Cement admixture for inhibiting alkali-aggregate reaction, and preparation method thereof

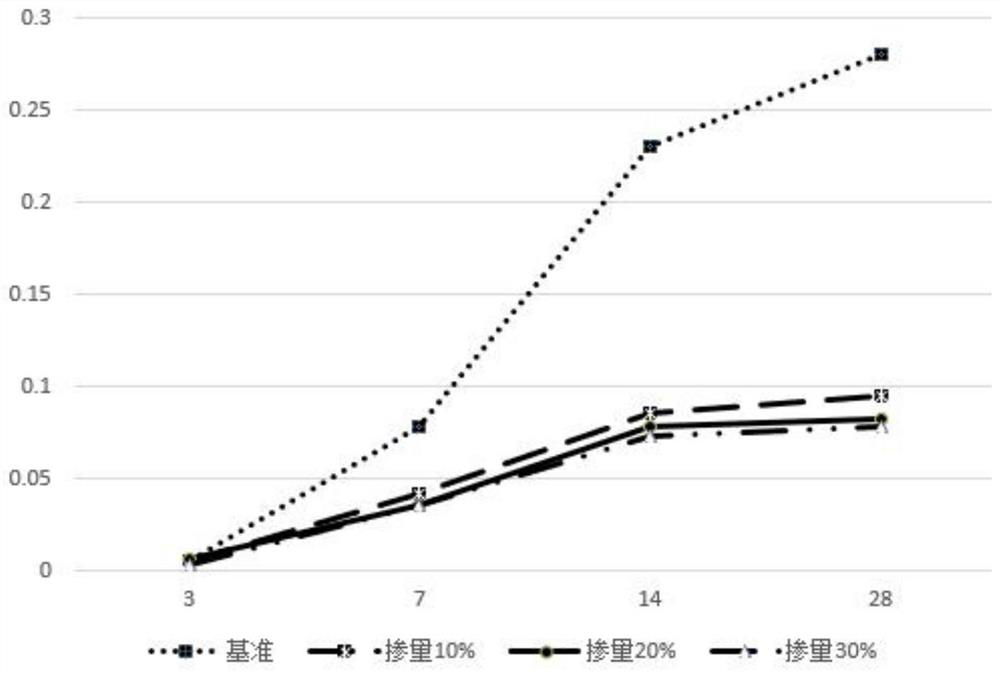

A technology of cement admixture and alkali aggregate, which is applied in the field of building materials and can solve the problems of inconspicuous inhibition effect and cumbersome use process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

