conducted on a three-dimensional entity model, a part feature additive forming method is divided, forming processparameters of all features are determined, forming sorting is conducted on all the features, slicing and layering treatment is conducted on all the features, and all the features are sequentially formed according to the feature forming sorting and a treatment method of a combination interface between the adjacent features. According to the complex metal part forming method, the advantages of efficient electric arc additive manufacturing forming and fine laser additive manufacturing forming are effectively combined, compared with traditional forging, the machining period is shortened, the overall forming performance of a part is guaranteed, the quality of a fine and complex structure is guaranteed, the production efficiency is improved, and the machining cost is reduced. Meanwhile, a laserremelting method is adopted, the number of cracks and air holes in a combination interface area of a dissimilar additive process is reduced, meanwhile, structure distribution is more uniform, and themechanical property of the combination interface is improved.

Owner:XI AN JIAOTONG UNIV

Preparation method of powder metallurgy titanium alloy

ActiveCN110791682AImprovement of sintering formabilityHigh densityRare-earth elementPowder metallurgy

The invention relates to a preparation method of a powder metallurgy titanium alloy, and belongs to the technical field of alloys. According to the method, the sintering formability of a blank is improved through addition of an additive formed through mixing of feldspar and fluorite, the vacuum hot-pressing sintering method is adopted further, then the density of the sintered titanium alloy is increased, and the number of holes in the sintered titanium alloy is reduced; meanwhile, sintering in the nitrogen protection manner is adopted, nitrogen can react with partial metal elements, nitride metal is formed, and deposition is performed on the surface; at the same time, according to the method, an aid is added, the sintering performance can be further improved by the aid, and partial impurities can be removed; besides, mixed powder formed through mixing of boron oxide, rare-earth elements and sodium cobaltate is added, the beta-Ti phase and the alpha-Ti phase are refined by boron elements and the rare-earth elements during sintering, and alpha-Ti is remarkably transformed from sheets to the form similar to equiaxed grains, so that the method is beneficial to the ductility.

Owner:SUZHOU ZHONGYAO TECH CO LTD

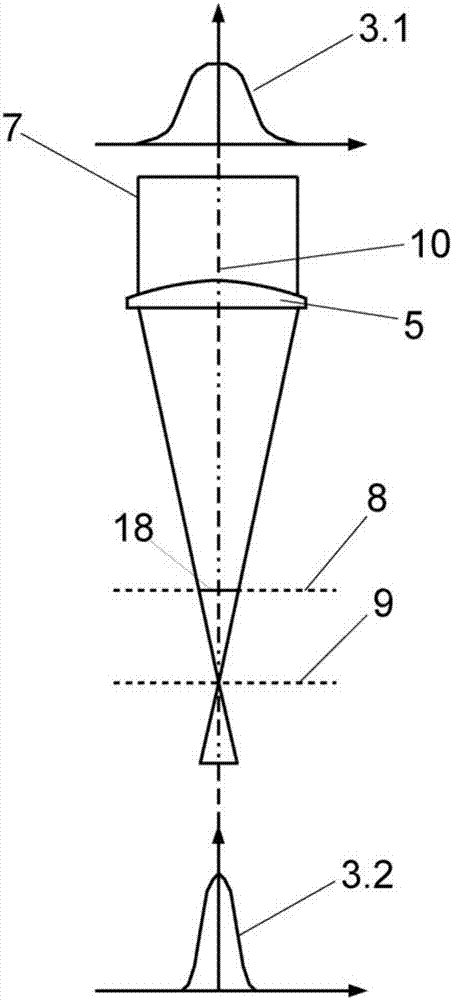

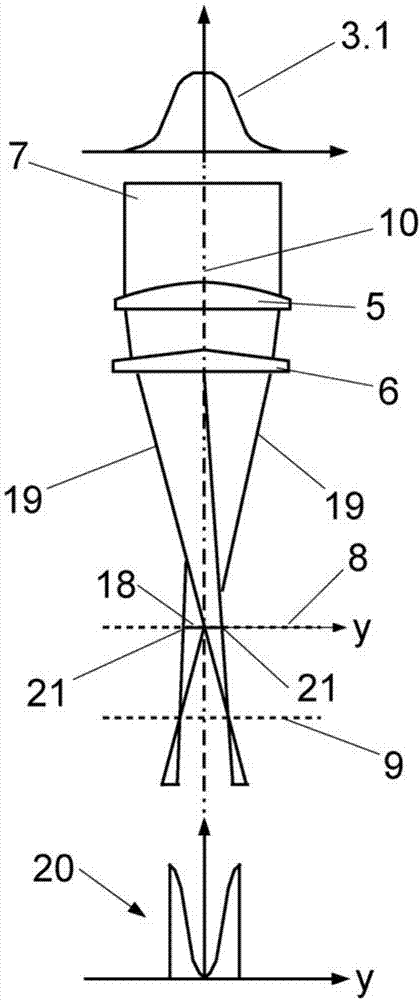

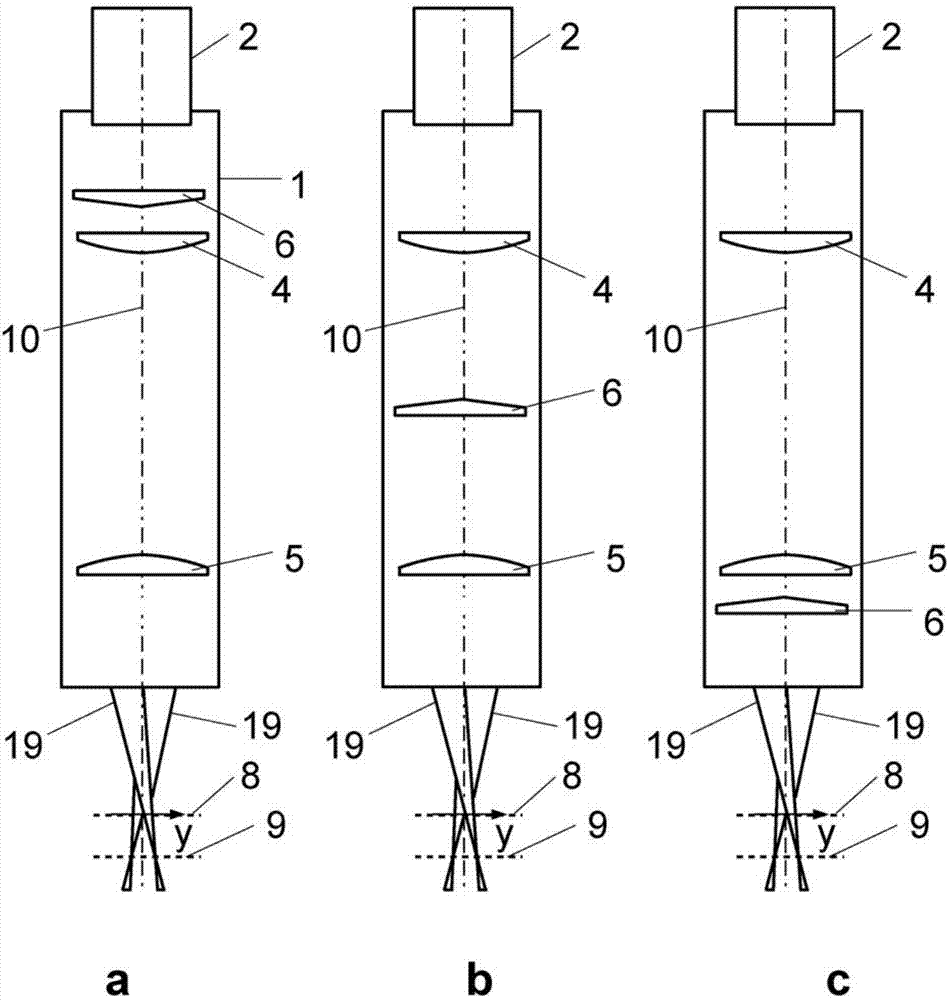

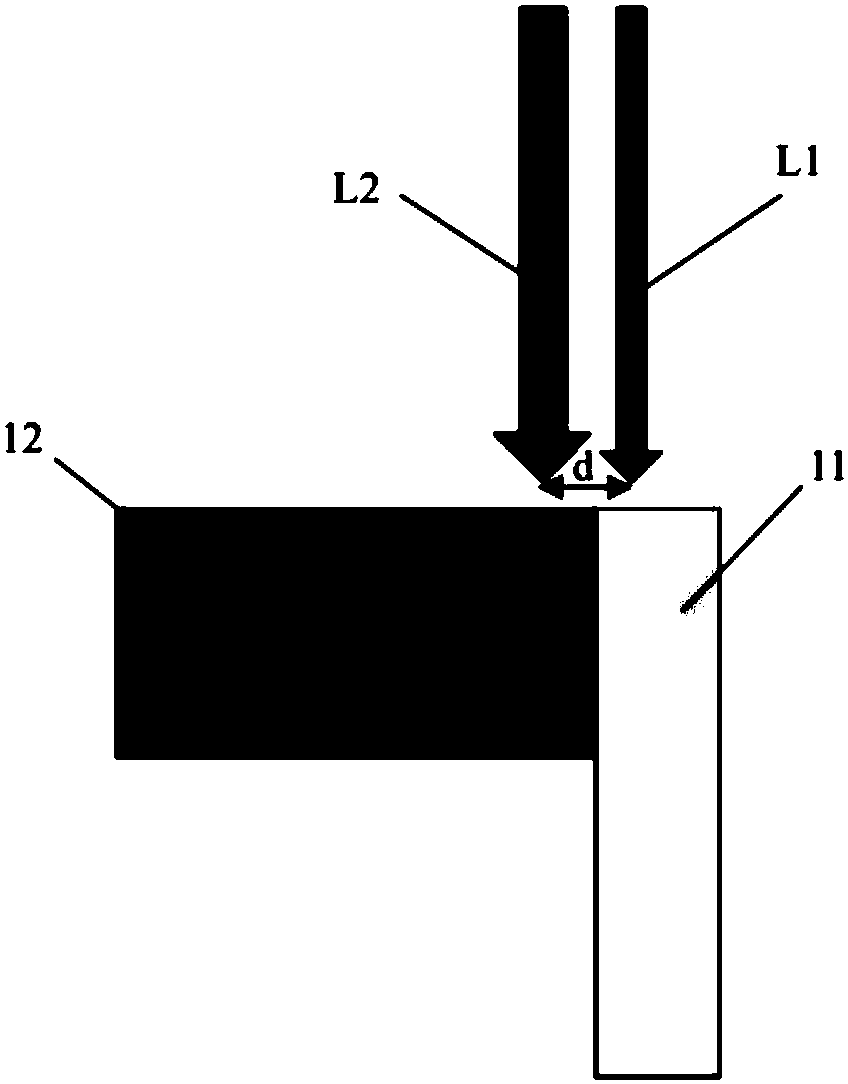

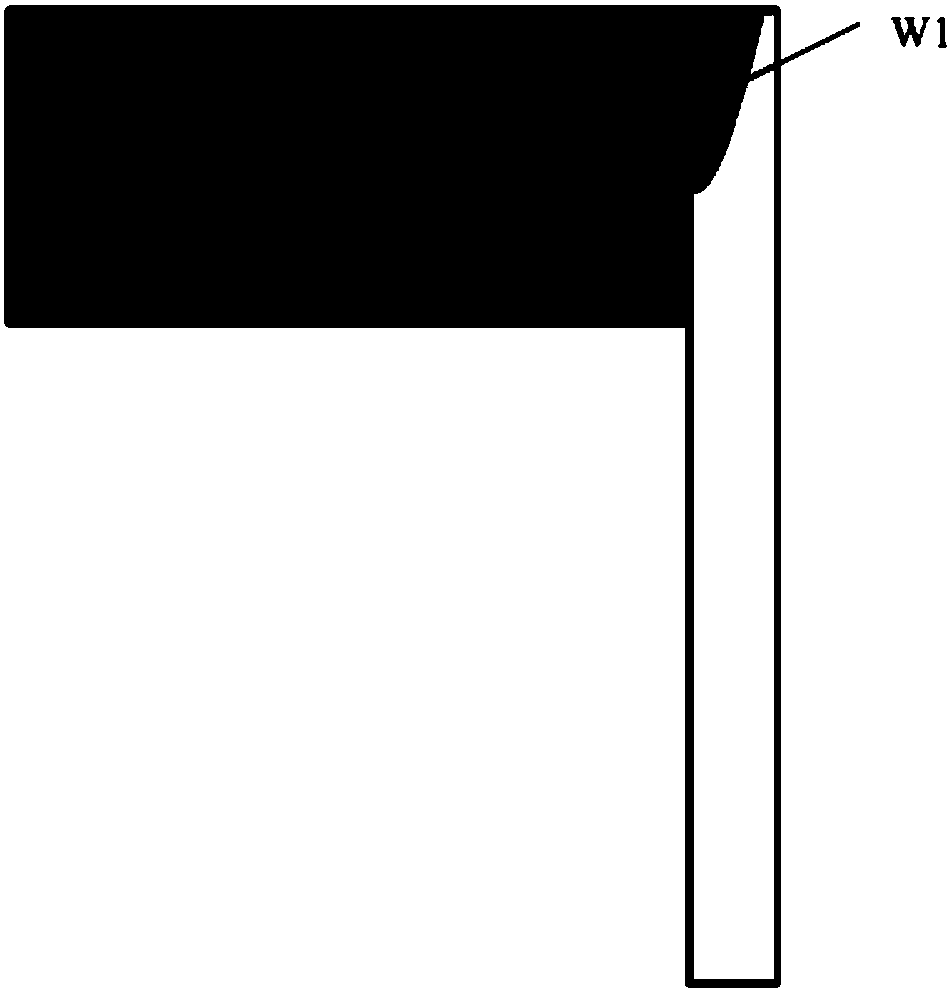

Laser beam joining method and laser machining optics

InactiveCN107405711AEasy dischargeReduce roughnessSoldering apparatusLaser beam welding apparatusLaser processingLight beam

The invention relates to a method for joining workpieces (12, 13) using a laser beam (7), wherein the laser beam (7) is focused onto a focal plane downstream of the machining plane in the beam propagation direction and subdivided into a plurality of partial beams (19) by means of a beam dividing device (6). The subdivision is effected in a geometric manner, i.e. the partial beam cross sections emerge from a division of the geometric form of the beam cross section of the laser beam (7). The partial beams (19) are guided onto the machining plane (8) in a crossed manner and with an offset from one another in such a way that an extended laser focus (18) is formed. The radiation intensity distribution of the superposed partial beams (19) in the machining plane (8) along a line perpendicular to the seam joint respectively has a maximum at the end regions thereof. As a result thereof and as a result of the spatially extended region of high radiation intensity on both sides along the seam joint compared to the prior art, there is, firstly, an improvement in the edge connection and hence in the quality of the seam joint and, secondly, an increase in the process efficiency.

