Stirring machine

A technology of agitator and agitating motor, which is applied in the directions of mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve the problems of low work efficiency, difficult movement, troublesome operation, etc., and achieves fast feeding speed, simple and convenient movement. , easy to move

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the construction industry, it is generally necessary to use a mixer to mix materials. The existing mixers are generally fixed on the ground, difficult to move, cumbersome to operate, and low in efficiency.

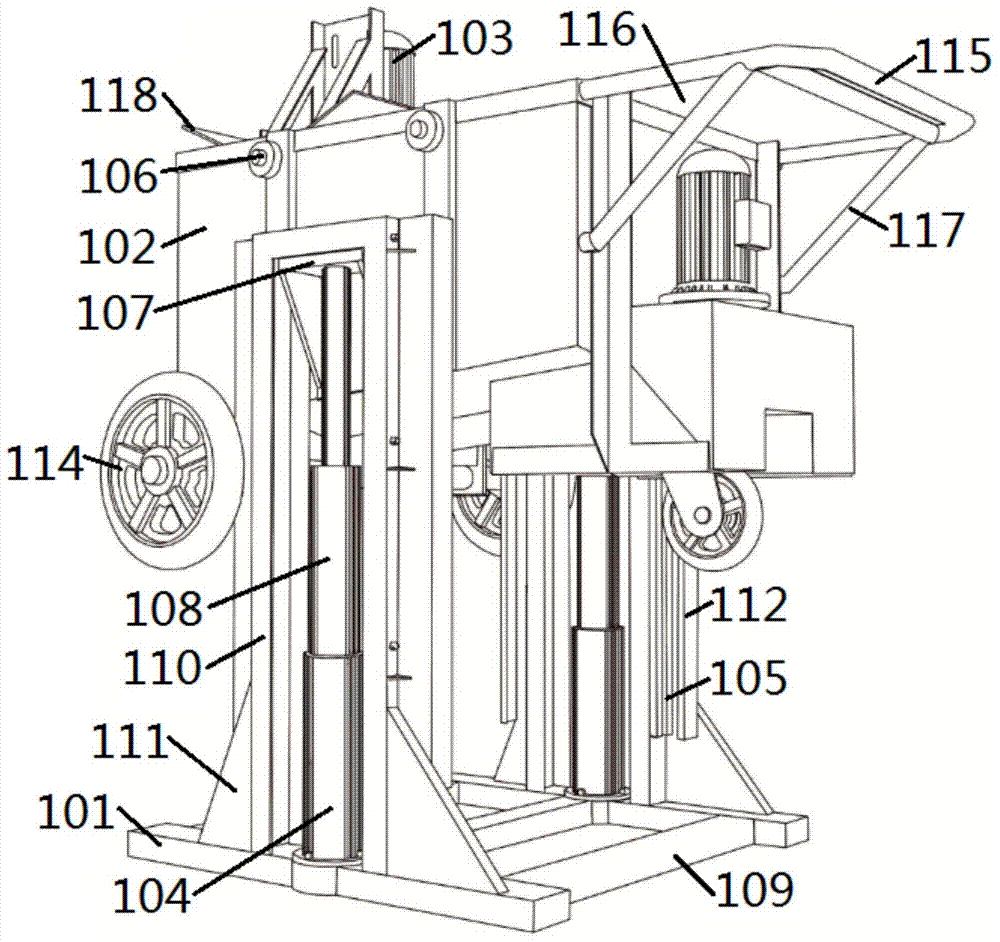

