Patents

Literature

101results about How to "Improve bubbles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

FFC glaze with high stain resistance, FFC sanitary ceramic and preparation method of FFC sanitary ceramic

ActiveCN111253071AExtended firing temperature rangeReduce glaze porosityPotassium feldsparSodium carboxymethylcellulose

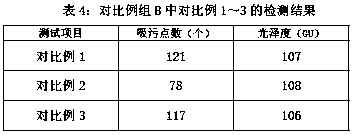

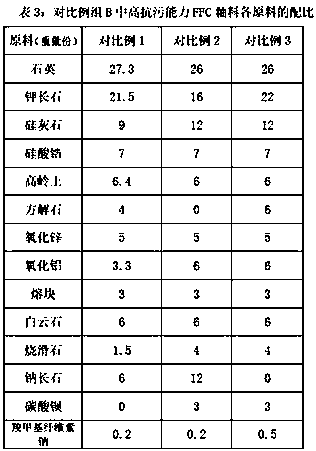

The invention discloses an FFC glaze with high stain resistance, an FFC sanitary ceramic and a preparation method of the FFC sanitary ceramic. The FFC glaze with high stain resistance comprises the following raw materials in parts by weight: 22-29 parts of quartz, 24-28 parts of potassium feldspar, 6-10 parts of wollastonite, 7-8 parts of zirconium silicate, 5-10 parts of kaolin, 0-5 parts of calcite, 5-7 parts of zinc oxide, 5-7 parts of aluminum oxide, 2-3 parts of frit, 4-8 parts of dolomite, 5-8 parts of calcined talc, 1-4 parts of barium carbonate and 0.2-0.5 part of sodium carboxymethylcellulose. According to the FFC glaze with high stain resistance, multi-alkali effect is utilized, barium carbonate is introduced, the use amount of calcined talc is increased, and the use amount of albite is reduced, so venting of a green body is more smooth, the porosity of a glaze surface is reduced, and microcracks of the glaze surface are reduced. Besides, the FFC glaze with high stain resistance also utilizes the principle of like dissolves like to increase the consumption of aluminum oxide and quartz, improve the bonding property of the blank and a glaze, and further reduce the microcracks on the glaze surface of the sanitary ceramic correspondingly.

Owner:江门市东鹏智能家居有限公司

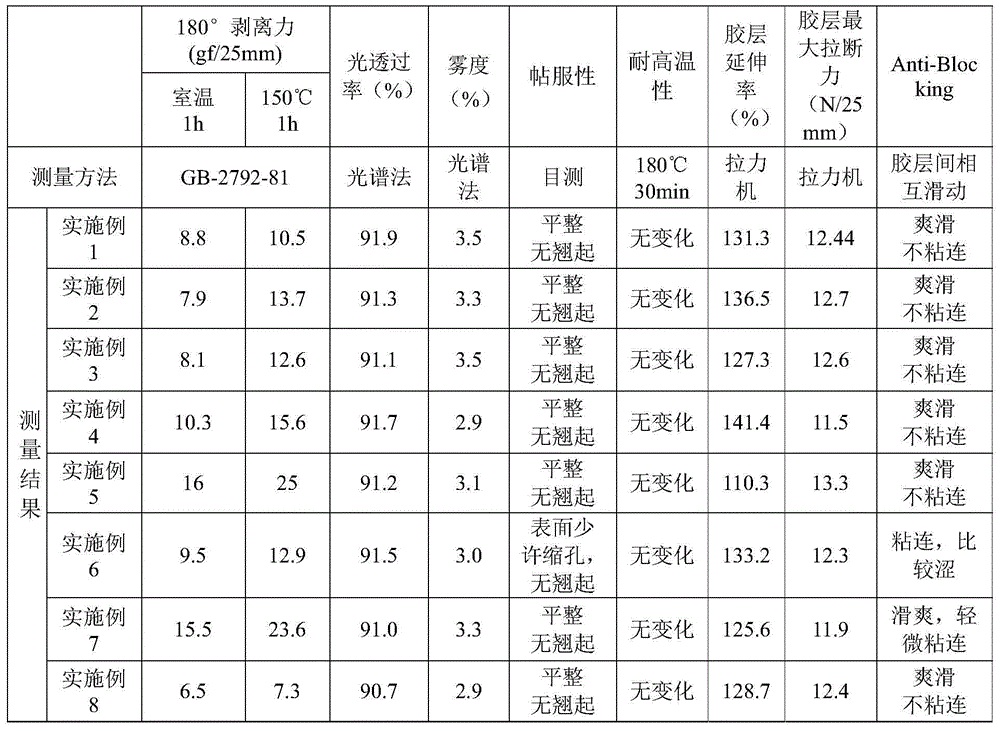

Peelable glue coating composition and peelable glue coating as well as preparation method and application of peelable glue coating

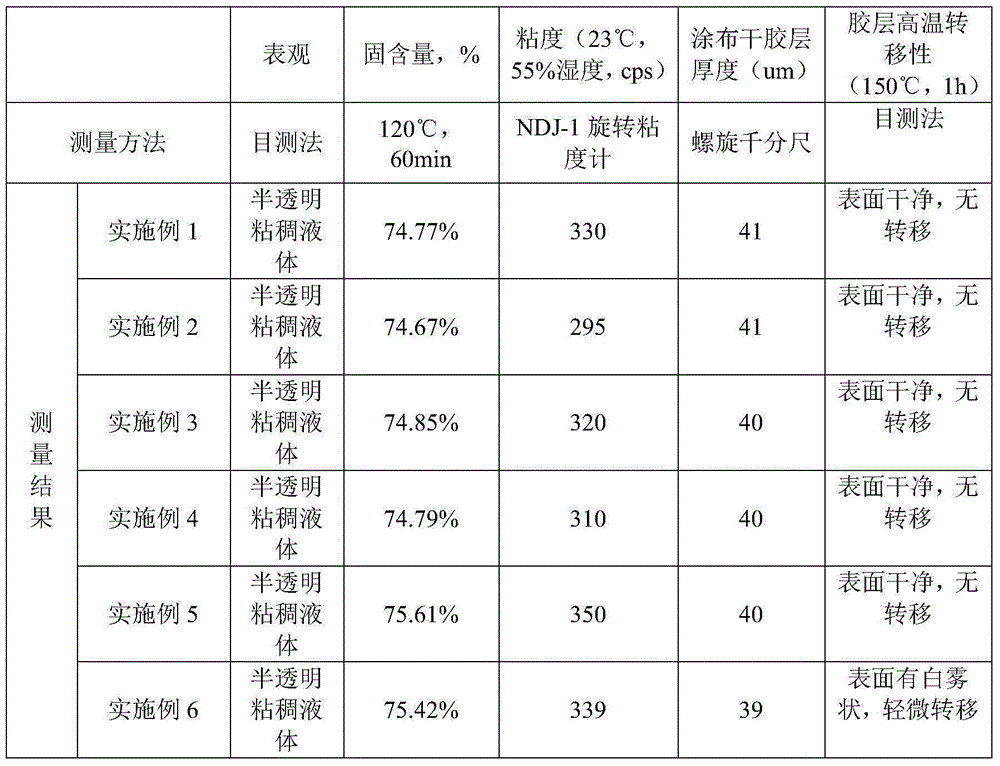

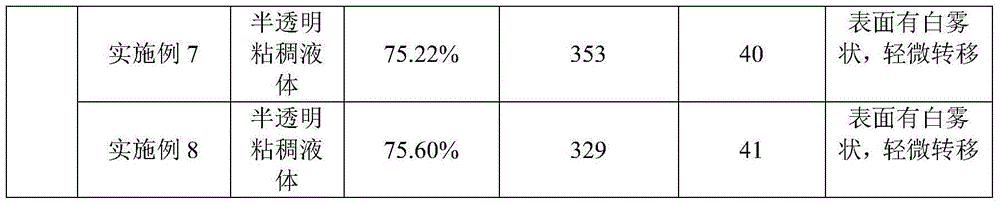

The invention provides a peelable glue coating composition and a peelable glue coating as well as a preparation method and an application of the peelable glue coating. The peelable glue coating composition comprises the following components in parts by weight: 80-120 parts of an acrylate type oligomer, 8-20 parts of a dilutive monomer, 0.1-1.5 parts of a peeling force modifying agent, 2-12 parts of a triggering agent and 30-50 parts of an organic solvent. The peelable glue coating composition is relatively high in transparency and relatively high in light transmittance and relatively low in haze after film formation. Meanwhile, a coating formed by curing the peelable glue coating composition is relatively high in high temperature resistance and relatively high in peelability. By the high temperature resistance, the coating is good in adhesion property on the surface of a functional hardened layer, and the problems of air bubbles and warping can be effectively improved. By the peelability, the problem of glue layer residues caused during peeling of the coating can be reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

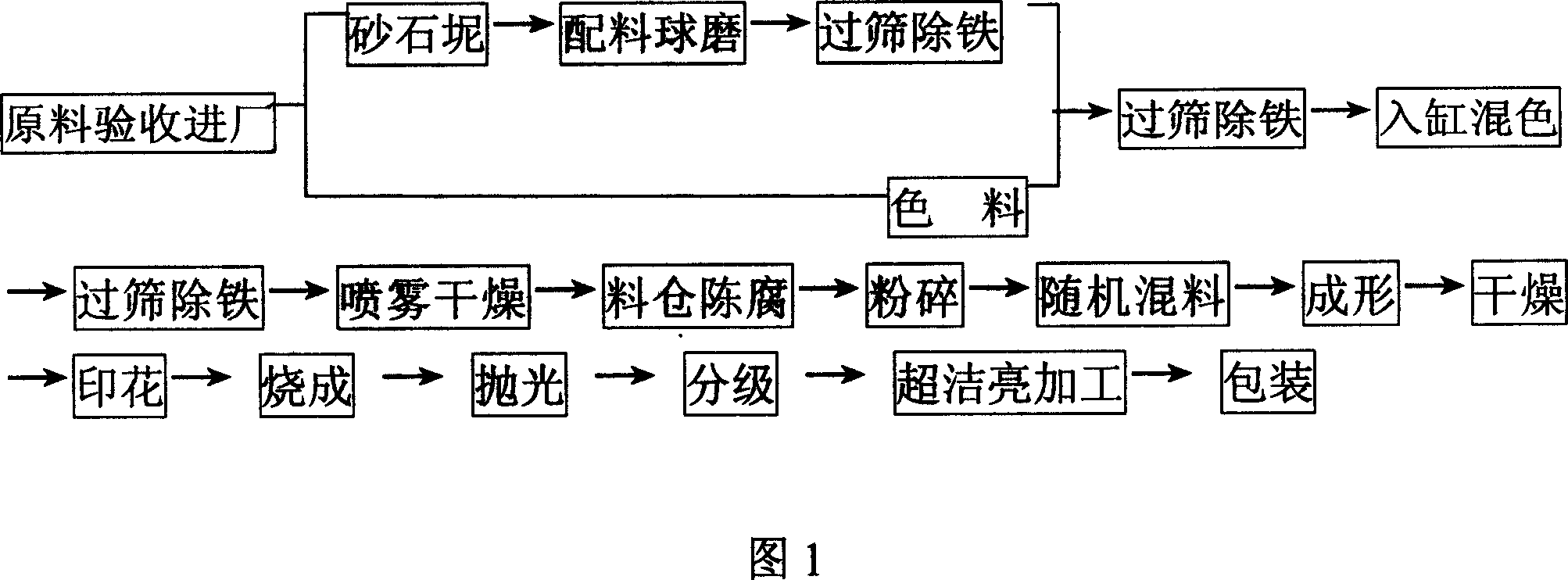

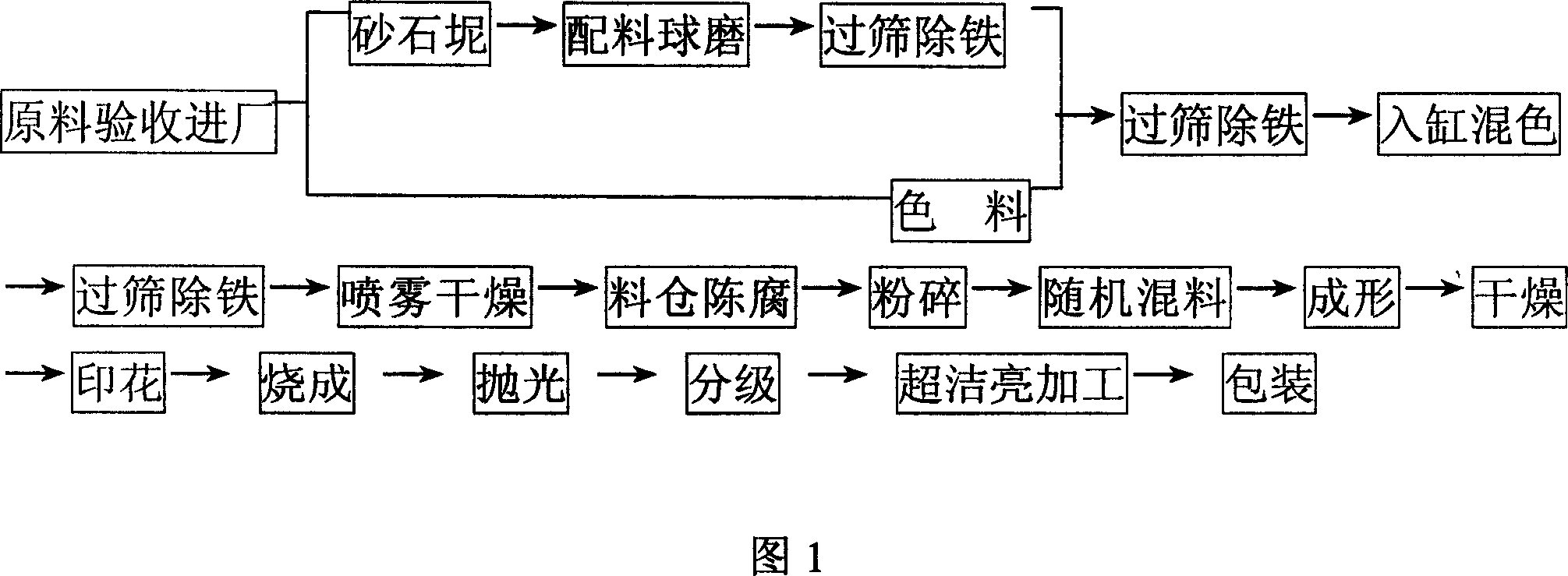

Natural travertine-imitated ceramic brick and making method

InactiveCN101007732APromote environmental protectionRealistic natural travertine decorative effectCeramicwareClaywaresLithiumBrick

