Patents

Literature

51 results about "N-butyl stearate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

PE wood/plastic composite sectional material and manufacturing method thereof

The invention discloses a PE wood / plastic composite sectional material and relates to the technical field of composite materials. The PE wood / plastic composite sectional material is made from the following raw materials in parts by weight: 10-70 parts of wood flour, 20-50 parts of polyethylene, 3-20 parts of calcium carbonate powder or talc powder, 0.1-1 part of stearic acid or n-butyl stearate, 0.4-1.5 parts of one or a combination of more than one of calcium stearate, lead stearate, barium stearate, cadmium stearate, lanthanum stearate, zinc stearate, PE wax, or oxidized polyethylene wax OPE or 0.1-1.5 parts of paraffin, 0.5-3 parts of a coupling agent, 0.5-2 parts of an antioxidant, 0.05-2 parts of a UV absorbent, a light shielding agent, quencher or free radical scavenger, and 3-12 parts of titanium pigment. The PE wood / plastic composite sectional material provided by the invention has the advantages of water resistance, insect resistance, rust corrosion resistance, convenience for fabrication, safety in use, strong plasticity, energy conservation, environmental friendliness and no formaldehyde, benzene or other poisonous substances.

Owner:LINYI KANGYIJIA ECOLOGY WOOD

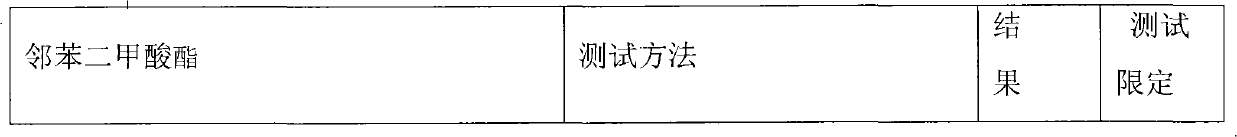

Phthalate-free medical polrvinyl chloride (PVC) plastic

The invention discloses phthalate-free medical polrvinyl chloride (PVC) plastic. The plastic is prepared by blending the following components in part by weight: 100 parts of PVC resin, 25 to 95 parts of eco-friendly plasticizer, 0.1-8 parts of polyolefin and chloroethylene function modifier, 4.5-9 parts of high-efficiency heat stabilizer and 0.3-1.5 parts of lubricant, wherein the eco-friendly plasticizer is cyclohexane1,2-diisononyl phthalate, SOFT-N-SAFE, EPN or acetyl tributyl citrate; the polyolefin and chloroethylene function modifier is more than two of styrene, maleic anhydride, diethyl maleate and chloroethylene; the chloroethylene is more than one of powdery, pasty and liquid calcium and zinc heat stabilizer; and the lubricant is butyl stearate or oxidized polyethlene wax. The phthalate-free medical PVC plastic is used for producing disposable medical supplies and is safe because the plastic is phthalate-free.

