Laminated glass, preparation method and applications thereof

A technology for laminated glass and glass, applied in chemical instruments and methods, glass/slag layered products, layered products, etc., can solve the problems of air bubbles, the need for improvement of laminated glass, and the inability to apply the technology to the actual production field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

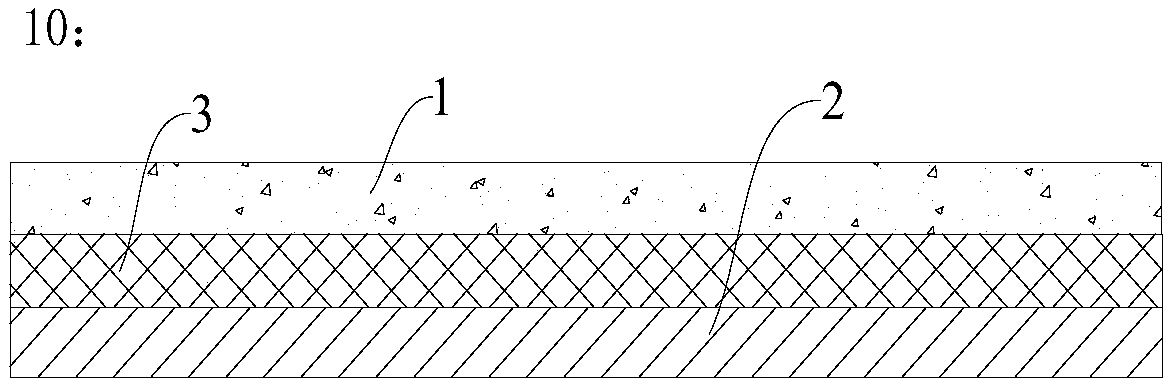

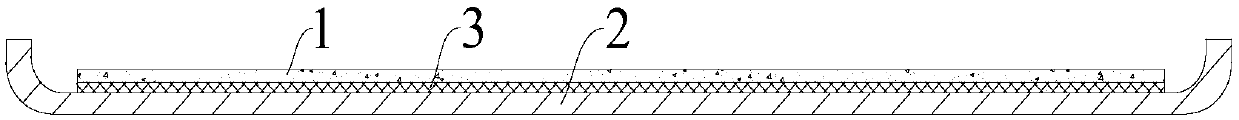

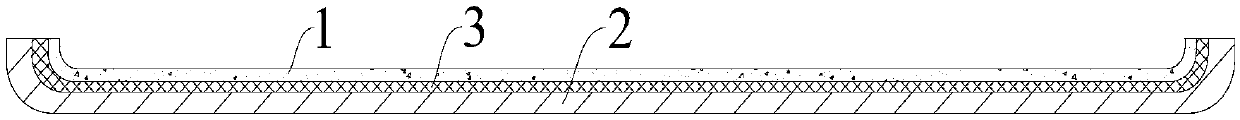

[0046] In this embodiment, two 0.25mm thick 3D glass pieces (inner glass piece and outer glass piece) bent on four sides are used, and the cross-sectional structure diagram can refer to Figure 4 ), a PVB film with a thickness of 0.075mm is subjected to a double-layer 3D composite process.

[0047] The production process is as follows: ① Slice the 0.25mm thick inner and outer glass, CNC (numerical control machine tool) processing, hot bending, polishing, edge sweeping, chemical strengthening and other processes, and process the inner glass and outer glass with 3D structure ②Put the above-mentioned outer glass parts into the positioning jig first, then put the laser-cut PVB film, and finally put the inner glass parts. The specific positioning method can be realized by means of jigs or CCD image sensors. ③Put the above products into a vacuum bag, and after sealing, vacuumize at room temperature for 60 minutes, then put it in a 110°C oven for 60 minutes to completely discharge th...

Embodiment 2

[0049] In this embodiment, three 2.5D glass pieces (upper glass piece, middle glass piece and lower glass piece) with a thickness of 0.4mm, 0.15mm (TFT display screen substrate glass, referred to as TFT glass) and 0.25mm respectively are used. A PVB film with a thickness of 0.025mm is subjected to a three-layer 2.5D composite process.

[0050] The production process is as follows: ① The upper, middle and lower glass of 0.4mm, 0.15mm (TFT glass), and 0.25mm thick are respectively sliced, CNC processed, polished, edge-swept, and chemically strengthened to process a 2.5D structure. The upper, middle and lower glass parts; ②Put the above lower glass parts into the jig first, then put in the laser-cut PVB film, and then put in the middle glass part, PVB film and upper glass part in turn. The specific positioning method can be adopted Fixtures, CCD and other ways to achieve. ③Put the above products into a vacuum bag, and after sealing, vacuumize at room temperature for 30 minutes, ...

Embodiment 3

[0052] In this embodiment, three 2.5D glass pieces (upper glass piece, middle glass piece and lower glass piece) with a thickness of 0.25 mm are used, and two PVB films with a thickness of 0.05 mm are used for a three-layer 2.5D composite process.

[0053] The manufacturing process is as follows: ① The upper, middle and lower glass parts with a thickness of 0.25mm are respectively sliced, CNC processed, polished, edge-swept, and chemically strengthened to process the upper, middle and lower glass parts with a 2.5D structure ;② Put the lower glass part into the jig first, then put the laser-cut PVB film, and then put the middle glass part, PVB film and upper glass part in turn. The specific positioning method can be realized by means of jig, CCD, etc. . ③Put the above products into a vacuum bag, and after sealing, vacuumize at room temperature for 30 minutes, then put it in a 100°C oven for 40 minutes to completely discharge the air in the bag. ④ Open the bag of the product th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com