Owner:霍镰泉

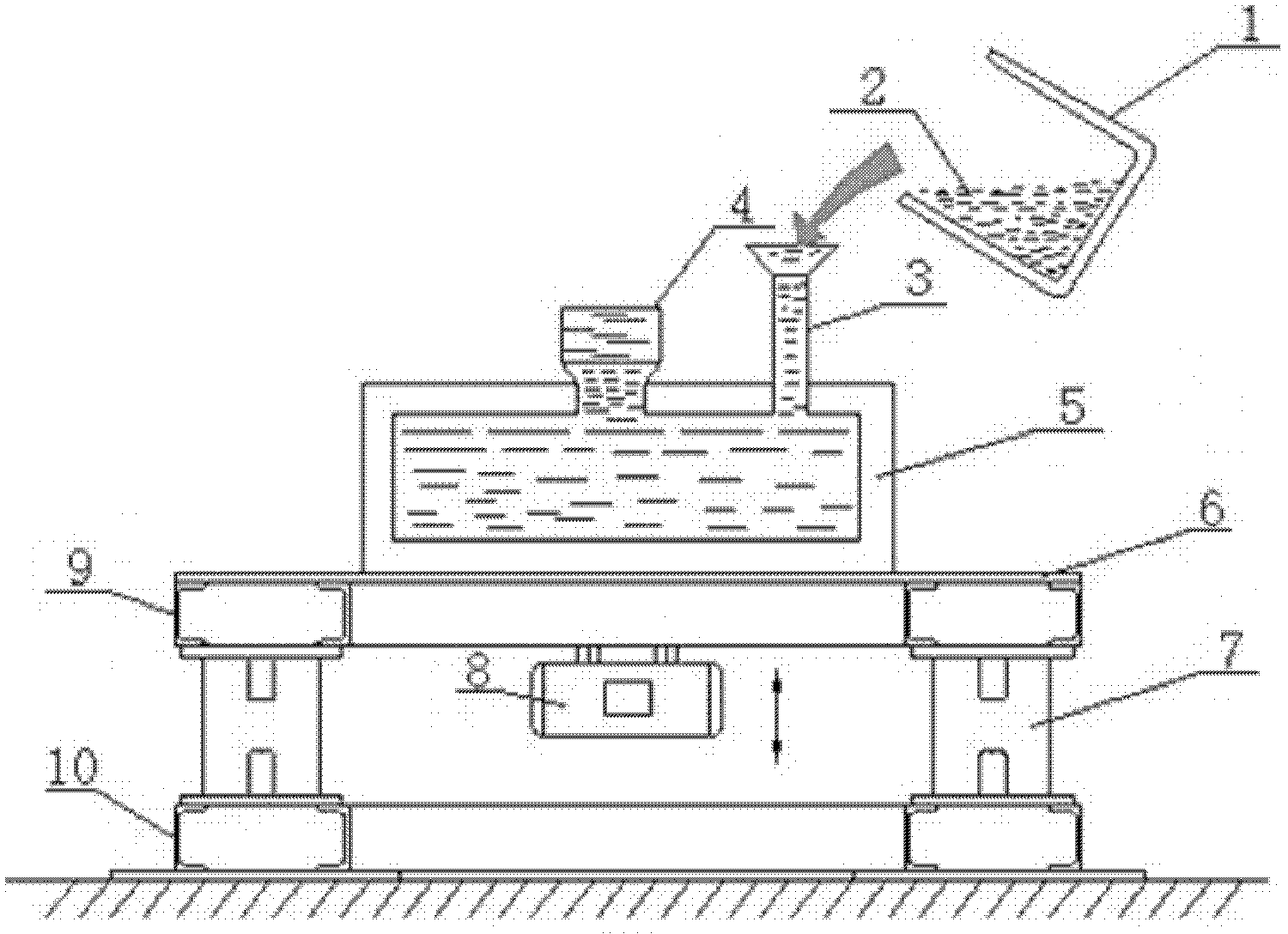

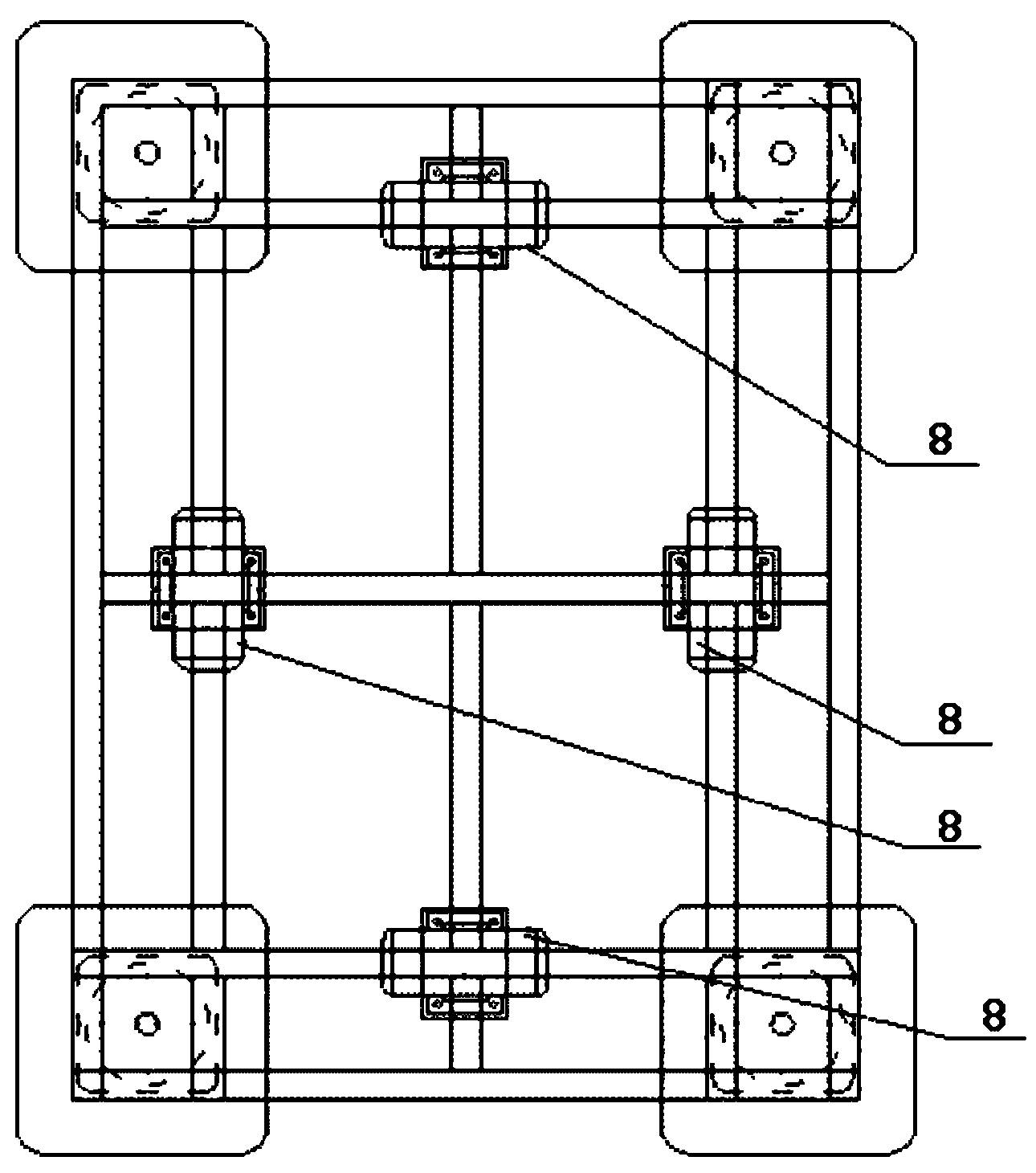

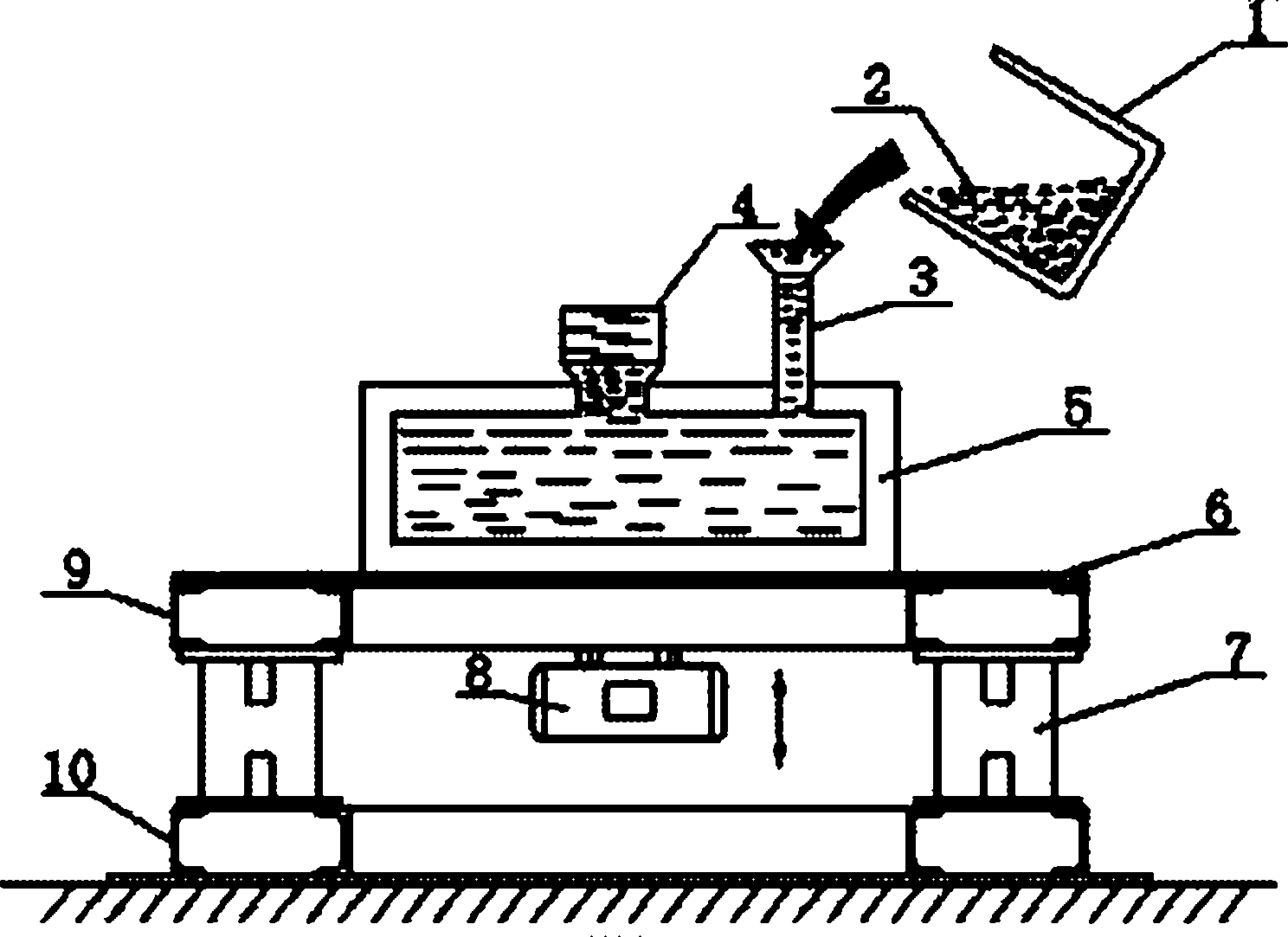

Sand mold casting technology and equipment

The invention relates to a sand mold casting technology comprising steps that: modeling sand is manufactured, wherein casting sand with a size of 40-70 meshes are added to 1-3% of water glass; the mixture is uniformly mixed in a fracturing blender; molding and core-making are carried out; a manufactured mould cavity is vibrated on a vibration platform; casting is carried out during vibration; when a metal solution starts to solidify, the vibration step is stopped. The equipment suitable for the sand mold casting technology comprises a lower platform rack which is used for supporting an upper platform rack used for bearing the mould cavity, wherein the supporting is realized by using a rubber spring. A high-frequency motor used for generating vibration is arranged on the upper platform rack. The equipment and the technology are advantaged in that: the technology and the equipment are environment-friendly; reproducibility for used sand recycling is good; and collapsibility of used sand is good.

Owner:ZHEJIANG MAYANG INDS

High-strength silane-modified polyether sealant for automobiles and preparation method thereof

InactiveCN108753233AHigh strengthExcellent primerless adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesHigh humidityAntioxidant

The invention belongs to the technical field of sealants and particularly relates to a high-strength silane-modified polyether sealant for automobiles and a preparation method thereof. The high-strength silane-modified polyether sealant for automobiles comprises, by weight, 25-60 parts of a silane-modified polyether resin, 5-20 parts of an environment-friendly plasticizer, 15-30 parts of a bulkingfiller, 10-30 parts of reinforcing carbon black, 0-1 part of a thixotropic agent, 0-1 part of a UV absorber, 0-1 part of a light stabilizer, 0-2 parts of an antioxidant, 0-4 parts of a water removalagent, 0.2-0.8 parts of an adsorbent, 0.1-4 parts of a curing accelerator, 0.1-2 parts of an adhesion promoter and 0-1 part of a catalyst. The high-strength silane-modified polyether sealant solves the problem that the traditional silane-modified polyether sealant has low mechanical properties, improves the complicated construction process of the polyurethane sealant for the traditional windshieldglass, realizes primerless bonding, solves the problem that the polyurethane sealant for the traditional windshield glass produces foam at a high temperature and high humidity and solves the problemthat the polyurethane sealant for the traditional windshield glass has poor environmental friendliness.

Owner:GUANGZHOU JOINTAS CHEM

Natural travertine-imitated decorative ceramic brick and making method

InactiveCN101007733APromote environmental protectionRealistic natural travertine decorative effectCeramicwareClaywaresSlagTalc

The invention discloses a decorative ceramic brick to imitate natural cavity stone and making method, which comprises the following steps: adding kinds of different inorganic pigments in the white material to form different colorful powders; blending pigment according to certain proportion; allocating foaming material in the ceramic brick with 8-15% ball-earth, 18-30% albite, 30-45% lithium feldspar, 12-20% limestone, 3-15% polishing slag and 0-1% burned talc.

Owner:霍镰泉

Preparation method of foamed cement insulation boards

ActiveCN102863194AHigh strengthGood sound insulation and noise reduction effectCeramicwareCoalPolymer chemistry

The invention discloses a preparation method of foamed cement insulation boards, comprising the following steps: uniformly mixing gel materials, coal ashes, fiber reinforced materials and foaming stable dispersants at the first, adding hot water with the temperature of 40-60 degrees centigrade in the mixed powder to stir and form sizes; adding foaming agents such as hydrogen peroxide into the uniformly-stirred sizes; stirring uniformly; pouring into moulds to foam; keep the temperature with greenhouses; curing and forming; demoulding; maintaining at the room temperature for 24 h; cutting to form decorative plates; and forming the foamed cement insulation boards with the strength the same as the service life of materials of walls and the flame retardant property reaching grade A after curing naturally for 30 d.

Owner:南通金信达建筑装饰工程有限公司

Method for preparation of high-strength stainless steel by using high alloy melt

InactiveCN103436768AImprove bubblesSmooth fusionProcess efficiency improvementElectric furnaceNitrogenAlloy

The invention relates to a method for the preparation of high-strength stainless steel by using high alloy melt. The method is characterized by comprising the following steps: firstly, preparing high nitrogen alloy melt and Fe-Cr-Mn melt respectively; then adding the Fe-Cr-Mn melt slowly into the high nitrogen alloy melt; discharging for pouring after temperature controlling and uniform stirring. According to the method, smooth and steady fusing of the high nitrogen alloy melt and the Fe-Cr-Mn melt is facilitated, the escape of nitrogen is obviously reduced, high nitrogen steel melt with higher nitrogen content and better stability can be obtained so as to obtain high nitrogen billet steel with less bubble and high nitrogen content, and the detection for the nitrogen content of the high nitrogen billet steel can be up to 1.0 wt%.

Owner:CHANGCHUN UNIV OF TECH

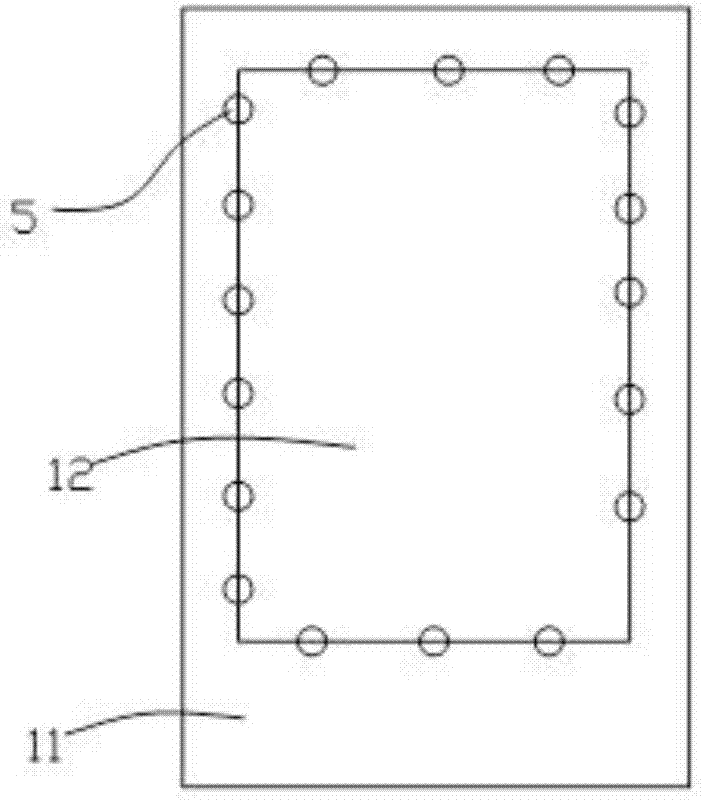

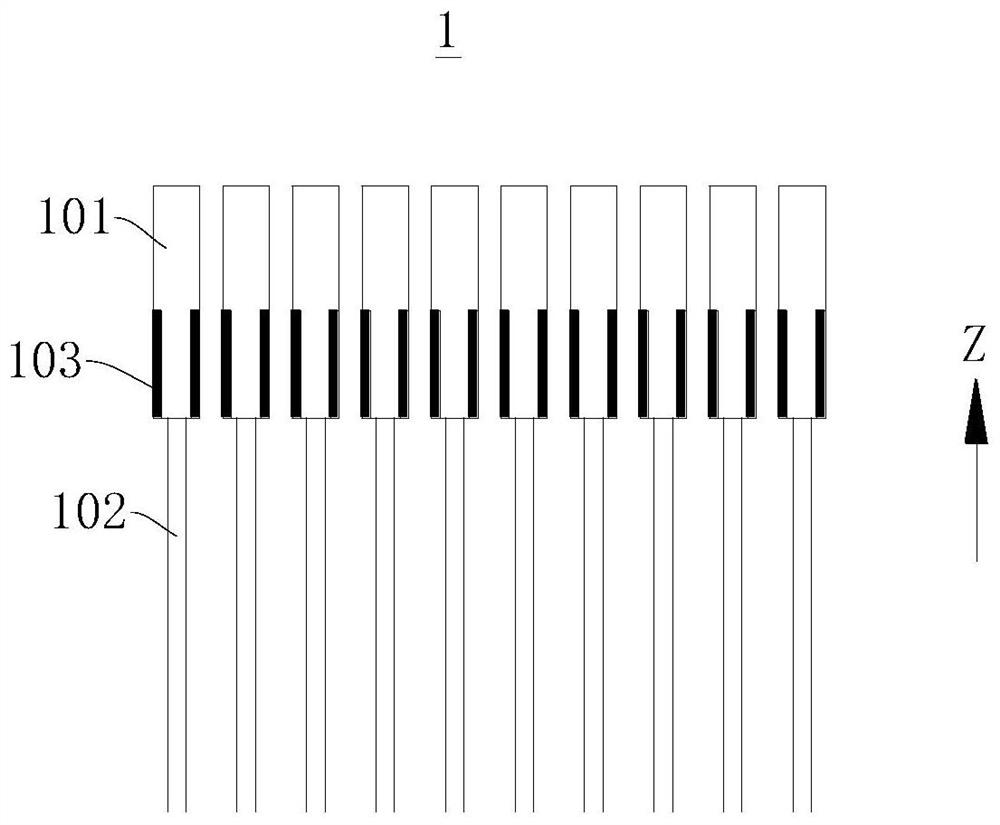

Capacitive touch screen and gluing method thereof

ActiveCN107340943AEasily deformedImprove the bubble problemInput/output processes for data processingFilm materialProtective glasses

The invention discloses a capacitive touch screen and a gluing method thereof. The method comprises the following steps: Step 1, gluing an OCA (optical clear adhesive) layer on the surface of a film material sensor; Step 2, punching a through hole in the thickness direction of the film material sensor glued with the OCA layer in Step 1, so that one end of the through hole is positioned in a segment gap area of printing ink; Step 3, cutting the film material sensor in Step 2 with a film cutter according to the specification; Step 4, gluing the cut film material sensor and protective glass; Step 5, defoaming the film material sensor and the protective glass that are glued with each other. The method has the beneficial effects that after the through hole is additionally formed in the film material sensor, on one hand, the segment gap of the printing ink of a film material becomes softer, so as to facilitate deformation, so that the segment gap is easily filled with an OCA; on the other hand, air can be discharged out of the through hole during gluing, so that the problem of bubbles at the position of the segment gap of the printing ink can be well solved. Therefore, the yield rate of products can be greatly improved.