Owner:欧阳伟

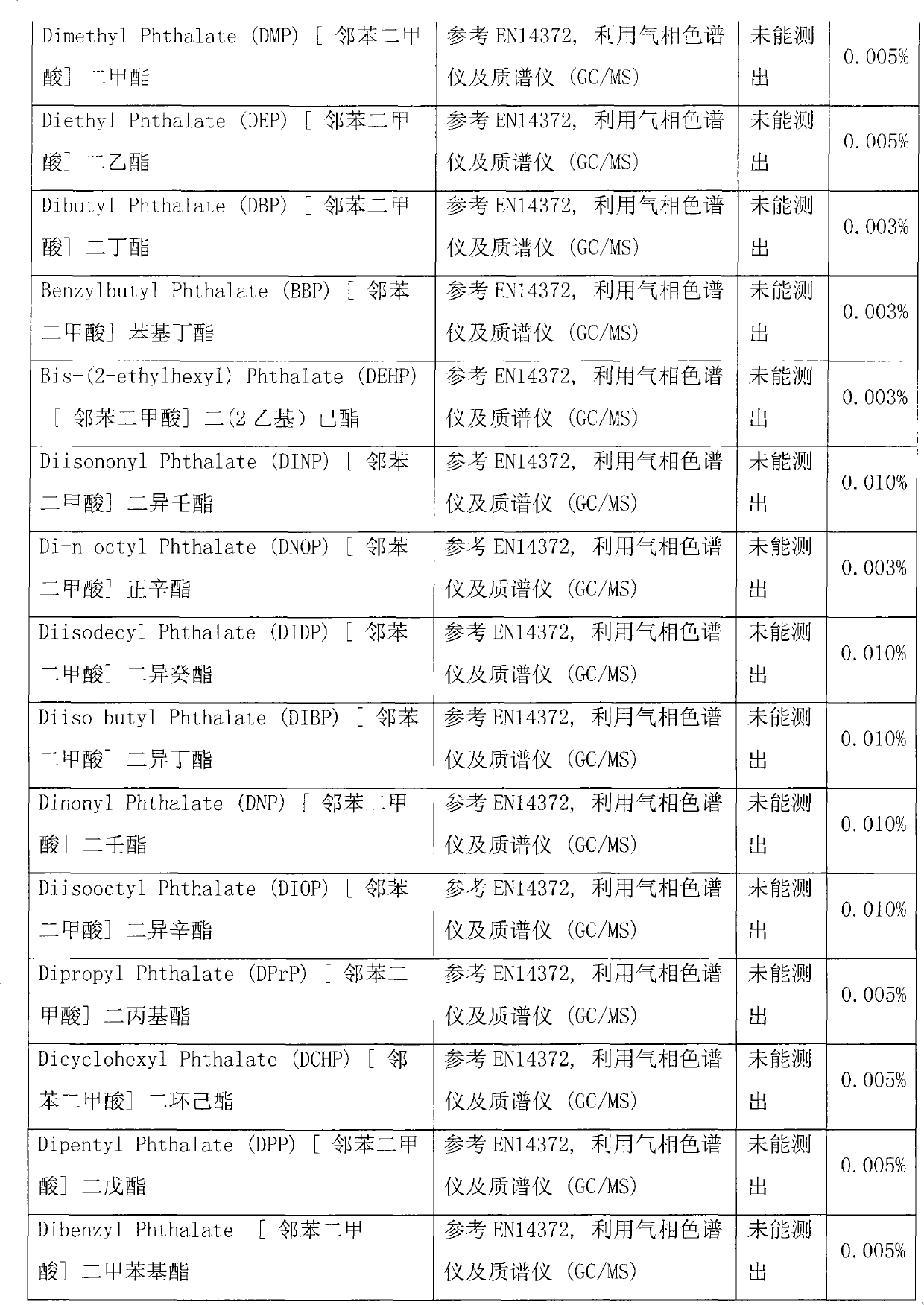

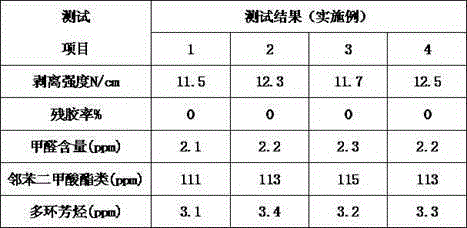

High-temperature type peelable glue for processing machining protection, and preparation method thereof

High-temperature type peelable glue for processing machining protection, and a preparation method thereof relate to peelable glue. The invention provides high-temperature-resistant type peelable glue mainly applied for machining protection of glass of a cover plate of a touch screen and for processing machining protection in an OGS (One-Glass Solution) technology, and a preparation method of the peelable glue. The high-temperature-resistant type peelable glue for processing machining protection comprises the following raw materials: rubber, a crosslinking accelerant, EVA resin, n-butyl stearate, liquid oil, esters, calcium carbonate, silica, dye, a defoaming agent and a leveling agent. The preparation method of the high-temperature-resistant type peelable glue for processing machining protection comprises the following steps of: 1) evenly dispersing the rubber, liquid oil, ester, EVA resin and n-butyl stearate; 2) then adding the dye and filler, and evenly stirring; 3) grinding the materials obtained from the step 2); and 4) adding the crosslinking accelerant into the materials ground in the step 3); and 5) filtering to obtain the high-temperature-resistant type peelable glue for processing machining protection.

Owner:XIAMEN HOWER MATERIAL

Formaldehyde-free aqueous timber glue and preparation method thereof

InactiveCN103834357AHigh bonding strengthLow costNon-macromolecular adhesive additivesProtein adhesivesFiberCalcium Chloride Hexahydrate

