Preparation method and application of macadamia nut green skin extract

An extract and green peel technology, applied in the field of preparation of macadamia nut green peel extract, can solve the problems of complicated operation process, hinder comprehensive utilization of macadamia nut green peel resources, unsuitable for industrial production, etc., and achieve the effect of simple extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

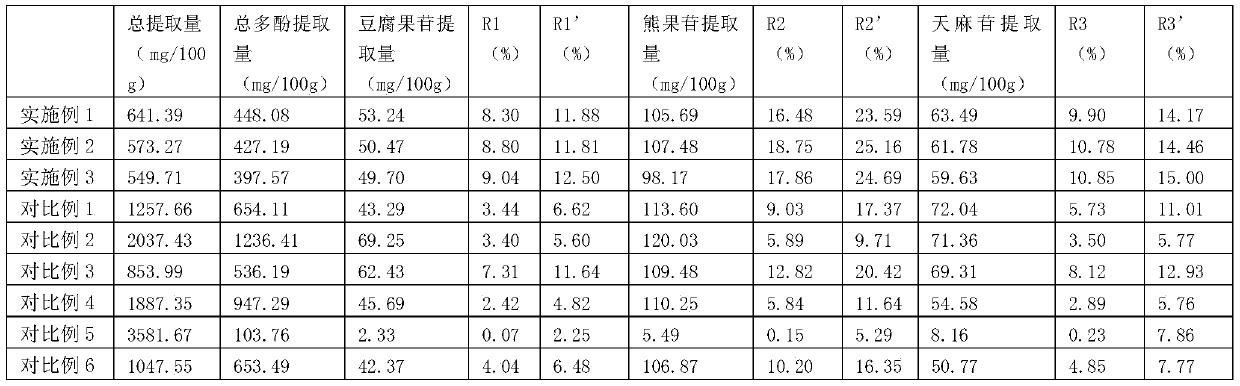

Examples

Embodiment 1

[0041] Embodiment 1: Preparation example of macadamia nut green bark extract

[0042] The preparation steps of macadamia nut green bark extract are as follows:

[0043] Step (1): Take fresh macadamia nut green skin, wash it, dry it in the shade, crush it and pass it through 40 meshes to obtain green skin powder;

[0044] Step (2): Add 20ml of water to every 1g of green bark powder, and then add cellulase (aladdin, C298989, CAS No.: 9012-54-8) to obtain enzymatic hydrolysis system I, and carry out the first enzymatic hydrolysis reaction. In the enzymatic hydrolysis system I, the mass concentration of cellulase was 3%, the enzymatic hydrolysis reaction time was 30min, and the temperature was 50°C.

[0045] After the first enzymatic hydrolysis reaction, the pH value was adjusted to 9.5, and then alkaline protease (McLean, P824138, CAS No.: 9014-01-1) was added to obtain enzymatic hydrolysis system II for the second enzymatic hydrolysis reaction. The mass concentration of alkali...

Embodiment 2

[0051] Example of preparation of macadamia nut green bark extract

[0052] The preparation steps of macadamia nut green bark extract are as follows:

[0053] Step (1): Take fresh macadamia nut green skin, wash it, dry it in the shade, crush it and pass it through 40 meshes to obtain green skin powder;

[0054] Step (2): Add 15ml of water to every 1g of green bark powder, and then add cellulase (aladdin, C298989, CAS No.: 9012-54-8) to obtain enzymatic hydrolysis system I, and carry out the first enzymatic hydrolysis reaction. In the enzymatic hydrolysis system I, the mass concentration of cellulase is 2%, the enzymatic hydrolysis reaction time is 30min, and the temperature is 40°C.

[0055] After the first enzymatic hydrolysis reaction, the pH value was adjusted to 10.5, and then alkaline protease (McLean, P824138, CAS No.: 9014-01-1) was added to obtain enzymatic hydrolysis system II for the second enzymatic hydrolysis reaction. The mass concentration of alkaline protease i...

Embodiment 3

[0060] Embodiment 3: Preparation example of macadamia nut green bark extract

[0061] The preparation steps of macadamia nut green bark extract are as follows:

[0062] Step (1): Take fresh macadamia nut green skin, wash it, dry it in the shade, crush it and pass it through 40 meshes to obtain green skin powder;

[0063] Step (2): Add 18ml of water to every 1g of green bark powder, and then add cellulase (aladdin, C298989, CAS No.: 9012-54-8) to obtain enzymatic hydrolysis system I, and carry out the first enzymatic hydrolysis reaction. In the enzymatic hydrolysis system I, the mass concentration of cellulase was 4%, the enzymatic hydrolysis reaction time was 25min, and the temperature was 55°C.

[0064] After the first enzymatic hydrolysis reaction, the pH value was adjusted to 10.0, and then alkaline protease (McLean, P824138, CAS No.: 9014-01-1) was added to obtain enzymatic hydrolysis system II for the second enzymatic hydrolysis reaction. The mass concentration of alkal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com