Double-cylinder hydraulic ejection control system and method thereof

A control method and control system technology, applied in the field of presses, can solve problems such as inconvenient maintenance, confusion between working status and maintenance status, and abnormal oil circuit operation, so as to facilitate maintenance, reduce the difficulty of later maintenance, and improve the processing speed of workpieces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with specific embodiments.

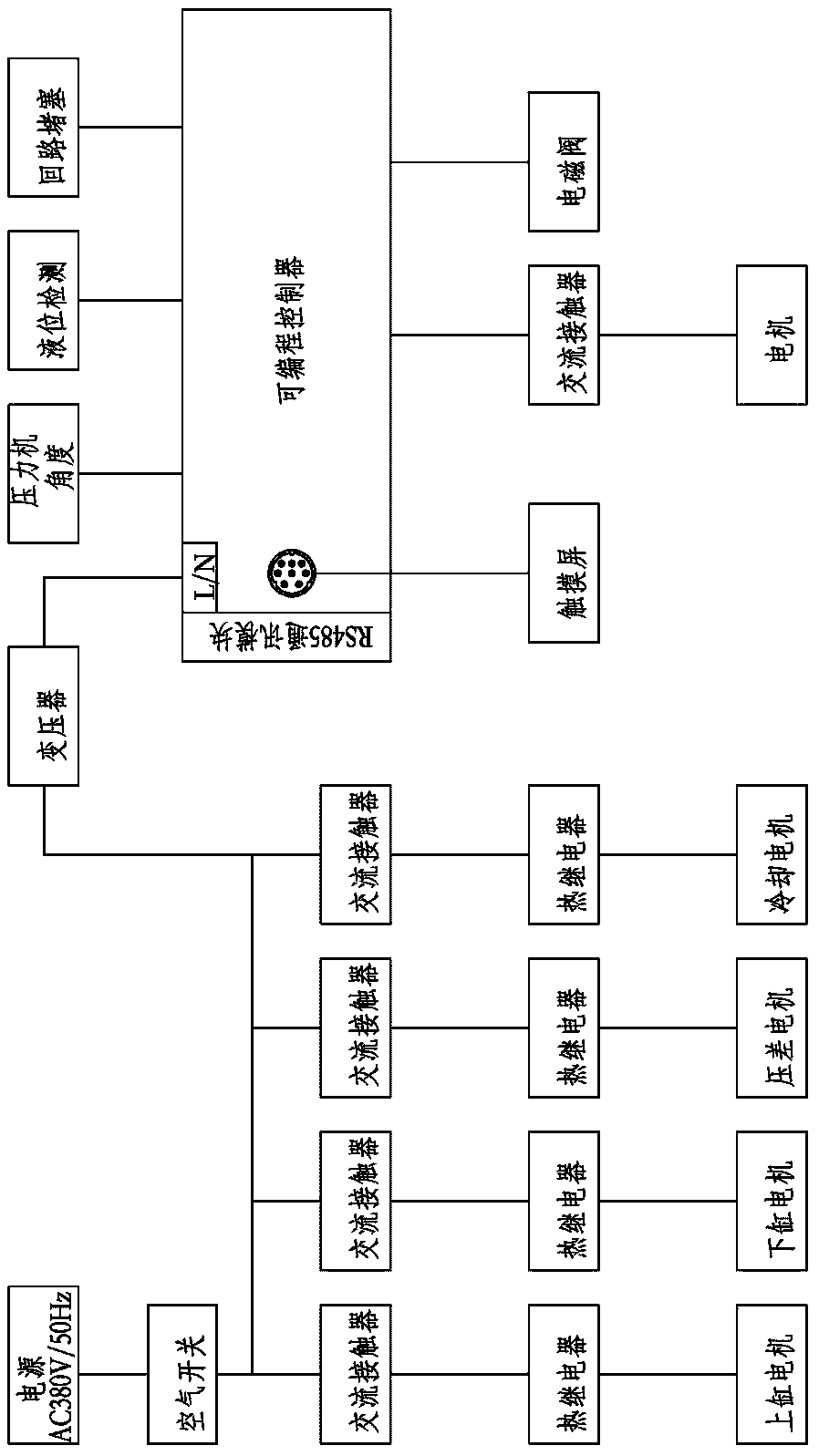

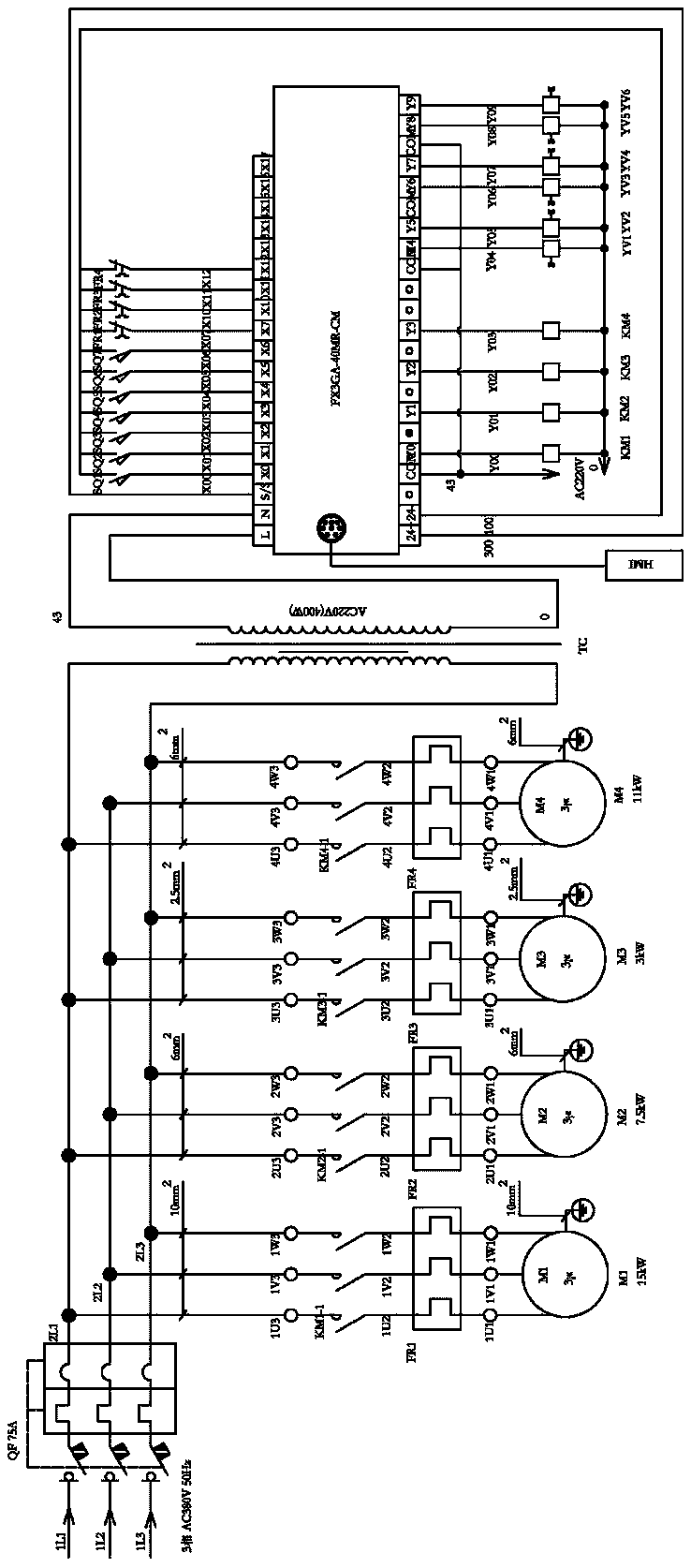

[0035] Such as Figure 1-2 A dual-cylinder hydraulic ejection control system shown includes:

[0036] Main circuit unit: Three-phase 380V, 50Hz power supply is protected by air switch QF, respectively connected to the upper ends of four AC contactor contacts KM1-1, KM2-1, KM3-1, KM4-1, and AC contactor KM1-1 , KM2-1, KM3-1, and KM4-1 are connected to thermal relays FR1, FR2, FR3, and FR4 at the lower ends, and are protected by thermal relays FR1, FR2, FR3, and FR4 for overcurrent protection, and then respectively connected to four motors, respectively for the following Cylinder motor M1, upper cylinder motor M2, differential pressure motor M3, cooling motor M4;

[0037] Control circuit: Two phases of three-phase 380V, 50Hz power supply are connected to the transformer TC, and the output AC220V AC control power supply is connected to the PLC power supply terminal, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com