The invention relates to a flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board and a manufacturing method thereof. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board solves the problem that in the existing composite board manufacture, formaldehyde content of used glue exceeds the limit. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board has the functions of flame resistance, water resistance and phase-change energy storage. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board comprises a solid-wood layer and a flame-retardant waterproof phase-change energy-storage layer superposition-compounded to the solid-wood layer by pressure. The flame-retardant waterproof phase-change energy-storage layer comprises expanded perlite, a silica sol solution, plant fibers, calcium carbonate, a penetrant, a fire retardant, a waterproof agent, a pigment and any one of mirabilite, calcium chloride hexahydrate, n-caprylic acid and n-butyl stearate as phase-change materials. The preparation method comprises the following steps of stirring the ingredients to obtain a uniform mixture, paving the mixture, paving a non-woven fabric on the mixture, carrying out rolling by a rolling machine to obtain the flame-retardant waterproof phase-change energy-storage layer board, coating formaldehyde-free aqueous glue on the surface of the flame-retardant waterproof phase-change energy-storage layer, putting the solid-wood layer board on the flame-retardant waterproof phase-change energy-storage layer, putting the boards into a pre-pressing device, carrying out superposition pre-compression treatment on the solid-wood layer and the flame-retardant waterproof phase-change energy-storage layer so that the solid-wood layer tightly clings to the flame-retardant waterproof phase-change energy-storage layer, pushing the compounded board into a hot press, and carrying out hot pressing to obtain the flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board. The flame-retardant waterproof phase-change energy-storage formaldehyde-free solid-wood composite board solves the problem that in the existing composite board manufacture, formaldehyde content of used glue exceeds the limit, and has the advantages of energy saving, flame resistance and water resistance.

Owner:HENAN LINGDIAN CONSTR CO LTD

Antibacterial microporous PHA preservative film and preparation method thereof

Belonging to the technical field of high polymer materials, the invention relates to an antibacterial microporous PHA preservative film and a preparation method thereof. The preservative film comprises the following raw materials by weight: 100-120 parts of PHA resin, 8-15 parts of acetyl triethyl citrate, 6-8 parts of calcium carbonate, 8-12 parts of modified attapulgite, 0.5-2 parts of an antioxidant, 0.5-2 parts of n-butyl stearate, 1-3 parts of a titanate coupling agent, and 4-7 parts of chitosan. The preparation method involved in the invention is simple, and the prepared antibacterial microporous PHA preservative film product has stable structure and good air permeability, is biodegradable, and avoids the pollution of preservative films adopting ethylene masterbatch as the raw material to the environment.

Owner:WUJIANG YINGLIDA PLASTIC PACKAGING

High-temperature type peelable glue for processing machining protection, and preparation method thereof

High-temperature type peelable glue for processing machining protection, and a preparation method thereof relate to peelable glue. The invention provides high-temperature-resistant type peelable glue mainly applied for machining protection of glass of a cover plate of a touch screen and for processing machining protection in an OGS (One-Glass Solution) technology, and a preparation method of the peelable glue. The high-temperature-resistant type peelable glue for processing machining protection comprises the following raw materials: rubber, a crosslinking accelerant, EVA resin, n-butyl stearate, liquid oil, esters, calcium carbonate, silica, dye, a defoaming agent and a leveling agent. The preparation method of the high-temperature-resistant type peelable glue for processing machining protection comprises the following steps of: 1) evenly dispersing the rubber, liquid oil, ester, EVA resin and n-butyl stearate; 2) then adding the dye and filler, and evenly stirring; 3) grinding the materials obtained from the step 2); and 4) adding the crosslinking accelerant into the materials ground in the step 3); and 5) filtering to obtain the high-temperature-resistant type peelable glue for processing machining protection.

Owner:XIAMEN HOWER MATERIAL

Silt-sintered energy storage brick and production process thereof

InactiveCN107311620AHigh compressive strengthGood wear resistanceHeat-exchange elementsCeramic materials productionBrickFire retardant

The invention discloses a silt-sintered energy storage brick and a production process thereof. The energy storage brick comprises the following raw materials in parts by weight: 20-30 parts of urban silt, 20-35 parts of ceramsite, 50-80 parts of nano-sized calcium carbonate, 30-45 parts of paraffin, 60-85 parts of a clayey raw material, 2-8 parts of an inorganic flame retardant and 30-50 parts of a phase-change energy storage material, wherein the phase-change energy storage material comprises the following raw materials in parts by weight: 40-60 parts of Portland cement, 20-30 parts of fly ash, 5-10 parts of aluminum oxide and 30-45 parts of n-butyl stearate. A preparation method of the energy storage brick comprises the following steps: blending, mixing, performing hot pressing and firing by the conventional method. The energy storage brick has good compressive strength and abrasive resistance, is strong in corrosion resistance and heat storage and refrigeration capacity, fire-proof and flame-retardant, and has a certain economic benefit.

