3D-printable aeolian sand anti-freezing concrete as well as preparation method and use method thereof

A 3D printing, aeolian sand technology, applied in the field of concrete, can solve the problems of reducing the integrity of the concrete matrix, weakening the mechanical properties and durability of printing materials, etc., to achieve printability, pumpability, and viscosity reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

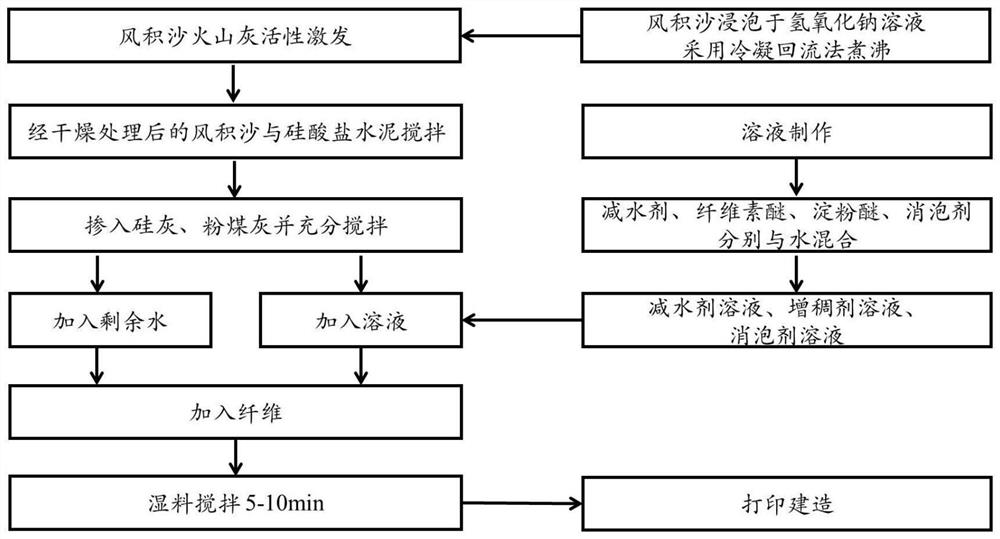

[0064] The present invention provides a method for preparing 3D-printable aeolian sand-resistant frost-resistant concrete described in the above scheme, comprising the following steps:

[0065] Mix Portland cement, silica fume, aeolian sand and fly ash to obtain a mixed material;

[0066] Mix the water reducer with the first part of water to obtain a water reducer solution;

[0067] mixing the cellulose ether, the starch ether and the second part of water to obtain a thickener solution;

[0068] Mixing the defoamer with the remaining water to obtain a defoamer solution;

[0069] The mixed material, the water reducer solution, the thickener solution, the defoamer solution and the polypropylene fiber are mixed to obtain the aeolian sand frost-resistant concrete which can be 3D printed.

[0070] The invention mixes Portland cement, silica fume, aeolian sand and fly ash to obtain a mixed material. In the present invention, there is no special limitation on the operation of mixi...

Embodiment 1

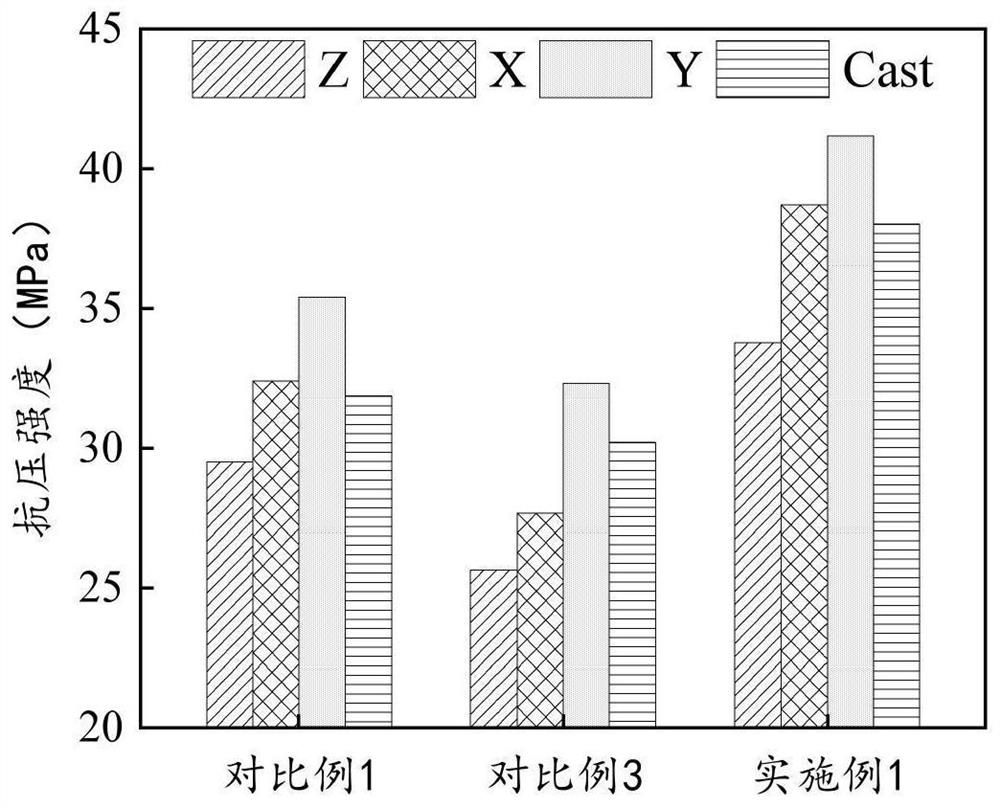

[0101] (1) In terms of parts by weight, 176 parts of Portland cement of grade 42.5, 8 parts of silica fume with a particle size of 6 μm to 8 μm, 16 parts of fly ash, and an apparent density of 2630 kg / cm 3 , bulk density 1400kg / cm 3 340 parts of wind-blown sand (after alkaline treatment) were mixed to obtain the mixed material; in parts by weight, 3 parts of polycarboxylate high-performance water reducer were mixed with 24 parts of water (the mass ratio of water reducer to water is 1:8), to obtain a water reducer solution; in parts by weight, mix 0.3 parts of hydroxyethyl cellulose ether with 15 parts of water (the mass ratio of cellulose ether to water is 1:50), and starch ether Mix 0.05 parts with 5 parts of water (the mass ratio of starch ether to water is 1:100), then mix the cellulose ether solution with the starch ether solution to obtain a thickener solution; in parts by weight, polyether modified organic Mix 0.3 parts of silicon type defoamer with 18 parts of water (t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com