Owner:SCANSONIC MI

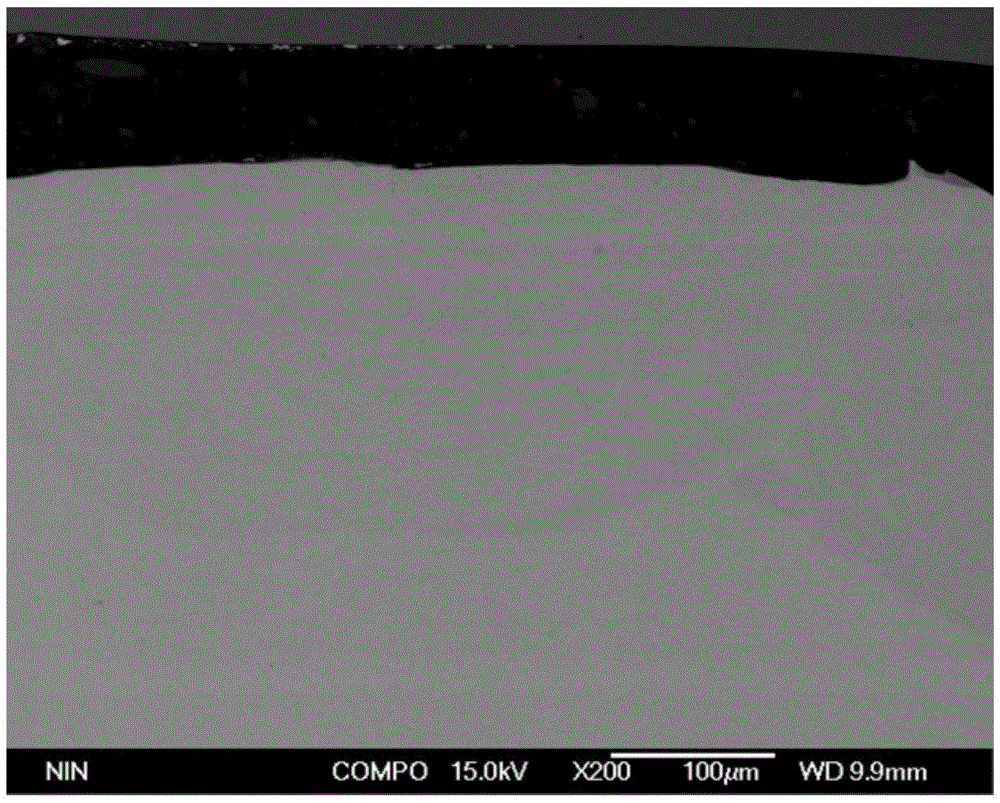

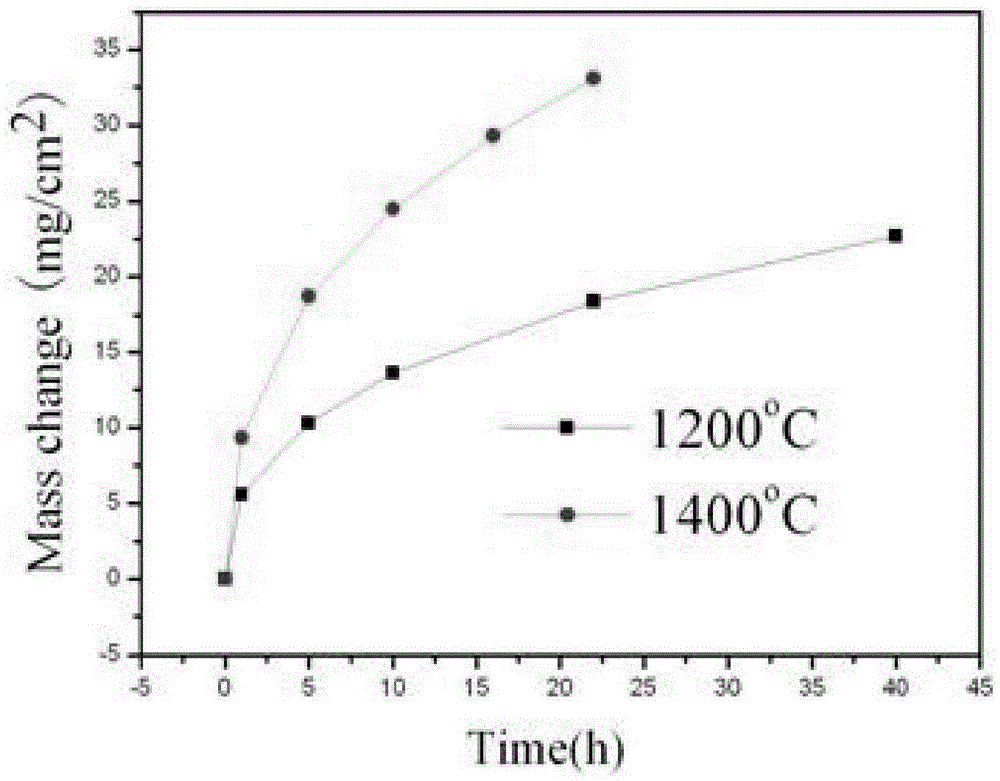

Method for preparing modified composite Hf-Ta metal coating through laser cladding

ActiveCN105386041AImprove antioxidant capacityShort-term protectionTransportation and packagingMetal-working apparatusMetal coatingSand blasting

The invention discloses a method for preparing a modified composite Hf-Ta metal coating through laser cladding. The method comprises the steps that firstly, refractory metal is subjected to acid pickling after polishing treatment and then subjected to sand blasting treatment and ungrease treatment in sequence; secondly, mixed powder and a dispersing agent are placed in a ball mill to be subjected to ball milling and mixed evenly to obtain modified composite Hf-Ta slurry; thirdly, the modified composite Hf-Ta slurry is pre-placed on the surface of the refractory metal to obtain a pre-placed layer on the surface of the refractory metal after drying, then presintering treatment is conducted, and a presintered layer is obtained on the surface of the refractory metal; and fourthly, laser cladding is conducted on the presintered layer, and the modified composite Hf-Ta metal coating with the thickness being 30 [mu]m-800 [mu]m is obtained on the surface of the refractory metal. According to the modified composite Hf-Ta metal coating prepared through the method, the oxidation resistance of the refractory metal in a superhigh-temperature and low-oxygen-pressure environment can be significantly improved, and short-term protection can be provided for the refractory metal in a superhigh-temperature oxidation environment or an ablation environment.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Manufacturing method of meta-aramid raw paper with high insulating property

InactiveCN110939008AImprove insulation performanceImprove adsorption capacitySpecial paperPulp beating methodsPolymer scienceElectric machinery

The invention discloses a manufacturing method of meta-aramid raw paper with high insulating property. Meta-aramid chopped fibers and meta-aramid fibrids are used as raw materials; the manufacturing method comprises the following steps: defibering and mixing the meta-aramid chopped fibers and the meta-aramid fibrids according to a ratio; and preparing the meta-aramid raw paper through screen loading forming. The manfacuring method is characterized in that the meta-aramid fibrids are high-pulp degree fibrids, and the meta-aramid fibrids are subjected to beating treatment to form the high-pulp degree fibrids with the beating degree of 65-95 DEG SR and the specific surface area of 60 m < 2 > / g or above; and screen loading forming is formed by adopting a fourdrinier forming process of high-speed pulp flowing. According to the invention, the beating degree and the specific surface area of the meta-aramid fibrids are improved; a fourdrinier forming process of high-speed slurry flowing is adopted for forming; the high insulating property of the prepared aramid base paper is effectively improved, the electrical strength of the base paper is 12 kV / mm or above, the electrical strength afterhot pressing can reach 30 kV / mm or above, and the meta-aramid raw paper completely has the capacity of safely and stably operating for a long time in a motor or transformer electric field environmentof a high voltage class.

