Copper and aluminum die casting composite polar plate conductive head and manufacturing method thereof

A technology of copper-aluminum composite and conductive head, which is applied in the direction of conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of copper-aluminum composite of conductive head, influence of conductive performance, large shape error, etc., and achieve superior conductive performance , Precise dimensions, good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

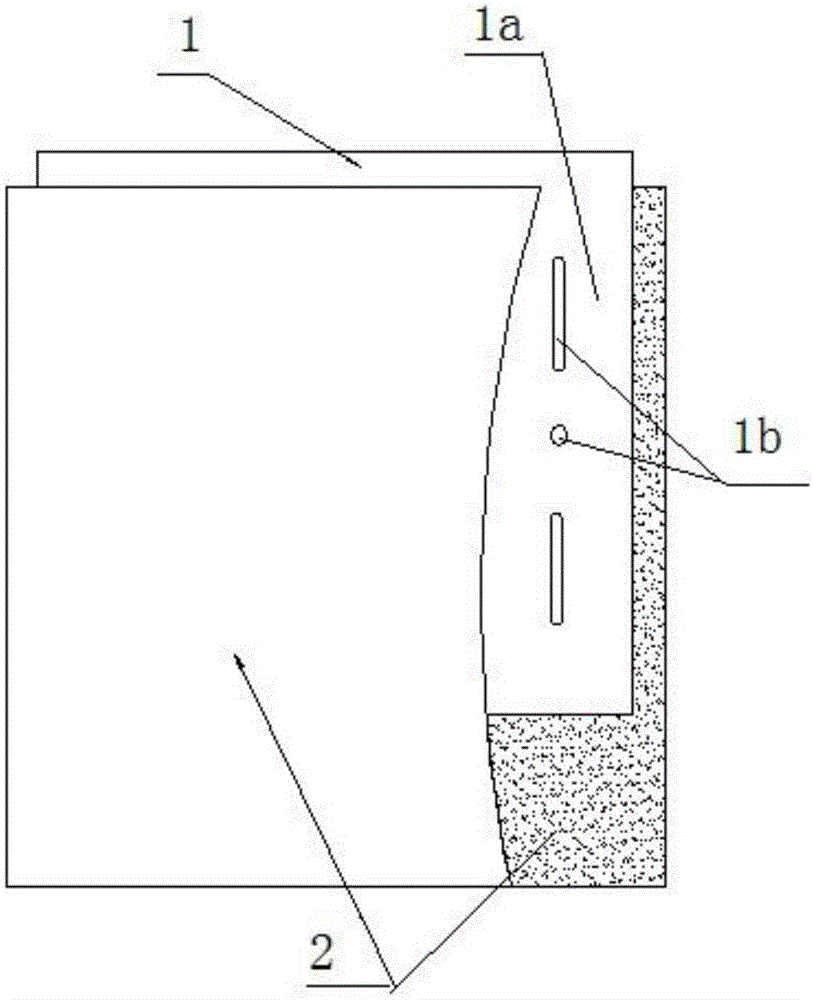

[0017] Such as figure 1 The copper-aluminum die-casting composite conductive head shown includes a conductive copper block 1 in the middle layer, and an aluminum or aluminum alloy substrate 2 that is compositely die-cast outside the conductive copper block. One end of the conductive copper block has a length 1a exposed on the aluminum or aluminum alloy substrate. in vitro. According to the different shapes of conductive heads used by different plates, the shape of the conductive copper block can be in different shapes, and a certain process groove and / or process hole 1b can be opened at the composite part of the conductive copper block and aluminum to increase the composite area of copper and aluminum and composite strength.

[0018] The preparation method of the conductive head of the copper-aluminum die-casting composite plate of the present invention is to use aluminum or aluminum alloy as the matrix, and the conductive copper block as the embedded part; use the die-cast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com