High-temperature-resistant peelable blue glue

A high temperature resistant type, blue glue technology, applied in coatings, conjugated diene coatings, chloroprene homopolymer coatings, etc., can solve the problem of low product yield, poor high temperature resistance, peelable adhesive Poor temperature performance and other problems, to achieve the effect of improving air bubbles and warpage, easy peeling, and good film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

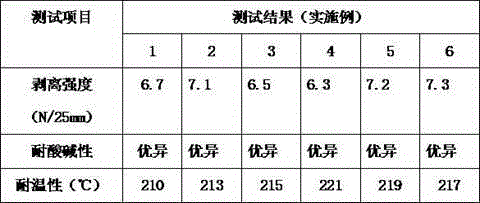

Examples

Embodiment 1

[0019] The heat-resistant peelable blue glue of the present invention includes the following components in parts by weight: 25 parts of vinyl resin, 24 parts of n-butyl stearate, 30 parts of neoprene, 5 parts of polyphenylene ether, and o-phthalate 8 parts of dioctyl dicarboxylate, 1 part of emulsified silicone oil, 7 parts of polydimethylsiloxane, 9 parts of phthalocyanine blue.

Embodiment 2

[0021] The heat-resistant peelable blue rubber of the present invention includes the following components in parts by weight: 35 parts of vinyl resin, 15 parts of n-butyl stearate, 20 parts of styrene butadiene rubber, 12 parts of polyphenylene ether, and o-phthalate 2 parts of diethyl diformate, 6 parts of higher alcohol fatty acid ester complex, 2 parts of polymethylphenylsiloxane, 3 parts of iron blue.

Embodiment 3

[0023] The heat-resistant peelable blue rubber of the present invention includes the following components in parts by weight: 29 parts of vinyl resin, 19 parts of n-butyl stearate, 25 parts of nitrile rubber, 8 parts of polyphenylene ether, and o-benzene 5 parts of dibutyl dicarboxylate, 3 parts of tributyl phosphate, 4 parts of alkyl modified organosiloxane, and 6 parts of ultramarine blue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com