Owner:ZHUZHOU TIMES FIBER PIONEER MATERIAL TECH CO LTD

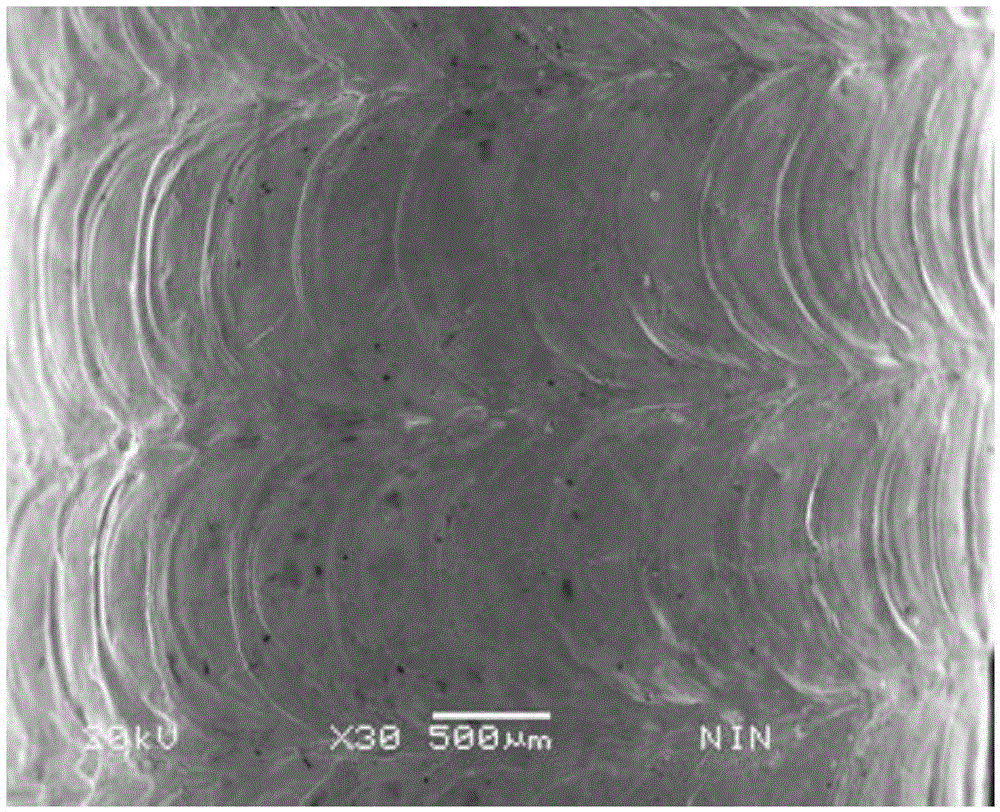

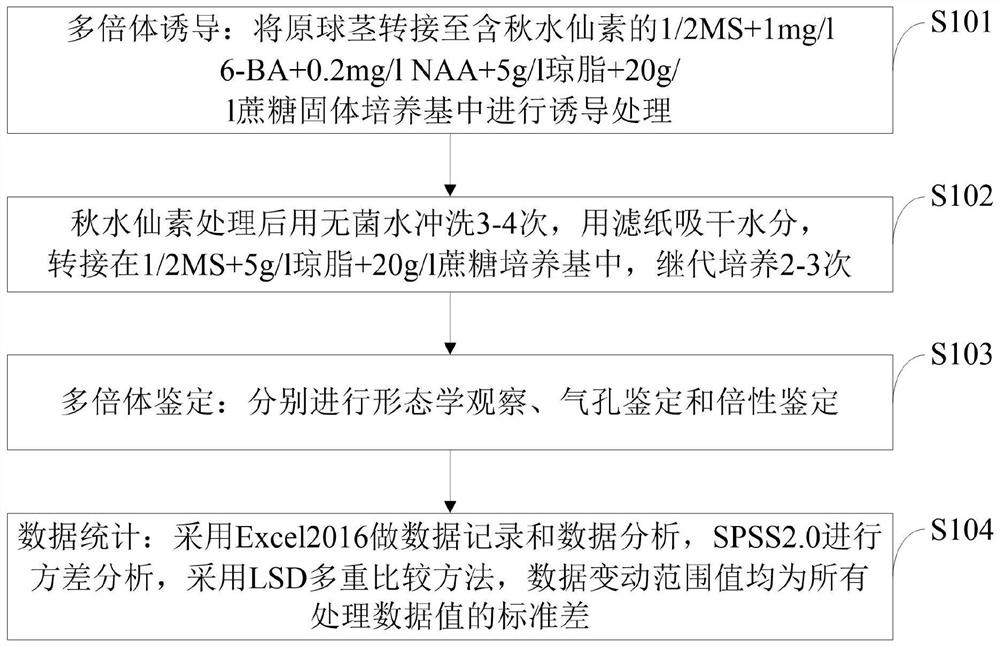

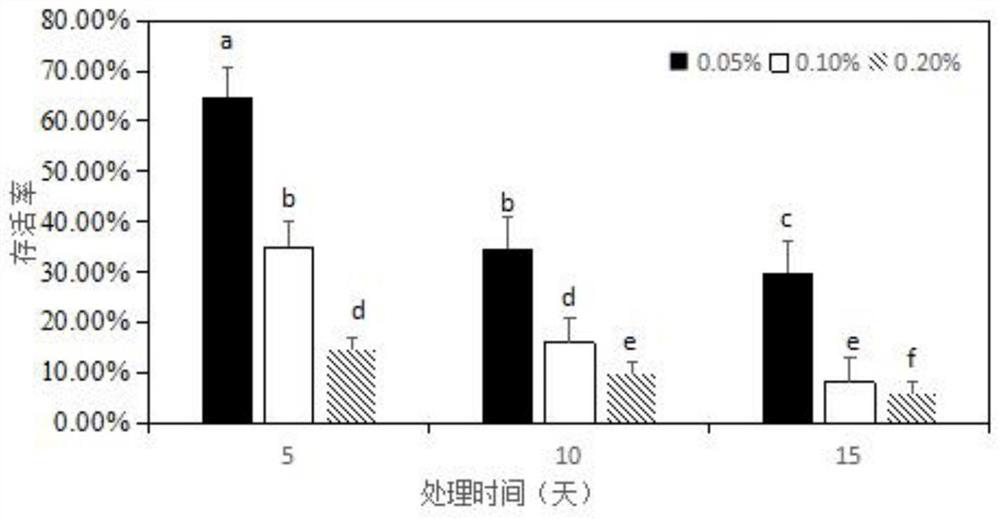

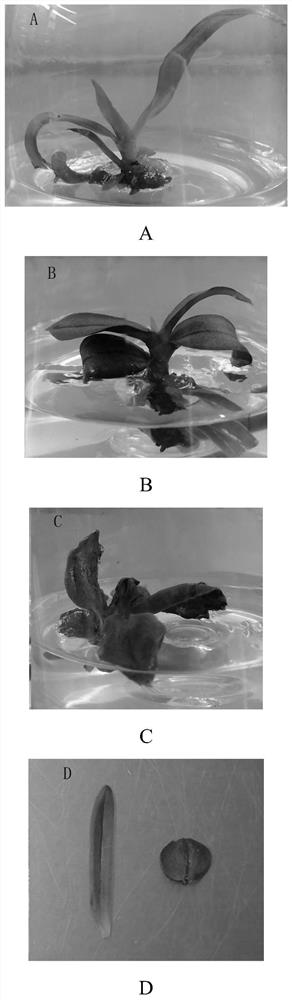

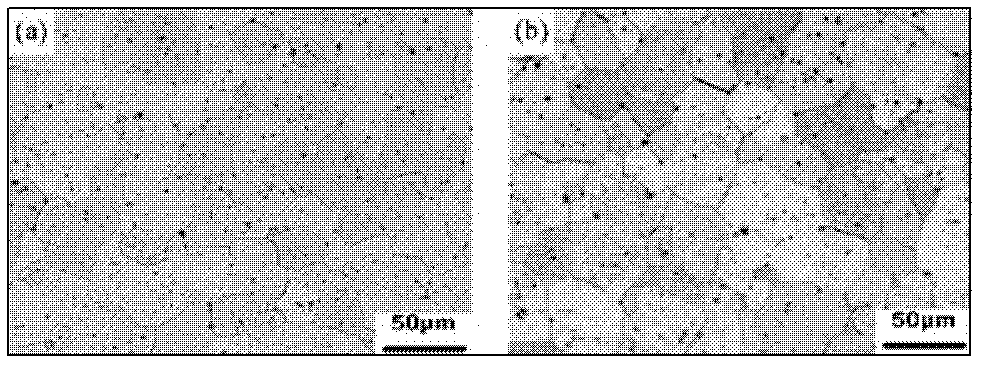

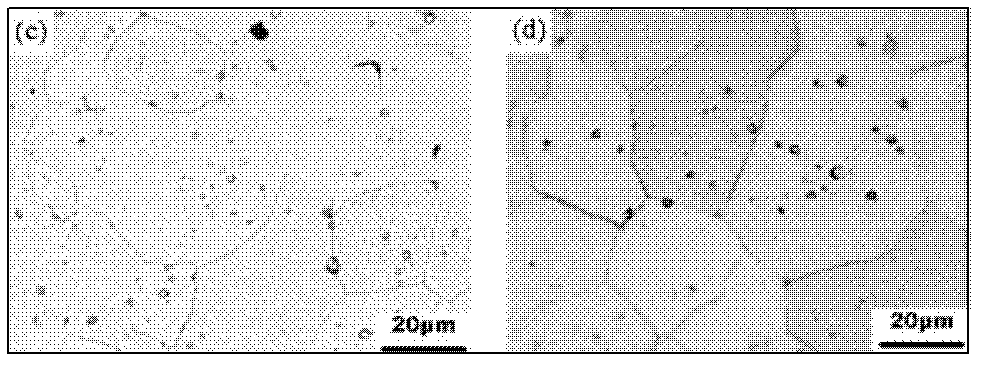

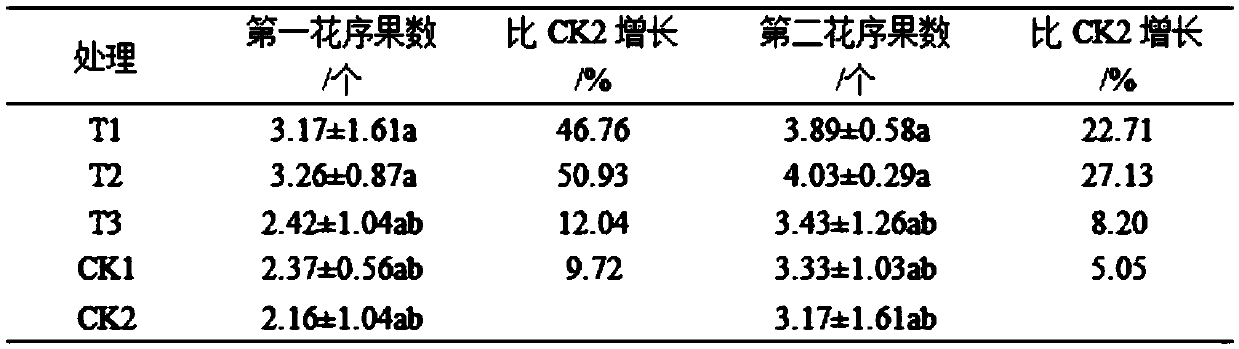

Method for inducing phalaenopsis protocorm to generate polyploid by colchicine

ActiveCN112293257ADecrease in the number of pores per unit areaReduce the number of poresPlant tissue cultureHorticulture methodsBiotechnologySucrose

The invention belongs to the technical field of polyploid breeding, and discloses a method for inducing phalaenopsis protocorm to generate polyploid by colchicine. The method comprises the following steps of transferring the protocorm into a 1 / 2MS+1mg / l 6-BA + 0.2 mg / l NAA+5g / l agar+20g / l sucrose solid culture medium containing 0.05% of colchicine, and culturing for 15 days for induction treatment; washing the protocorm for 3-4 times by using sterile water after treatment, absorbing moisture by using filter paper, transferring the protocorm into a 1 / 2MS+5g / l agar+20g / l sucrose culture medium,and carrying out subculture for 2-3 times; performing polyploid identification, namely respectively carrying out morphological observation, stomatal identification and ploidy identification; and performing data statistics. According to the method, colchicines with different concentrations and different treatment time are used for doubling the phalaenopsis protocorm by a co-culture method, so thata foundation is laid for polyploid induction culture of a new phalaenopsis variety with large flower size, bright color and high ornamental value.

Owner:INST OF VEGETABLE & FLOWERS CHINESE ACAD OF AGRI SCI +1

Process for preparing large-specification tungsten plate billet by means of resistance sintering

InactiveCN102581282AImprove organizationImprove performanceElectrical resistance and conductanceEconomic benefits

The invention discloses a process for preparing a large-specification tungsten plate billet by means of resistance sintering. The process includes the steps: firstly, taking tungsten powder of needed amount; secondly, selecting a rubber sleeve or a steel sleeve according to the specification of a pre-produced tungsten plate billet, compactly and uniformly filling the tungsten powder of the needed amount into the rubber sleeve or the steel sleeve, and then sealing the rubber sleeve or the steel sleeve; thirdly, performing isostatic pressing (at 180MPa); fourthly, releasing pressure and demoulding; and fifthly, sintering the pre-produced tungsten plate billet by means of resistance sintering. The resistance sintering temperature is lower than traditional vertical sintering temperature, temperature rises slowly, and a temperature field is uniform, so that the texture and the performance of the large-specification tungsten plate billet can be improved. Yield is high, energy consumption is low, economic benefits are high, corner and edge chipping of products in subsequent machining of a traditional process is eliminated, fine machining performance is achieved, and the number of pores at a grain boundary is relatively decreased. The process is simple, convenient, easy to implement and suitable for popularization and use in tungsten plate billet preparation.

Owner:苏州先端稀有金属有限公司

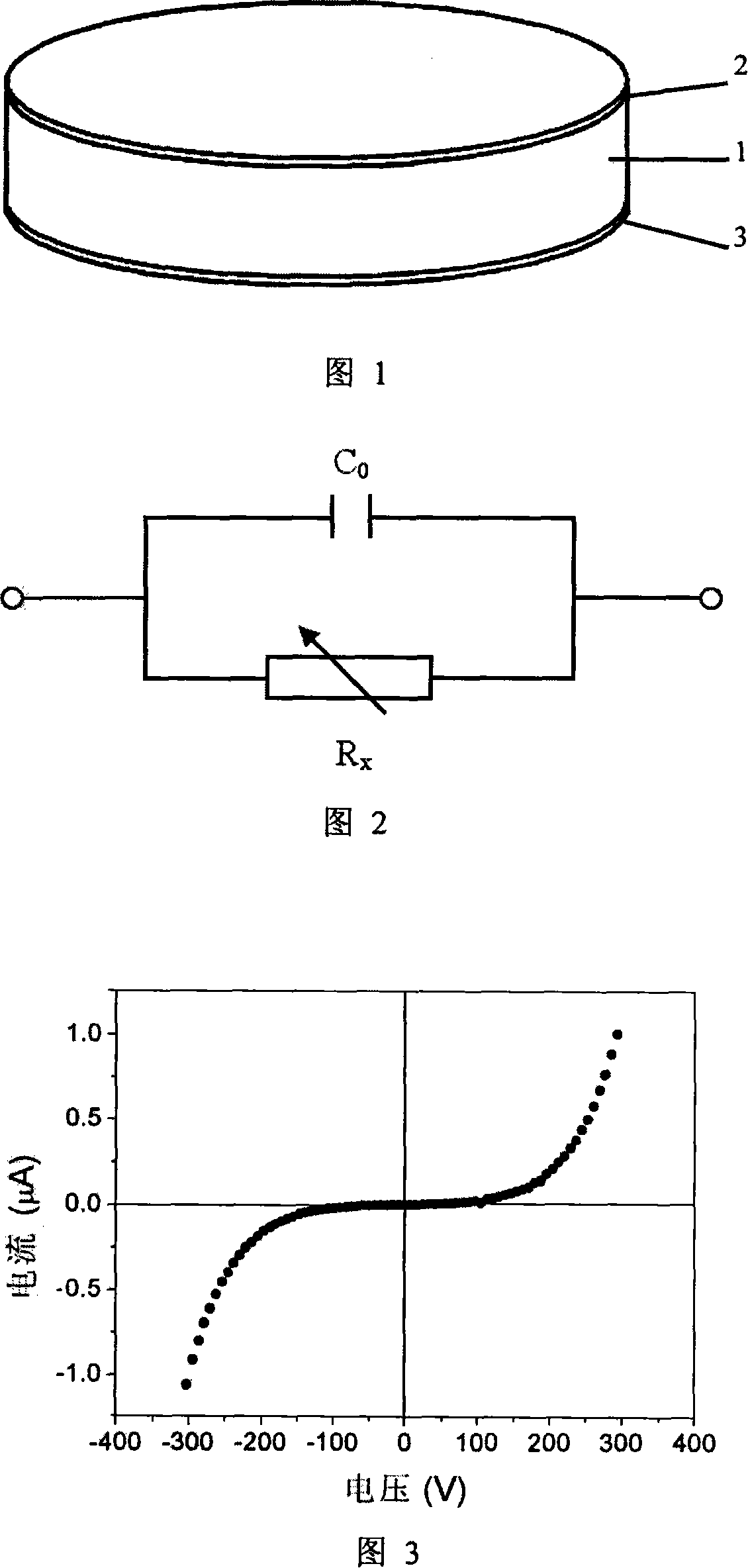

Multifunctional element possessing large electric capacitance and pressure-sensitive character and its preparation method

InactiveCN101150010ACompact bodyReduce the number of poresFixed capacitor electrodesFixed capacitor dielectricPressure sensitiveSolid state reaction method

This invention provides a multifunction element with a large electric volume and voltage-sensitive character and its preparation method, which sets an Ag top electrode and an Ag bottom electrode on the up and down surfaces of a medium wafer of CCTO ceramic material, both of which are wafer electrodes, applies a solid reaction method to synthesize CCTO powder and applies a dry-pressing and cooling static-pressing technology and ceramic sintered technology to prepare CCTO ceramic medium wafer with the synthesized powder to modify its shape and surface of the wafer to be polished and then applies silk-screen printing to prepare Ag top electrode and an Ag bottom electrode on the top and bottom surfaces of the wafer.

