Double-beam laser welding equipment and method used for power battery welding

A power battery, laser welding technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

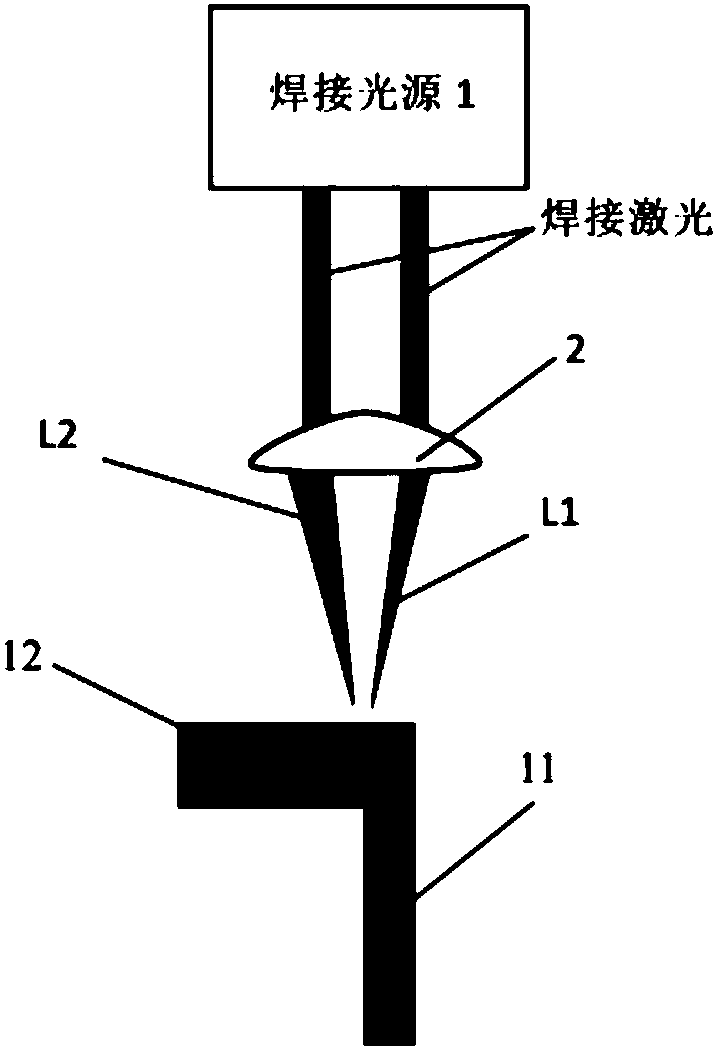

[0026] figure 1 It shows a schematic structural view of the double-beam laser welding equipment used for power battery welding according to the present invention, which includes:

[0027] Welding light source 1, which is used to provide welding laser, the welding light source is preferably a 6KW continuous fiber laser, and the welding light source 1 can also include a collimation device, preferably, the diameter of the collimation device is 150mm;

