Ultrafine grained Ta material and preparation method thereof

An ultra-fine grain and tantalum material technology, applied in the field of ultra-fine grain Ta material and its preparation, can solve the problems of unsuitable for industrial production of ultra-fine grain high-purity tantalum strip, affecting the performance of Ta material, introducing impurities, etc. Slip suppression, large deformation, and prevention of deformation and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

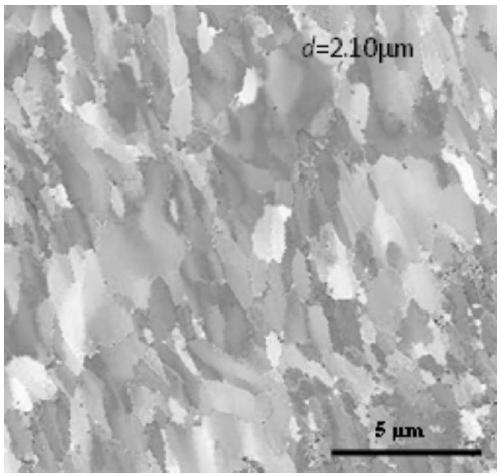

[0039] The tantalum ingot (purity 99.996%) was vacuumed at 10 -4Under the condition of Pa, carry out electron beam smelting (melting temperature is 1310°C). After ingot casting, the ingot is covered with high-purity iron in an argon chamber; three-dimensional hot forging is carried out to open the billet, the total deformation of the billet is 75%, and the billet temperature 1200°C. Remove the high-purity iron sheath on the surface of the tantalum ingot after billeting, and cool the forged billet under liquid nitrogen. After cooling completely, carry out ultra-low temperature rolling (the temperature of low-temperature cold rolling is -80~-100°C), Pass deformation 50%. The ultra-low temperature cold-rolled 50% tantalum plate is heated to 1100 ° C, and the direction perpendicular to the ultra-low temperature cold rolling rolling direction is hot-rolled here (the temperature of the hot rolling is 1100-1120 ° C), and the rolling deformation is 50%. Repeat step A, step B to 7 ti...

Embodiment 2

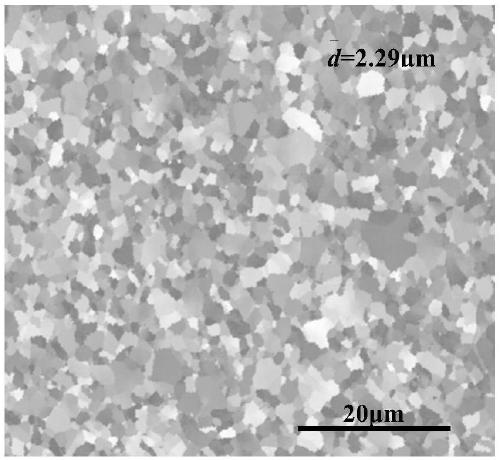

[0041] The tantalum ingot (purity 99.997%) was vacuumed at 10 -4 Under the condition of Pa, carry out electron beam smelting (melting temperature is 1305 ℃), after ingot casting, the ingot is sheathed with high-purity iron in an argon chamber; three-dimensional hot forging is carried out to open the billet, the total deformation of the billet is 70%, and the billet temperature 1100°C. Remove the high-purity iron sheath on the surface of the billeted tantalum ingot, cool the forged billet under liquid nitrogen, and then carry out ultra-low temperature rolling (the temperature of low-temperature cold rolling is -100~-136°C), Pass deformation 50%. The ultra-low temperature cold-rolled 50% tantalum plate is heated to 1100 ° C, and the direction perpendicular to the ultra-low temperature cold rolling rolling direction is hot-rolled here (the temperature of the hot rolling is 1100-1120 ° C), and the rolling deformation is 50%. Repeat steps A and B6 times in turn to obtain the micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average grain size | aaaaa | aaaaa |

| Ultimate strength | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com