Owner:XIAMEN UNIV

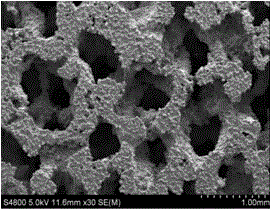

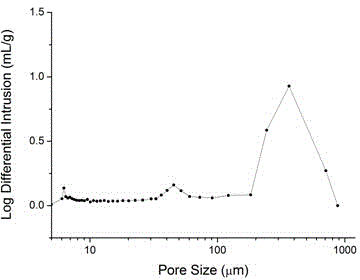

Bioactive porous titanium medical implant material and preparation method

ActiveCN104922727AImprove adhesionImprove biological activityCoatingsProsthesisImplant materialTitanium oxide

The invention discloses a bioactive porous titanium medical implant material and a preparation method and belongs to the technical field of biomedical materials. The material comprises a base layer and a surface layer; the base layer is made of porous titanium; the surface layer includes a dense titanium oxide layer, a titanium oxide gel mediate layer and a calcium phosphate external layer. The method includes porous titanium blank preparation, blank sintering and surface chemical and electrochemical treatment. The material prepared by the method has the advantages of a three-dimensional communicated porous structure with adjustable porosity and pore size, the mechanical strength matches with the body's natural bones, the bioactivity can be improved through the bioactive layer with the three layered surface structure, the porous material with a gradient pore structure can be prepared through combination of organic foam with different pore sizes, and the material is particularly adaptive to serving as a bone defect repair or replace material of the human body load-bearing portion.

Owner:SICHUAN UNIV

Wear-resistant ceramic tube and preparation method thereof

InactiveCN104529403AGood wear resistanceReduce the number of poresCarbide siliconPressureless sintering

The invention relates to a wear-resistant ceramic tube and a preparation method thereof and belongs to the technical field of production of ceramic materials. The wear-resistant ceramic tube comprises the following components in parts by weight: 30-50 parts of silicon oxide, 40-55 parts of aluminum oxide, 10-20 parts of aluminum nitride, 10-20 parts of yttrium oxide and 0.5-10 parts of silicon carbide. The preparation method comprises the following steps of weighting raw materials, mixing, stirring, drying in vacuum, ball milling, sieving, carrying out dry pressing and cold isostatic pressing, removing binder and carrying out pressureless sintering. The ceramic tube has the characteristics of good wear resistance, few air pores and good density.

Owner:FOSHAN MINGQIAN TECH

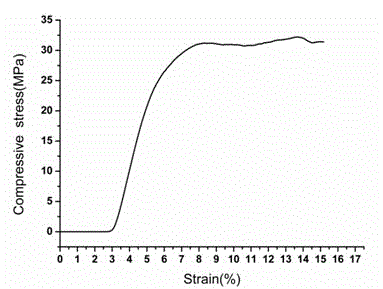

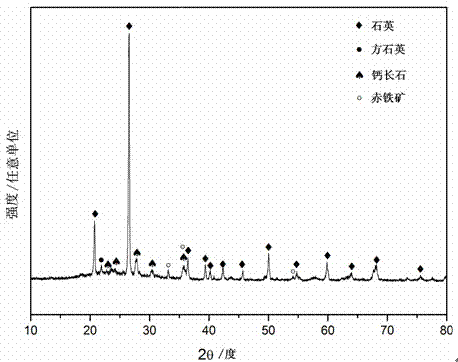

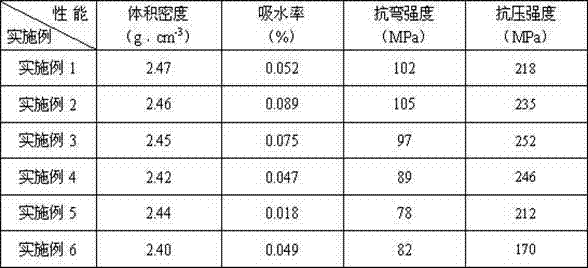

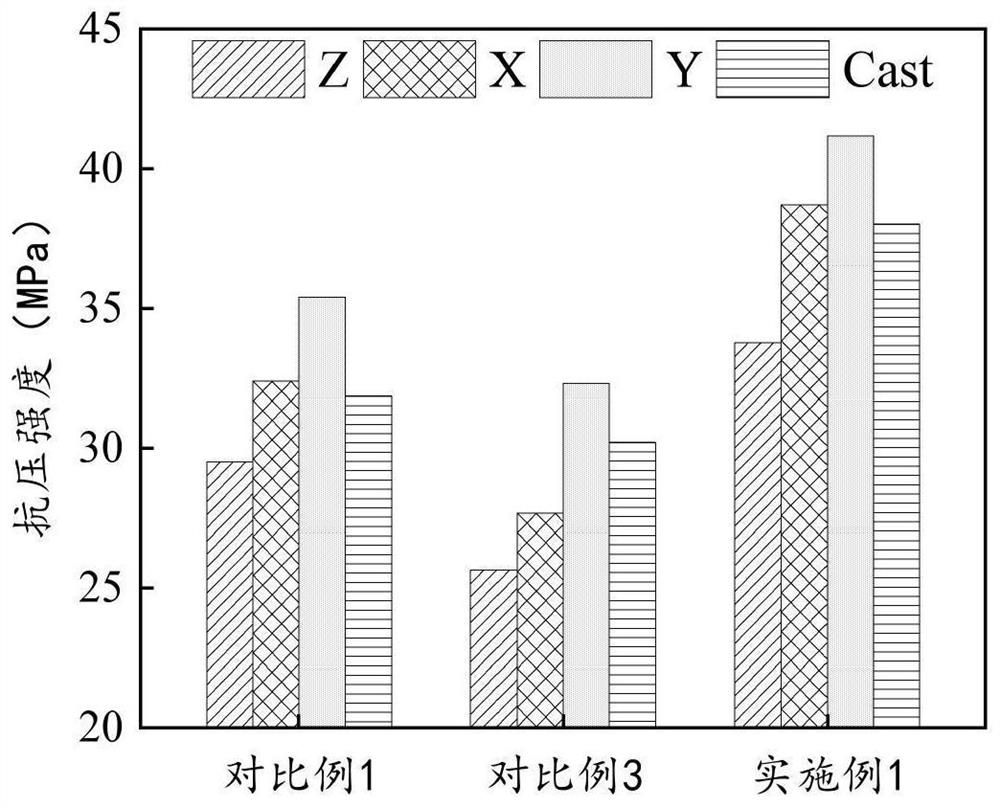

High-strength ceramic mainly prepared from tungsten tailings and preparation method of high-strength ceramic

InactiveCN104496433AEfficient manufacturingHigh strengthSolid waste disposalCompression moldingCompressive strength

The invention provides high-strength ceramic mainly prepared from tungsten tailings and a preparation method of the high-strength ceramic. The high-strength ceramic comprises the following raw materials in percentage by mass: 80%-90% of tungsten tailings, 10%-20% of albite and 1%-5% of a binder. The preparation method comprises the following steps: firstly preprocessing the tungsten tailings, mixing the preprocessed tungsten tailings with albite, carrying out ball milling, and carrying out compression molding by virtue of a stainless steel mold; sintering after drying, so as to obtain the high-strength ceramic. The high-strength ceramic has the coefficients that the volume density is 2.42g / cm<3>-2.47g / cm<3>, the water absorption rate is 0.018%-0.089%, the bending strength is 78MPa-105MPa, and the compressive strength is 170MPa-252MPa. The preparation method has the beneficial effects that the utilization rate of the tungsten tailings is high (the mass percent is 80%-90%); by combining the tungsten tailings with a traditional raw material, namely albite, the sintering temperature is substantially decreased; the preparation process is simple, and the production cost is relatively low; the preparation method is suitable for large-scale production, and the environmental pollution caused by the tungsten tailings can be effectively reduced.

Owner:CENT SOUTH UNIV

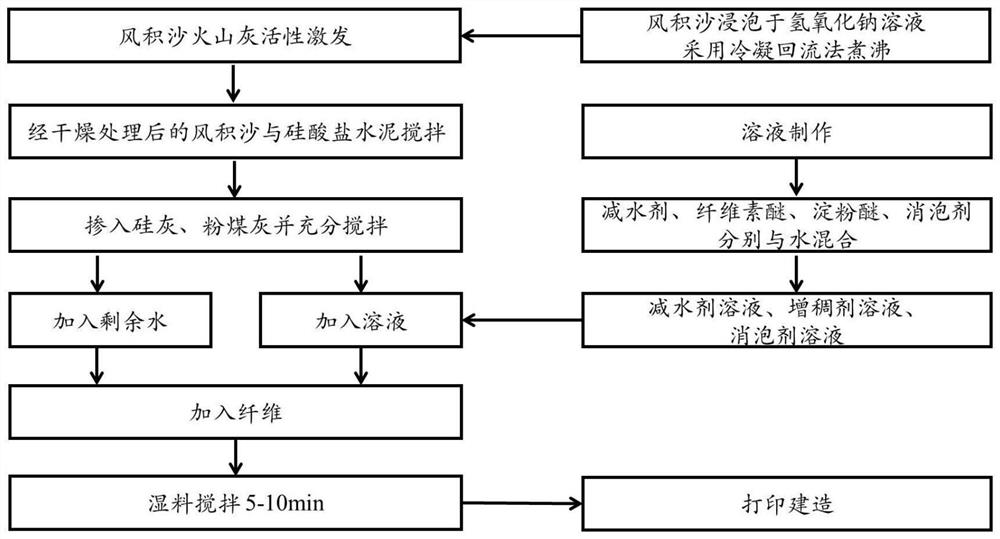

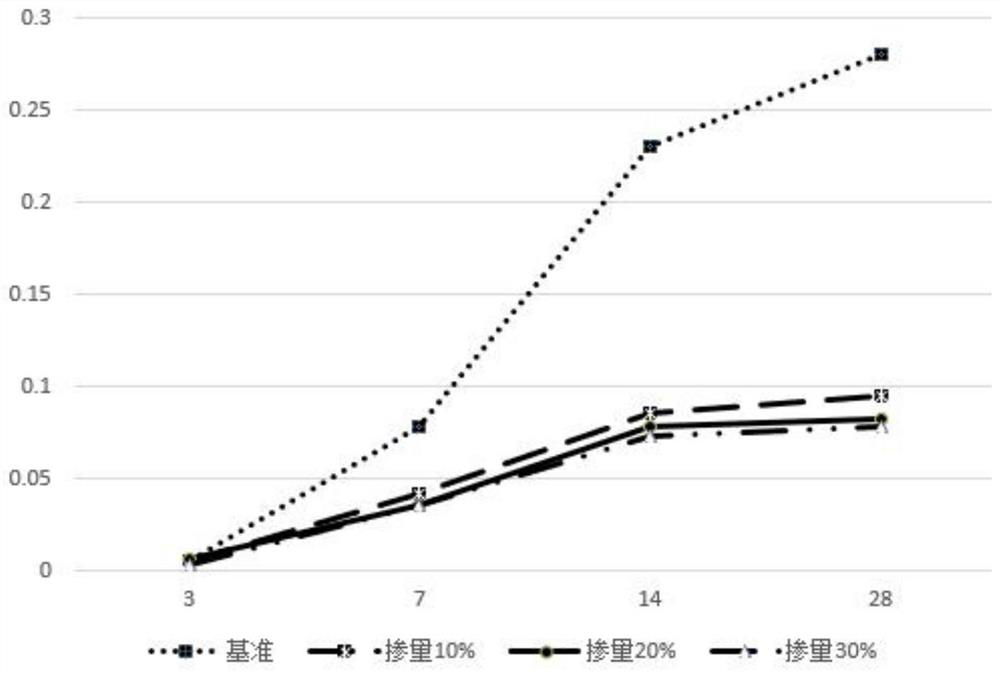

3D-printable aeolian sand anti-freezing concrete as well as preparation method and use method thereof

ActiveCN114292073AImprove mechanical propertiesIncreased durabilityAdditive manufacturing apparatusSolid waste managementCelluloseWater reducer

The invention provides 3D-printable aeolian sand anti-freezing concrete as well as a preparation method and a use method thereof, and belongs to the technical field of concrete. The aeolian sand anti-freezing concrete capable of 3D printing provided by the invention is prepared from the following preparation raw materials in parts by weight: 166-186 parts of Portland cement not lower than 42.5 grade; 3 to 13 parts of silica fume; 6 to 16 parts of fly ash; 330 to 350 parts of aeolian sand; 1-5 parts of a water reducing agent; 0.1 to 1.5 parts of cellulose ether; 0.05 to 0.5 part of starch ether; 0.1 to 1.5 parts of a defoaming agent; 0.2 to 4 parts of polypropylene fiber; 60 to 75 parts of water; the aeolian sand is aeolian sand subjected to alkali treatment. The aeolian sand anti-freezing concrete provided by the invention not only can realize 3D printing, but also is excellent in mechanical property and durability, and the conditions of shortage of natural sand and abundant aeolian sand resources in desert areas are adjusted according to local conditions, and local materials are used.

