Bioactive porous titanium medical implant material and preparation method

An implant material and bioactive technology, which is applied in the field of preparation of bioactive porous titanium medical implant materials, can solve the problem of poor bonding between the coating and the substrate, slow growth of the coating, and complex composition of the hydroxyapatite coating, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

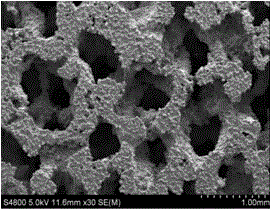

Embodiment 1

[0064] Add 10 g of PVA into a beaker containing 150 mL of deionized water, heat and stir it evenly; then add 50 mL of absolute ethanol into the beaker, and mix evenly. Weigh a certain amount of commercially pure titanium powder (with a particle size of 38-45 microns) into the PVA solution to prepare three titanium slurries with a solid-liquid ratio of 8g / 10mL, 6g / 10mL, and 3g / 10mL. Use 40 PPI polyurethane foam (20×20×32 mm 3) impregnated into titanium slurry, after the foam pores are filled with titanium slurry, put it into a high-speed centrifuge to remove excess slurry, and then put it in a vacuum drying oven to dry. Repeat the above process for a total of 3 times in the titanium slurry with a solid-to-liquid ratio of 6g / 10mL, and repeat the above-mentioned process for a total of 3 times in a titanium slurry with a solid-to-liquid ratio of 3g / 10mL. The green body that paddles 7 times. Sinter the green body obtained in a vacuum sintering furnace, raise the temperature to 20...

Embodiment 2

[0067] Add 10 g of PVA into a beaker containing 150 mL of deionized water, heat and stir it evenly; then add 50 mL of absolute ethanol into the beaker, and mix evenly. A certain amount of commercially pure titanium powder (38-45 microns in particle size) was weighed into the PVA solution to prepare two titanium slurries with a solid-liquid ratio of 8g / 10mL and 6g / 10mL. Use 40 PPI polyurethane foam (20×20×32 mm 3 ) impregnated into titanium slurry, after the foam pores are filled with titanium slurry, put it into a high-speed centrifuge to remove excess slurry, and then put it in a vacuum drying oven to dry. The above process was repeated for a total of 3 times, and the above process was performed once in a titanium slurry with a solid-to-liquid ratio of 6g / 10mL, to obtain a green body with a total of 4 paddles. Sinter the green body obtained in a vacuum sintering furnace, raise the temperature to 200°C at 5°C / min, raise the temperature to 600°C at 2°C / min, and then hold it fo...

Embodiment 3

[0070] Add 10 g of PVA into a beaker containing 150 mL of deionized water, heat and stir it evenly; then add 50 mL of absolute ethanol into the beaker, and mix evenly. Weigh a certain amount of commercially pure titanium powder (with a particle size of 38-45 microns) into the PVA solution to prepare three titanium slurries with a solid-liquid ratio of 8g / 10mL, 6g / 10mL, and 3g / 10mL. Use 20 PPI polyurethane foam (20×20×32 mm 3 ) impregnated into titanium slurry, after the foam pores are filled with titanium slurry, put it into a high-speed centrifuge to remove excess slurry, and then put it in a vacuum drying oven to dry. Repeat the above process for a total of 3 times in the titanium slurry with a solid-to-liquid ratio of 6g / 10mL, and repeat the above-mentioned process for a total of 3 times in a titanium slurry with a solid-to-liquid ratio of 3g / 10mL. The green body that paddles 7 times. Sinter the green body obtained in a vacuum sintering furnace, raise the temperature to 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Large hole size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com