Owner:CHANGSHA YUSHUN DISPLAY TECH +3

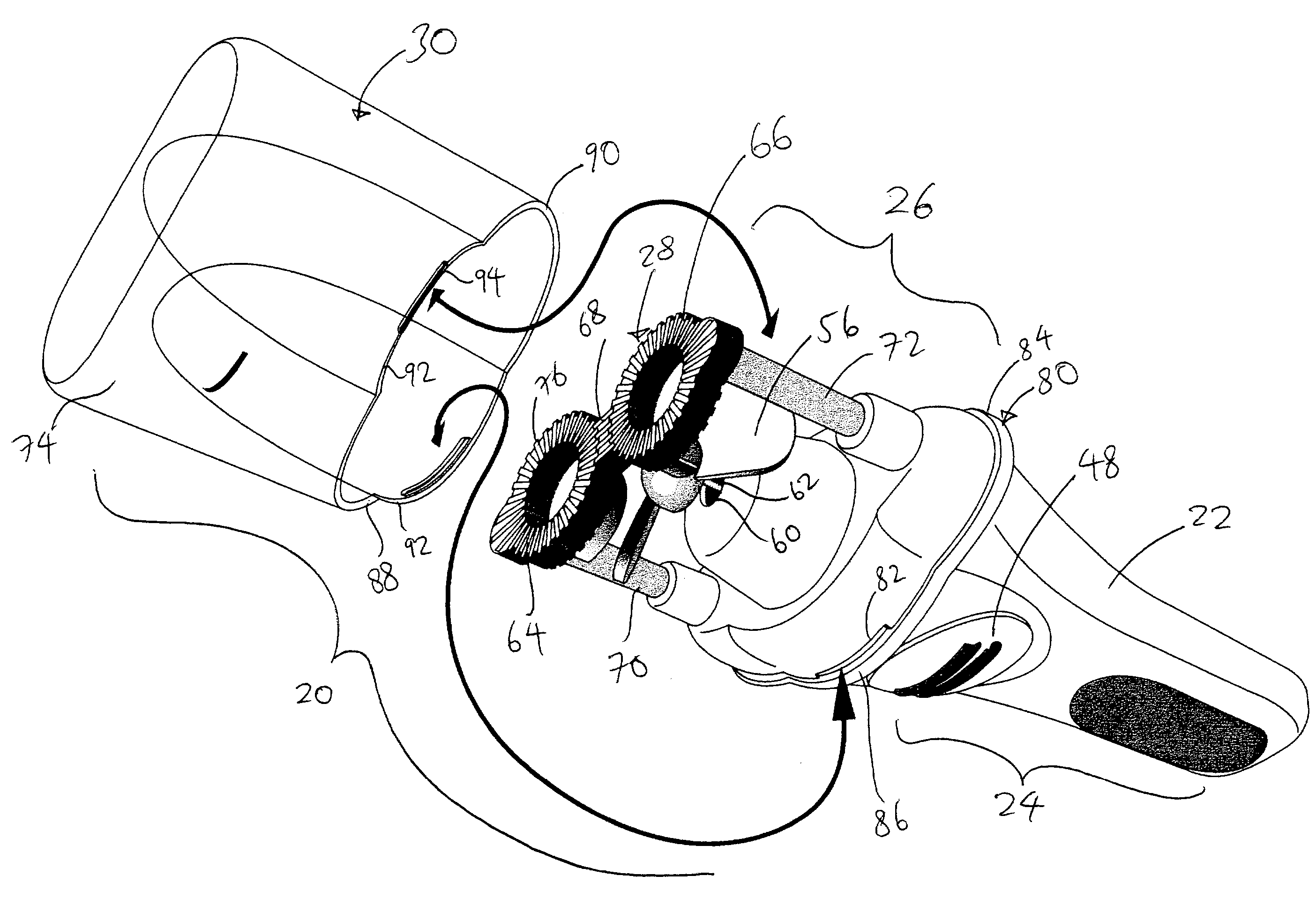

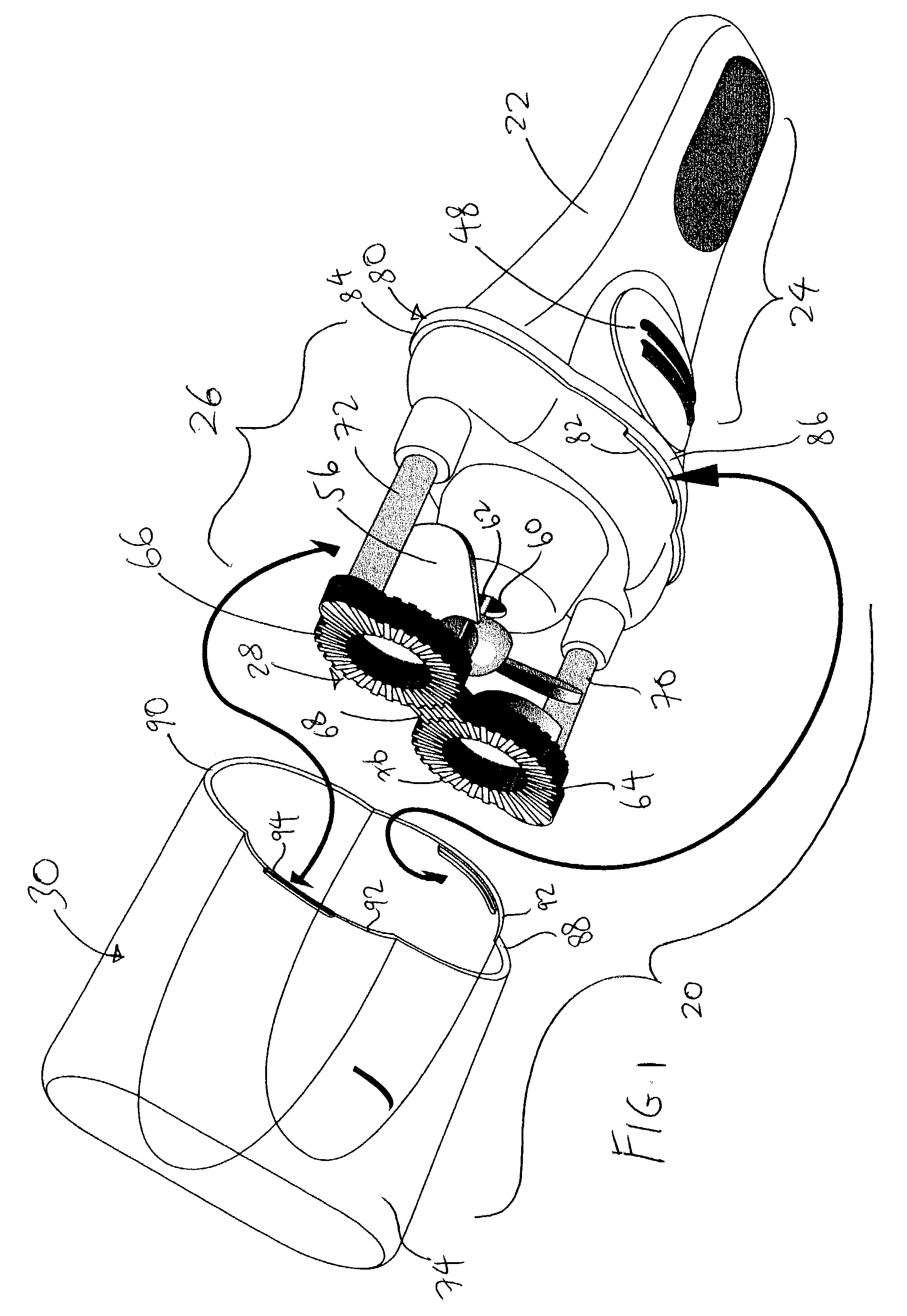

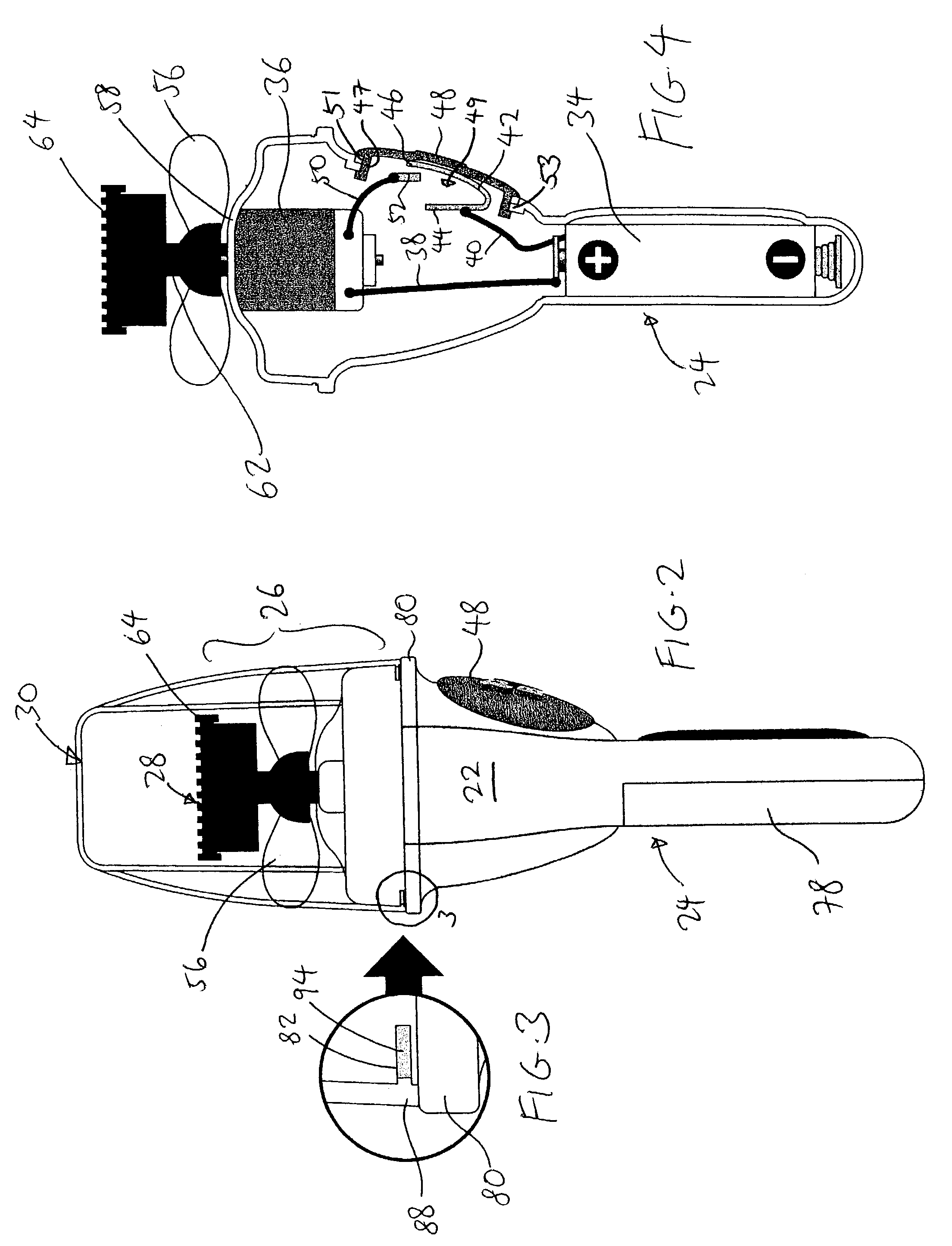

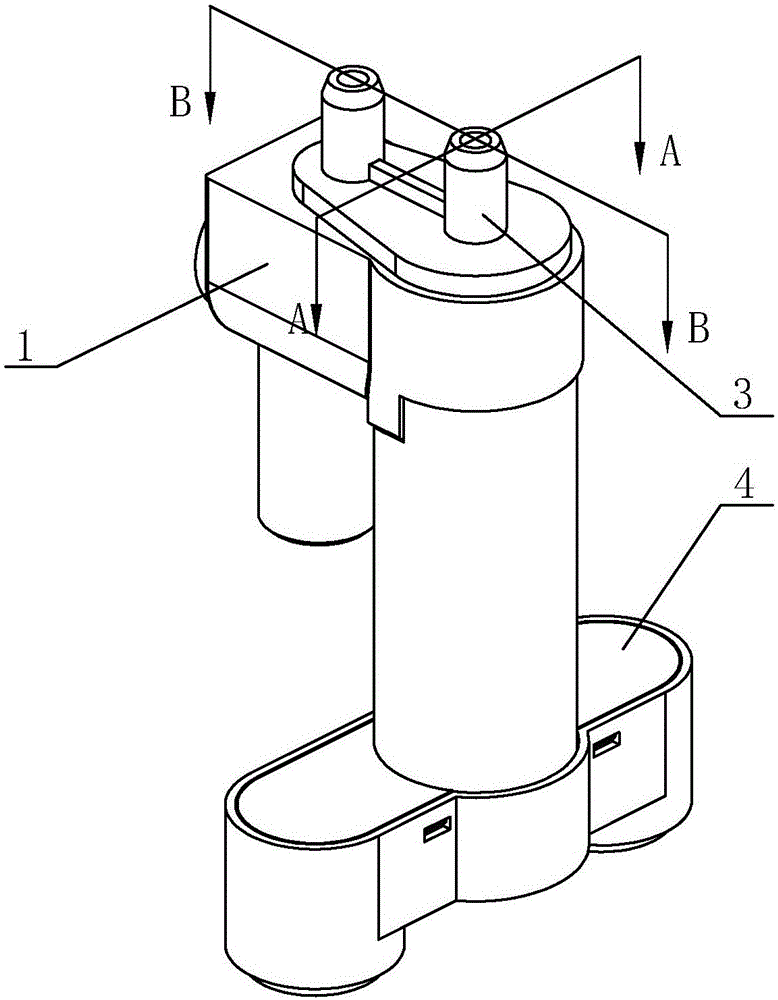

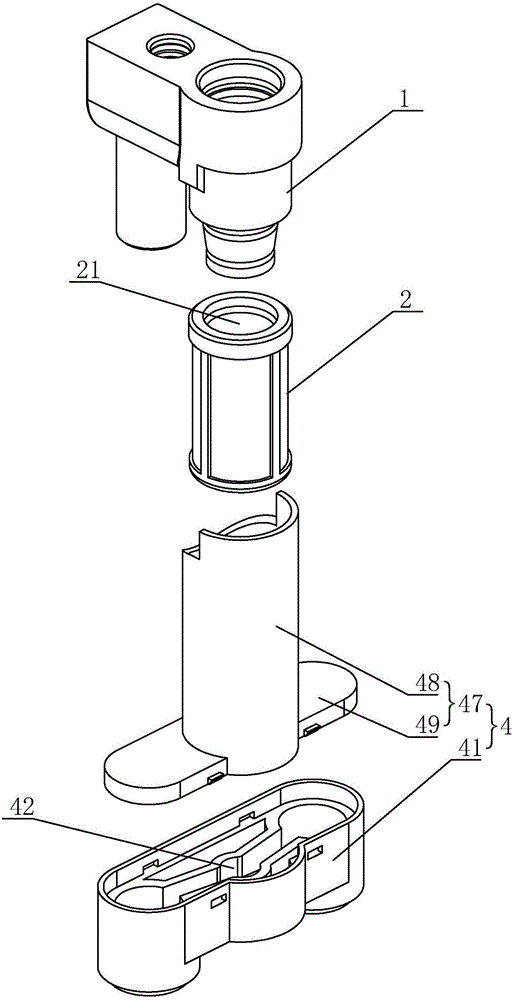

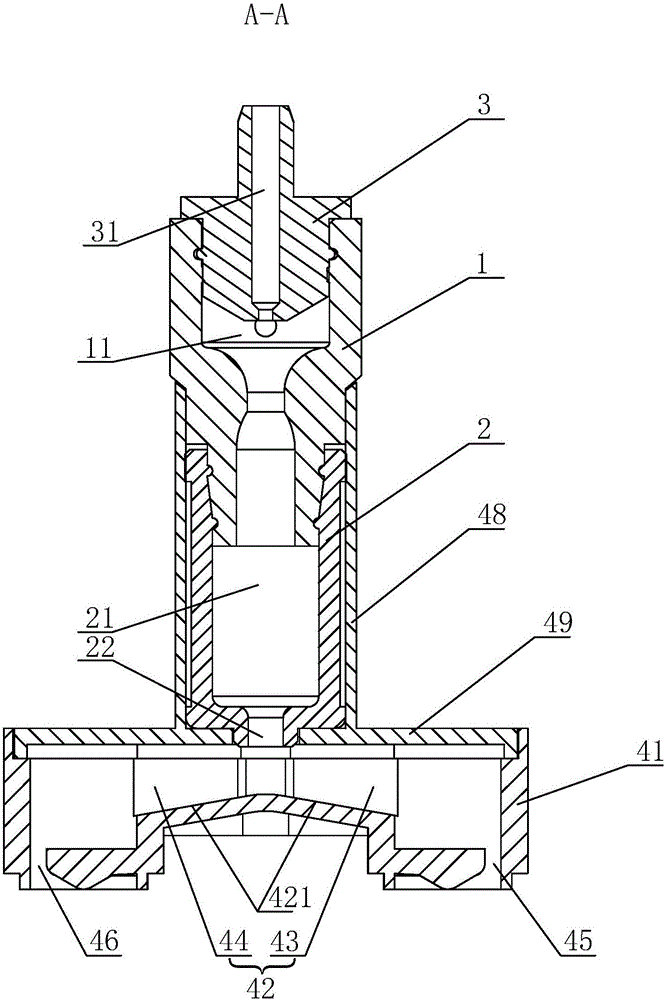

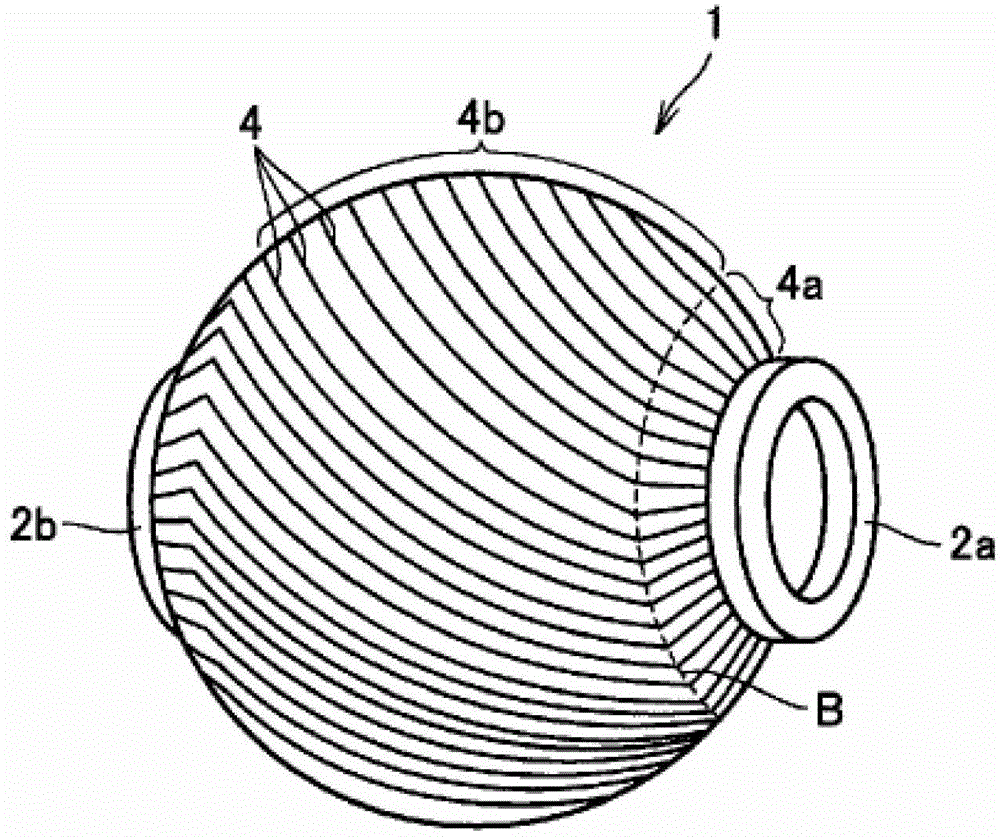

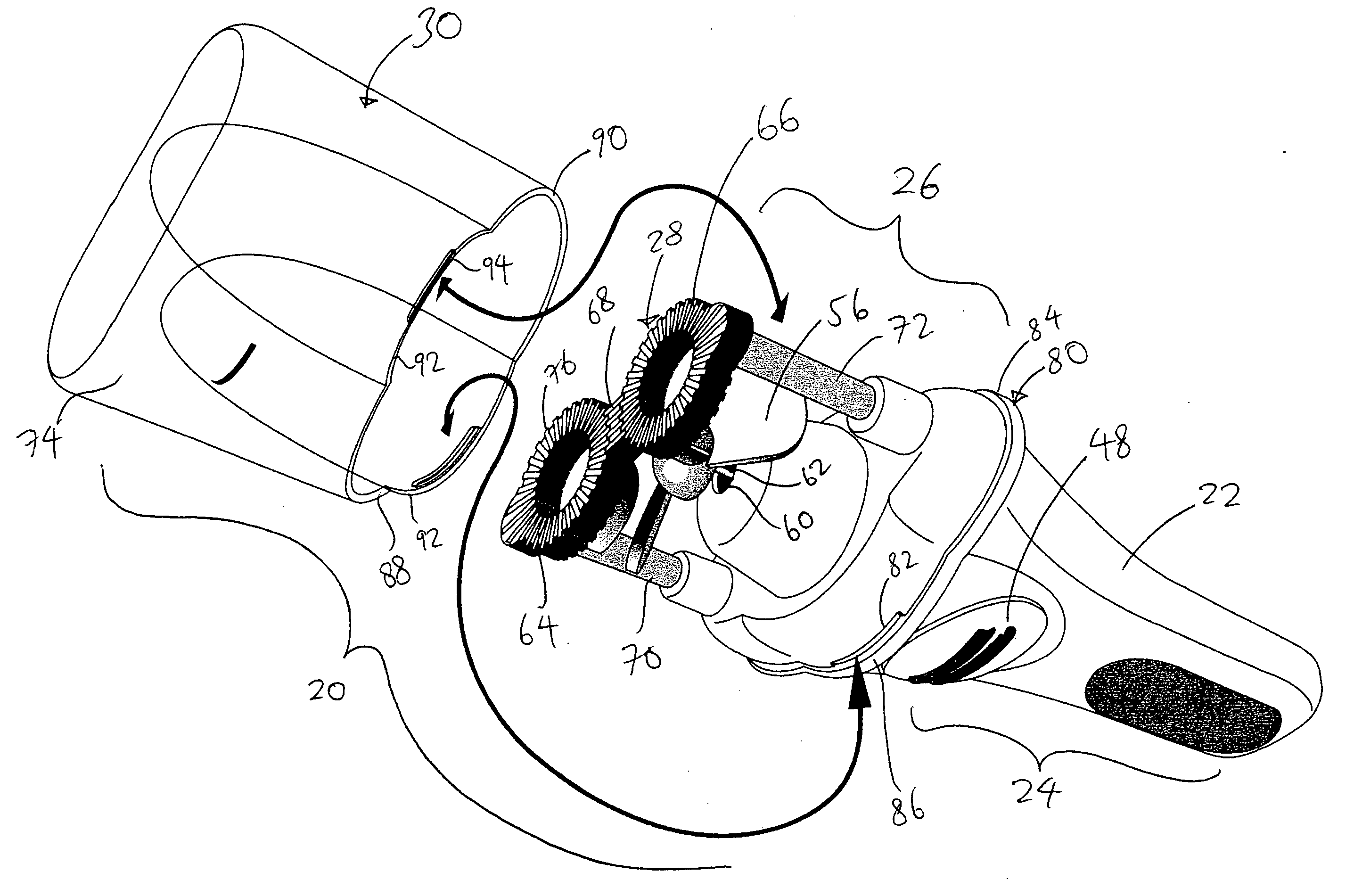

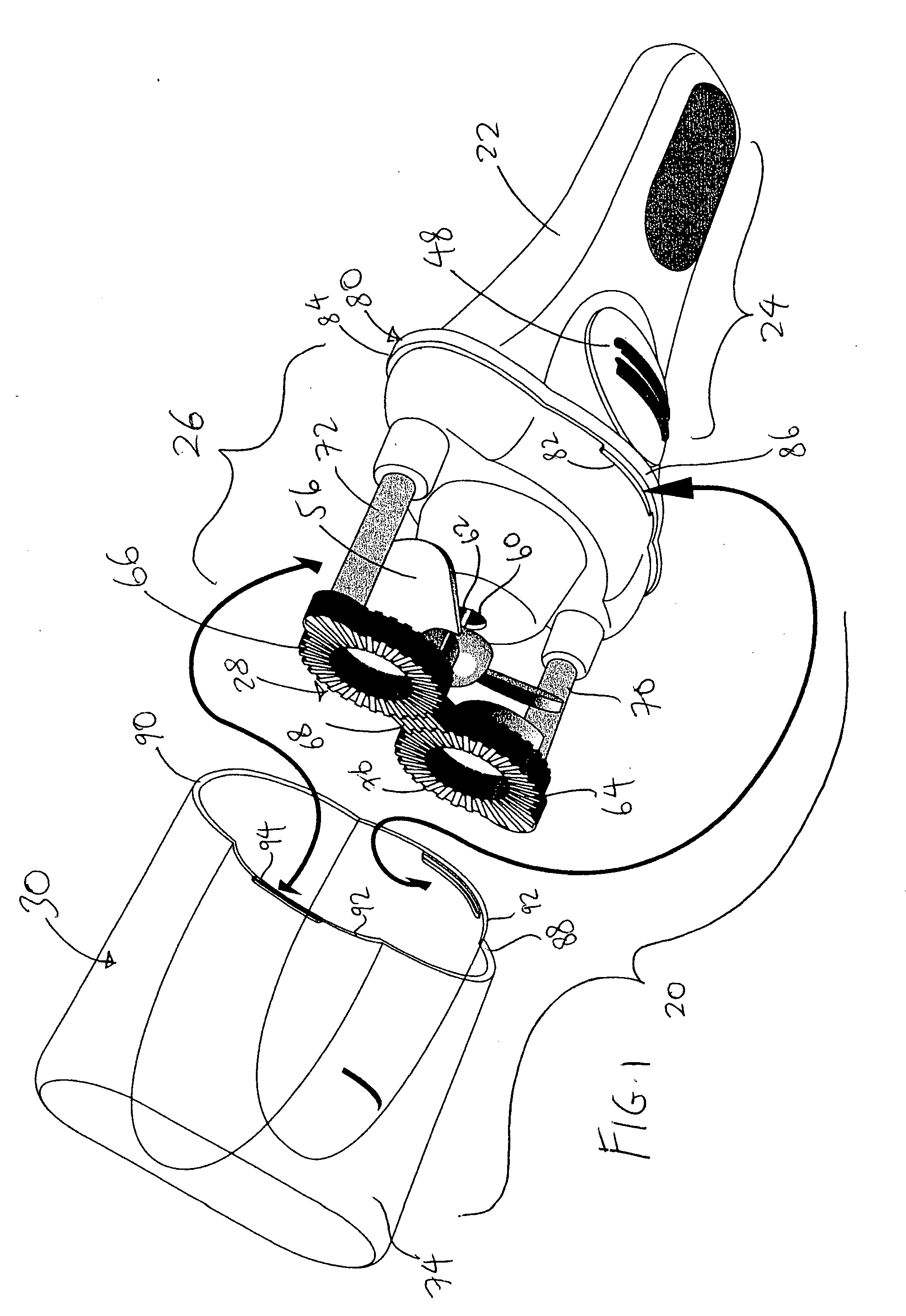

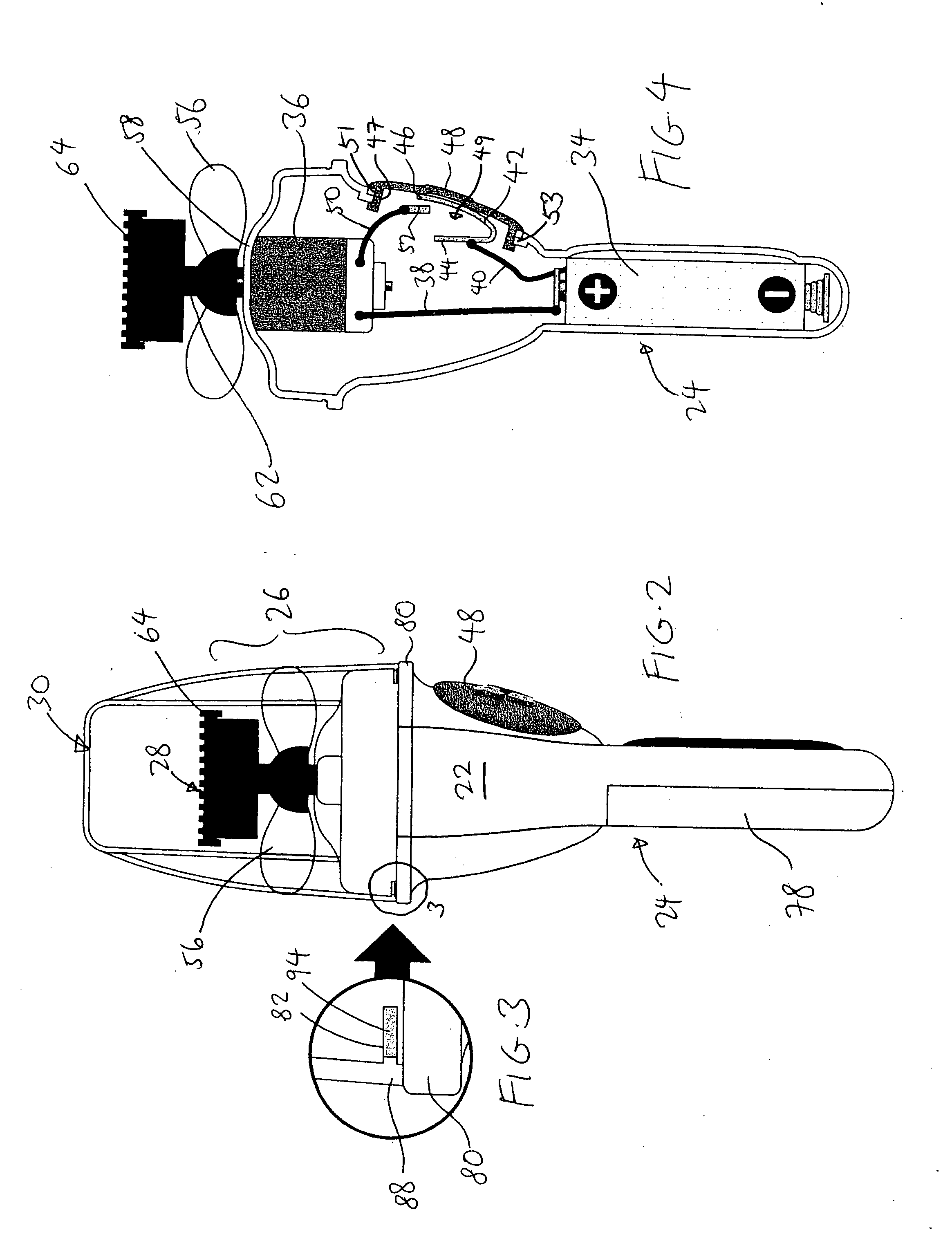

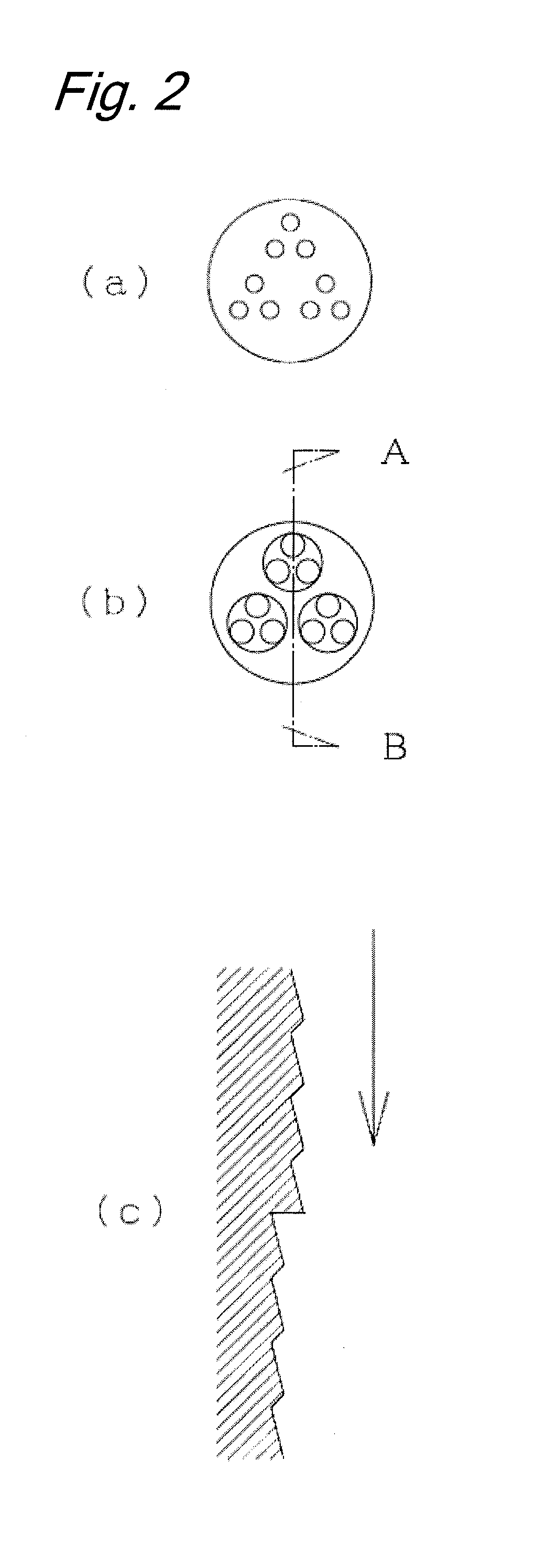

Bubble generating assemblies

InactiveUS7008287B2Enhance bubble productionEnhances amusement value and play varietyDollsLocking mechanismEngineering

A bubble generating assembly has a housing, an air generator associated with the housing, a bubble producing device positioned in front of the air generator to receive air generated from the air generator, and a cover or dipping cup configured as an inverted cup. The cover or dipping cup has an interior and a locking mechanism that removably connects the housing, and the cover or dipping cup retains the bubble producing device in the interior when the cover or dipping cup is connected to the housing. In addition, a bubble generating device has a loop with a cylindrical wall extending from the opening of the loop. The cylindrical wall has a plurality of ridges provided on the inner circumferential surface thereof.

Owner:ARKO DEVMENT

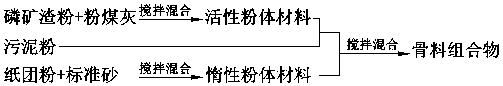

Inorganic polymer foaming material prepared from sludge and preparing method of inorganic polymer foaming material

ActiveCN108516755ASimple preparation stepsReduce pollutionSolid waste managementCeramicwarePorosityPolymer science

