High-strength ceramic mainly prepared from tungsten tailings and preparation method of high-strength ceramic

A main raw material, tungsten tailings technology, applied in the field of building materials, high-strength ceramics and its preparation, can solve the problems of lack of ceramic raw materials, low utilization rate of tungsten tailings, etc., and achieve high yield, high strength and chemical stability , the effect of fewer types of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

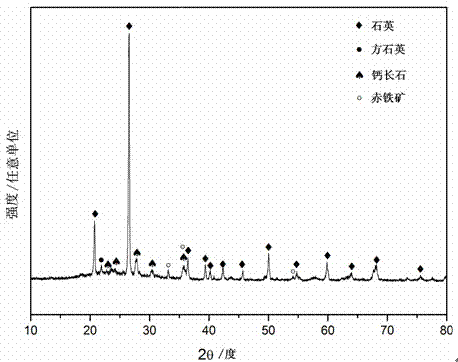

Image

Examples

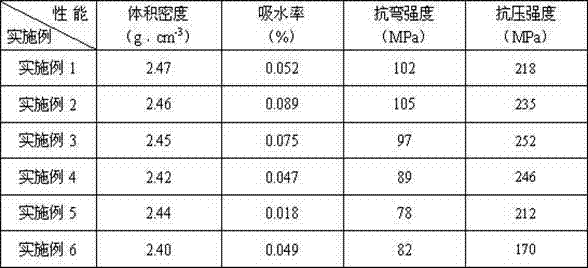

Embodiment 1

[0029] A high-strength ceramic with tungsten tailings as the main raw material and a preparation method thereof. In terms of weight percentage, the tungsten tailings are 90%, albite 10%, and polyvinyl alcohol binder accounting for 5% of the total amount of raw materials is added. Pretreat the tungsten tailings at 900°C for 2 hours; accurately weigh the pretreated tungsten tailings and feldspar, mix, ball mill, pass through a 200-mesh sieve, and add polyvinyl alcohol binder accounting for 5% of the total amount of raw materials , mixed evenly to make the batch material; put the batch material into a stainless steel mold, and press it with a pressure of 30MPa; put the pressed green body in the air and dry it naturally for 1 hour; put the dried green body into the sintering furnace Sintering, the firing temperature is 1050 ℃, heat preservation for 1 hour.

Embodiment 2

[0031] A high-strength ceramic with tungsten tailings as the main raw material and a preparation method thereof. In terms of weight percentage, the tungsten tailings are 85%, albite 15%, and a polyvinyl alcohol binder accounting for 1% of the total amount of raw materials is added. Pretreat the tungsten tailings at 600°C for 2 hours; accurately weigh the pretreated tungsten tailings and feldspar, mix, ball mill, pass through a 300-mesh sieve, and add polyvinyl alcohol binder accounting for 1% of the total amount of raw materials , mixed evenly to make a batch; put the batch into a stainless steel mold, and press it with a pressure of 20MPa; put the pressed green body in the air and dry it naturally for 3 hours; put the dried green body into a sintering furnace For sintering, the firing temperature is 1050°C and kept at high temperature for 2 hours.

Embodiment 3

[0033] A high-strength ceramic with tungsten tailings as the main raw material and a preparation method thereof. In terms of weight percentage, tungsten tailings are 80%, albite feldspar 20%, and polyvinyl alcohol binder accounting for 3% of the total raw materials. Pretreat the tungsten tailings at 900°C for 1 hour; accurately weigh the pretreated tungsten tailings and feldspar, mix, ball mill, pass through a 200-mesh sieve, and add polyvinyl alcohol binder accounting for 3% of the total amount of raw materials , mixed evenly to make a batch; put the batch into a stainless steel mold, and press it with a pressure of 25MPa; put the pressed green body in the air and dry it naturally for 2 hours; put the dried green body into a sintering furnace Sintering, the firing temperature is 1050°C, and the temperature is kept at high temperature for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com