Owner:HEBEI UNIV OF TECH +1

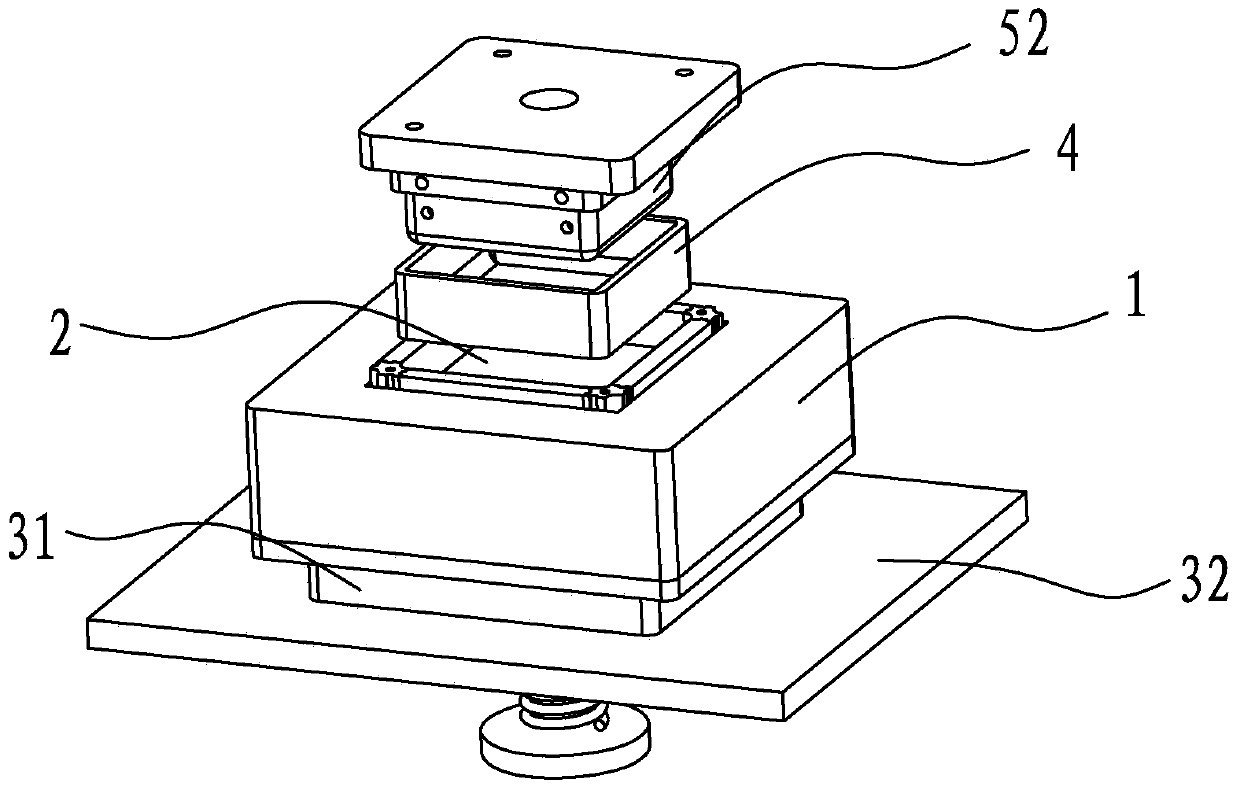

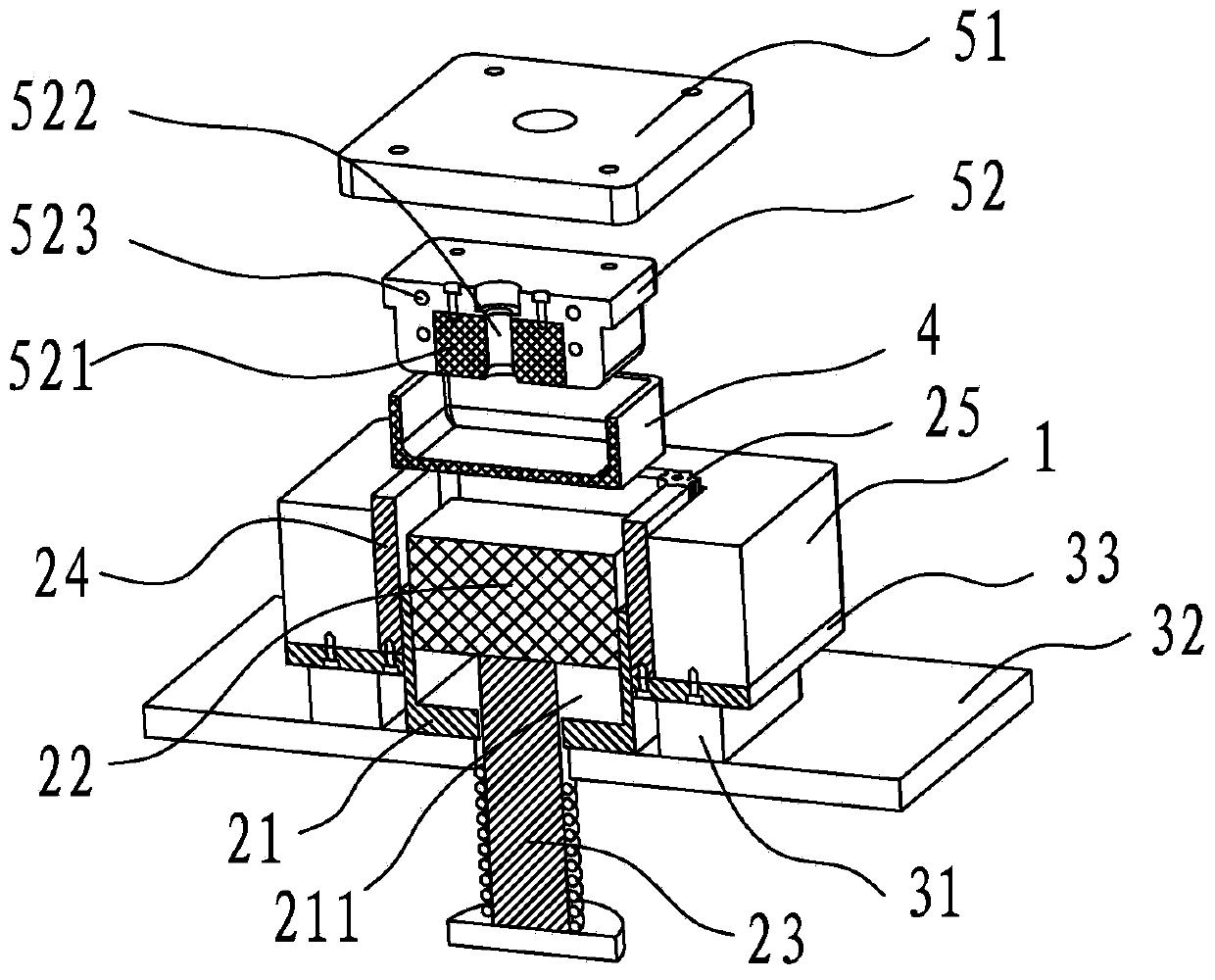

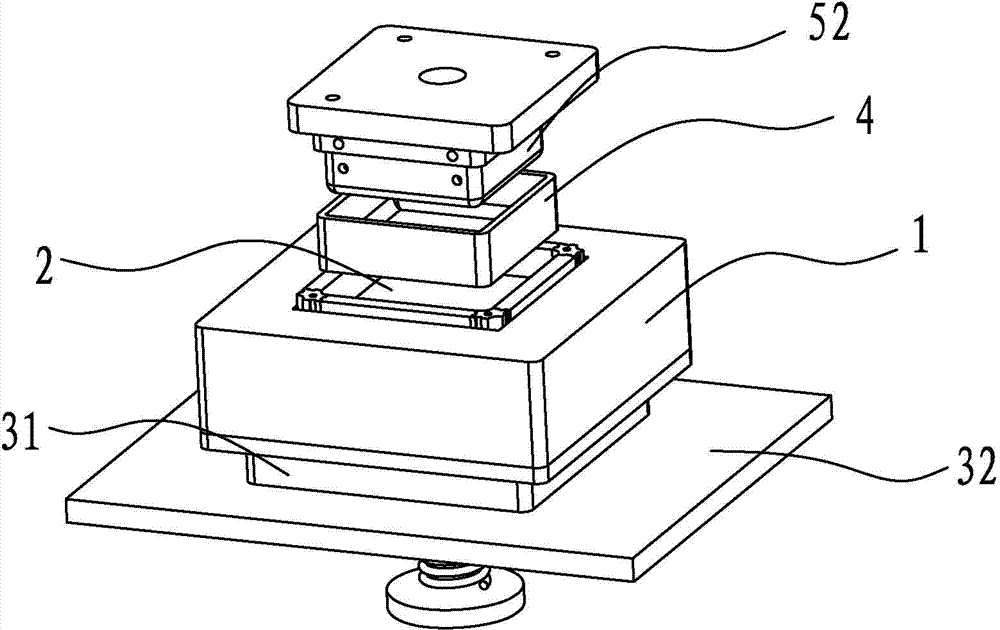

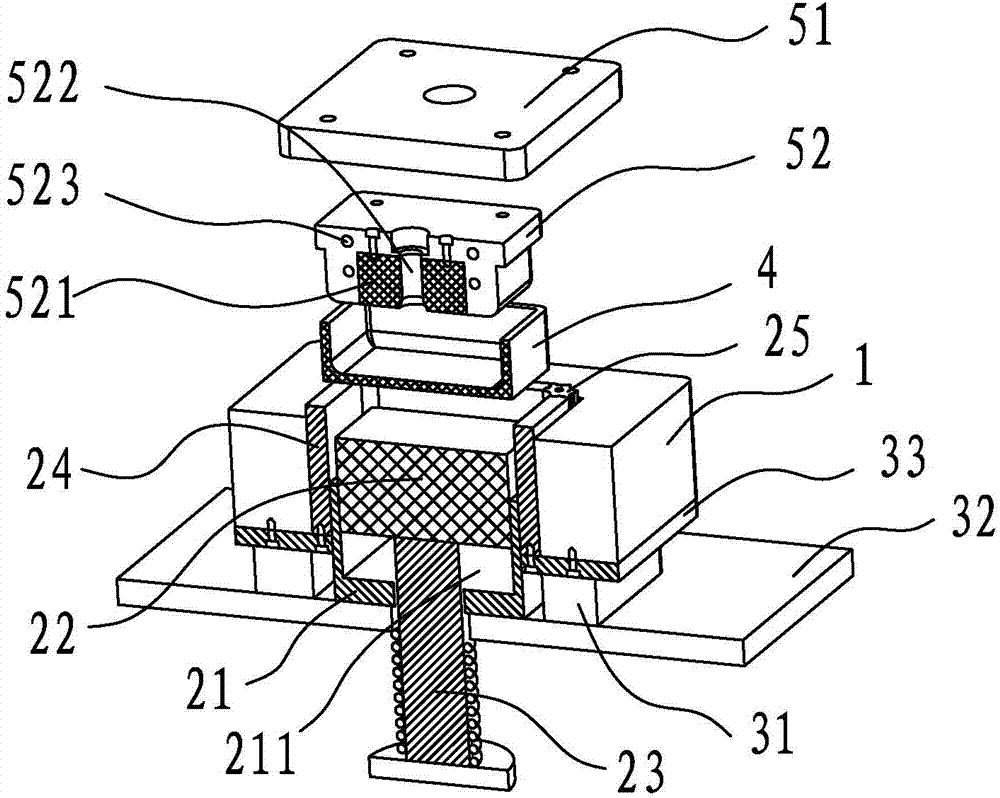

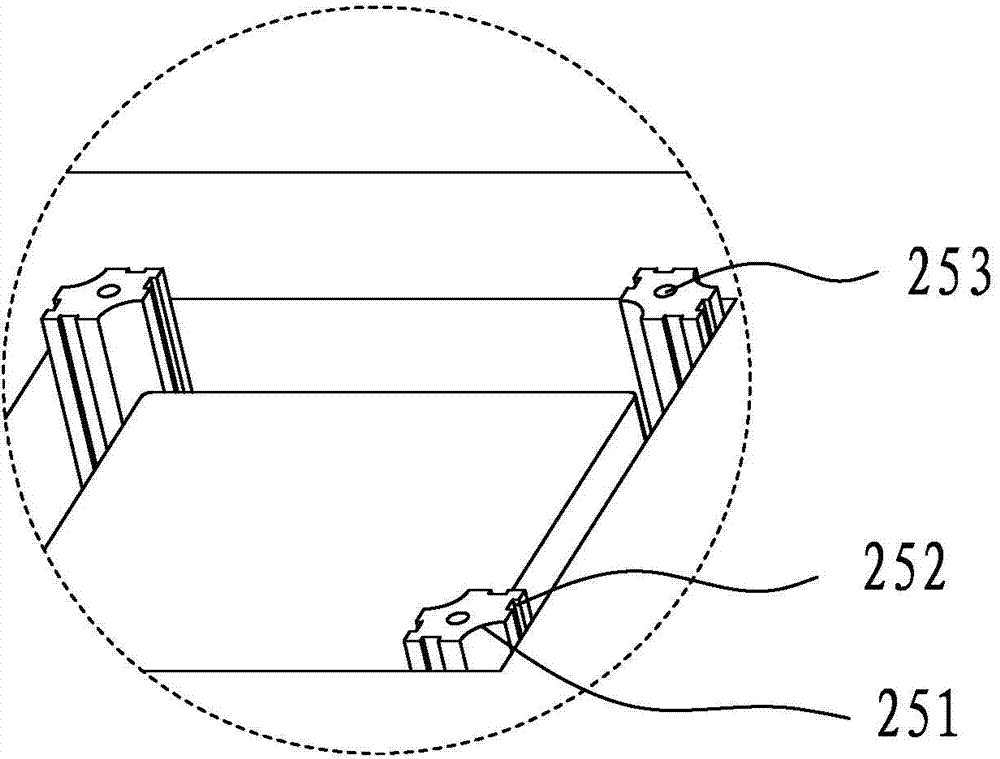

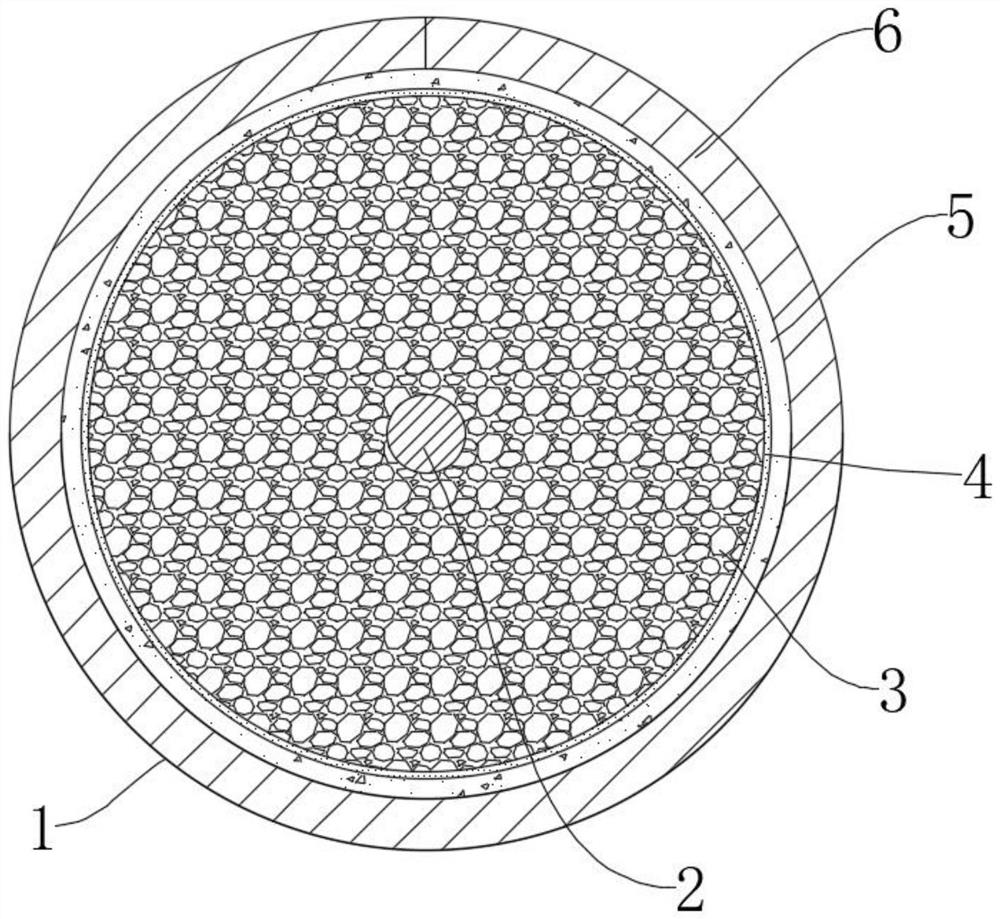

Die for casting saggar

The invention discloses a die for casting a saggar. The die comprises a lower die outer frame, the middle of the lower die outer frame is provided with a lower die core, an upper die core is arranged above the lower die core in a matched mode, and the lower die core is of a floating die core structure and is composed of a lower die fixing die core and a lower die floating die core. A die core inner cavity is formed in the top of the lower die fixing die core, a through hole is formed in the bottom of the die core inner cavity, the lower die floating die core is arranged in the die core inner cavity, and a center ejecting cylinder is arranged at the bottom of the lower die floating die core. The center ejecting cylinder penetrates through the through hole in the lower die fixing die core and extends to the position below a worktable top of a pressing machine, and four wall plates are arranged between the inner wall of the lower die outer frame and the outer wall of the lower die core respectively. The four wall plates are connected and fixed at the four corners through inserts, and a filling block is embedded in the upper die core. The outer side of the filling block is provided with a cooling water channel, and an exhaust pipeline longitudinally penetrates the center of the upper die core. The die is good in exhausting and cooling effect and capable of facilitating discharging and solving the problems that the pressed saggar is large in number of air vents and uneven in thickness.

Owner:浙江立鑫高温耐火材料有限公司

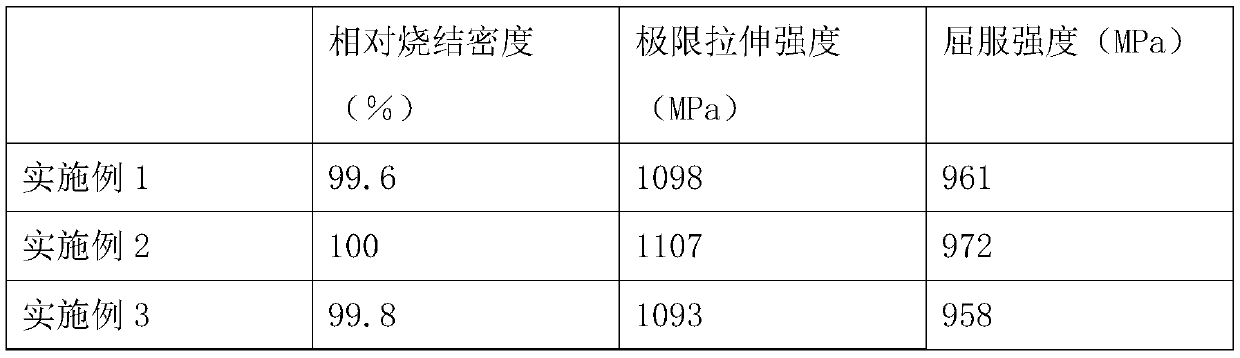

Silver powder-containing metallurgic titanium-molybdenum-aluminum-vanadium alloy and preparation method thereof

The invention provides a silver powder-containing metallurgic titanium-molybdenum-aluminum-vanadium alloy and a preparation method thereof. The alloy comprises the following components in percentage by weight: 2 to 8 percent of Mo, 3 to 7 percent of Al, 2 to 6 percent of V, 2 to 10 percent of Ag and the balance of titanium and inevitable impurities. The preparation method comprises the following steps of: according to the weight percentages of the components, weighing titanium powder, molybdenum