The invention relates to the field of preparation of inorganic polymer building materials, in particular to an inorganic polymer foaming material prepared from sludge and a preparing method of the inorganic polymer foaming material. The inorganic polymer foaming material comprises inorganic polymer slurry prepared by mixing an aggregate composition and an alkali activator. The aggregate composition comprises sludge powder and a powder material containing aluminum oxide and / or silicon oxide. The sludge powder is prepared by drying the sludge. The alkali activator comprises sodium hydroxide and / or sodium silicate. The good utilization approach is provided for sludge and industrial solid waste produced during urban sewage treatment, the labor and material consumption in the processing processis reduced, the environment pollution is reduced, and great economic environment-friendly benefits are achieved; meanwhile, through multiple times of stirring and standing treatment and fermenting oforganic mass in the sludge, bubbles in the slurry are increased to the maximum extent, and the prepared foaming material is high in porosity, high in water absorption rate and good in thermal insulation and heat storage effect.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

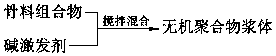

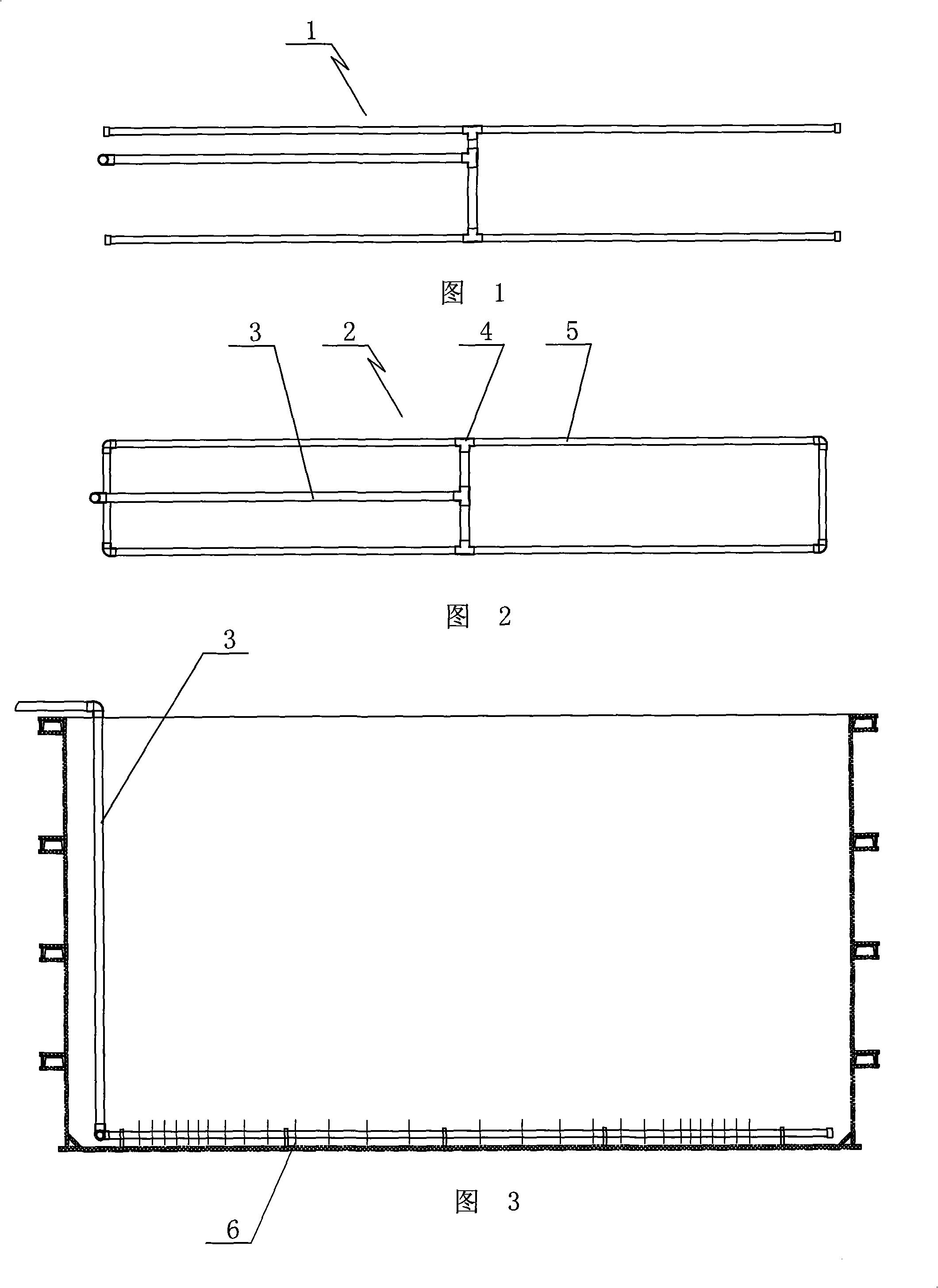

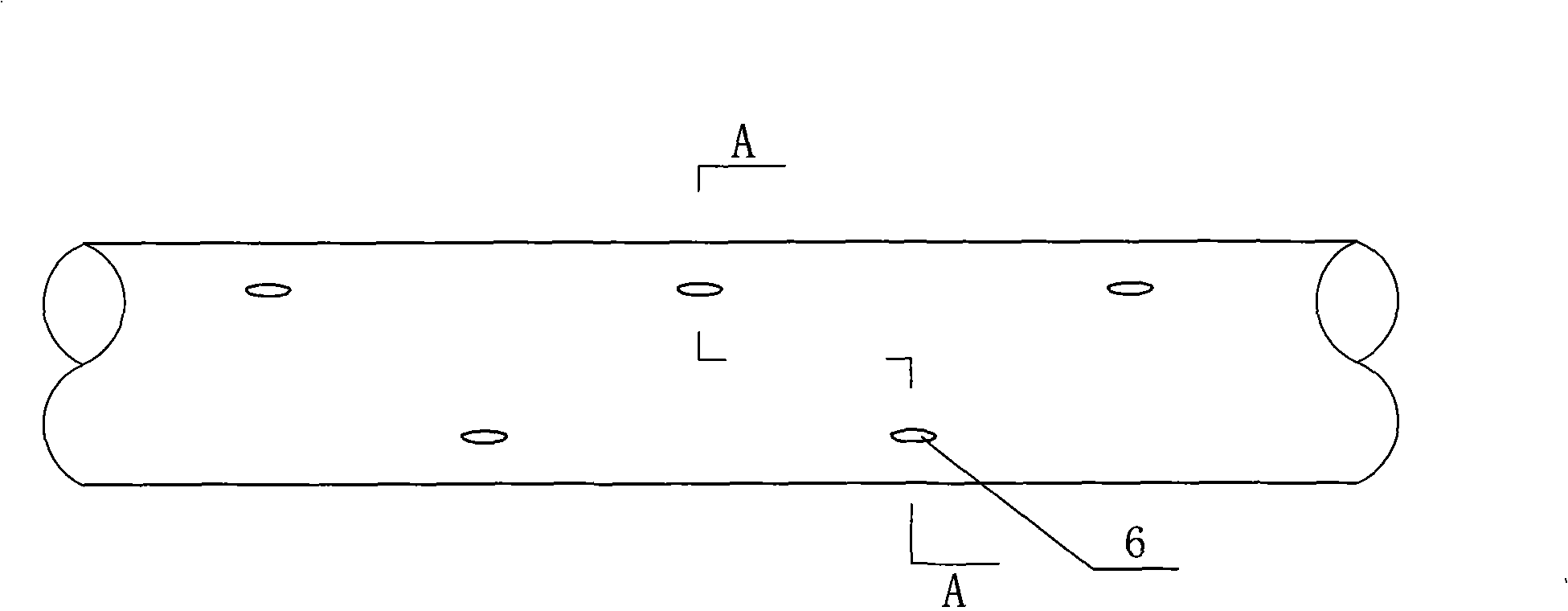

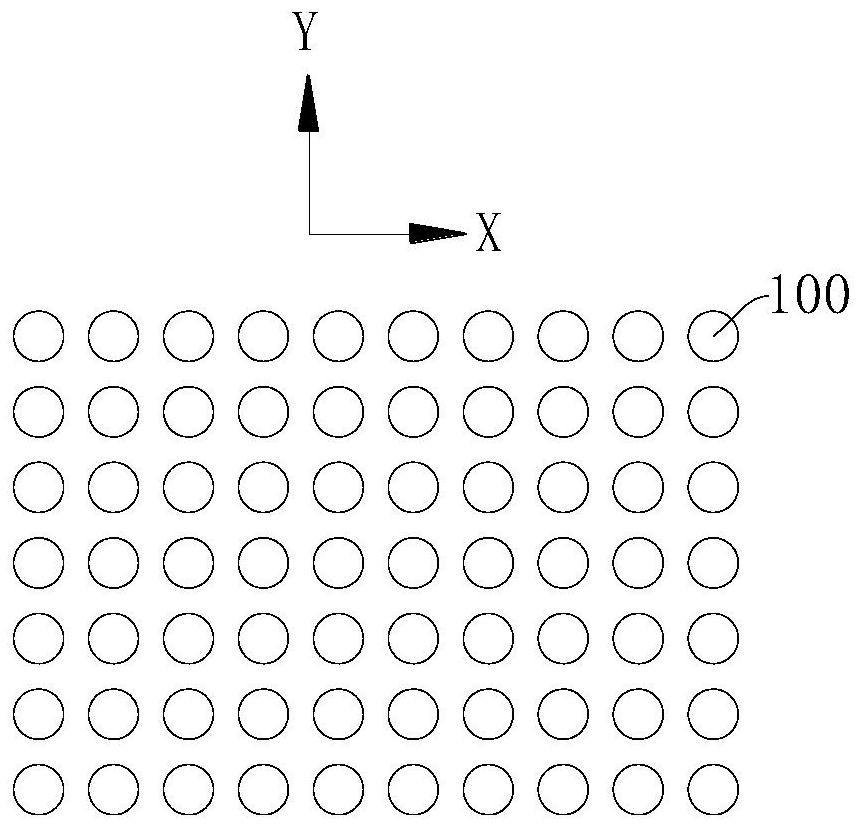

Air stirring pipe for electroplating production equipment

ActiveCN101403133AEvenly distributedIncrease the mixing areaCellsTransportation and packagingChinese charactersAir cavity

