Preparation method of powder metallurgy titanium alloy

A technology of powder metallurgy and titanium alloy, which is applied in the alloy field, can solve the problems of poor ductility and difficult sintering of titanium alloy powder, and achieve the effects of improving sintering performance, density and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

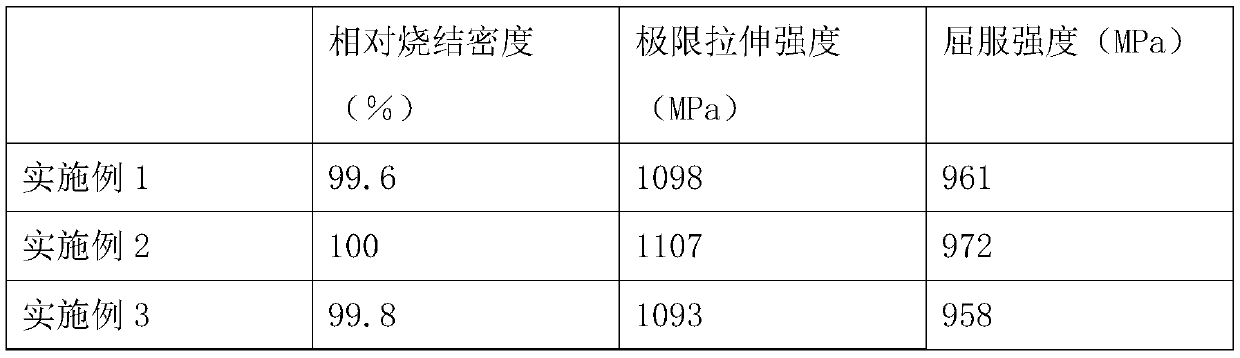

Examples

preparation example Construction

[0027] A preparation method of a powder metallurgy titanium alloy, the preparation method comprising the steps of:

[0028] (1) In parts by weight, take 200-230 parts of titanium powder, 20-22 parts of aluminum powder, 13-16 parts of molybdenum powder, 11-14 parts of mixed powder, 3-8 parts of additives, and 2-5 parts of auxiliary agents , 4 parts of auxiliary agent, 1 to 3 parts of binder, first put titanium powder, aluminum powder, molybdenum powder and binder into the ball mill for 2 hours at 800r / min, and collect the ball mill;

[0029] (2) Put the ball mill, mixed powder, auxiliary agent, additive and auxiliary agent into the extruder to extrude at 15MPa, dry, pulverize, pass through a 200 mesh sieve, collect the sieved particles, and pack the sieved particles into the cold Isostatic pressure sleeve, cold isostatic pressure treatment, the height-to-diameter ratio of the cold isostatic pressure sleeve is controlled at 3:12~18:4, the pressure during cold isostatic pressure ...

Embodiment 1

[0033] The mixed powder is formed by mixing boron oxide, rare earth elements and sodium cobaltate at a mass ratio of 11:1 to 3:0.2.

[0034] The rare earth element is any one of lanthanum hexaboride powder and yttrium oxide.

[0035] The additive is any one of feldspar and fluorite.

[0036] The adhesive is any one of polyurethane adhesive and acrylate adhesive.

[0037] The auxiliary agent is polyethylene glycol.

[0038] Auxiliary agent is any one in lithium carbonate, lithium chloride.

[0039] A preparation method of a powder metallurgy titanium alloy, the preparation method comprising the steps of:

[0040] (1) In parts by weight, 200-230 parts of titanium powder, 20-22 parts of aluminum powder, 13-16 parts of molybdenum powder, 11-14 parts of mixed powder, 3-8 parts of additive, 4 parts of auxiliary agent, 2 ~5 parts of additives, 1~3 parts of binder, first put titanium powder, aluminum powder, molybdenum powder and binder into the ball mill for 2 hours at 800r / min, ...

Embodiment 2

[0045] The mixed powder is formed by mixing boron oxide, rare earth elements and sodium cobaltate at a mass ratio of 11:1 to 3:0.2.

[0046] The rare earth element is any one of lanthanum hexaboride powder and yttrium oxide.

[0047] The additive is any one of feldspar and fluorite.

[0048] The adhesive is any one of polyurethane adhesive and acrylate adhesive.

[0049] The auxiliary agent is polyethylene glycol.

[0050] Auxiliary agent is any one in lithium carbonate, lithium chloride.

[0051] A preparation method of a powder metallurgy titanium alloy, the preparation method comprising the steps of:

[0052] (1) In parts by weight, 200-230 parts of titanium powder, 20-22 parts of aluminum powder, 13-16 parts of molybdenum powder, 11-14 parts of mixed powder, 3-8 parts of additive, 4 parts of auxiliary agent, 2 ~5 parts of additives, 1~3 parts of binder, first put titanium powder, aluminum powder, molybdenum powder and binder into the ball mill for 2 hours at 800r / min, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com