powder, aluminum powder, silver powder and aluminum vanadium intermediate alloy powder with certain granularity; uniformly mixing the powder by adopting a mixing method; and pressing the powder to prepare a green body with certain shape through a compression molding process; putting the green body in a vacuum sintering furnace for sintering, and obtaining the argentiferous titanium-molybdenum-aluminum-vanadium alloy after the furnace is cooled. In the preparation method, the process flow is simple, the silver powder is added into mixture to improve the compactibility of the green body and further increase the density of a sintered body, and thus, the highly-densified silver powder-containing metallurgic titanium alloy is obtained. The preparation method is suitable for industrialized production.

Owner:CENT SOUTH UNIV

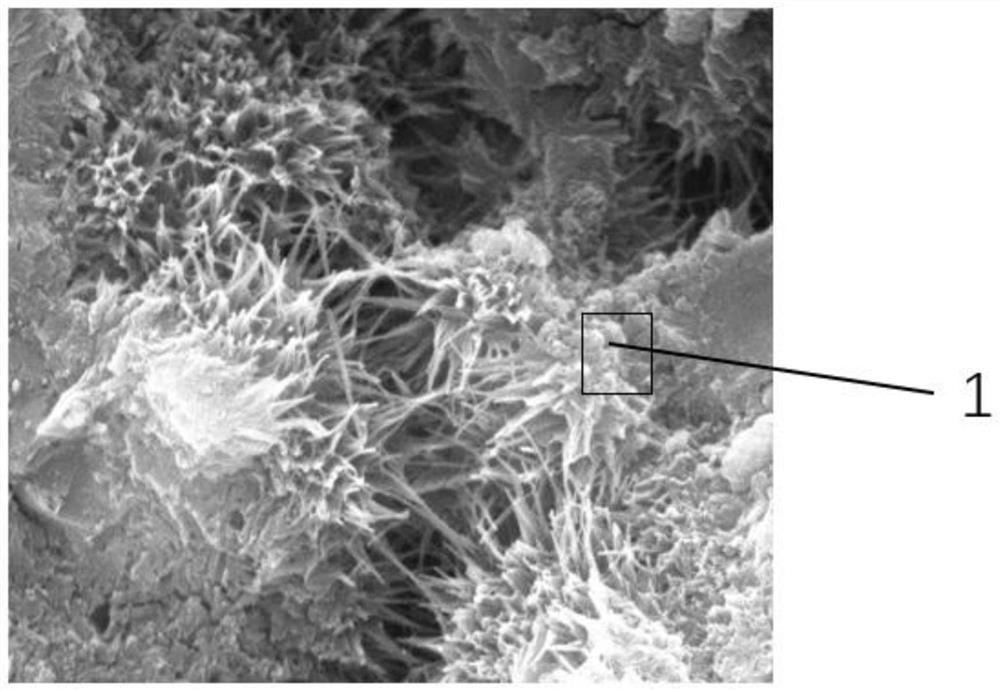

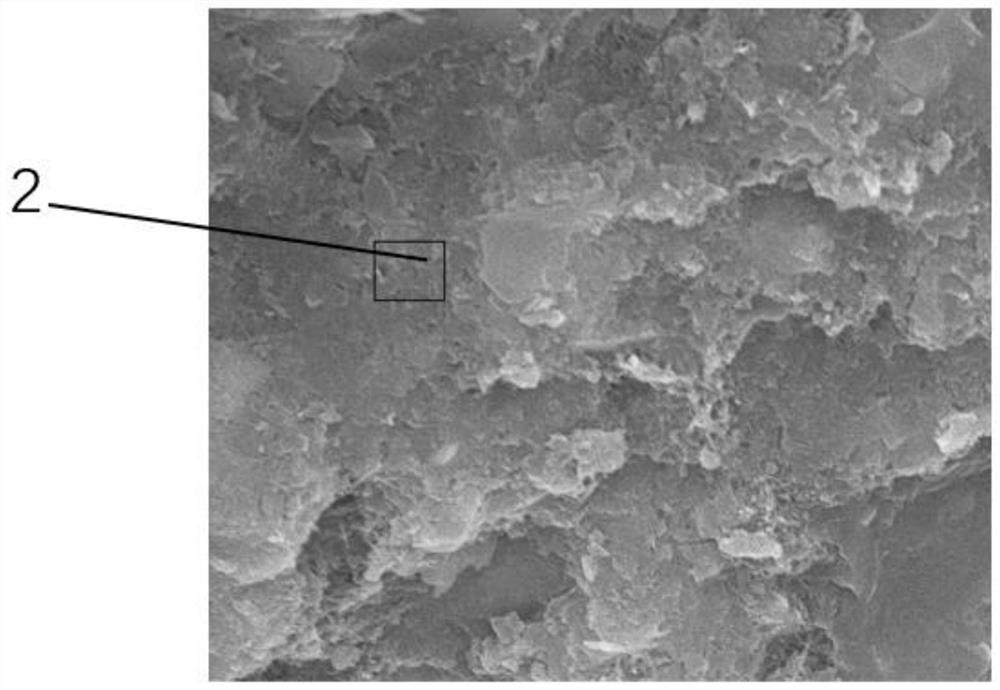

Method of preparing oxidation film on surface of magnesium alloy by utilizing micro-arc oxidation

InactiveCN108642544AImprove conductivityMicroporous reductionAnodisationEthylenediamineMicro arc oxidation

The invention provides a method of preparing an oxidation film on the surface of a magnesium alloy by utilizing micro-arc oxidation. The method comprises the following steps that the magnesium alloy is placed into an electrolytic tank filled with an alkaline electrolyte, the magnesium alloy serves as an electrolytic anode, the electrolytic tank serves as an electrolytic cathode, voltage is appliedto allow plasma discharge to be generated on the magnesium alloy, the oxidation film is formed on the surface of the magnesium alloy by utilizing the micro-arc oxidation, and the components of the alkaline electrolyte are 8-12 g / L of NaOH, 10-15 g / L of Na2SiO3, 6-8 g / L of KF, 2-3 mL / L of H2O2, 6-8 mL / L of glycerol, 1-2 g / L of sodium ethylenediamine teramethylene phosphonate and the balance water;and in the micro-arc oxidation process, zeolite powder and gamma-aluminum oxide nano micropowder are sequentially added into the electrolyte, and a micro-arc oxidation reaction is continued to be carried out until the preparation of the oxidation film is completed. The reaction process of the micro-arc oxidation is affected through the synthetic action of the components, the amount of microporeson the surface layer of the oxidation film is reduced, the compactness of the oxidation film is improved basically, and the corrosion-resistant performance is strengthened.