The invention relates to an air stirring pipe used for an electroplating production device. The stirring pipe can not only stir the solution uniformly, but also can save air flow. The stirring pipe comprises a stirring pipe body and is characterized in that the stirring pipe is assembled and connected by a pipe and a bend head into a shape of Chinese character 'ri', a middle crossing pipe is connected with an inlet manifold, and air outlet holes are distributed at the bottom of the stirring pipe outwards along the flowing direction of the air flow, and the amount of the air outlet holes is more and more.

Owner:WUXI XINGYI INTELLIGENT ENVIRONMENT EQUIP CO LTD

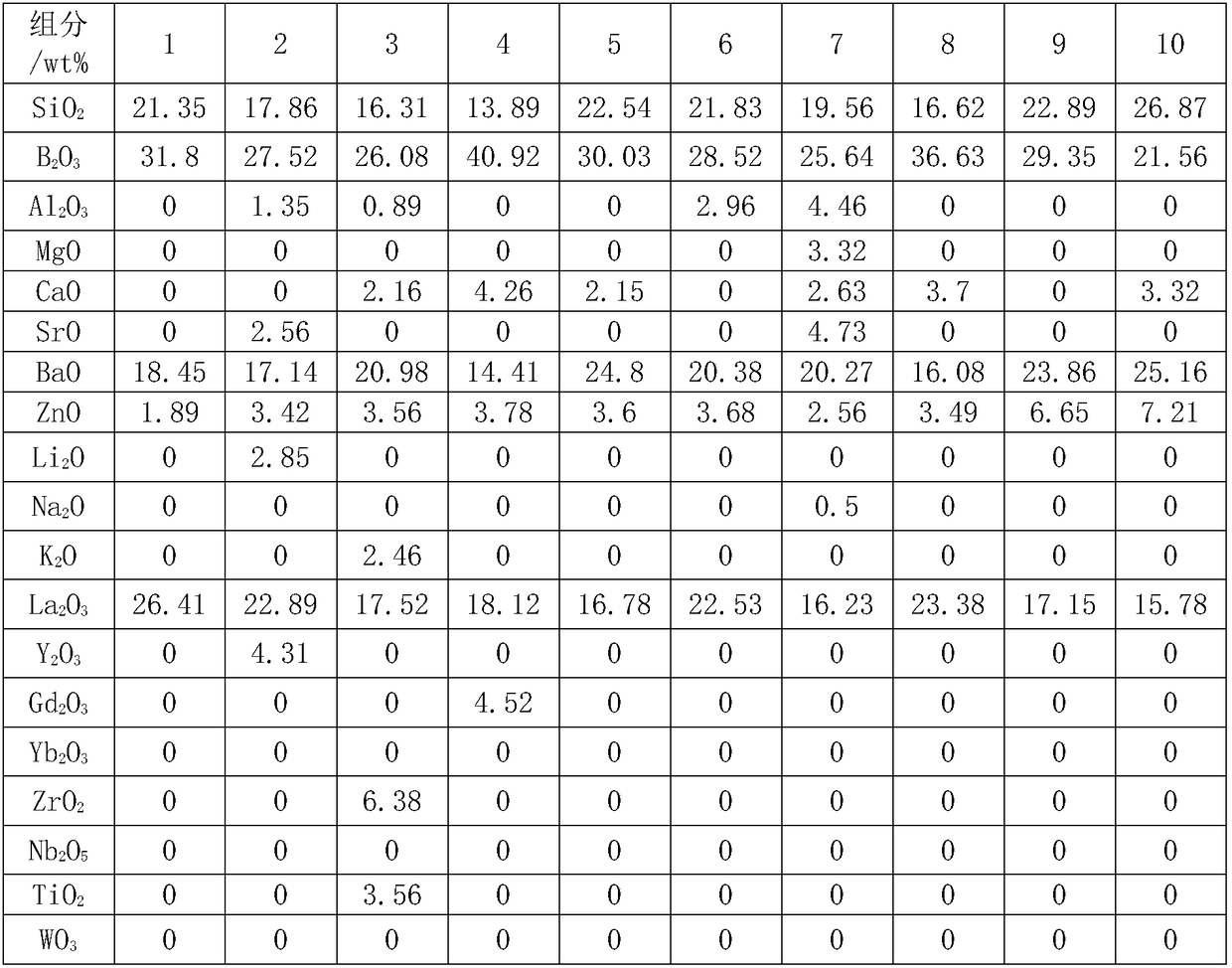

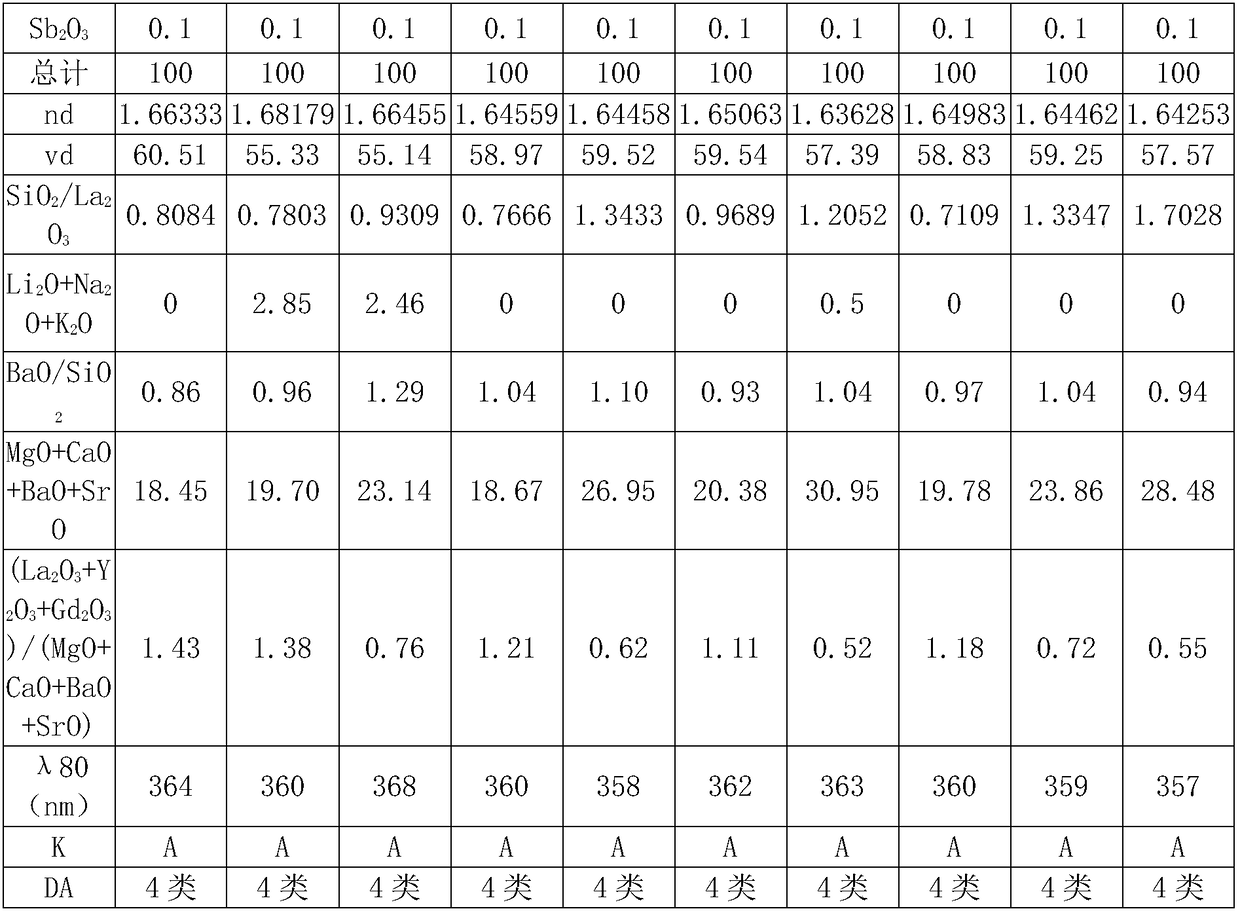

Optical glass

The invention provides optical glass which has reduced or no tantalum, low cost and good bubbles and stripes and is easy to be stably produced. The optical glass comprises 10-30% by weight of SiO2, 20-45% by weight of B2O3, 10-35% by weight of La2O3, 12-30% by weight of BaO, 0-10% by weight of ZrO2, and 0-10% by weight of ZnO. Through reasonable refractive index design, the refractive index of theoptical glass is 1.62-1.70, and the Abbe number is 55-62. The optical glass has low cost, good chemical stability, excellent anti-crystallization property and good transmittance. At the same time, the bubbles and stripes of the glass are good, and the optical glass is easy to be stably produced, and can be widely applied to digital cameras, digital video cameras, camera cell phones and the like.

Owner:CDGM OPTICAL GLASS

Laminating device and laminating method

The embodiment of the invention provides a laminating device and a laminating method, and the laminating device comprises a plurality of supporting units, and each supporting unit comprises: an elastic bearing part which is provided with a wall part, wherein an accommodating cavity which is formed by the wall part in an enclosing manner and is used for accommodating a filling medium, and an opening which communicates with the accommodating cavity; and a medium conveying part which is connected to the opening and used for conveying a filling medium to the elastic bearing parts so that the elastic bearing parts can be converted between a material punching state and an emptying state, and the elastic bearing parts of the multiple supporting units are used for being mutually spliced in the material punching state to form a spliced adaptive supporting face so as to support a target object. The elastic force of the elastic bearing part acts on the special-shaped part of the target device, and the elastic force and the pressure applied to the target object by the target device act together, so that the special-shaped part of the target device is tightly attached to the target object, bubbles between the target device and the target object can be effectively eliminated, and the product yield is improved.

Owner:YUNGU GUAN TECH CO LTD

High-permeability composite heat dissipating coating

InactiveCN103740184ASmooth coatingCoating stabilityPowdery paintsPolyester coatingsPolypropyleneGlass microsphere

The invention discloses a high-permeability composite heat dissipating coating comprising the following raw materials in parts by weight: 96-100 parts of polypropylene, 10-16 parts of 191 unsaturated polyester resin, 1-2 parts of potassium titanate, 2-3 parts of cyclohexanhexol, 2-4 parts of triglycidyl isocyanurate, 0.3-0.6 part of tris [2, 4-di-tert-butylphenyl] phosphite, 7-10 parts of acrylic ester, 1-2 parts of 2, 6-di-tert-butyl-p-cresol, 1-2 parts of dimethylethanolamine, 10-14 parts of nanometer bentonite, 2-3 parts of hollow glass microspheres and 5-10 parts of modified padding. The powder coating disclosed by the invention is flat, smooth and clean in coat, free of obvious bubbles, shrinkage cavities or particles, stable in coat, good in construction property, good in permeability and strong in heat dissipating effect.

Owner:WUHU BAOYI AMUSEMENT EQUIP

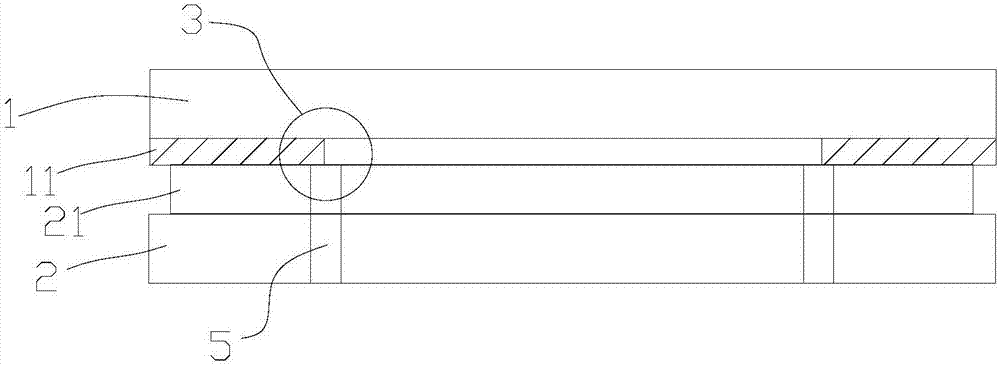

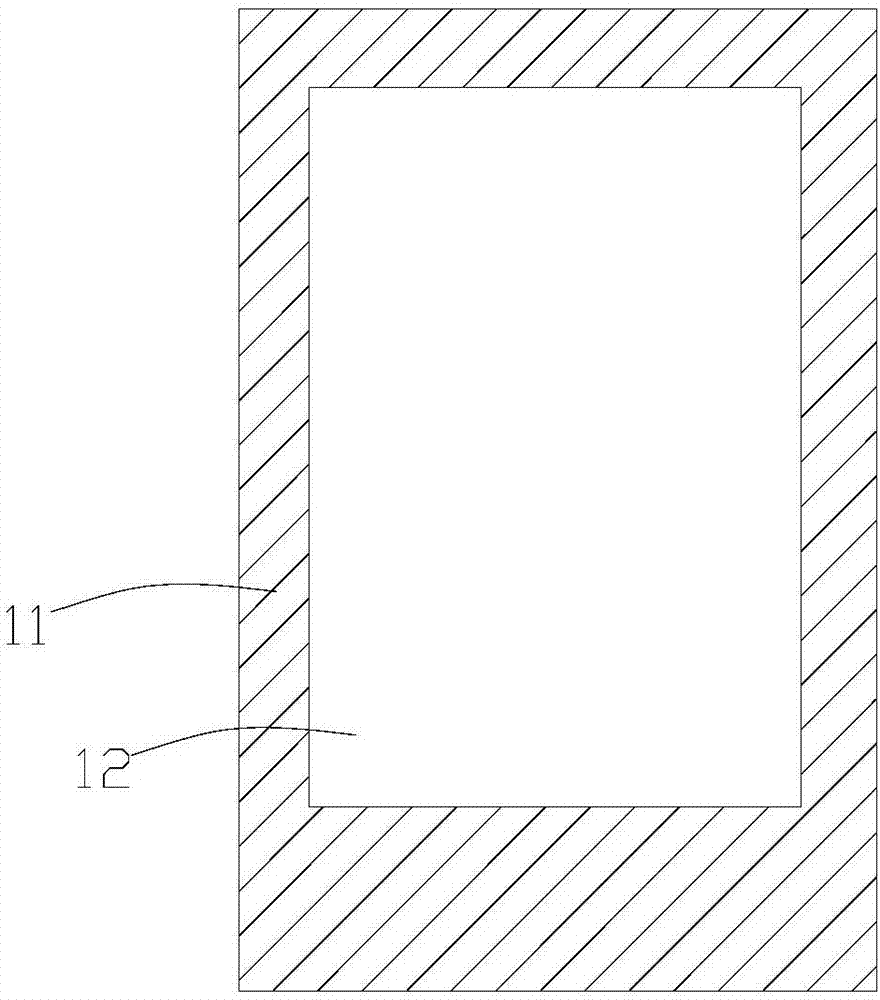

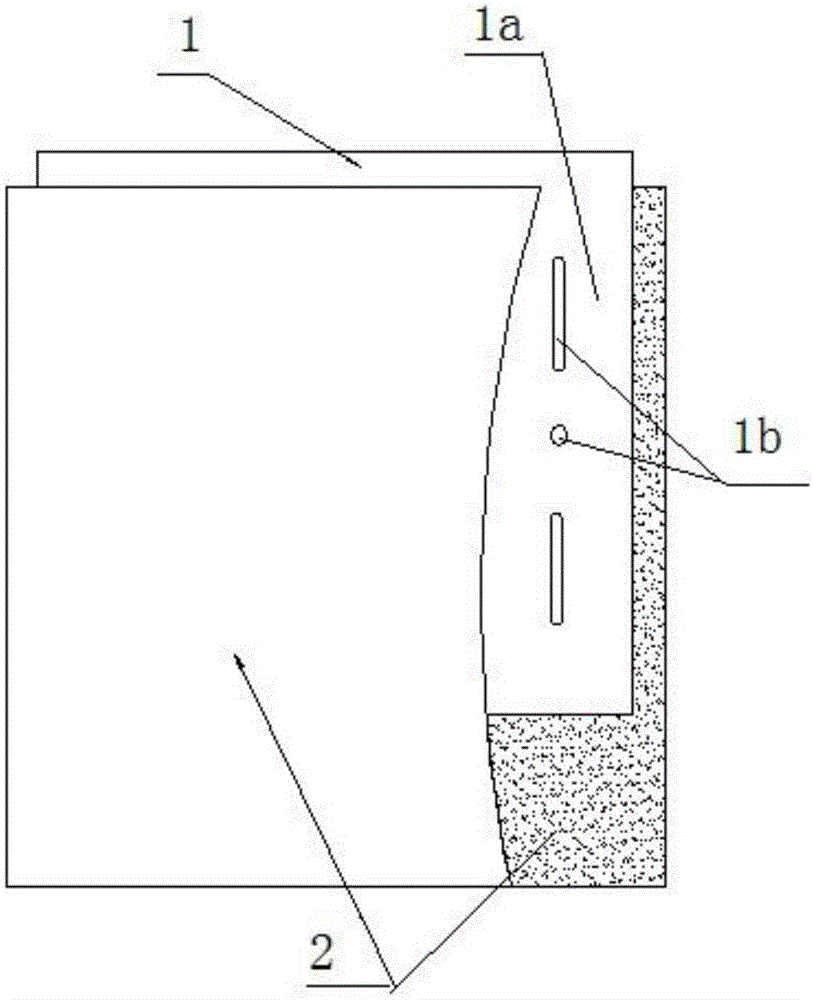

Copper and aluminum die casting composite polar plate conductive head and manufacturing method thereof

InactiveCN106735098AImprove compactnessImprove surface qualityNon-insulated conductorsConductive materialDie castingAlloy substrate

The invention relates to a copper and aluminum die casting composite polar plate conductive head and a manufacturing method thereof. The conductive head comprises a middle layer conductive copper block (1), an aluminum or aluminum alloy substrate (2) compositely die cast outside the conductive copper block, one end of the conductive copper block is exposed for a certain length (1a) outside the aluminum or aluminum alloy substrate. The method comprises the steps of aluminum melting, mold preparation, die casting, cooling and cleaning. By means of the copper and aluminum die casting composite polar plate conductive head and the manufacturing method thereof, the problems that for an existing conductive head, due to the fact that copper and aluminum composition is not close and the shape error is large, the conductive property is affected, and the manufacturing cost is too high can be solved.

