High-temperature-resistant tough well cementation cement slurry system

A technology of cementing slurry and high temperature resistance, applied in the direction of drilling composition, chemical instruments and methods, etc., can solve the problems of cement stone strength decline, insufficient toughness, etc., achieve small cement specific surface area, reduce the number and size of pores , the effect of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

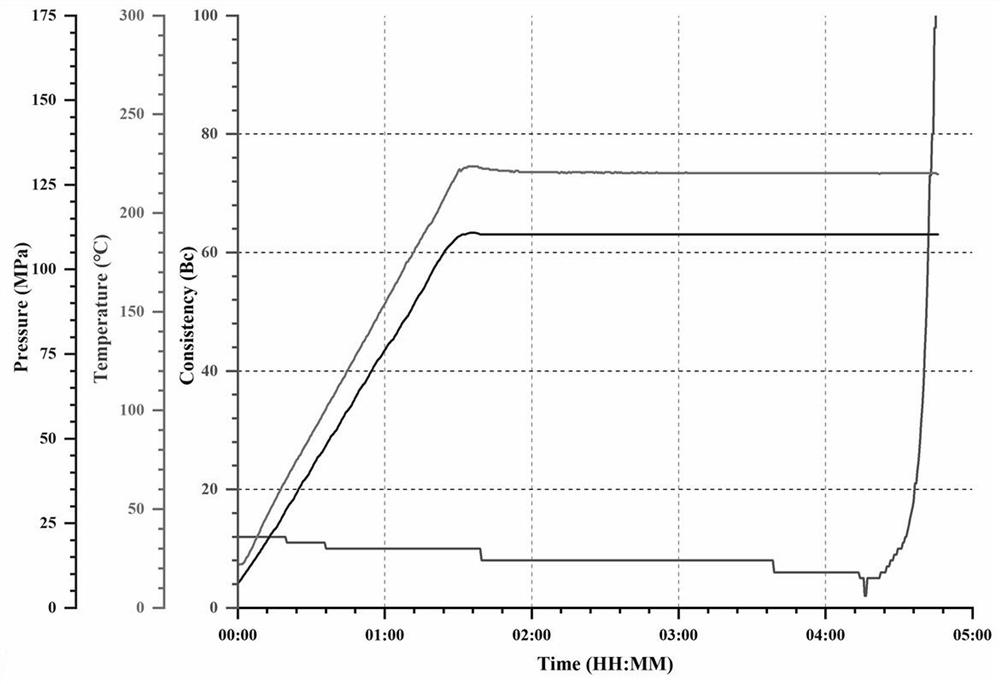

Embodiment 1

[0033] As a preferred embodiment of the present invention, this embodiment discloses a high temperature resistant ductile cement slurry system, using low heat of hydration cement as the base cement, wherein C 2 S content ≥ 40%, specific surface area is 280-330m 2 / Kg, 7d heat of hydration ≤ 240kJ / kg; the specific components are shown in the table below:

[0034]

[0035] The high-temperature toughening material is polyetheretherketone resin; the high-temperature strength-stabilizing material is waste refractory brick powder, SiO 2 Content ≥ 95%, powder fineness ≥ 800 mesh. The organosilicon resin micropowder is white powder, the active substance content is >99%, and the powder fineness is >=800 mesh. The high temperature stabilizer is clay. Mix the raw materials according to the specific composition ratio in the above table, and prepare the cement slurry according to GB / T19139, and the cement slurry system with a water-cement ratio of 0.44.