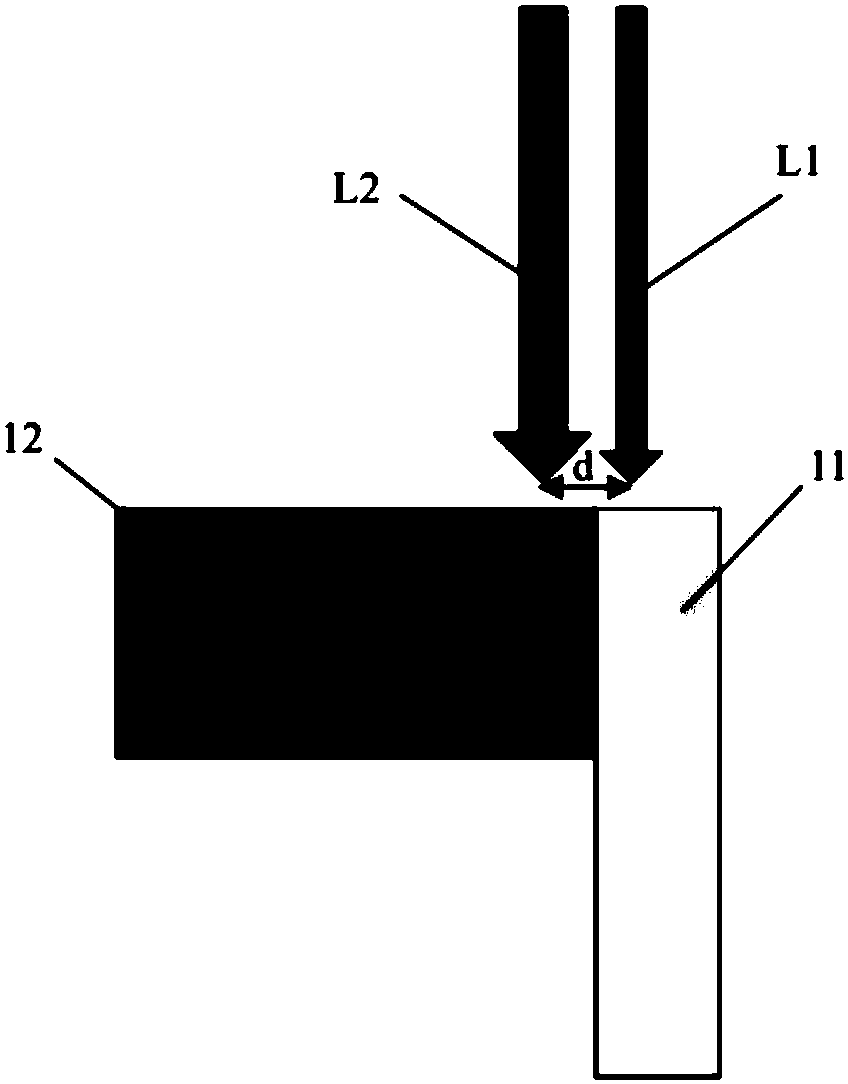

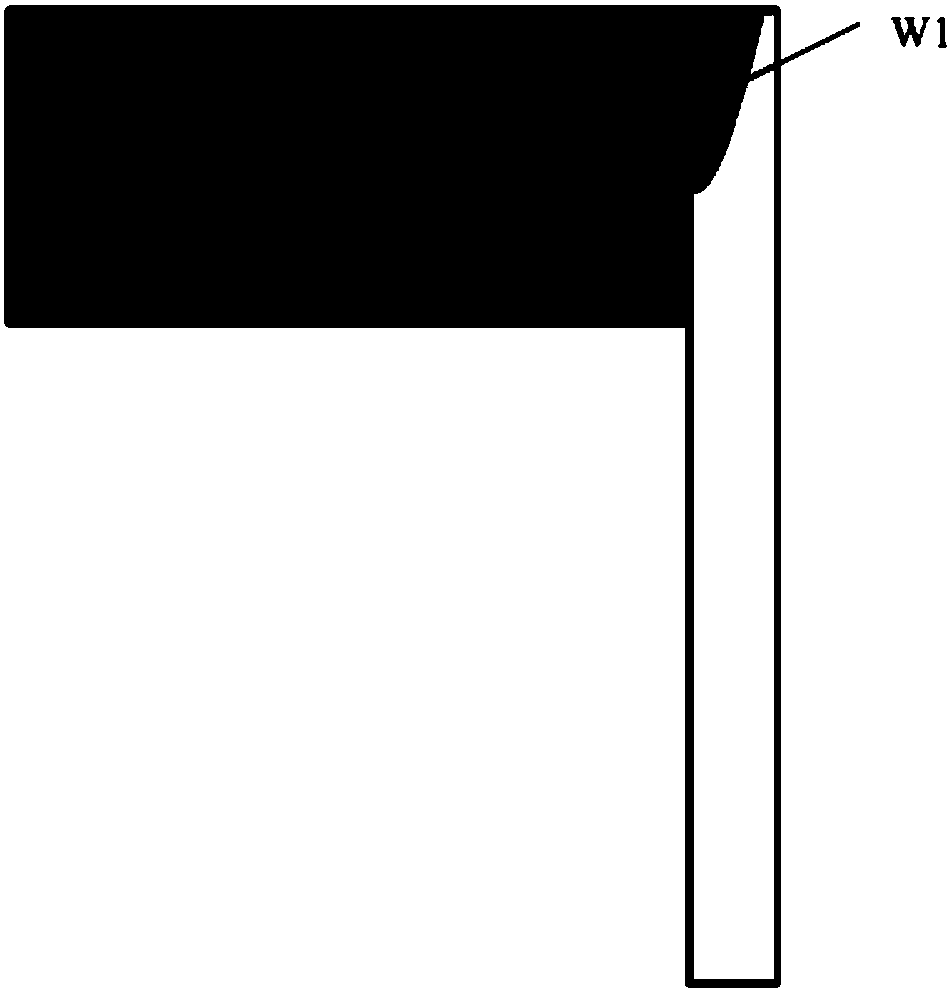

[0028] Focusing beam splitting system 2, which is used to focus the welding laser, and after focusing the welding laser, divide the welding laser into two laser beams; through the two laser beams, the power battery module side plate 11 and The surface to be welded of the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com