Owner:晋宁理工恒达科技有限公司

Milk froth generator and coffee machine

ActiveCN104997414AImprove bubblesReduce the presence of air bubblesBeverage vesselsThermodynamicsProcess engineering

The invention relates to a milk froth generator. The milk froth generator comprises a milk froth generator body, a milk froth buffer body, a steam nozzle and a milk froth distribution assembly, wherein a first chamber allowing steam and milk to be mixed and a first pipeline communicated to the first chamber are formed in the milk froth generator body, a second chamber used for milk froth buffering is formed in the milk froth buffer body, the first chamber and the second chamber are communicated, an outlet is formed in the lower end of the second chamber, and a steam nozzle is provided with a second pipeline and a third pipeline which are communicated with the first chamber; the milk froth distribution assembly comprises a milk froth distribution main body, the milk froth distribution main body comprises a plurality of distribution channels, and milk froth outlets are formed in the distribution channels. The milk froth generator can distribute milk froth and can make multiple cups of milk froth simultaneously; the buffered flow-out travel of the milk froth is extended by means of the distribution channels of the milk froth distribution assembly, the milk froth is secondarily buffered in the distribution channels, and larger bubbles in the milk froth are eliminated.

Owner:SUZHOU KALERM COFFEE MASCH TECH CO LTD

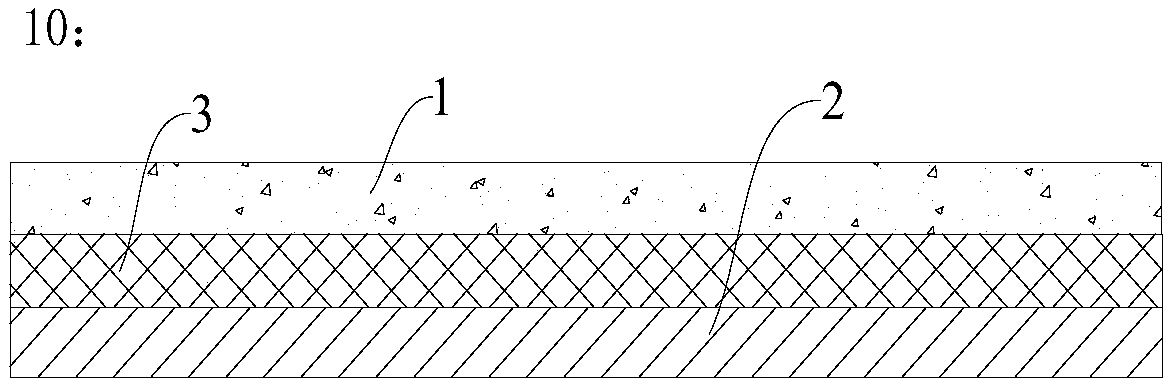

Laminated glass, preparation method and applications thereof

ActiveCN110871612AImprove bubblesGood optical performanceCasings/cabinets/drawers detailsGlass/slag layered productsOrganic filmElectronic equipment

The invention provides laminated glass, a preparation method and applications thereof. The laminated glass comprises at least two glass members and at least an organic film, wherein the organic film is arranged between the two adjacent glass members, the thickness of the glass member is 0.1-0.5 mm, and the thickness of the organic film is 25-100 [mu]m. According to the invention, the laminated glass is proper in the thicknesses of the glass member and the organic film, attractive in appearance, good in optical performance, excellent in mechanical property, good in falling resistance, free of glass splashing during breaking and good in safety, can be used for shells of electronic equipment, and can be effectively applied to the field of actual production.

Owner:BYD CO LTD

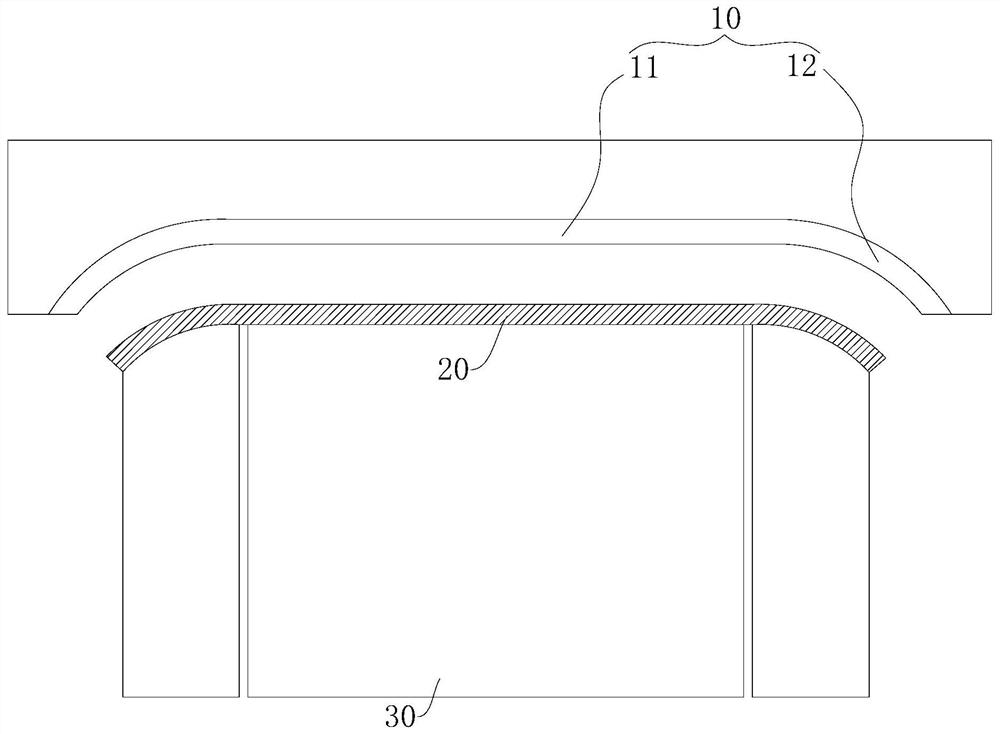

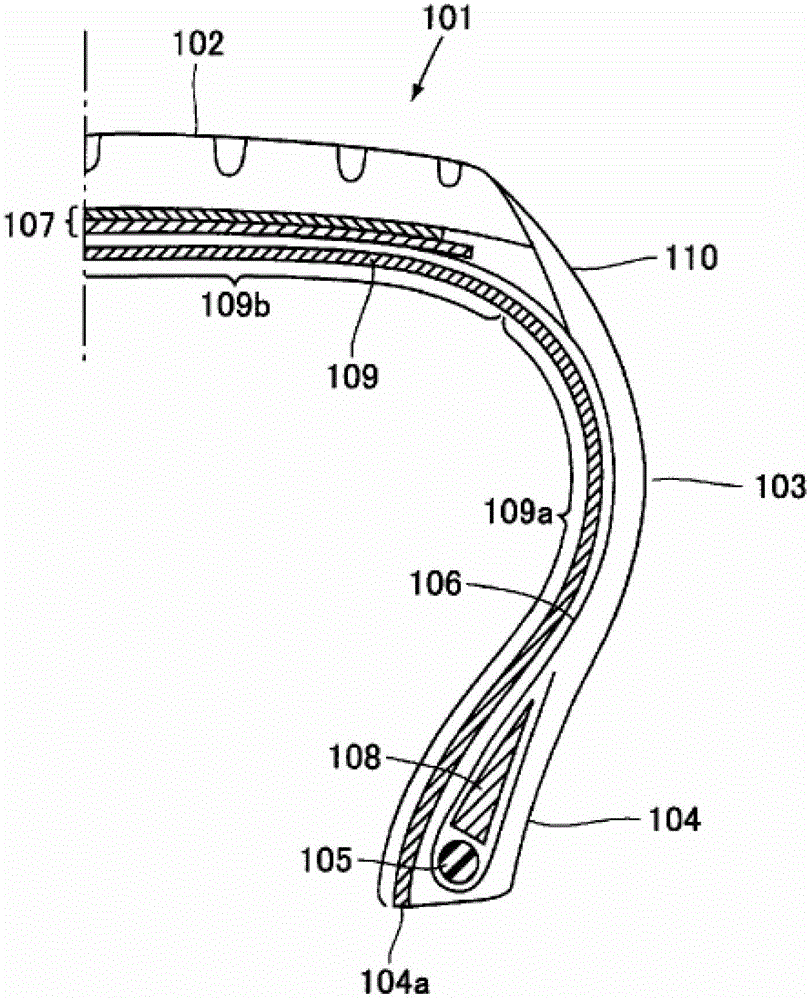

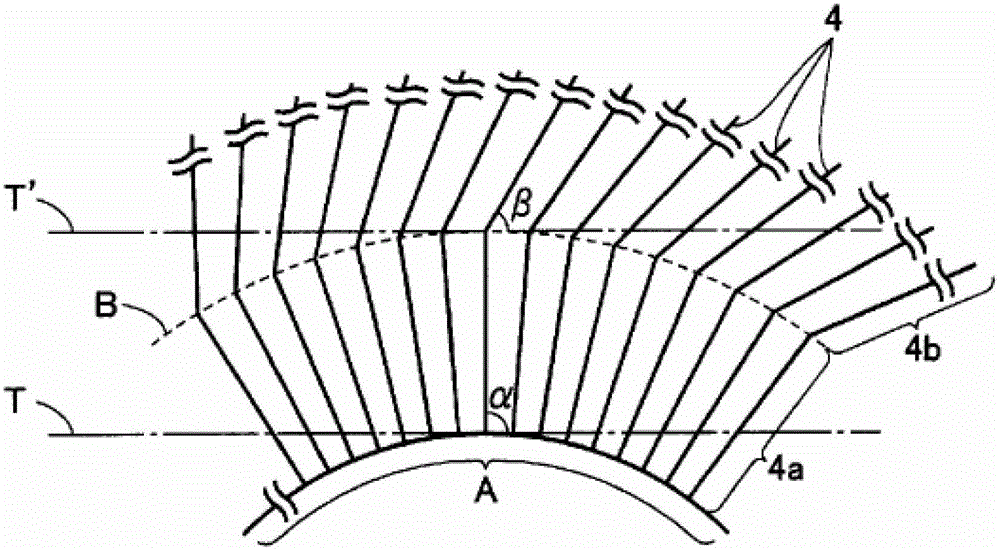

Pneumatic tire and process for production thereof, and tire curing bladder

InactiveCN103068541AWon't hurtImprove rolling resistanceWithout separate inflatable insertsSpecial tyresTire beadMechanical engineering

This process for producing a pneumatic tire utilizes a tire curing bladder having multiple vent lines, and is characterized in that the pneumatic tire has an inner liner on the inner surface thereof, the inner liner has an SIBS layer containing a styrene-isobutylene-styrene triblock copolymer, the SIBS layer has a thickness of 0.05 to 0.6 mm inclusive, the SIBS layer contains 0.5 to 40 mass% inclusive of a polymer produced by polymerizing monomer units each having 4 carbon atoms, and the vent lines include a first vent line which is a part corresponding to a part between a tire bead toe part and a tire buttress part and a second vent line which is a part corresponding to a part between the tire buttress part and a tire crown part.

Owner:SUMITOMO RUBBER IND LTD

Bubble generating assemblies

InactiveUS20060141895A1Enhances amusement value and play varietyImprove bubblesDollsLocking mechanismEngineering

A bubble generating assembly has a housing, an air generator associated with the housing, a bubble producing device positioned in front of the air generator to receive air generated from the air generator, and a cover or dipping cup configured as an inverted cup. The cover or dipping cup has an interior and a locking mechanism that removably connects the housing, and the cover or dipping cup retains the bubble producing device in the interior when the cover or dipping cup is connected to the housing. In addition, a bubble generating device has a loop with a cylindrical wall extending from the opening of the loop. The cylindrical wall has a plurality of ridges provided on the inner circumferential surface thereof.

Owner:ARKO DEVMENT

Intelligent fruit and vegetable cleaning method

ActiveCN110367558AEfficient cleaning and removalAchieve flowSpecific water treatment objectivesTreatment involving filtrationHigh densityPesticide residue

The invention belongs to the field of intelligent home and agricultural product processing, in particular to an intelligent fruit and vegetable cleaning device and method. Through the specific arrangement of each component in the cleaning device, impurities and pesticide residues on the surfaces of fruits and vegetables are adhered and removed through high-density bubbles sprayed at the bottom after the fruits and vegetables enter water, and then the surfaces of the fruits and vegetables are rapidly dried by spraying gas on the fruits and vegetables after the water is discharged by lifting a cleaning groove, so that efficient cleaning and efficient drying are realized, and the corruption speed of the fruits and vegetables is not accelerated under the condition of efficient cleaning of thefruits and vegetables.

Owner:浙江敏达环保设备有限公司

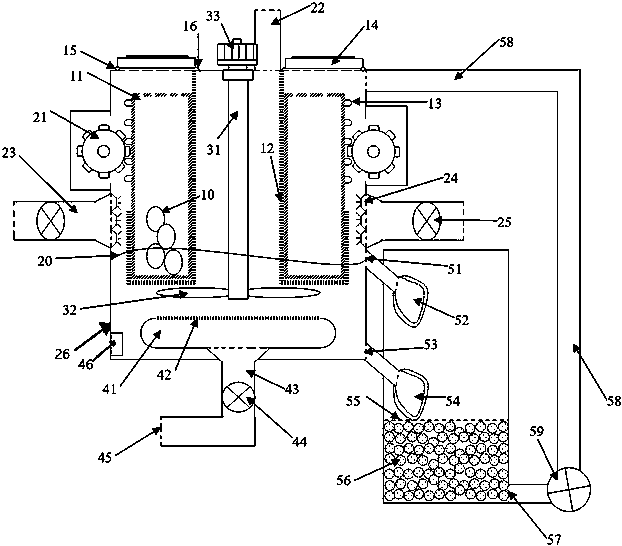

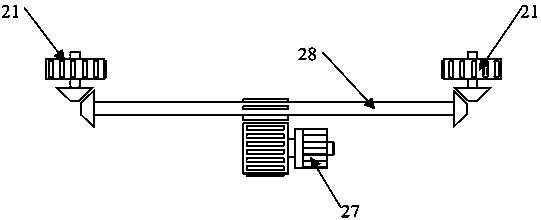

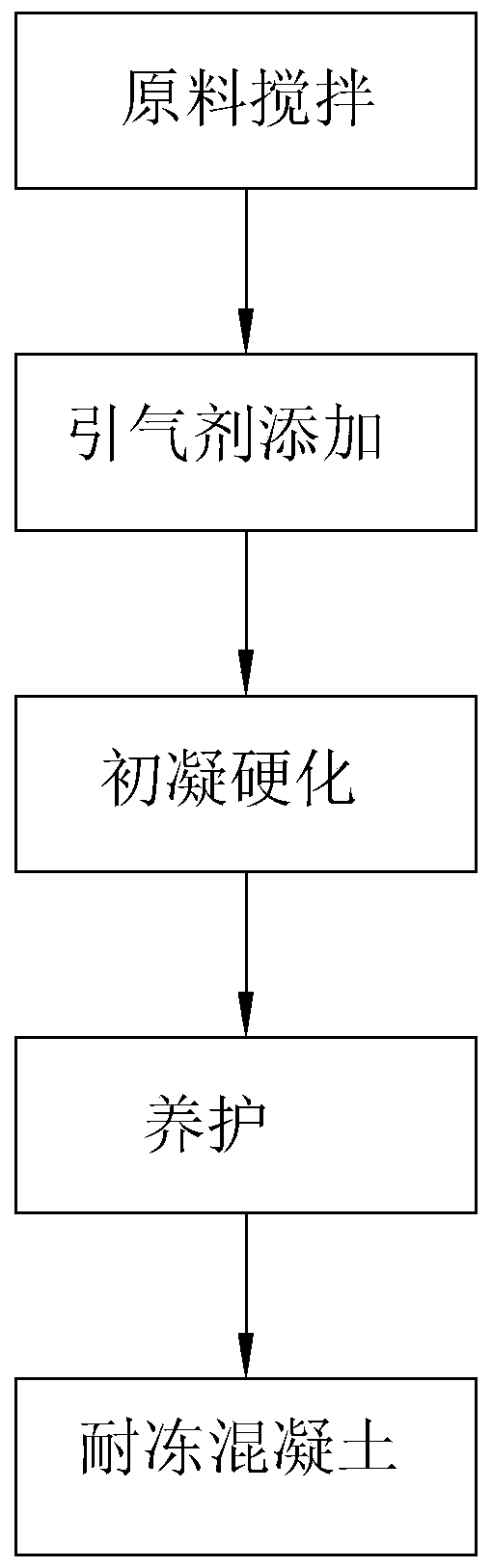

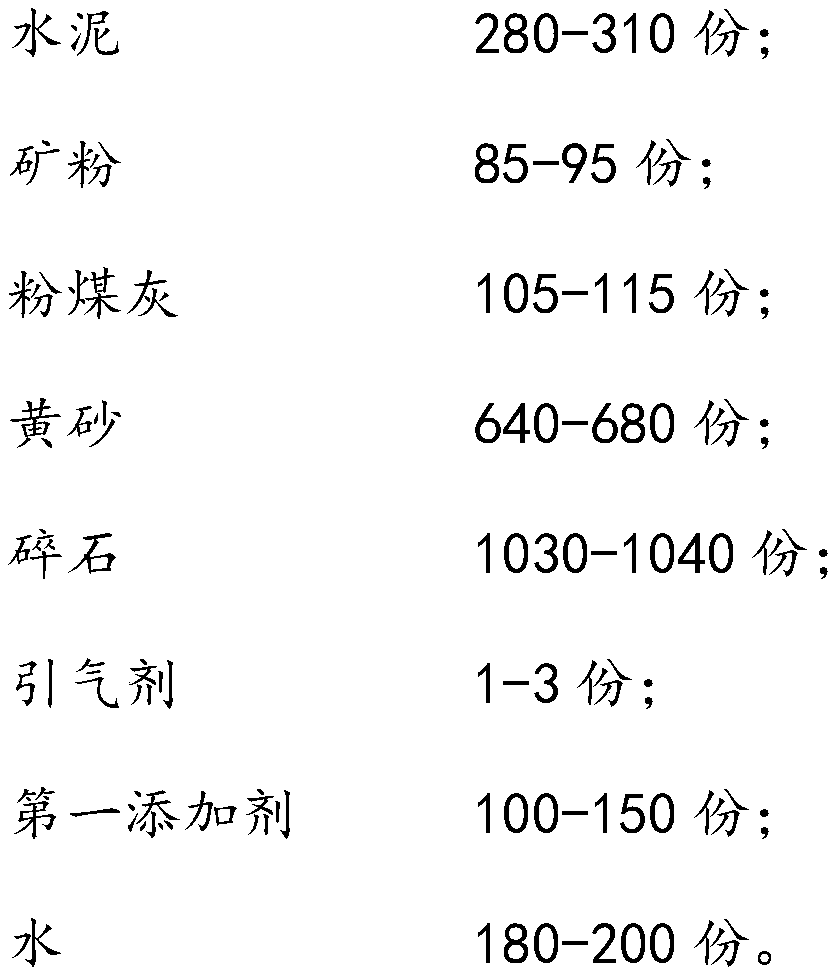

Freeze-resistant concrete and preparation method thereof

The invention discloses freeze-resistant concrete and a preparation method thereof, and relates to the technical field of concrete. Raw materials of the concrete comprise the following materials in parts by weight: 280-310 parts of cement; 85-95 parts of mineral powder; 105-115 parts of fly ashes; 640-680 parts of yellow sand; 1030-1040 parts of crushed stone; 1-3 parts of air-entraining agents; 100-150 parts of first additives; and 180-200 parts of water. The method has the effect of improving the frost resistance of the concrete.

