Laser beam joining method and laser machining optics

A technology for laser processing and optical instruments, applied in the field of laser processing optical instruments, can solve problems such as increasing the scope, and achieve the effect of improving energy balance and increasing light intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

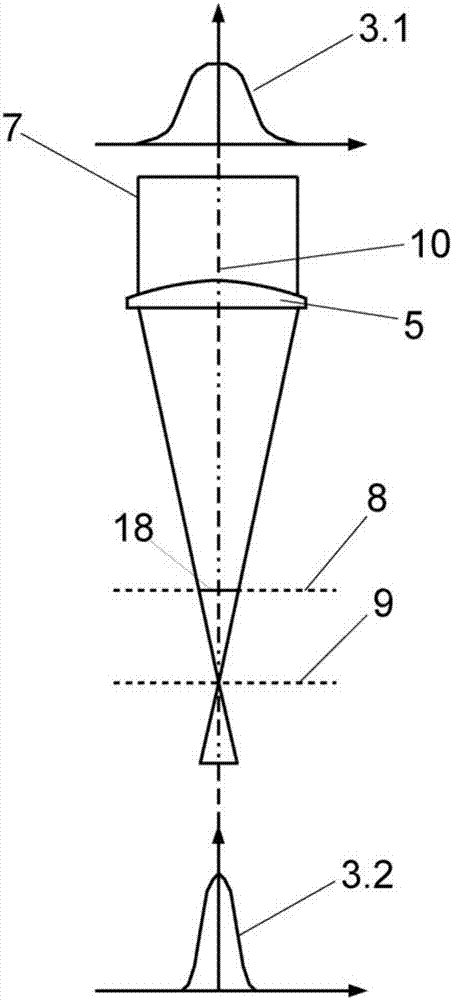

[0060]FIG. 1 shows the beam path of a laser beam 7 in a laser processing optics according to the prior art. The laser beam 7 with a Gaussian radiation intensity distribution 3.1 in cross-section is focused by the focusing device 5 onto the laser focal plane 9, whereby a (out-of-focus) laser focal spot 18 is formed in the processing plane 8, in which The cross-section contains the radiation intensity distribution 3.2. The two Gaussian radiation intensity distributions 3.1 and 3.2 each have a maximum on the beam axis 10 .

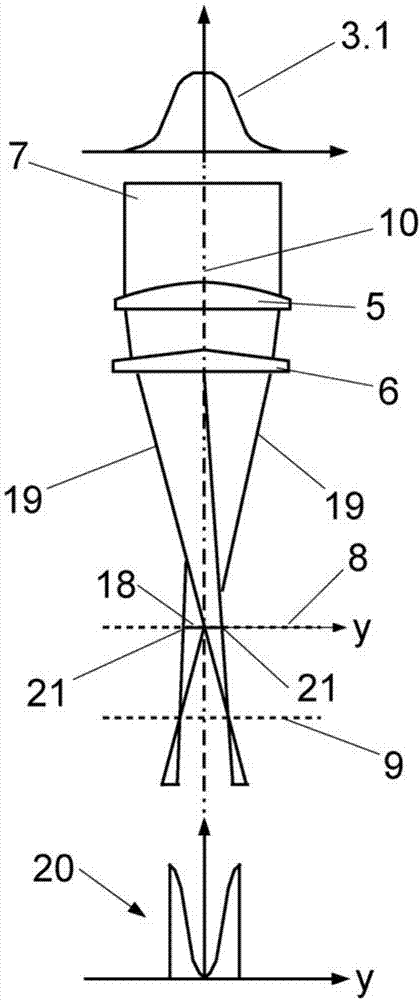

[0061] figure 2 The beam path of the laser beam 7 according to the invention is shown. A laser beam 7 with a radiation intensity distribution 3.1 in cross-section is focused by a focusing device 5 onto the laser focal plane 9 and split into two partial beams 19 by a beam splitter 6 here of the top plate type and deflected in this way , ie a coherent laser focal spot 18 is formed in the processing plane 8 by the two partial beams 19 . In this case, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com