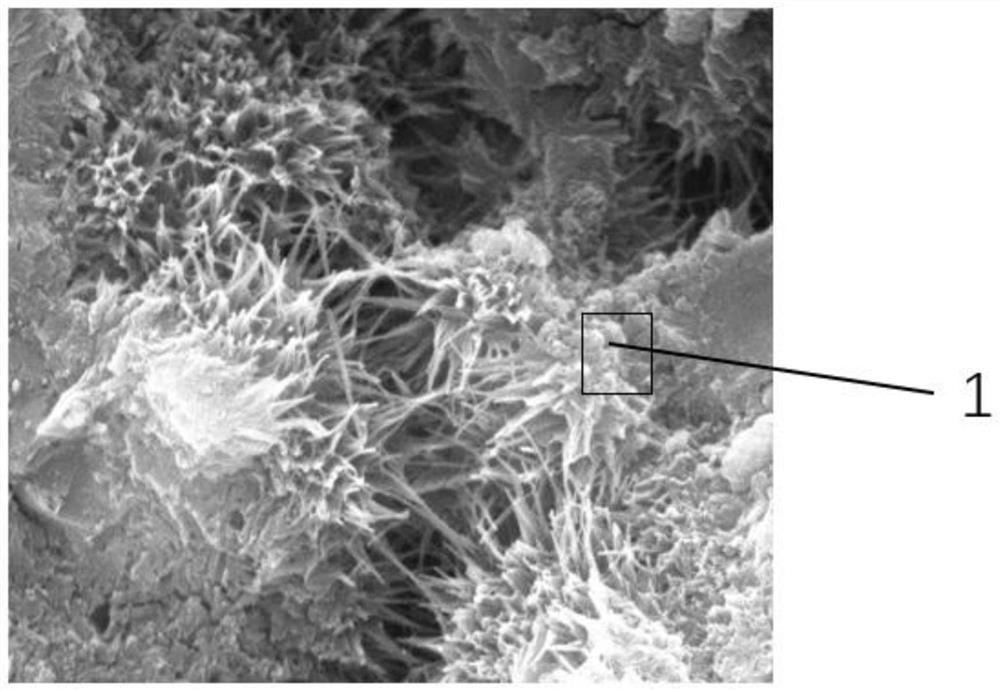

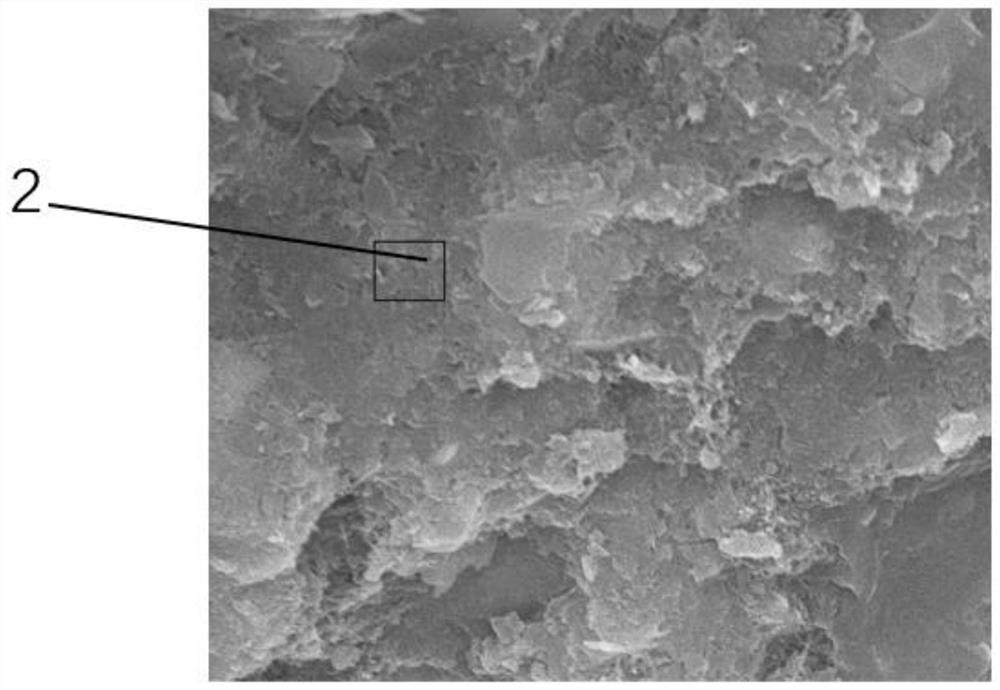

Method used

Image

Examples

Embodiment 1

[0038] (1) After cleaning, drying and grinding the collected waste glass bottles, the obtained waste glass powder, slag and slag are mixed into the ball mill according to the weight ratio of 2:1:1, and the ball mill is used to control the ball milling time for grinding , to obtain a particle size of 68.17μm and a specific surface area of 217.00m 2 / kg of waste mixture;

[0039] (2) Soak the wool in 0.13mol / l triethanolamine solution at 50°C, pretreat for 30 minutes, take it out and dry it for later use.

[0040] (3) The waste mixture after grinding is uniformly mixed with the pretreated wool, alkylbenzenesulfonate, gelatin and lithium sulfate in proportion to obtain the cement admixture. Among them, the weights of waste mixture, wool, alkylbenzenesulfonate, gelatin, and lithium sulfate are: 75g, 3g, 5g, 0.5g, and 16.5g, respectively.

Embodiment 2

[0042] (1) After cleaning, drying and grinding the collected waste glass bottles, the obtained waste glass powder, slag and slag are mixed into the ball mill according to the weight ratio of 2:1:1, and the ball mill is used to control the ball mill grinding, Obtained particle size 80μm, specific surface area 280.00m 2 / kg of waste mixture;

[0043] (2) Soak the wool in 0.13mol / l triethanolamine solution at 55°C, pretreat for 45 minutes, take it out and dry it for later use.

[0044] (3) The waste mixture after grinding is uniformly mixed with the pretreated wool, alkylbenzenesulfonate, gelatin and lithium sulfate in proportion to obtain the cement admixture. Wherein, the weight ratios of waste mixture, wool, alkylbenzenesulfonate, gelatin and lithium sulfate are: 80g, 3g, 3g, 0.03g, 13.7g respectively.

Embodiment 3

[0046] (1) After cleaning, drying and grinding the collected waste glass bottles, the obtained waste glass powder, slag and slag are mixed into the ball mill according to the ratio of 2:1:1 by weight, and the particle size is obtained by ball milling with the ball mill. 10-200μm, specific surface area 100-900m 2 / kg of waste mixture;

[0047] (2) Soak the wool in 0.13 mol / l triethanolamine solution at 52°C, pretreat for 1 hour, take it out and dry it for later use.

[0048] (3) The waste mixture after grinding is uniformly mixed with the pretreated wool, alkylbenzenesulfonate, gelatin and lithium sulfate in proportion to obtain the cement admixture. Wherein, the weight ratios of waste mixture, wool, alkylbenzenesulfonate, gelatin and lithium sulfate are: 70g, 3g, 5g, 0.5g, 21.5g respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com