Multifunctional element possessing large electric capacitance and pressure-sensitive character and its preparation method

A capacitance and multi-function technology, which is applied in the manufacture of fixed capacitance parts, electrical components, capacitors, etc., can solve the problems of single function of electronic components, limit the miniaturization of electronic equipment, etc., and achieve a small number of pores and a low shrinkage rate , The effect of improving the dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

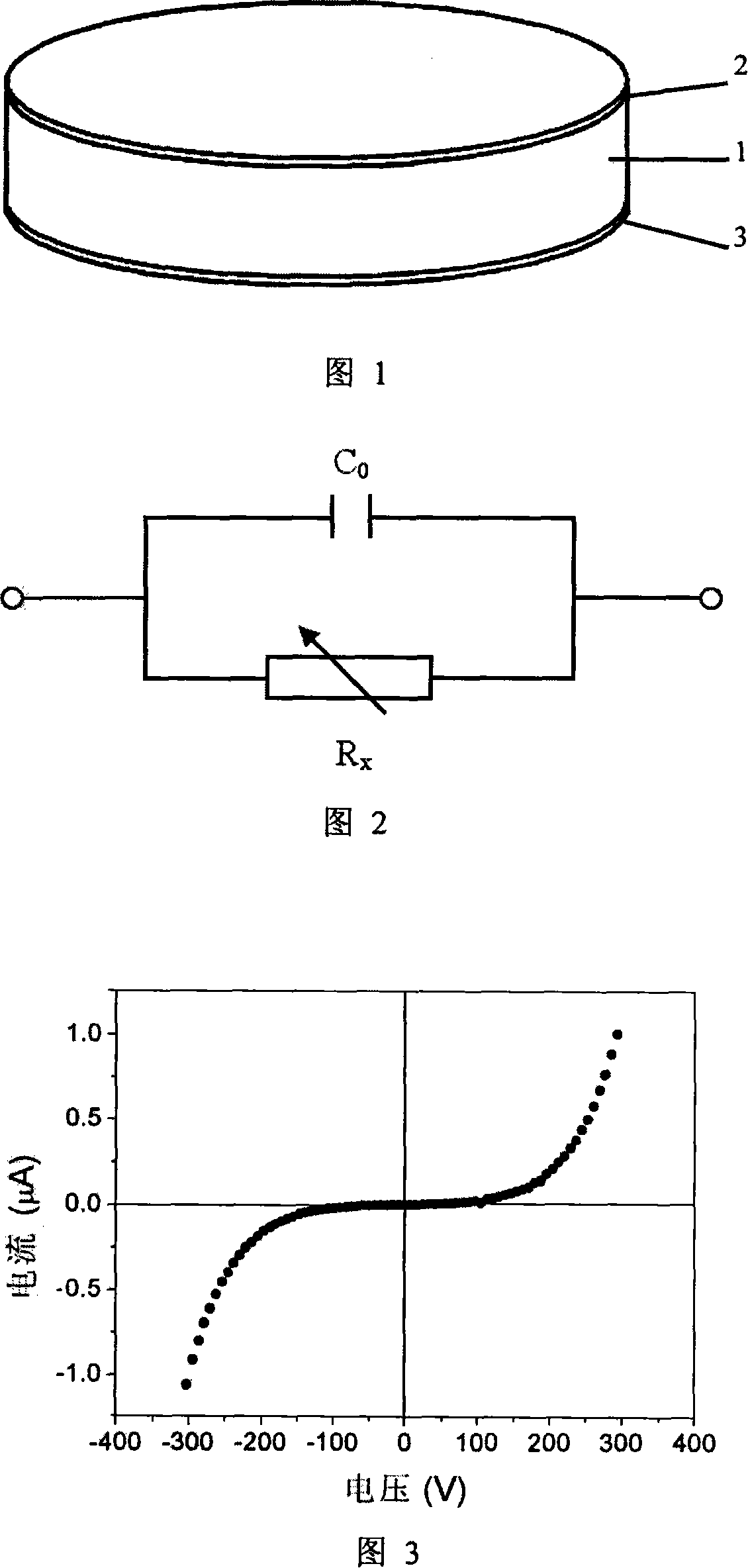

Embodiment 1

[0024] The raw materials calcium carbonate, titanium dioxide and copper oxide are mixed in a molar ratio of 1:4:3, wet ball milled, and the ball milled powder is dried in an oven. Then pre-fire the powder in an agate crucible at 950°C for 3 hours and keep it warm for 2 hours. The calcined powder was dry-pressed at 150MPa, and cold isostatically pressed at 200MPa to form a disc with a diameter of 10mm and a thickness of 2mm. The green body is sintered in an electric furnace at 1020°C for 3 hours, held for 2 hours, and then cooled with the furnace. The shape of the ceramic body is modified, the surface is polished, the upper and lower surfaces are covered with Ag top electrodes and Ag bottom electrodes by screen printing, and heat treatment is carried out at 500 ° C to make the Ag top electrodes and Ag bottom electrodes combined with the CCTO ceramic medium densely. Its electrical performance test, the following results can be obtained. Performance 1: High capacitance characte...

Embodiment 2

[0026]Mix the raw materials calcium carbonate, titanium dioxide and copper oxide in a molar ratio of 1:4:3, wet ball mill in an agate ball mill jar, pass through a 80-mesh sieve, and use distilled water as the ball milling medium. Raw materials by mass ratio: agate ball: distilled water=1 :1:1.2. The planetary ball mill was used for ball milling for 4 hours at a speed of 250 rpm, and the mixed powder after ball milling was dried in an oven. Pre-fire the mixed powder in an agate crucible at 950°C and keep it warm for 2h. After heat preservation, the mixed powder is ball milled and dried. Then add 10% by mass of PVA, grind and granulate in an agate mortar. The granulated powder was dry-pressed at 150 MPa, and then cold-isostatically pressed at 200 MPa to form a disc with a diameter of 9 mm and a thickness of 2 mm. The green body is sintered in an electric furnace at 1020°C and held for 2 hours, and then cooled with the furnace. The surface is polished, silver electrodes are ...

Embodiment 3

[0028] Similar to Example 2, the raw materials were mixed, ball milled, and passed through a 100-mesh sieve, according to the mass ratio of raw materials: agate balls: distilled water=1: 1.1: 1.1. Pre-fire the mixed powder in an agate crucible at 850°C and keep it warm for 6h. After heat preservation, the mixed powder is ball milled and dried. Then add 7% by mass of PVA. The granulated powder was dry-pressed at 200 MPa, and then cold-isostatically pressed at 150 MPa to form a disc with a diameter of 9 mm and a thickness of 2 mm. The green body is sintered in an electric furnace at 1050°C and held for 2 hours, then cooled with the furnace, the surface is polished, and silver electrodes are applied.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com