Owner:HEFEI FANTENG ENVIRONMENTAL PROTECTION TECH CO LTD

Method for manufacturing transparent PVC corrugated sheet

The invention provides a manufacturing method for a transparent PVC corrugated sheet which consists of PVC, single-n-butyl maleate dibutyltin, dibutyltin dilaurate, n-butyl stearate, stearic acid, and oxygen dihydroxy benzophenone tetracarboxylic; after being mixed at high speed, plasticized by two rollers, and calendered by three rollers into a film, the formula materials are heated at 145-160 DEG C, pressed and rolled into a wave shape by two corrugated shape steel rollers of a press corrugating machine, and finally cooled. The method has the advantages of easy used material drawing and simple method, light weight, flame resistance and high transparent degree for the manufactured products, and lower production cost.

Owner:韩燕

High-temperature-resistant peelable blue glue

InactiveCN105176403AGood film formingFit closelyConjugated diene hydrocarbon coatingsChloropene polymer coatingsPlasticizerPolyphenyl ether

The invention discloses high-temperature-resistant peelable blue glue.The high-temperature-resistant peelable blue glue comprises the following components in parts by weight: 25-35 parts of vinyl resin, 15-24 parts of n-butyl stearate, 20-30 parts of rubber, 5-12 parts of polyphenyl ether, 2-8 parts of a plasticizer, 1-6 parts of a defoaming agent, 2-7 parts of a flatting agent and 3-9 parts of an organic pigment. The high-temperature-resistant peelable blue glue prepared by the invention is good in film forming property; the surface of a hardened layer has a relatively good attaching property; and air bubble and warpage problems can be effectively improved. The film has good resistance to acid and base, and is easy to peel without residual glue on the surface of the material.

Owner:ZHONGSHAN BRK SPECIAL CHEM PROD

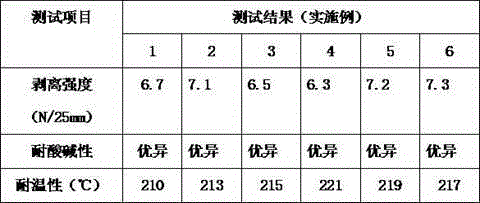

High ring crush compression strength modified calcium carbonate used for paper, and preparation method thereof

ActiveCN103510423ALarge specific surface areaGood ring compressive strengthInorganic compound additionDispersityPolyvinyl alcohol

The invention provides a high ring crush compression strength modified calcium carbonate used for paper. The modified calcium carbonate comprises following raw material ingredients, by weight, 95 to 100 portions of 325 meshes heavy calcium carbonate, 1 to 2 portions of polyoxyethylene stearates, 0.3 to 0.5 portions of soluble glass, 0.1 to 0.2 portion of triethylhexyl phosphoric acid, 0.1 to 0.3 portion of sodium dodecyl benzene sulfonate, 2 to 3 portions of phenolic resin, 0.1 to 0.2 portion of ammonium sulfate, 2 to 4 portions of n-butyl stearate, 0.2 to 0.4 portion of polyving akohol, 0.3 to 0.4 portion of poly(4-methyl-1-pentene), 0.1 to 0.3 portion of peregal O, 0.2 to 0.3 portion of hollow glass microbead, 0.1 to 0.2 portion of glass fibre and 0.2 to 0.3 portion of nano-titania. The preparation method comprises following steps, part of the raw material ingredients are mixed; calcium carbonate is dried, and is added into the mixed raw material ingredients; the rest raw material ingredients are added according to the ratio and a preset sequence; and the mixture is mixed fully in a high-speed mixed, is dried, and is grinded so as to obtain the modified calcium carbonate. The modified calcium carbonate is high in dispersity and ring crush compression strength, and can be used for boxboard paper so as to reduce cost and improve physical properties of boxboard paper, especially ring crush compression strength.

Owner:上海任谷实业有限公司

Foamed ceiling and preparation method thereof

The invention discloses a foamed ceiling and a preparation method thereof. The preparation method comprises the following steps: in parts by weight, weighing LDPE (low-density polyethylene), stearic acid, DOP (dioctyl phthalate), barium stearate, calcium carbonate, dibutyl tin dialurate, a flame retardant, n-butyl stearate, zinc stearate, dihydroxyl tetramethoxy diphenyl ketone, an antioxidant, triphenyl phosphate, an AC (azodicarbonamide) foaming agent, MBS (methyl methacrylate) and chlorinated paraffin, plastifying, discharging, foaming and performing mould pressing to obtain the foamed ceiling. According to the foamed ceiling, the relative density is 0.1-0.5, the bending strength is 8-12Mpa, the tensile strength is 1.8-2.2Mpa, the gap impact strength at 80 DEG C is 20-25kJ / m<2>, the break elongation rate is 240%-260%, the shore hardness is 45-65, and the vicat softening point is 90-110 DEG C.

