Method for continuous production of magnesium alloy strip basal plane texture through corrugated pre-rolling weakening

A magnesium alloy plate and corrugation technology, applied in the field of magnesium alloy rolling, can solve the problems of low yield, high cost, long process, etc., and achieve the effect of improving mechanical properties and room temperature forming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The description is better understood and described through the following specific examples. The described examples are only some of the examples of the present invention, not all of them, but they do not limit the present invention.

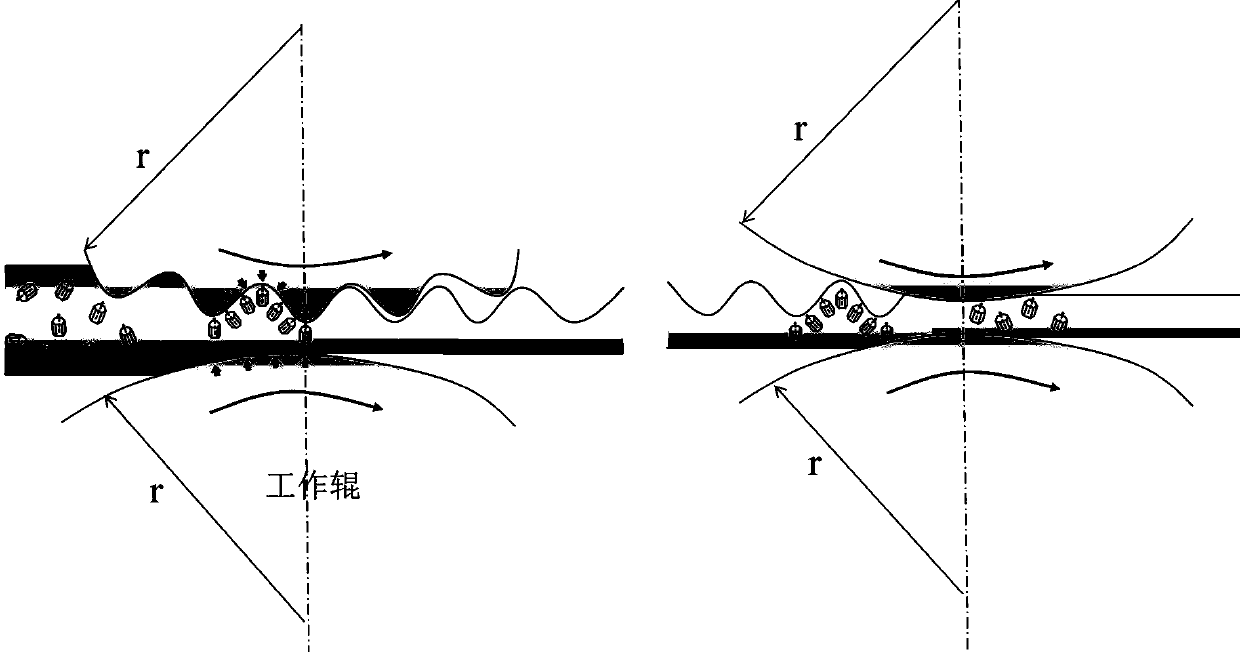

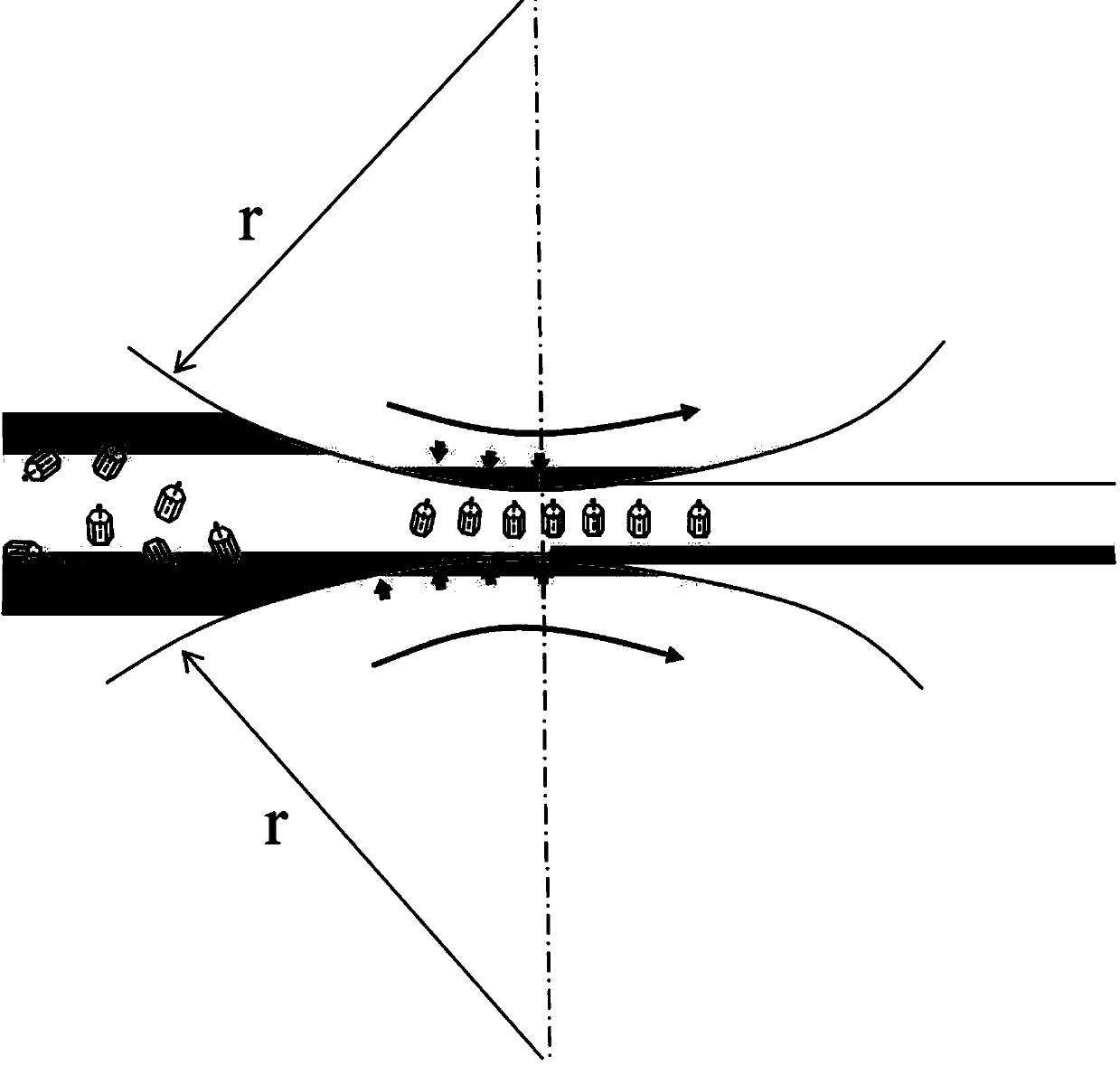

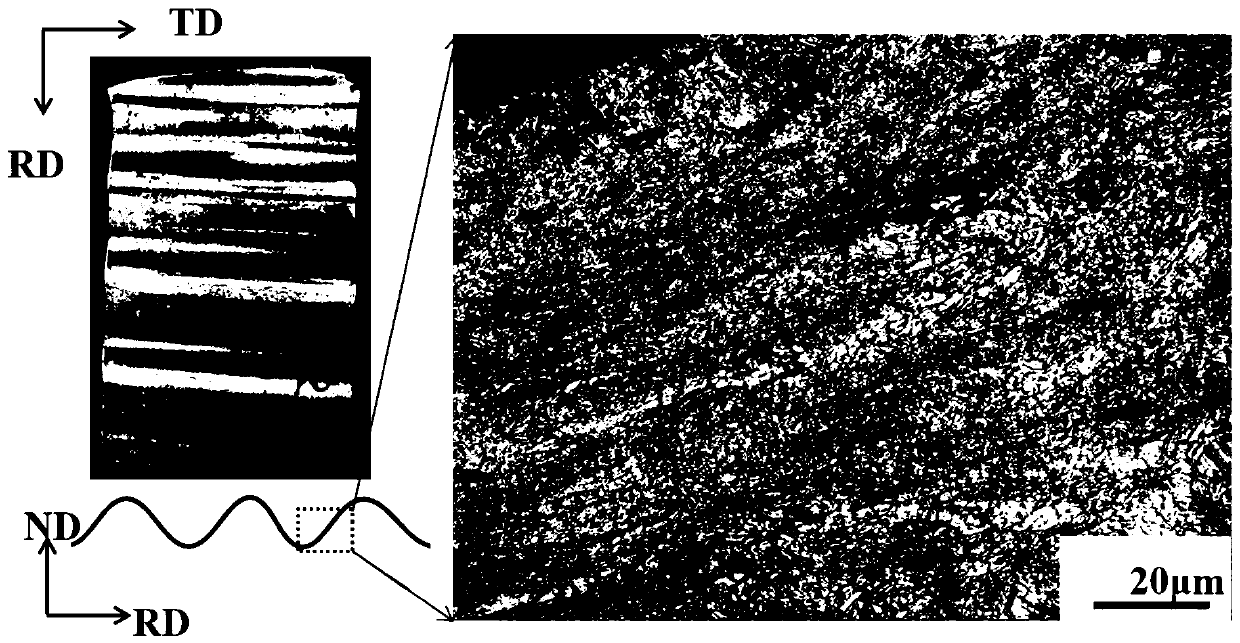

[0029] Such as figure 1 As shown, the present invention provides a method for corrugated pre-rolling to weaken the continuous production of the base surface texture of magnesium alloy strips, and its specific implementation steps are as follows:

[0030] (1) The as-cast AZ31 magnesium alloy is placed in a holding furnace and heated to 400°C and held for 1 hour for homogenization treatment, and the obtained plate is used as a test piece;

[0031] (2) The test strip obtained in (1) is first pre-rolled with 50% of the corrugated deformation, so as to promote the formation of regular local plastic deformation on the upper and lower surfaces of the plate, and obtain the pre-rolled AZ31 plate with corrugated appearance ;

[0032] (3) Use corru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com