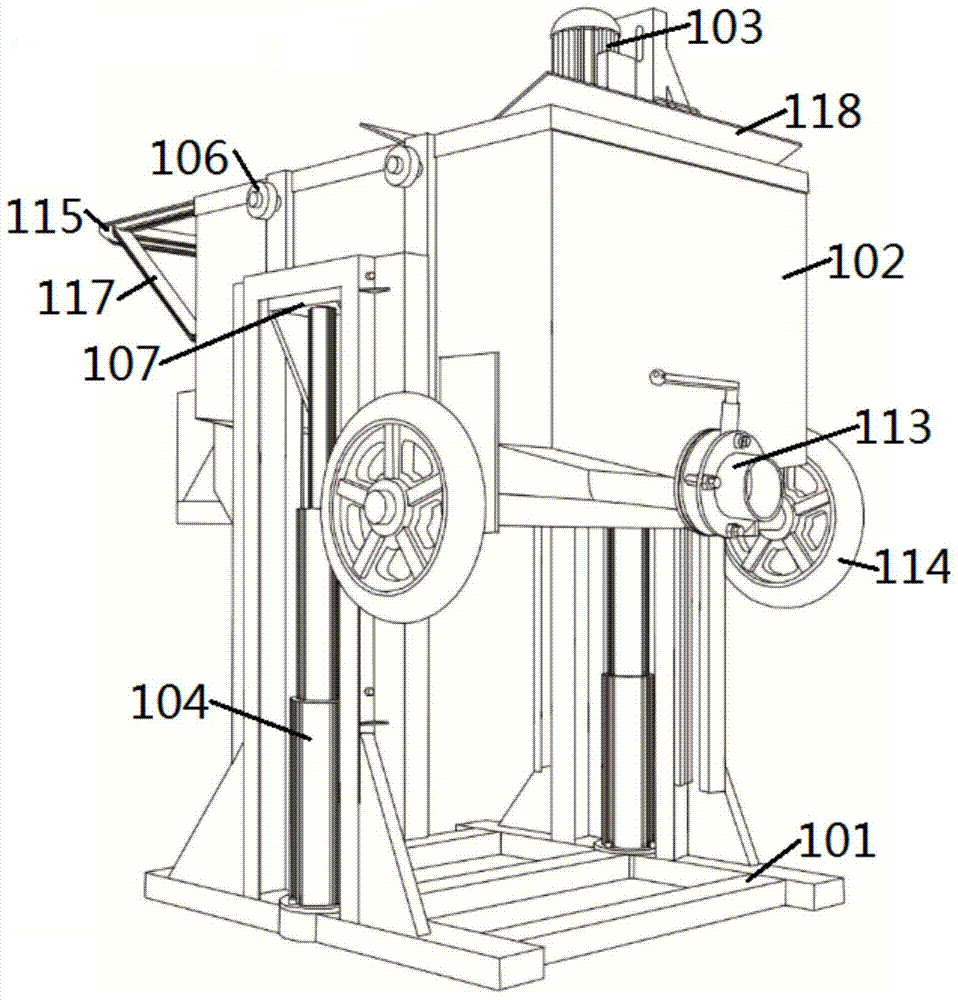

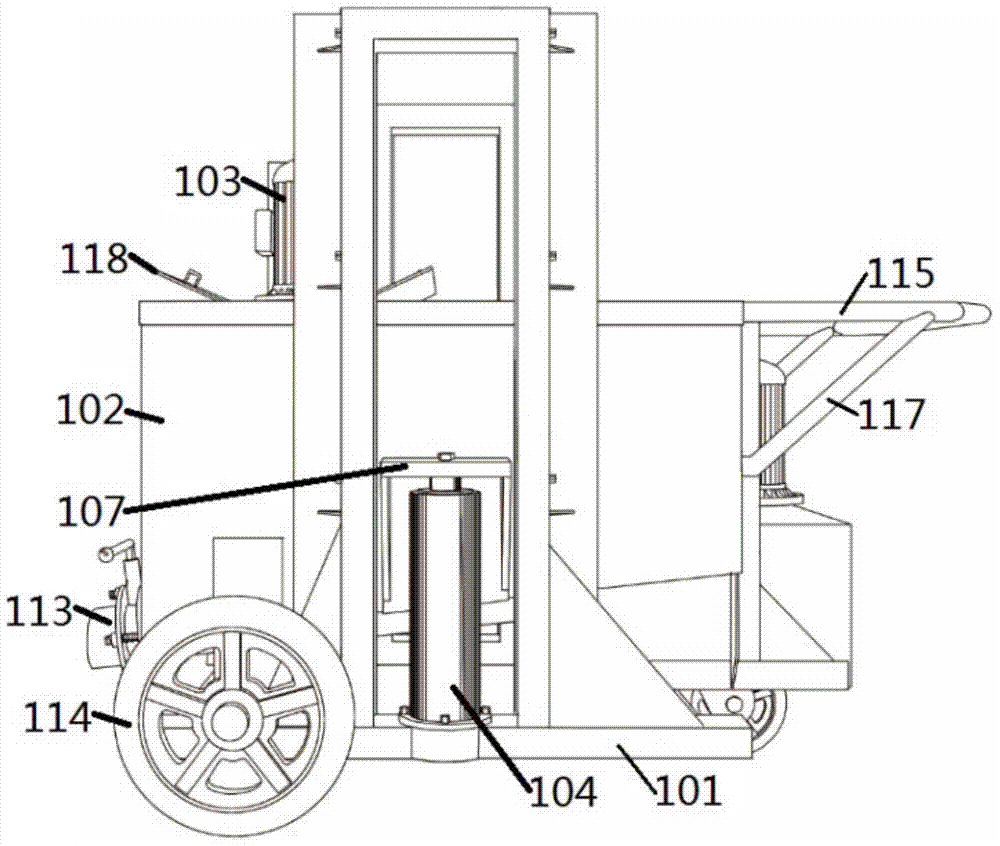

[0036]In order to improve the above problems, the present invention provides a mixer. Wheels or rollers are installed at the bottom of the mixing bucket, so that the mixing bucket can walk on the ground, so that the staff can push the mixer to the designated position, and then pass the mixing bucket on the support. Sliding up makes the wheels etc. off the ground for mixing and discharging of materials, which can be operated by a single person, and the movement is simple and convenient, which improves work efficiency.

[0037] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com