Owner:湖北德居沃家新材料科技有限公司

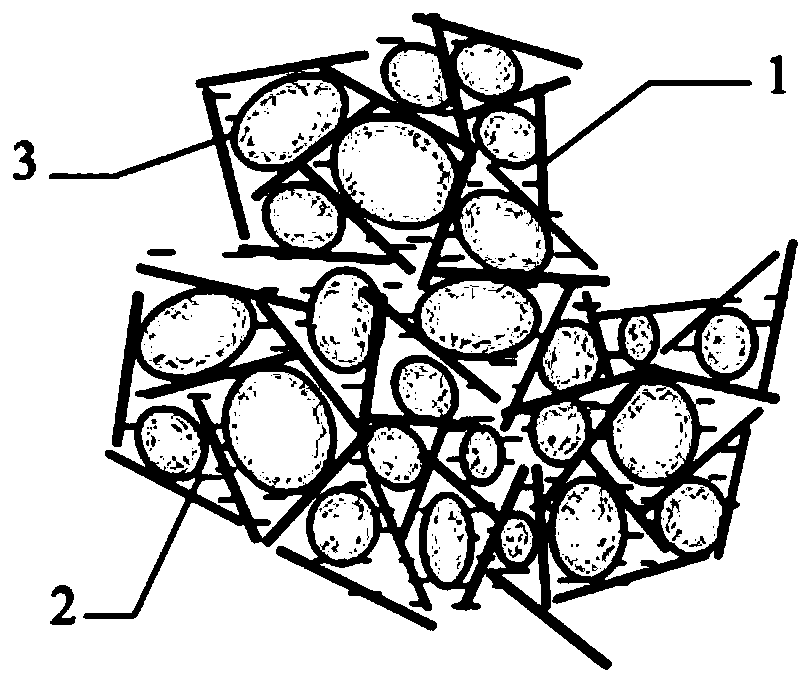

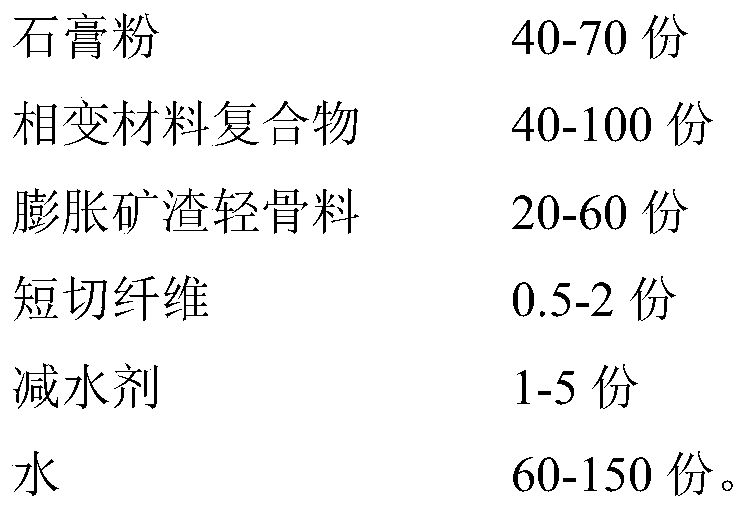

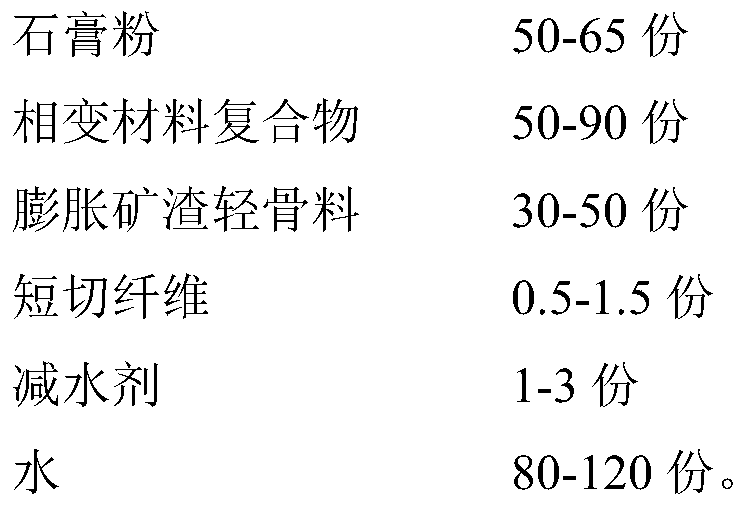

Phase change gypsum board for construction

PendingCN110092629AEasy to assembleHigh mechanical strengthPaper/cardboard layered productsConstructions elementsFiberSlag

