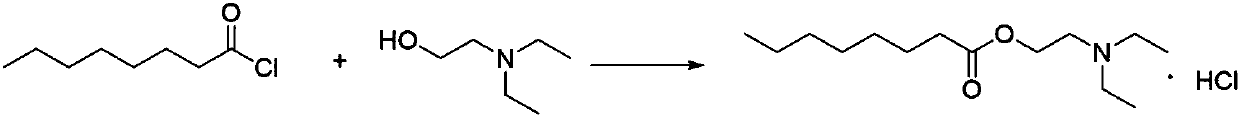

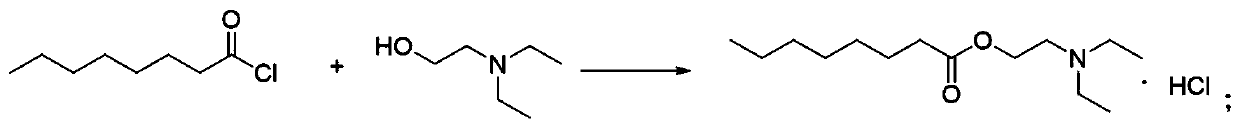

Preparation method and application of plant growth regulator N,N-diethylaminoethyl caprylate

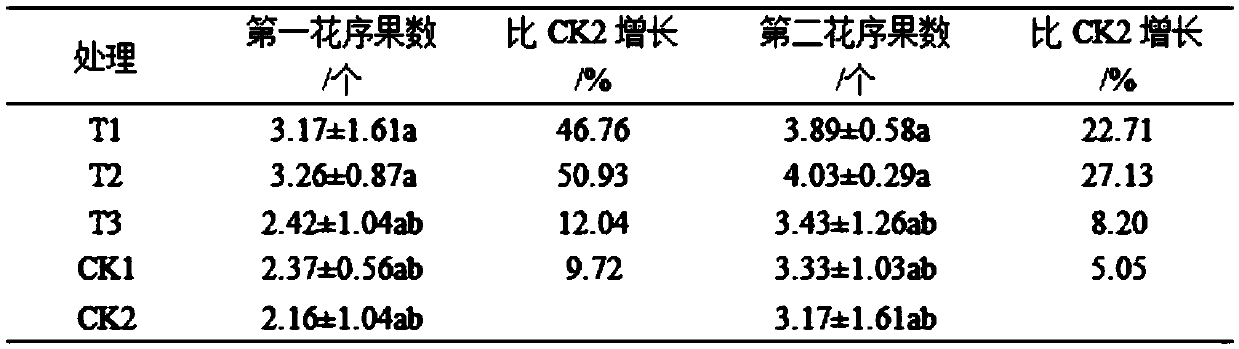

A technology of diethylaminoethyl ester and diethylaminoethanol, which is applied in the field of plant growth regulator octanoic acid-N, can solve the problem of low yield of organic acid catalysis, high price of tetrabutyl phthalate, and catalyst preparation. cumbersome and other problems, to achieve the effect of improving plant stress resistance, increasing fruit setting rate, and thickening leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A plant growth regulator caprylic acid-N, the preparation of N-diethylaminoethyl ester hydrochloride comprises the steps:

[0037] In the there-necked flask, add 200 grams of diethylaminoethanol, dissolve in dichloromethane, stir and cool down in a cryogenic cold trap, then add 10 grams of sodium bicarbonate, and when the temperature is lowered to 0 degrees Celsius, add 250 grams of octanoyl chloride dropwise, Adding time is 1 hour, and the dropping temperature is controlled at -10 to 20 degrees Celsius; react at low temperature for two hours, then stir at room temperature for three hours, stop stirring, and remove the solvent to obtain caprylic acid-N,N-diethylaminoethyl ester Hydrochloride.

Embodiment 2

[0039] In the three-neck flask, add 100 grams of diethylaminoethanol, stir in the cryogenic cold trap to cool down, when the temperature drops to 0 degrees Celsius, add 150 grams of octanoyl chloride dropwise, the dropping time is 1 hour, and the dropping temperature is controlled at -10 to 20 degrees Celsius . React at low temperature for 3 hours, then stir at 40-60 degrees Celsius for 2 hours, stop stirring, discharge, and cool slightly to obtain octanoic acid-N,N-diethylaminoethyl ester hydrochloride as a white solid.

Embodiment 3

[0041] A plant growth regulator octanoic acid-N, the preparation of N-diethylaminoethyl citrate comprises the steps:

[0042] Step 1, preparation of octanoic acid-N,N-diethylaminoethyl ester hydrochloride: in a three-necked flask, add 200 grams of diethylaminoethanol, dissolve in dichloromethane, stir and cool down in a cryogenic cold trap, and cool down When the temperature reaches 0 degrees Celsius, 280 grams of octanoyl chloride is added dropwise for 1 hour, and the dropping temperature is controlled at -10 to 20 degrees Celsius. React at low temperature for two hours, then stir at room temperature for three hours, stop stirring, and remove the solvent to obtain octanoic acid-N,N-diethylaminoethyl ester hydrochloride.

[0043] Step 2, alkali neutralization and extraction to obtain octanoic acid-N,N-diethylaminoethyl ester: preferably use aqueous sodium bicarbonate as a base to neutralize octanoic acid-N,N-diethylaminoethyl ester salt obtained in step 1 salt, and extracted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com