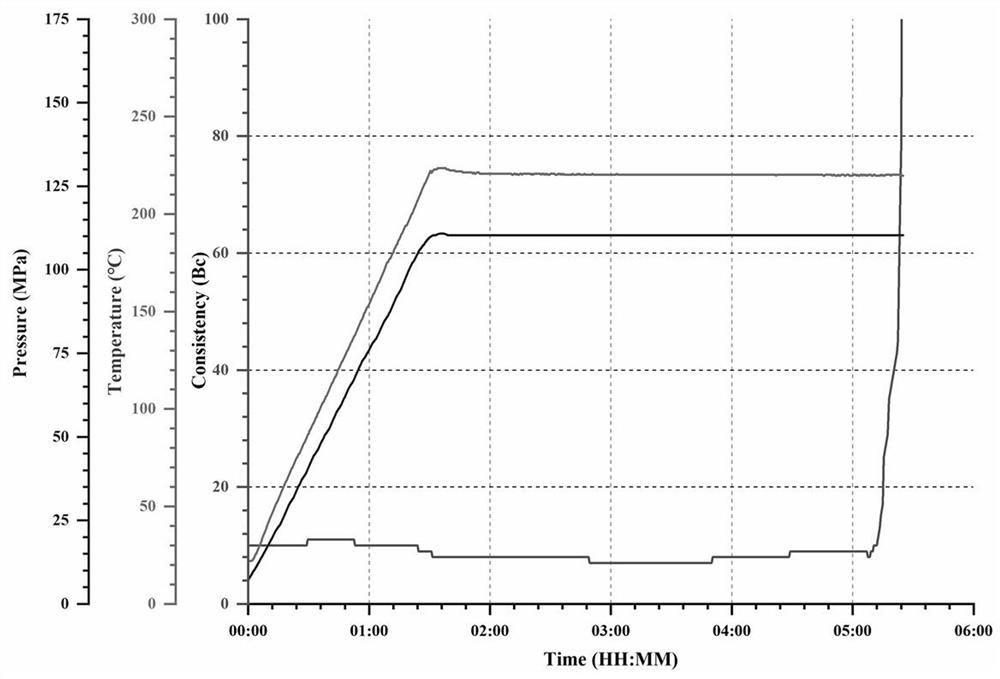

Embodiment 2

[0037] As another preferred embodiment of the present invention, this embodiment discloses a high-temperature-resistant ductile cement slurry system, which uses low-heat-of-hydration cement as the base cement, wherein C 2 S content ≥ 40%, specific surface area is 280-330m 2 / Kg, 7d heat of hydration ≤ 240kJ / kg; the specific components are shown in the table below:

[0038]

[0039] The high-temperature toughening material is polyetheretherketone resin; the high-temperature strength-stabilizing material is waste refractory brick powder, SiO 2 Content ≥ 95%, powder fineness ≥ 800 mesh. The organosilicon resin micropowder is white powder, the active substance content is >99%, and the powder fineness is >=800 mesh. The high temperature stabilizer is clay. Mix the raw materials according to the specific composition ratio in the above table, and prepare the cement slurry according to GB / T19139, and the cement slurry system with a water-cement ratio of 0.44.

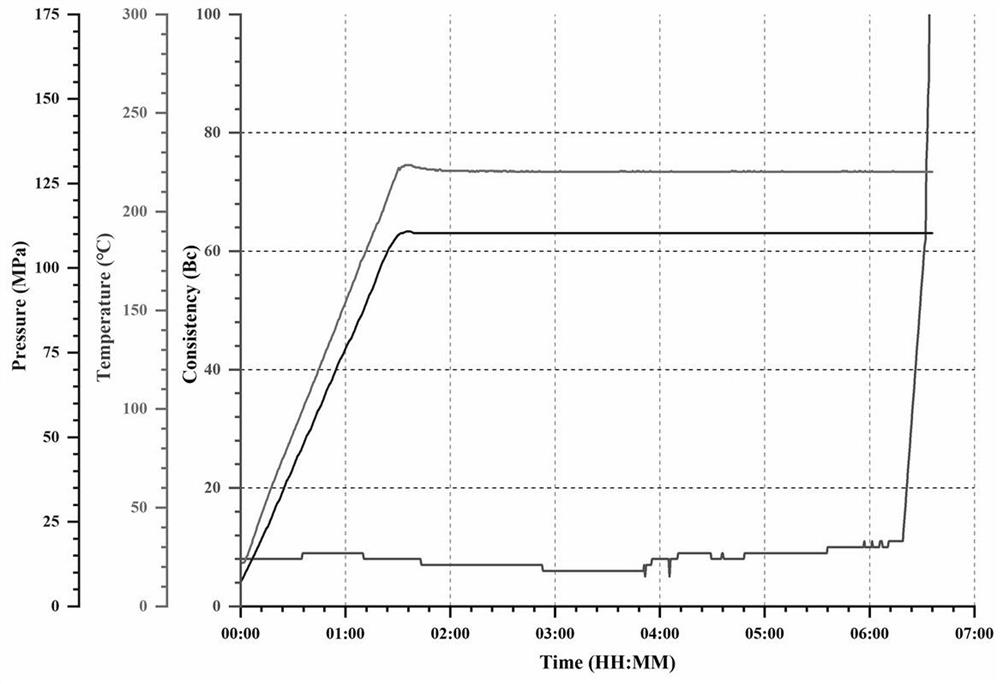

Embodiment 3

[0041] As another preferred embodiment of the present invention, this embodiment discloses a high-temperature-resistant ductile cement slurry system, which uses low-heat-of-hydration cement as the base cement, wherein C 2 S content ≥ 40%, specific surface area is 280-330m 2 / Kg, 7d heat of hydration ≤ 240kJ / kg; the specific components are shown in the table below:

[0042]

[0043] The high-temperature toughening material is polyetheretherketone resin; the high-temperature strength-stabilizing material is waste refractory brick powder, SiO 2 Content ≥ 95%, powder fineness ≥ 800 mesh. The organosilicon resin micropowder is white powder, the active substance content is >99%, and the powder fineness is >=800 mesh. The high temperature stabilizer is clay. Mix the raw materials according to the specific composition ratio in the above table, and prepare the cement slurry according to GB / T19139, and the cement slurry system with a water-cement ratio of 0.44.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| hydration enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com