The invention discloses a phase change gypsum board for construction. The gypsum board includes, by weight, 40-70 parts of gypsum powder, 40-100 parts of a phase change material compound, 20-60 partsof expanded slag lightweight aggregate, 0.5-2 parts of a chopped fiber, 1-5 parts of a water reducing agent, and 60-150 parts of water; the phase change material compound includes, by weight, 90-110 parts of a phase change material, 20-40 parts of montmorillonite, and 100-300 parts of water; the phase change material includes one or more of an aliphatic hydrocarbon compound, an alcohol compound oran ester compound; the aliphatic hydrocarbon compound is selected from one or more of N-hexadecane, n-octadecane or eicosane; the alcohol compound is selected from one or more of dodecyl alcohol, cyclohexanol, tert-butyl alcohol or neopentylene glycol; and the ester compound is n-butyl stearate. The gypsum board is good in product mechanical strength, large in energy storage density and suitablefor energy-saving insulation materials of assembly type buildings, and the fireproof grade of the gypsum board can reach an A1 grade.

Owner:GUANGDONG INST OF SCI & TECH

Recyclable graphene

The invention discloses recyclable graphene which comprises the following substances in parts by weight: 5-12 parts of benzoyl peroxide, 5-8 parts of silicon carbide, 3-5 parts of vanadium phosphorate, 3-6 parts of silver methacrylate, 11-16 parts of nonyl hexyl trimellitate, 10-17 parts of n-butyl stearate, 20-35 parts of polyethylene glycol benzoate, 20-26 parts of solution polymerized butadiene styrene rubber, 5-9 parts of a hexabromine water dispersion, 55-65 part of graphite and 65-81 parts of water. The process is simple and can be performed in multiple polar solvents, the prepared recyclable graphene is good in quality, and a graphene quantum dot for peeling assistance can be recycled.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

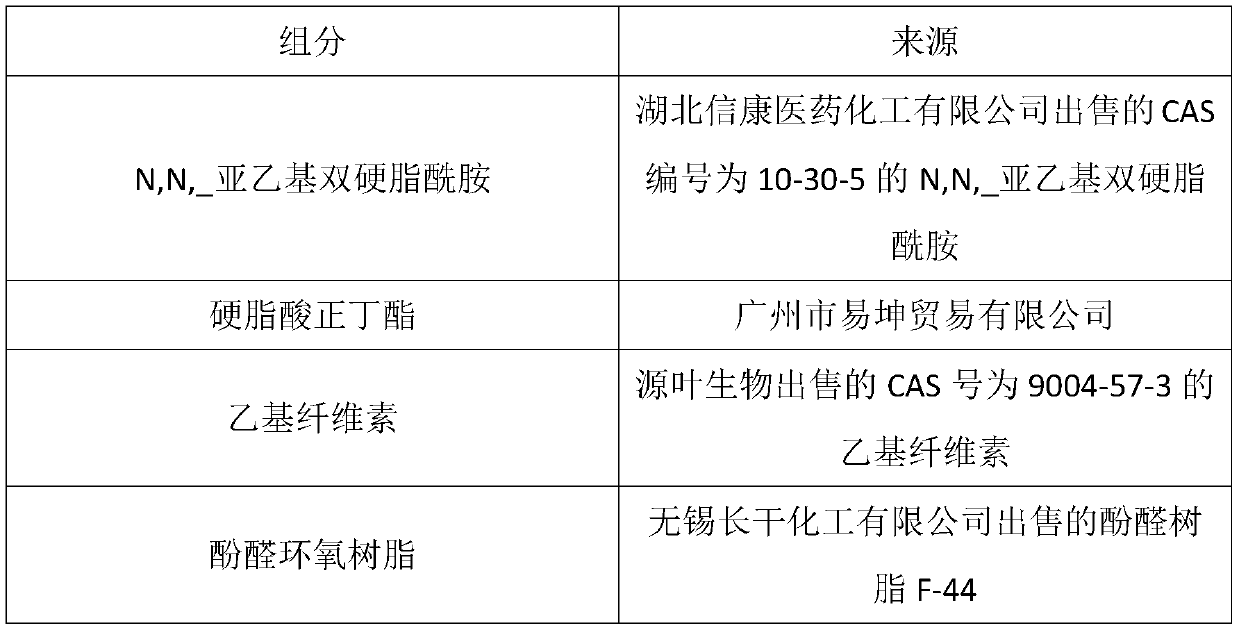

Warm-mix modifier and preparation method thereof

InactiveCN110643077AReduce brittlenessImprove impact resistanceBuilding insulationsCellulosePolymer science