Owner:HENAN UNIV OF SCI & TECH

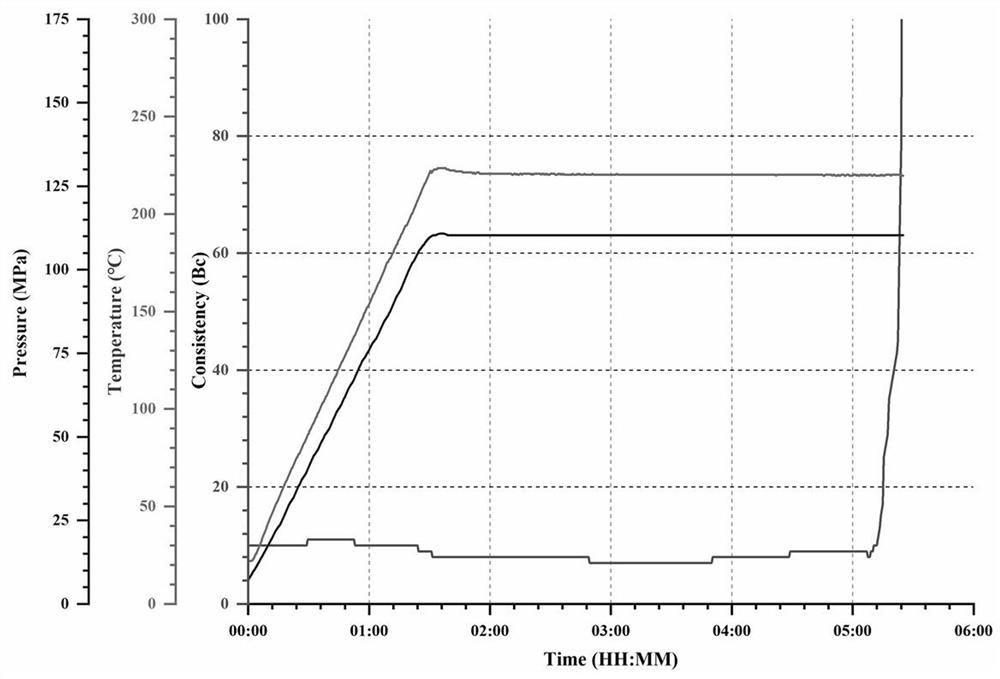

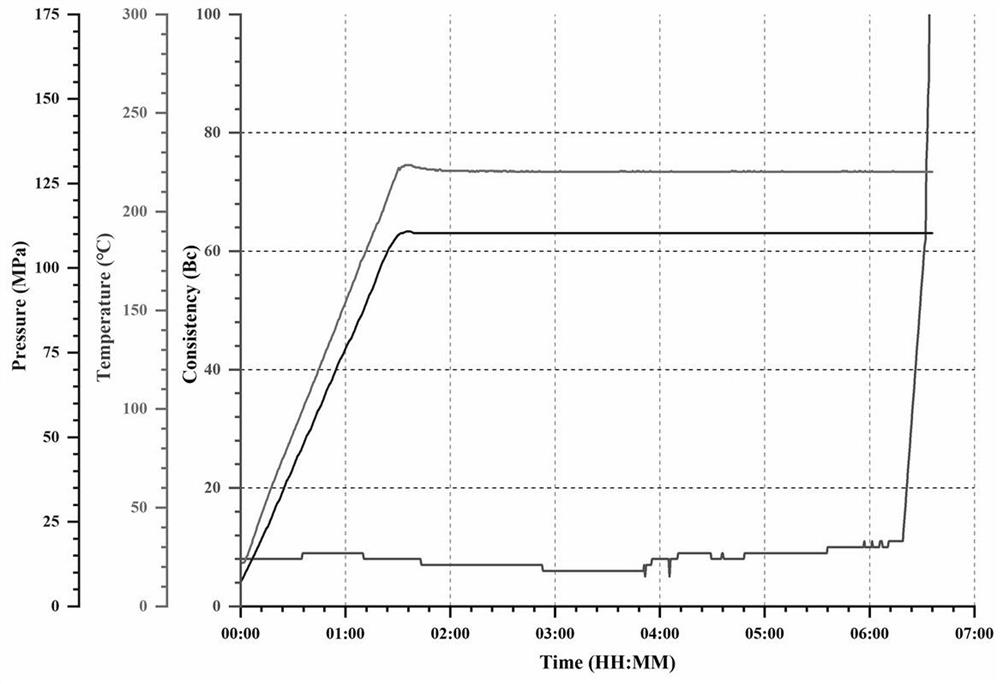

High-temperature-resistant tough well cementation cement slurry system

ActiveCN114350334AHigh compressive strengthGood adaptability to high temperature admixturesSolid waste managementDrilling compositionPoly ether ether ketoneToughening

The invention discloses a high-temperature-resistant tough well cementation cement slurry system, and relates to the technical field of well cementation materials for oil and gas field development. The well cementation cement slurry system is composed of the following raw materials in percentage by weight: 47-60 wt% of low hydration heat cement; 25 wt%-30 wt% of a high temperature strength stable material; 10 wt%-15 wt% of a high temperature strength reinforcing material; 2 wt%-5 wt% of a high-temperature toughening material; 2 wt% of a high-temperature stabilizer and 0.5 wt% of a dispersant; the high-temperature strength reinforcing material is a mixture formed by mixing silicon nitride micro powder and organic silicon resin micro powder; the high-temperature toughening material is polyether-ether-ketone resin. The high-temperature-resistant tough well cementation cement slurry system has the advantages of high-temperature strength recession resistance and high toughness, can effectively relieve the problems of strength recession and insufficient toughness of set cement under a high-temperature condition, and meets the requirements of oil and gas well cementation.

Owner:JIAHUA SPECIAL CEMENT

Method for producing carbon intermediate by using ball pressing process

ActiveCN103130208AAnisotropy implementationEvenly arrangedCarbon preparation/purificationHigh densityGranularity

The invention relates to a method for producing a carbon intermediate by using a ball pressing process. The method is characterized in that at least one of calcined petroleum coke, pitch coke, electrically calcined coal, metallurgical coke, natural graphite, synthetic graphite, carbon product return scrap and carbon product reclaimed material is used as the material of the carbon intermediate. The production method comprises the steps of selecting raw materials, carrying out grain composition, selecting a binding agent, controlling the addition of the binding agent, mixing or kneading and pressing balls to obtain the carbon intermediate. The carbon intermediate has a shape of sphere, has uniformly and directionally arranged carbons, is a carbon green body of anisotropy, and has plasticity when the temperature is higher than the softening temperature of the binding agent, and the volume density is 1.65-1.80g / cm<3>. The high density and anisotropy of the carbon intermediate are realized with the granularity of the supplied materials maintained.

Owner:任利华

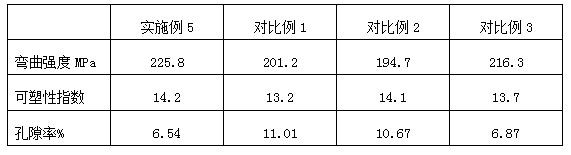

High-strength siliceous brown glaze electric porcelain and preparation method thereof

ActiveCN112898003ALow softening temperatureImprove liquidityCeramic materials productionClaywaresSesquioxideManganese

The invention discloses high-strength siliceous brown glaze electric porcelain and a preparation method thereof, and relates to the technical field of siliceous electric porcelain. The invention discloses a high-strength siliceous brown glaze electric porcelain, the raw materials comprise a blank material and a brown glaze material; the blank material comprises the following raw materials: kaolin, wollastonite, Jiepai mud, siliceous porcelain waste powder, low-melting-point glass powder, spodumene, yttrium oxide, ceramic-grade talcum powder and a nucleating agent; the brown glaze material is composed of the following raw materials: potassium feldspar powder, quartz powder, blank mud, calcite powder, cooked talcum powder, iron oxide, chrome green, manganese sesquioxide and Jiepai mud. The invention also discloses the preparation method of the brown glaze electric porcelain. The siliceous brown glaze electric porcelain has the advantages of simple and easily available raw materials, low cost, high bending strength, good plasticity and good stability; and the brown glaze is low in cost, short in glaze dipping time, good in glazing effect, ruddy and full in glaze surface, bright in luster, stable in color generation and free of color difference, and the strength of the brown glaze electric porcelain is improved by 10% or above compared with the strength of the brown glaze electric porcelain before glazing.

Owner:湖南省醴陵市华电电瓷制造有限公司

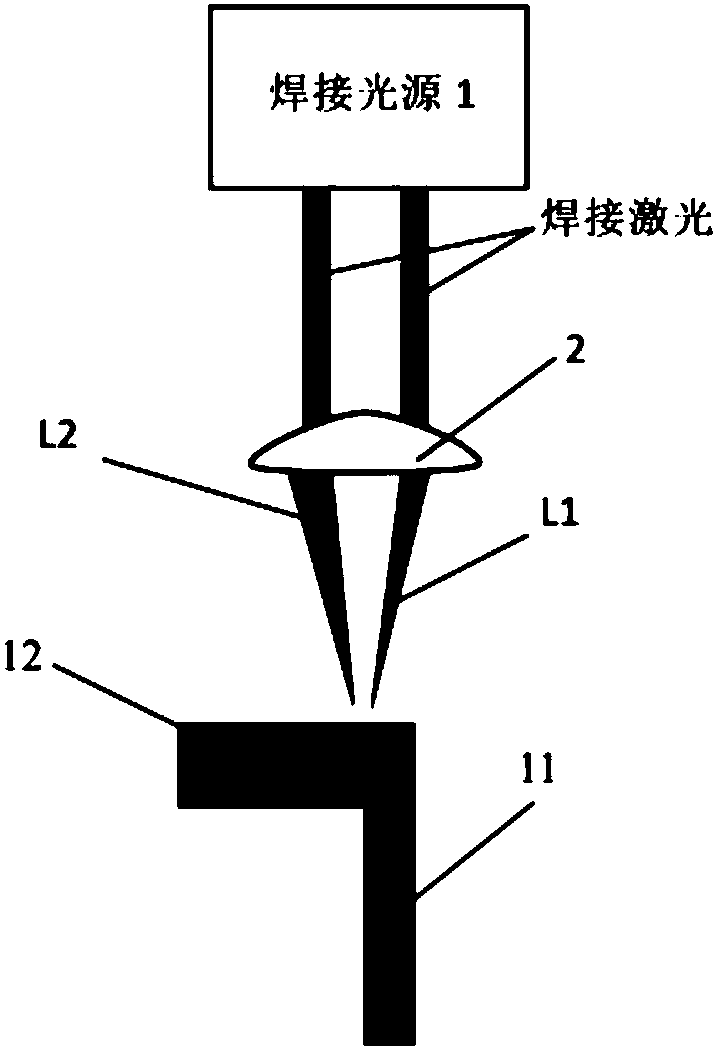

Double-beam laser welding equipment and method used for power battery welding

ActiveCN107649784ALow costLow stomataWelding/soldering/cutting articlesMetal working apparatusWeld seamLight source

The invention discloses double-beam laser welding equipment and method used for power battery welding. The equipment comprises a welding light source used for providing welding lasers and a focusing beam splitting system used for focusing welding lasers; after being focused, the welding lasers are divided into two laser beams; a power battery module end plate and a side plate are welded through the two laser beams; and the focusing beam splitting system comprises a focusing lens and an optical beam splitter mirror. According to the double-beam laser welding equipment and method, single-beam lasers emitted by one laser device is divided by the optical beam splitter mirror into two light beams with a certain energy ratio and distance, and cost is reduced; and meanwhile, a parallel manner isadopted by the two light beams for welding, the small hole size can be improved to the maximum degree, the effect of being small in number of air holes in a welding seam is achieved, the welding stability is improved, the welding seam strength is higher, and the welding effect is guaranteed.

Owner:深圳市大族锂电智能装备有限公司

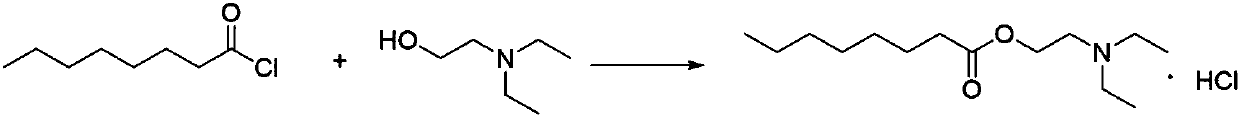

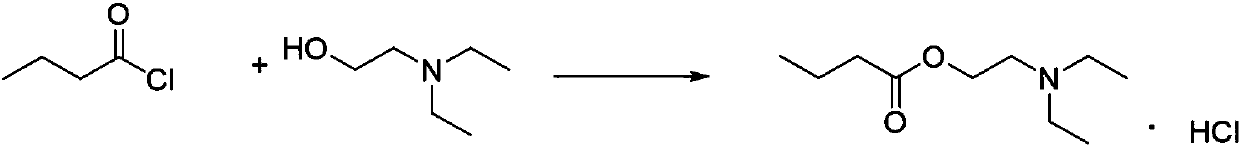

Preparation method and application of plant growth regulator N,N-diethylaminoethyl caprylate

PendingCN111362817AReduce usageRaw materials are easy to getBiocidePlant growth regulatorsGrowth plantEthyl ester

The invention discloses a preparation method of a plant growth regulator N,N-diethylaminoethyl caprylate. The preparation method comprises the following steps: 1, preparing N,N-diethylaminoethyl caprylate hydrochloride by using a reaction chemical formula shown in the specification; 2, carrying out alkali neutralization and extraction to obtain N,N-diethylaminoethyl caprylate; and 3, preparing N,N-diethylaminoethyl caprylate citrate by using a solvent method or a solvent-free method. During use, the N,N-diethylaminoethyl caprylate hydrochloride and the N,N-diethylaminoethyl caprylate citrate can be used for spraying, irrigating and spraying agricultural products, commercial crops and fruits. The N, N-diethylaminoethyl caprylate salt is prepared through a reaction at a low temperature, andthe raw materials are easy to obtain and low in price, so the synthesis method is simple and safe, and the yield is high; in the salifying process, the use of a solvent is reduced, so the cost is saved; and the reaction time is short, so the efficiency is high, energy is saved, and the method is suitable for industrial production.