Owner:浙江三门永泰建材有限公司

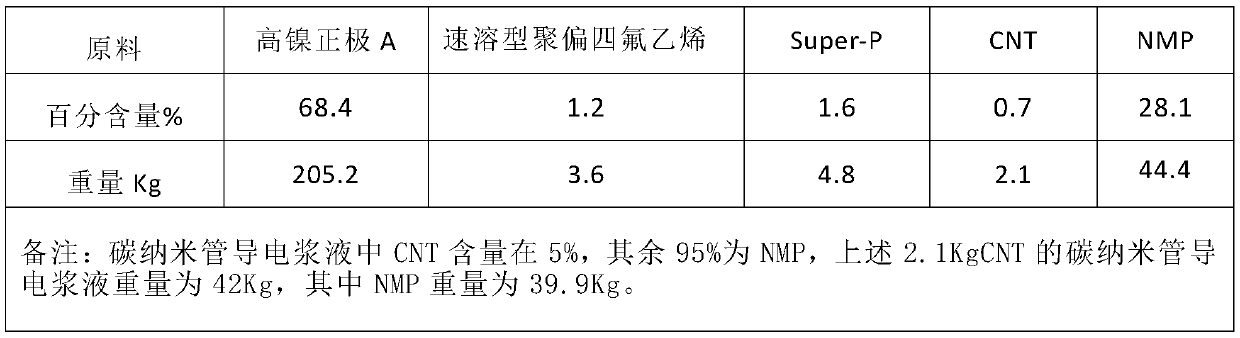

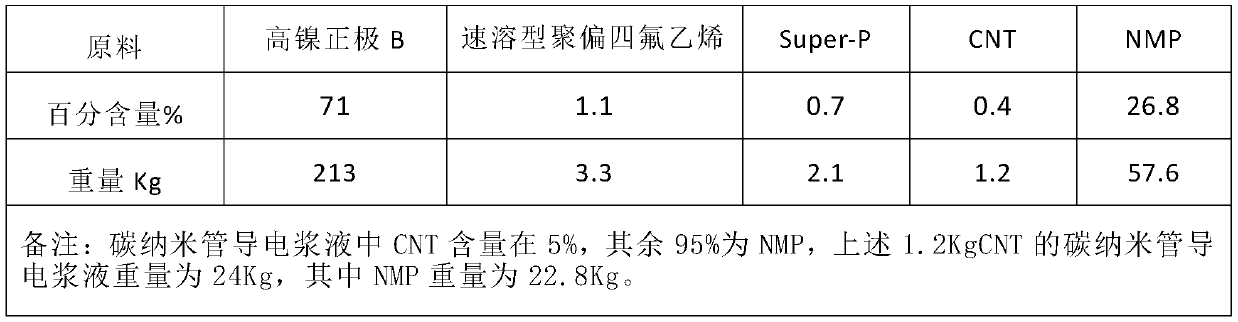

Lithium ion battery high-nickel positive electrode material and preparation process thereof

InactiveCN111162280AImprove compactnessIncrease compaction densityMaterial nanotechnologyElectrode manufacturing processesElectrical batteryAdhesive glue

The invention discloses a lithium ion battery high-nickel positive electrode slurry mixing process. A high-nickel positive electrode slurry comprises a high-nickel positive electrode, a carbon black Super-p conductive agent, a CNT conductive agent, and adhesives PVDF and NMP, and the process comprises the following steps of (1) adding the adhesive and NMP into a planetary stirrer, stirring, preparing an adhesive glue solution with the solid content of 6.0-12.0%, and standing for later use; (2) adding the carbon black Super-p conductive agent and a high-nickel positive electrode into a double-planet stirrer, quickly and uniformly stirring, and then adding part of the glue solution in the step (1) and a CNT conductive agent for premixing; and (3) adding the residual glue solution into a planetary stirrer, uniformly stirring, and then revolving to prepare the positive electrode slurry with the solid content of 68%-75%. Through the application of the cathode material premixing and mixing process, the use problem of the high-nickel cathode in the battery is solved, the mixing uniformity is improved, meanwhile, the batching time is shortened, and the specific capacity and the rate discharge performance of the lithium ion battery are greatly improved.

Owner:河南新太行电源股份有限公司

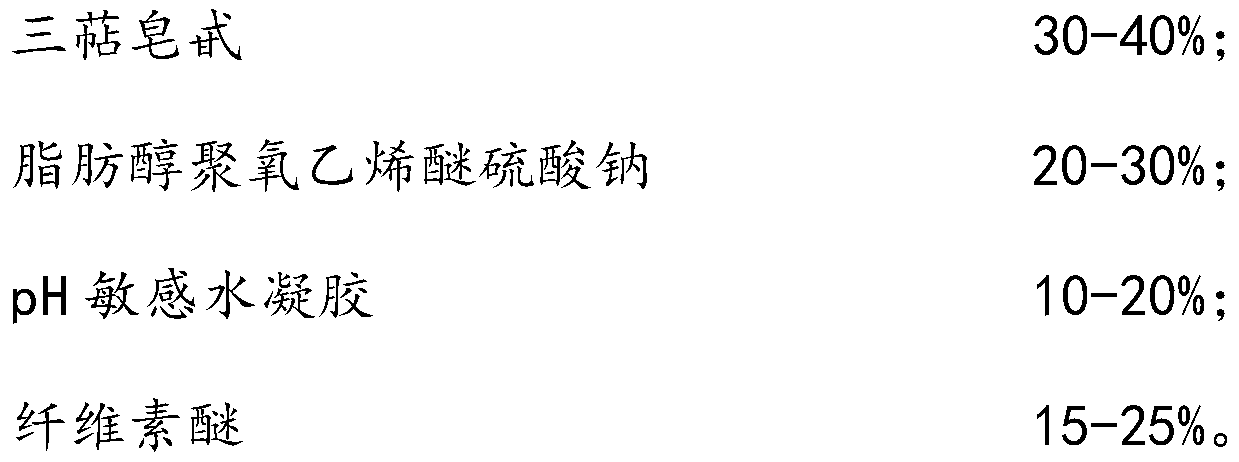

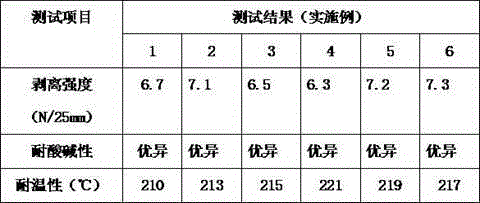

High-temperature-resistant peelable blue glue

InactiveCN105176403AGood film formingFit closelyConjugated diene hydrocarbon coatingsChloropene polymer coatingsPlasticizerPolyphenyl ether

The invention discloses high-temperature-resistant peelable blue glue.The high-temperature-resistant peelable blue glue comprises the following components in parts by weight: 25-35 parts of vinyl resin, 15-24 parts of n-butyl stearate, 20-30 parts of rubber, 5-12 parts of polyphenyl ether, 2-8 parts of a plasticizer, 1-6 parts of a defoaming agent, 2-7 parts of a flatting agent and 3-9 parts of an organic pigment. The high-temperature-resistant peelable blue glue prepared by the invention is good in film forming property; the surface of a hardened layer has a relatively good attaching property; and air bubble and warpage problems can be effectively improved. The film has good resistance to acid and base, and is easy to peel without residual glue on the surface of the material.

Owner:ZHONGSHAN BRK SPECIAL CHEM PROD

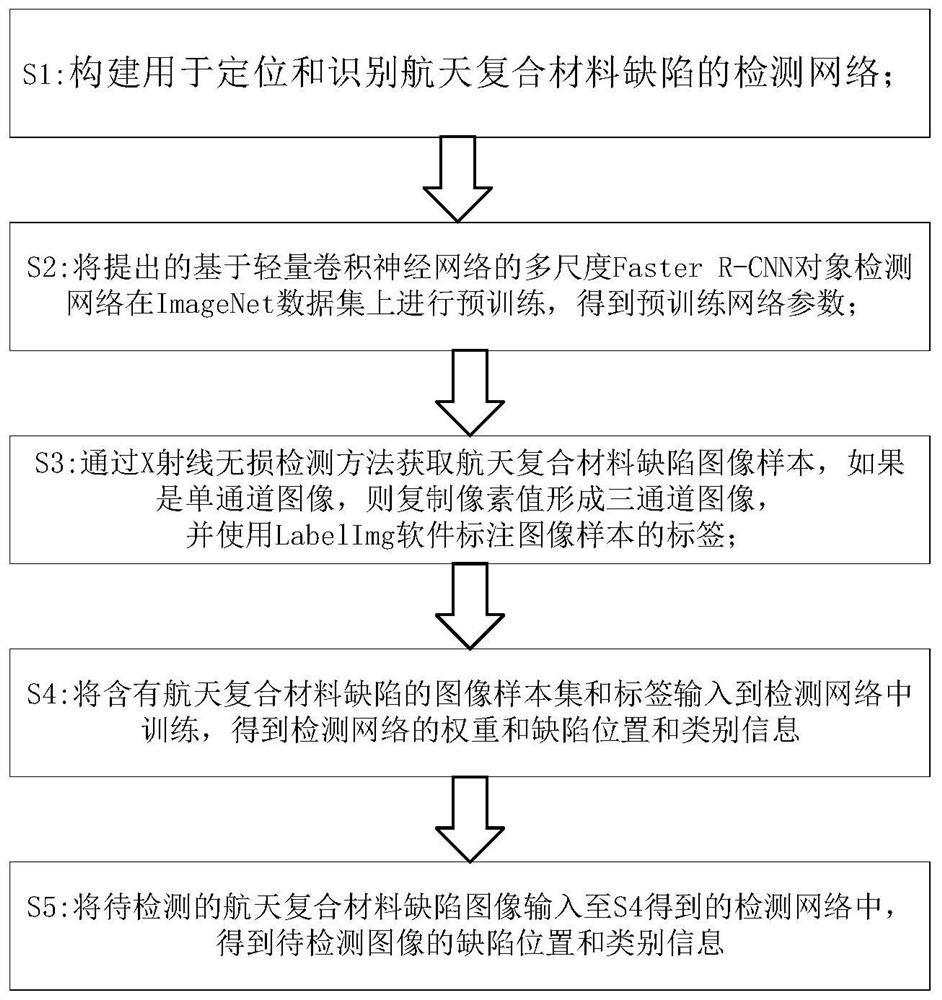

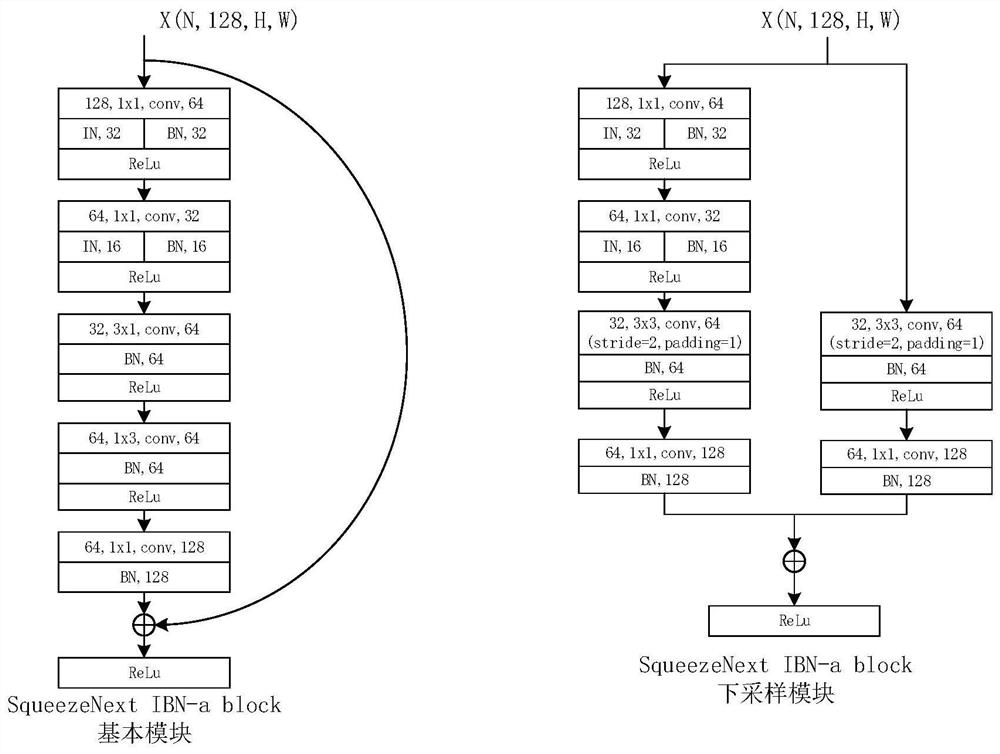

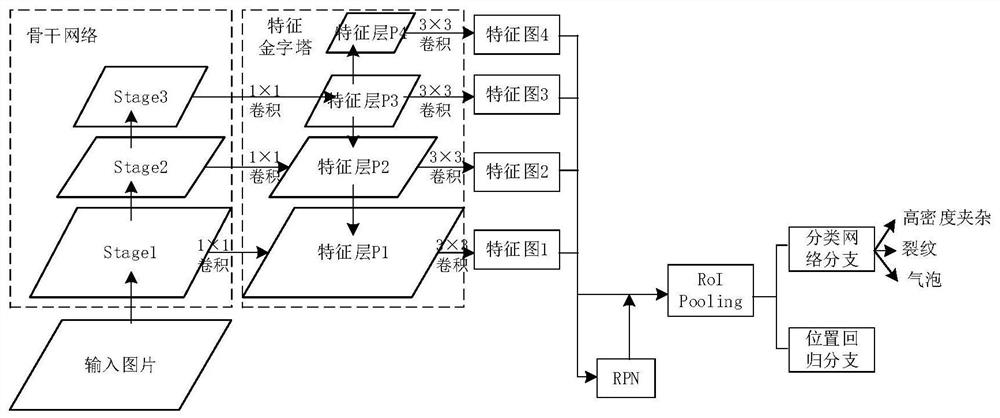

Aerospace composite material defect positioning and identification method and system

PendingCN113724204AHigh speedHigh precisionImage enhancementImage analysisFeature extractionData set

The invention provides an aerospace composite material defect positioning and identification method and system. The method comprises the following steps: S1, constructing a detection network for positioning and identifying defects of aerospace composite materials; S2, pre-training the detection network on an ImageNet data set, and obtaining pre-training weight values of a backbone network and a feature extraction network; S3, acquiring aerospace composite material defect image samples, and marking labels of the image samples; S4, inputting an image sample set and the labels into the whole detection network for training to obtain a weight, a defect position and category information of the detection network; and S5, obtaining a to-be-detected aerospace composite material defect image, inputting the image into the detection network, and calculating to obtain the defect position and defect category information in the to-be-detected image. According to the invention, defect positioning and identification are carried out on images containing aerospace composite material defects, the problem that the real-time performance is not high when X-ray images containing the aerospace composite material defects are manually identified is solved, and the defect identification precision is guaranteed.

Owner:SHANGHAI INST OF SATELLITE EQUIP

A method for preparing high-strength stainless steel from high-alloy melt

InactiveCN103436768BImprove bubblesSmooth fusionElectric furnaceProcess efficiency improvementSS - Stainless steelAlloy

The invention relates to a method for the preparation of high-strength stainless steel by using high alloy melt. The method is characterized by comprising the following steps: firstly, preparing high nitrogen alloy melt and Fe-Cr-Mn melt respectively; then adding the Fe-Cr-Mn melt slowly into the high nitrogen alloy melt; discharging for pouring after temperature controlling and uniform stirring. According to the method, smooth and steady fusing of the high nitrogen alloy melt and the Fe-Cr-Mn melt is facilitated, the escape of nitrogen is obviously reduced, high nitrogen steel melt with higher nitrogen content and better stability can be obtained so as to obtain high nitrogen billet steel with less bubble and high nitrogen content, and the detection for the nitrogen content of the high nitrogen billet steel can be up to 1.0 wt%.

Owner:CHANGCHUN UNIV OF TECH

Strippable adhesive coating composition, peelable adhesive coating, preparation method and application of peelable adhesive coating

The invention provides a peelable glue coating composition and a peelable glue coating as well as a preparation method and an application of the peelable glue coating. The peelable glue coating composition comprises the following components in parts by weight: 80-120 parts of an acrylate type oligomer, 8-20 parts of a dilutive monomer, 0.1-1.5 parts of a peeling force modifying agent, 2-12 parts of a triggering agent and 30-50 parts of an organic solvent. The peelable glue coating composition is relatively high in transparency and relatively high in light transmittance and relatively low in haze after film formation. Meanwhile, a coating formed by curing the peelable glue coating composition is relatively high in high temperature resistance and relatively high in peelability. By the high temperature resistance, the coating is good in adhesion property on the surface of a functional hardened layer, and the problems of air bubbles and warping can be effectively improved. By the peelability, the problem of glue layer residues caused during peeling of the coating can be reduced.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