The invention discloses a warm-mix modifier and a preparation method thereof. According to technical main points in the invention, the warm-mix modifier comprises the following raw materials in partsby weight: 25 to 56 parts of N,N'-ethylene bis-stearamide, 18 to 35 parts of n-butyl stearate, 16 to 36 parts of ethyl cellulose, 15 to 35 parts of an aromatic hydrocarbon oil compatilizer and 12 to 30 parts of a flexibilizer. The preparation method comprises the following steps: mixing N,N'-ethylene bis-stearamide liquid, n-butyl stearate liquid, ethyl cellulose liquid, the aromatic hydrocarbon oil compatilizer and the flexibilizer to obtain a liquid mixture; and cooling the liquid mixture to a viscous state, carrying out granulating, then performing airing at normal temperature, carrying outcrushing, then performing sieving with a 15-to-20-mesh sieve, and taking a undersize product to obtain the warm-mix modifier. The warm-mix modifier disclosed by the invention can effectively reduce the mixing temperature of an asphalt mixture, so the problems of energy consumption and increase of the emission of wastes such as smoke and dust during production of the asphalt mixture are solved; and the warm-mix modifier can be smoothly constructed in winter with a relatively low environment temperature, and the toughness, cohesiveness and the like of the asphalt mixture are not excessively influenced.

Owner:江苏路耐德交通科技有限公司

Modified hard polyvinyl chloride film

The present invention discloses one kind of improved R-PVC film prepared through material intermingling process. The film consists in weight portions of PVC resin 100, DOP 3-5, 8831 material 1.5-2.2, composite liquid calcium-zinc stabilizer 1.5-2.0, MBS resin 4-6, n-butyl stearate 1.0-1.5, polyoxyethylene 0.8-1.2, ACR-401 2.0-3.0, EVA chloride 1.0-2.0 and D80X or S-18 1.0-2.0. The EVA chloride may be replaced by EVA at most 50%. The film has hot sealing temperature of about 140 deg.c and surface resistivity of 10 to the power 11 ohm.cm, and may be used in packing candy, food, medicine, costume and cigarette.

Owner:邵万春 +2

Automobile brake pad made from semimetal composite material

InactiveCN110657183AReduce wear rateImprove thermal shock resistanceOther chemical processesFriction liningCarbon fibersMixed materials

The invention relates to the technical field of manufacturing of automobile brake pads, in particular to an automobile brake pad made from a semimetal composite material. The automobile brake pad is prepared from the following raw materials: steel fibers, iron powder, tantalum powder, barite, modified phenolic resin, nano graphite, white carbon black, carbon fibers, graphite powder, n-butyl stearate, a carbon nanotube and basalt fibers. A preparation method comprises the following steps: first, crushing the modified phenolic resin; dissolving the modified phenolic resin into a phenolic ethanolsolution by ethanol; then successively adding various powder; uniformly mixing the powder and putting the mixture in an oven to be thermally treated for 1-2 hours at 60-90 DEG C; after drying, putting the mixed material in a brake pad mold to be thermally pressed for 10-20 minutes at 160-180 DEG C, wherein the pressing pressure is 20-30 MPa; and after thermal pressing, carrying out mold stripping, cooling and packaging to obtain the brake pad. The brake pad overcomes the problem that a brake fails as an existing semimetal brake pad braking frequently is at a high temperature and is overheatedto deform and has stable friction coefficient, excellent thermal shock resistance and high-temperature friction performance.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

Easy-to-degrade antioxidation multilayer composite preservation film

InactiveCN108656681AImprove the preservation effectImprove structural strengthSynthetic resin layered productsFlat articlesEnvironmental resistancePolymer science

The invention relates to the technical field of packaging films, in particular to an easy-to-degrade antioxidation multilayer composite preservation film which comprises a structural layer, a light shading layer and a sealing layer. The sealing layer is made of polyethylene or polyvinylidene chloride, the structural layer is made of an easy-to-degrade biofilm and composed of PHA resin, polyvinyl alcohol, acetyl triethyl citrate, n-butyl stearate, chitosan, nano silicon dioxide, monoalkoxy titanate coupling agent, plasticizer and film forming aid, the light shading layer is made of black polyvinyl chloride, and a thickness ratio of the structural layer, the light shading layer and the sealing layer is 4:1:1. The preservation film can preserve food through sealing and shading, so that food preservation effect is improved; the preservation film is higher in degradability and more environment-friendly.