Owner:河南福联生物科技有限公司

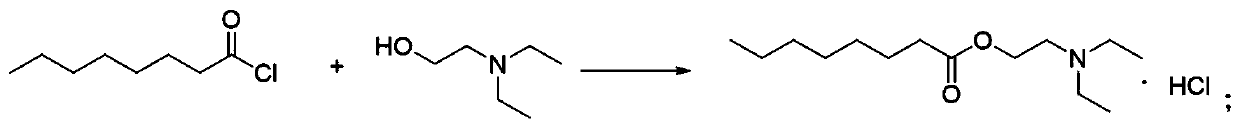

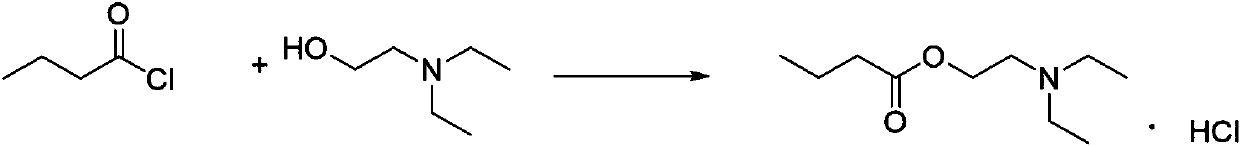

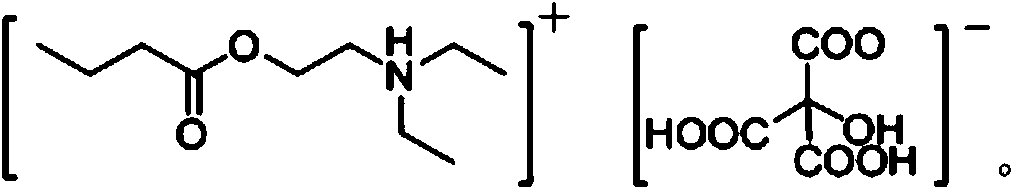

Preparation and application of plant growth regulator N,N-diethylaminoethyl butyrate

PendingCN111362818ALow costRaw materials are easy to getBiocidePlant growth regulatorsGrowth plantButyrate

The invention discloses a preparation method of a plant growth regulator N,N-diethylaminoethyl butyrate. The preparation method comprises the following steps: 1, preparing N,N-diethylaminoethyl butyrate hydrochloride according to a reaction principle shown in the description; 2, carrying out alkali neutralization and extraction to obtain N,N-diethylaminoethyl butyrate; and 3, preparing N,N-diethylaminoethyl butyrate citrate by using a solvent method or a solvent-free method. The intermediate N,N-diethylaminoethyl butyrate hydrochloride and the finally obtained N,N-diethylaminoethyl butyrate citrate can be used as plant growth regulators to be applied, and specifically, the intermediate N,N-diethylaminoethyl butyrate hydrochloride and the finally obtained N,N-diethylaminoethyl butyrate citrate are sprayed or irrigated to crops, commercial crops and fruit plants. The N,N-diethylaminoethyl butyrate is prepared through a low-temperature normal-pressure reaction, and the raw materials are easy to obtain and are low in price, so the preparation method is simple, convenient and feasible; and the using method is simple, and the N,N-diethylaminoethyl butyrate can be compounded with multiplecomponents according to different purposes, so the application field of the N,N-diethylaminoethyl butyrate is expanded, efficiency is high, and cost is low.

Owner:河南福联生物科技有限公司

Cement admixture for inhibiting alkali-aggregate reaction, and preparation method thereof

The invention discloses a cement admixture for inhibiting alkali-aggregate reaction. The cement admixture comprises the following components in parts by weight: 30-40 parts of waste glass powder, 15-20 parts of furnace slag, 15-20 parts of mineral slag, 3 parts of wool, 0.3-0.5 part of gelatin, 3-5 parts of alkyl benzene sulfonate sulfate and 10-22 parts of lithium sulfate. The method comprises the following steps: cleaning, airing and grinding waste glass bottles, mixing the waste glass bottles with furnace slag and mineral slag, and performing ball milling to obtain a waste mixture; and uniformly mixing the waste mixture with wool, alkylbenzene sulfonate sulfate, gelatin and lithium sulfate to obtain the cement admixture capable of inhibiting the alkali-aggregate reaction. The preparation process is simple, the use is convenient, the inhibition effect on the alkali aggregate reaction is obvious, the green and environment-friendly effects are realized, and the prepared concrete has excellent performance.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

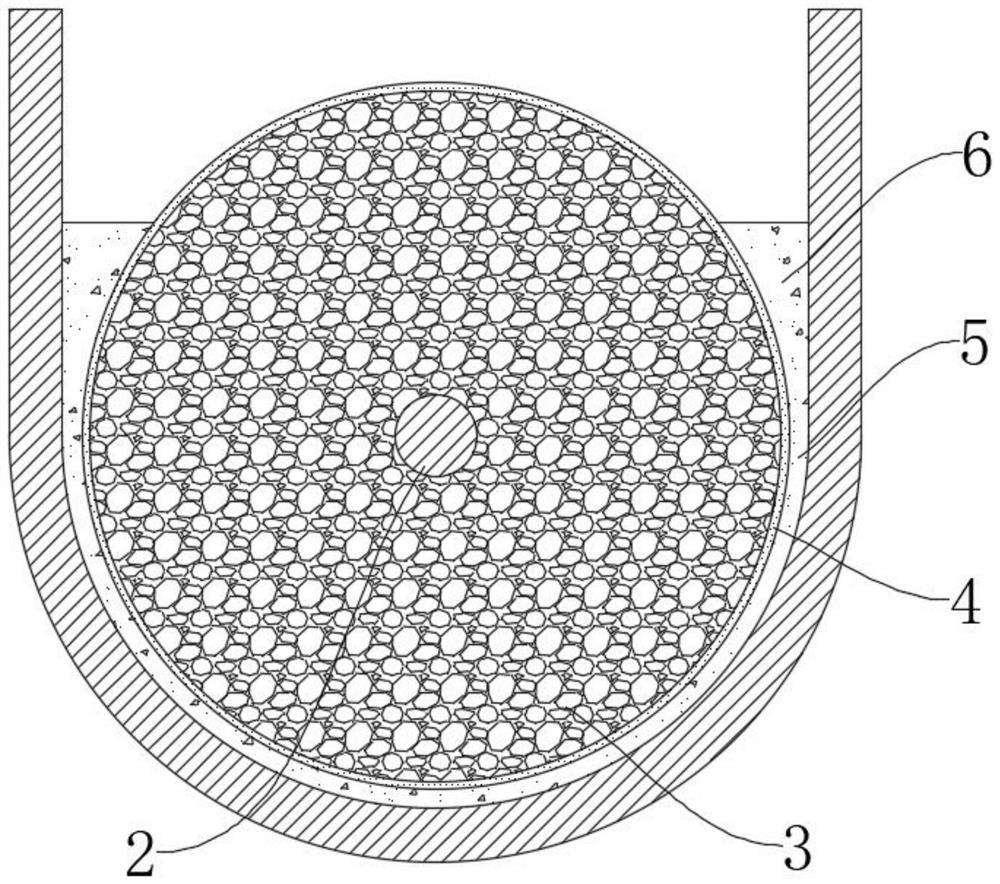

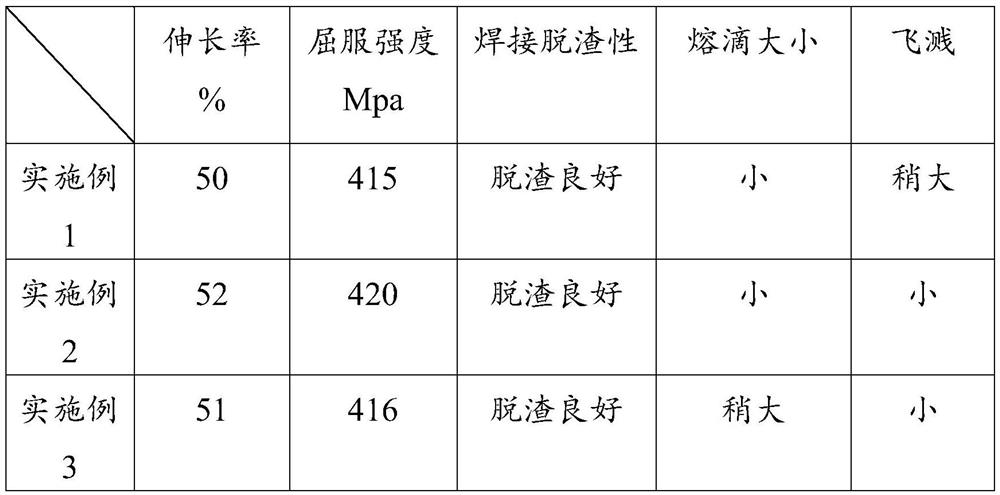

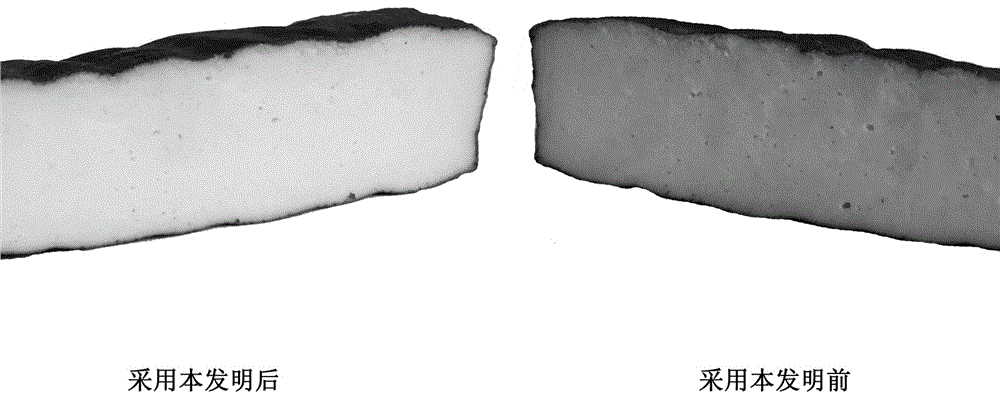

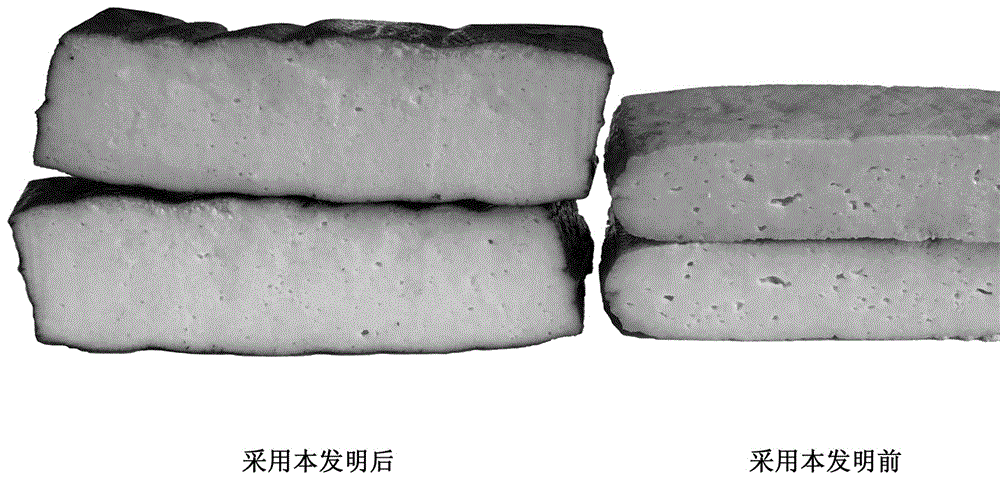

Self-shielded flux-cored wire formula and process

InactiveCN112404789AImprove welding effectImprove ductilityWelding/cutting media/materialsSoldering mediaAustemperingThermodynamics

The invention discloses a self-shielded flux-cored wire formula and a process. The self-shielded flux-cored wire formula comprises a flux-cored wire body, the flux-cored wire body is made of an aluminum strip, a flux-cored layer, a wrapping layer, an isolation layer and an outer coiled steel layer, wherein the aluminum strip, the flux-cored layer, the wrapping layer, the isolation layer and the outer coiled steel layer are coaxially distributed, and the aluminum strip, the flux-cored layer, the wrapping layer, the isolating layer and the outer coiled steel layer are sequentially arranged in awrapping manner from inside to outside. The overall welding performance of a flux-cored wire is improved through the formula, it is guaranteed that the welding process performance is optimal, the flux-cored wire body is of a nested structure of the aluminum strip, the flux-cored layer, the wrapping layer, the isolation layer and the outer coiled steel layer, the flux-cored compactness of the flux-cored wire can be improved during production in cooperation with the machining process of the self-shielded flux-cored wire, uniform distribution of flux cores is guaranteed, cold-rolled coil steel rolls into a U-shaped groove and is subjected to isothermal quenching treatment, the ductility and toughness of an external coiled steel layer are improved, the tensile property and yield strength of the flux-cored wire body are improved through cooperation with the aluminum strip, and damage is avoided.

Owner:ZHANGJIAGANG HENGCHANG WELDING MATERIALS

Magnesium zirconium brick

The invention relates to a magnesium zirconium brick, and belongs to the field of fireproof materials. A cooker built by magnesium zirconium bricks is capable of effectively preventing acidic corrosion and alkali corrosion of liquid-state lithium. According to the technical scheme, the magnesium zirconium brick comprises the following components by weight percent: 90%-95% of MgO, 4.5%-7.1% of ZrO2, 0.3%-1.7% of TiO2 and 0.2%-1.2% of SiO2.

Owner:浙江立鑫高温耐火材料有限公司

Method for enhancing texture profile of dried tofu

InactiveCN105685253AImprove functional propertiesHigh nutritional valueCheese manufactureFood scienceChlorideGlutamine transaminase

The invention relates to the field of food processing, and in particular relates to a method for enhancing a texture profile of dried tofu. The method comprises the following steps: 1, soybean milk cooking and cooling: heating prepared soybean milk to 90 to 100 DEG C, and then cooling to 60 to 70 DEG C; 2, preparation of curing bittern: adding glutamine transaminase, starches and magnesium chloride into bittern according to a proportion to prepare the curing bittern; 3, curing and standing: adding the prepared curing bittern into the soybean milk for full stirring, and standing to form tofu; 4, pressing; 5, cutting and molding; 6, roasting: roasting the molded tofu under high temperature; 7, marinating: marinating the roasted tofu blocks in high-temperature bittern. According to the method, under certain temperature, glutamine transaminase makes macro-molecular proteins in the soybean milk reacted to form small-molecular proteins, so that the fineness of dried tofu structures is increased, and the dried tofu tastes smooth.

Owner:劲仔食品集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com