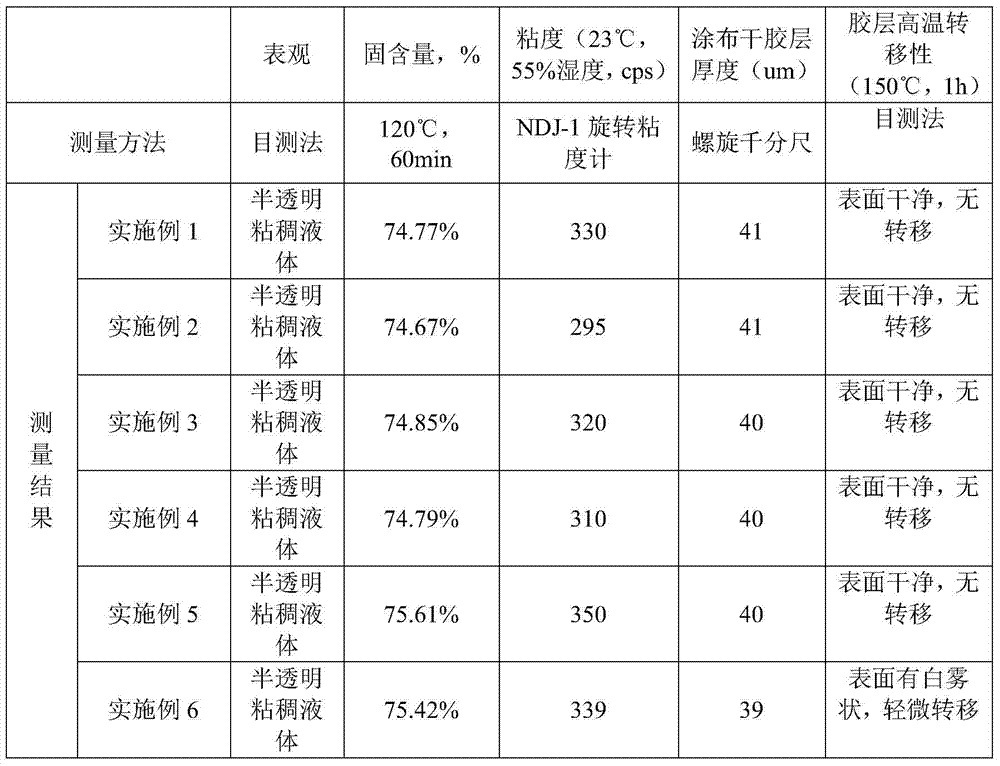

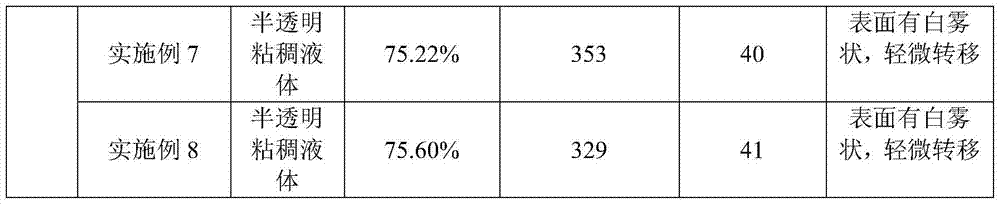

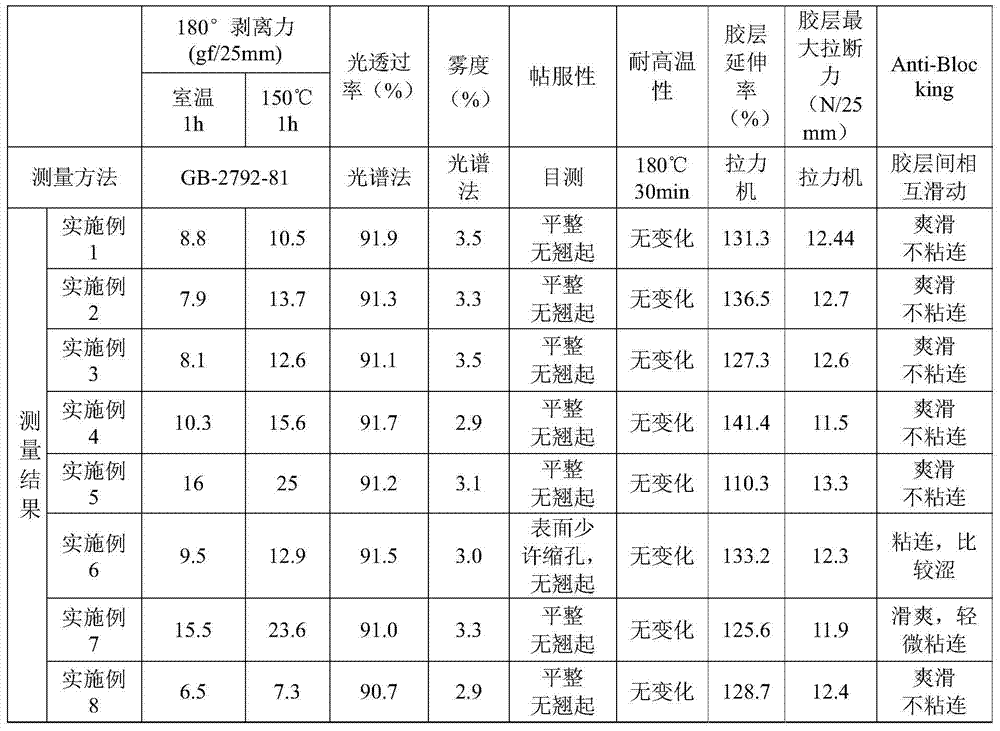

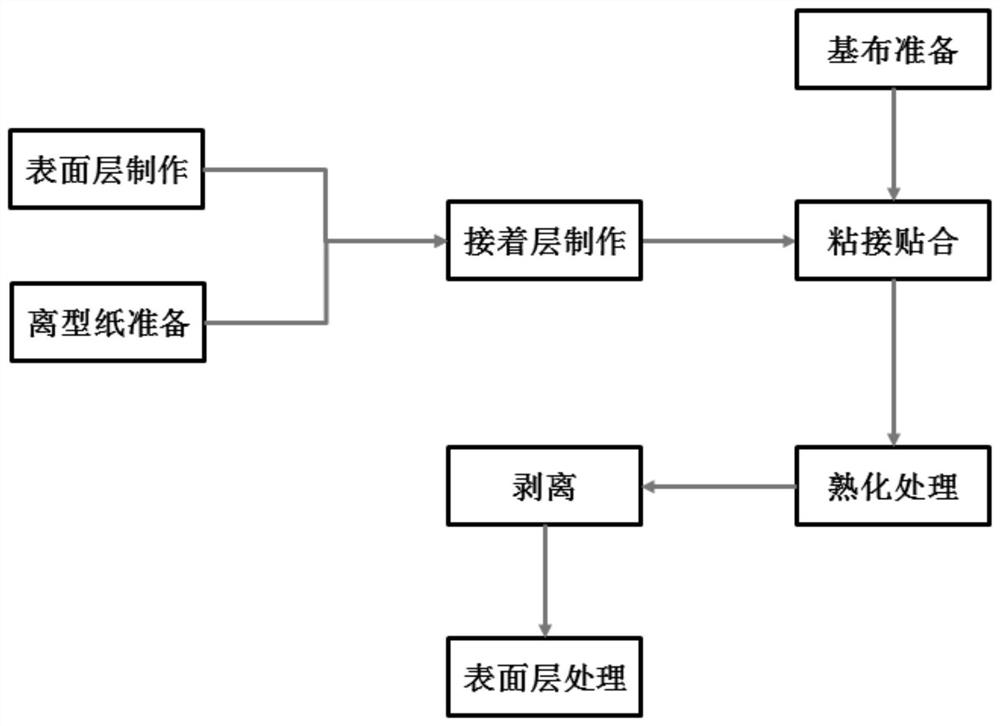

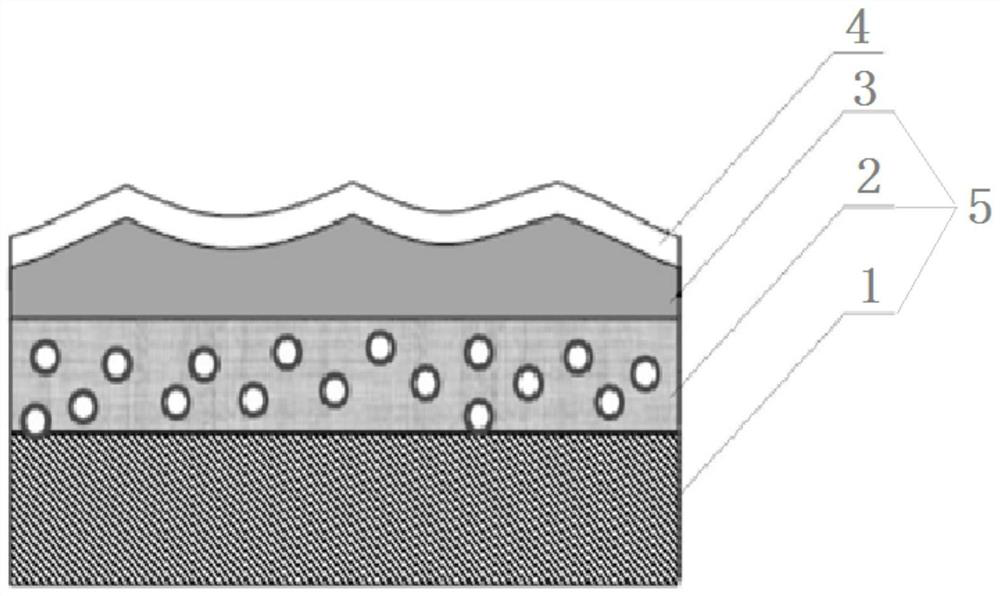

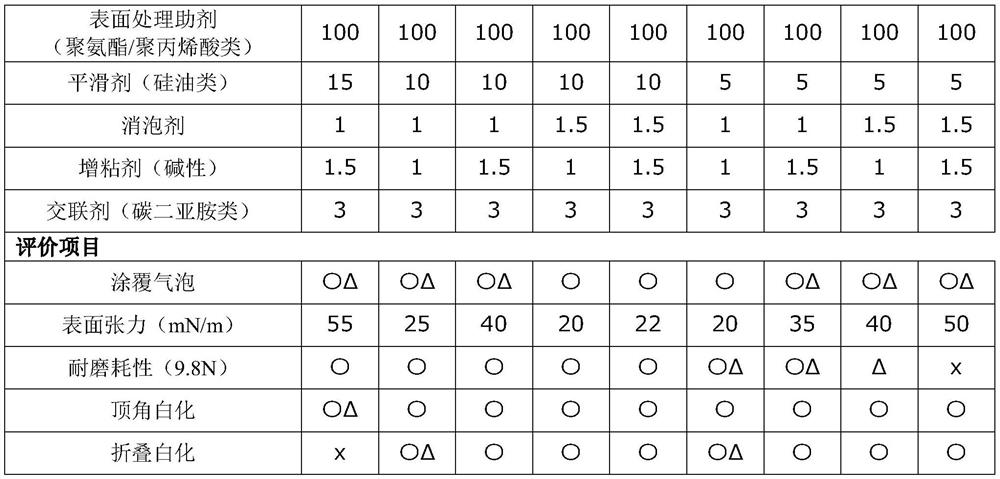

PU (Polyurethane) composite leather and preparation method thereof

PendingCN113605107AStable surface tensionExcellent abrasion resistanceCoatingsTextiles and paperPolymer scienceFire retardant

The invention provides PU (polyurethane) composite leather which comprises a leather blank and a surface treatment layer. The components of the surface treatment layer comprise polyurethane, a bridging agent, a tackifier and a smoothing agent; the leather blank comprises a base cloth layer, a bonding layer and a surface layer; and the material components of the blank comprise polyurethane, a dissolving medium, a hardening agent, a catalyst, a solvent, a flame retardant, a pigment and the like. The invention also provides a preparation method of the composite leather. The preparation method comprises the following steps of preparing the surface layer, preparing the bonding layer, bonding the surface layer, the bonding layer and the base cloth layer together, stripping, curing and treating the surface layer. According to the PU composite leather obtained through the preparation method, the dispersity and the leveling property of the raw materials are fully exerted, the mesh surface of the product is free of black spots and uneven coating, a hand feeling agent is evenly dispersed and free of bubbles, the abradability is excellent, and then the flatness and the high yield of the product are achieved.

Owner:SEIREN SUZHOU CO LTD

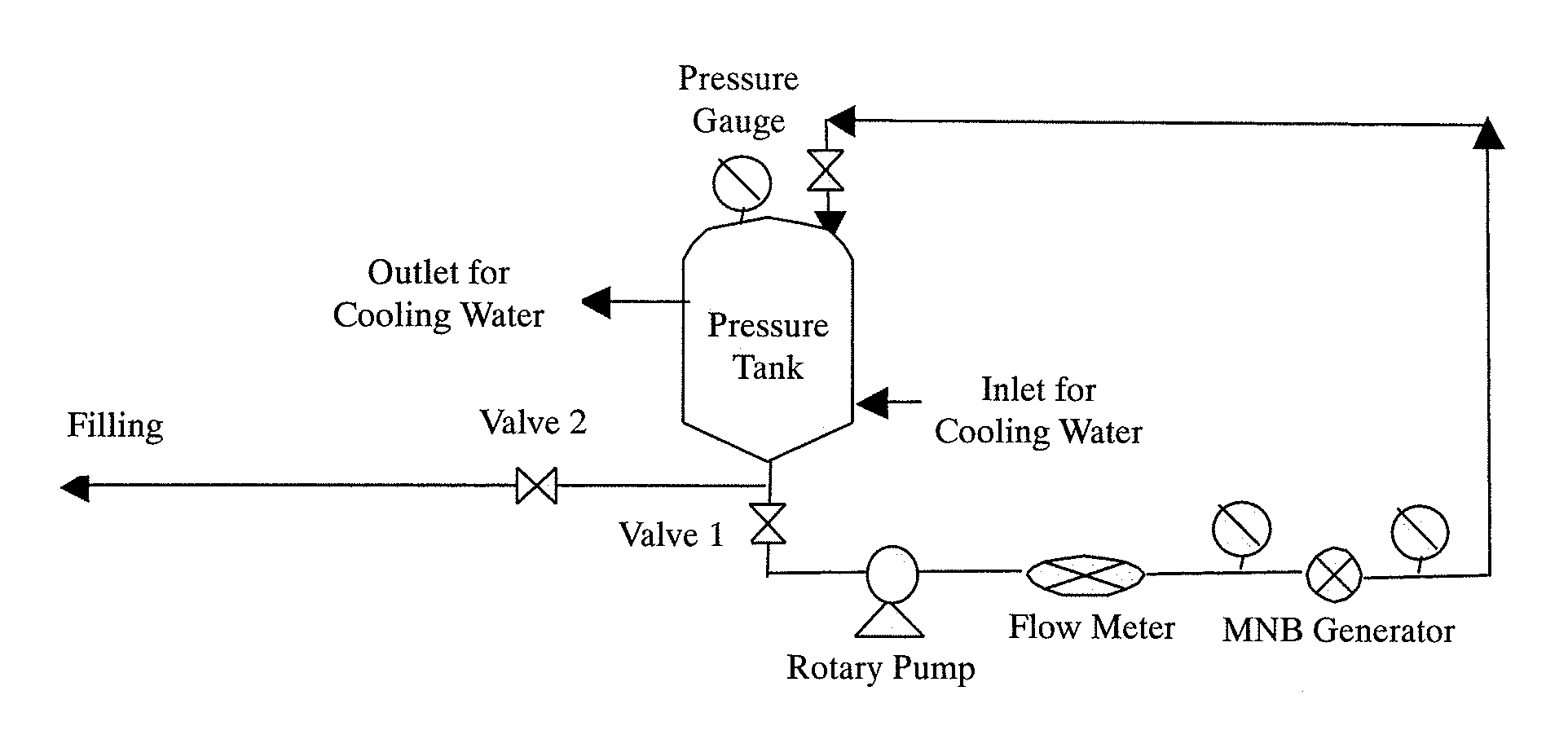

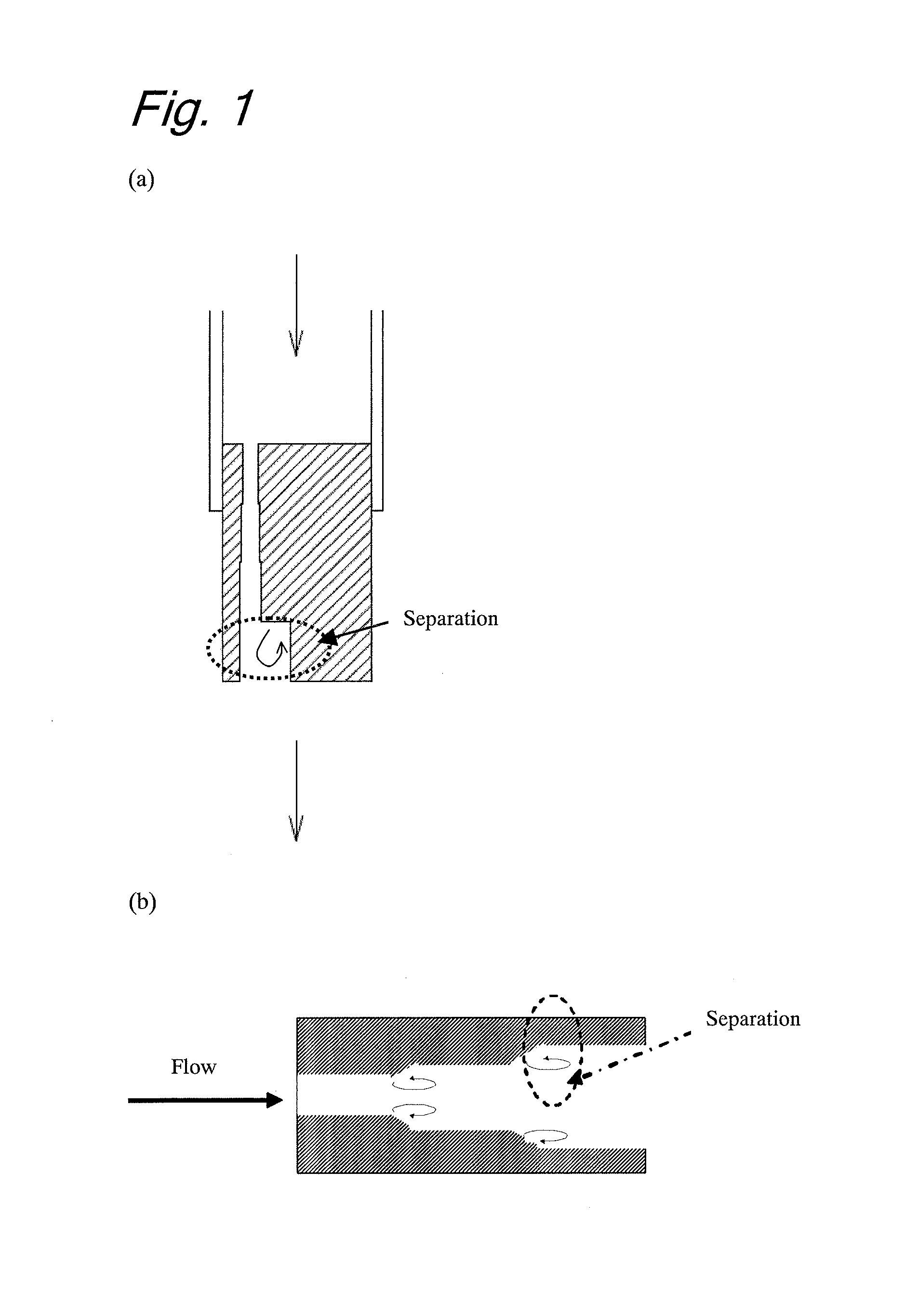

Method for producing carbonated beverage

InactiveUS20120225177A1Improve bubblesShort-time productionFlow mixersBeer fermentationCavitationProduct gas

The present invention provides carbonated beverages that have new qualities of being less likely to release carbon dioxide dissolved therein, bringing the feeling of fine bubbles in drinking, and allowing a full control of their sparkling characteristic, and a method for producing the carbonated beverages.A liquid containing carbon dioxide gas is passed through an apparatus to generate cavitation under pressure conditions to generate cavitation in the liquid, thereby making finer the bubbles of the dissolved carbon dioxide gas.

Owner:SUNTORY HLDG LTD +1

Repairing agent for subway shield segments and preparation method of repairing agent

InactiveCN111995349AGuaranteed crack resistanceImprove compactnessSolid waste managementAluminateCellulose

The invention discloses a repairing agent for subway shield segments and a preparation method of the repairing agent. The repairing agent is prepared from the following raw materials in parts by mass:200 to 300 parts of ordinary Portland cement; 150-200 parts of white cement; 100 to 250 parts of sulphoaluminate cement; 20-50 parts of microbeads; 50 to 100 parts of silica fume (silica powder); 150to 250 parts of active glass powder; 1 to 10 parts of excitant; 50 to 100 parts of concrete expanding agent; 0.1 to 0.4 part of plastic expanding agent; 1 to 5 parts of water reducing agent; 0.1 to 0.4 part of defoaming agent; 0 to 0.5 part of cellulose; 15 to 35 parts of redispersible latex powder; and A parts of water. The sum of the dosages of the components excepting water, namely the sum ofthe parts of the components excepting water is B, and the water-material ratio, namely the ratio of A to B, is 0.15-0.20: 1. The invention further provides a preparation method of the repairing agent.Through the synergistic effect of all the components, the repairing agent is high in early and later compressive strength, good in wear resistance and small in color difference with old concrete repairing, has the characteristics of good bonding performance and crack resistance, and is convenient to apply and popularize.

Owner:刘翠芬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com