Owner:HEFEI JINTONGWEI LOW TEMPERATURE TECH CO LTD

High-barrier degradable packaging material and preparation method thereof

InactiveCN106496967AImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersGlycerolMechanical property

The invention provides a high-barrier degradable packaging material and a preparation method thereof. The preparation method comprises the following steps that 1, 2,6-naphthalic acid glycol ester, polypropylene carbonate, polycaprolactone, petroleum resin, an ethylene-ethenol copolymer, sodium-based montmorillonite, nano titanium dioxide, chitin and hydroxypropyl methyl cellulose are mixed and are stirred with a high-speed mixer; 2, erucyl amide, n-butyl stearate, castor oil and glycerol are added, and stirring continues by using the high-speed mixer; 3, the mixture is charged into a double-screw extruder for extrusion and granulation; 4, blow-molding is performed with a blow-molding machine after cooling. The high-barrier degradable packaging material has good mechanical properties, excellent barrier performance, meanwhile has good degradation performance and is green and environmentally friendly.

Owner:汕头市东发印务有限公司

High temperature tolerant paint

InactiveCN104927436AImprove high temperature resistanceImprove water resistanceCoatingsXylylenePolymer science

A high temperature tolerant paint is made from, by weight, 4 to 8 parts of tritolyl phosphate, 3 to 7 parts of clay gel, 8 to 14 parts of tung oil, 5 to 7 parts of linseed oil, 9 to 16 parts of thinner, 20 to 25 parts of antistatic agent, 4 to 6 parts of leveling agent, 25 to 36 parts of matrix resin, 8 to 12 parts of ethyl acetate, 14 to 17 parts of xylene, 6 to 15 parts of maleic acid diethyl ester, 4 to 8 parts of phenoxy carboxylic acid, 20 to 26 parts of thermoplastic polyimide, 15 to 22 parts of diatomite, 20 to 30 parts of styrene butadiene rubber, 4 to 8 parts of n-butyl stearate, and 10 to 24 parts of methyl malonate. The high temperature tolerant paint is excellent in high temperature tolerance and water tolerance, good in construction stability, high in wear resistance, and widely applicable.

Owner:QINGDAO ENGAO MOTION CONTROL TECH

Heat tracing cable sheath material capable of preventing growth of mildew and preparation method of heat tracing cable sheath material

InactiveCN104448472AImprove anti-mold and anti-bacterial propertiesGuaranteed efficient growthPlastic/resin/waxes insulatorsInsulated cablesPhosphateStearic acid

The invention discloses a heat tracing cable sheath material capable of preventing growth of mildew and a preparation method of the heat tracing cable sheath material. The heat tracing cable sheath material is prepared from the following raw materials in parts by weight: 35-55 parts of ultra-high molecular weight polyethylene, 22-34 parts of nylon 11, 17-26 parts of a cyclic olefin copolymer, 10-15 parts of germanite powder, 8-14 parts of tourmaline powder, 5-10 parts of tetrachloroisophthalonitrile, 6-12 parts of dicyclohexyl phthalate, 2-4 parts of zinc undecylenate, 3-6 parts of tri(2,3- dibromopropyl)isotriazinetriol ester, 10-15 parts of organic bentonite, 5-7 parts of n-butyl stearate, 1-2 parts of caprylic-capric neodymium, 2-3 parts of cadmium laurate, 4-8 parts of ammonium fluoroborate, 5-10 parts of tri(2-chloroethyl)phosphate, 1-2 parts of dodecyl dimethyl benzyl ammonium bromide and 3.5-5.5 parts of an aid. The heat tracing cable sheath material has excellent mildew-proof and antibacterial property and is capable of preventing the growth, generation and breeding of the mildew at a humid environment, so that a heat tracing cable cannot be encroached by the mildew; meanwhile, the heat tracing cable sheath material has excellent weather resistance, heat resistance, fire resistance and corrosion resistance, so that the service life of the cable is greatly prolonged, a lot of unnecessary losses can be avoided, and the use coat of the cable is lowered.

Polystyrene transparent color master batch and preparation method thereof

The invention provides a polystyrene transparent color master batch. The polystyrene transparent color master batch comprises, by mass, 40-50% of polystyrene resin, 10-20% of a coloring agent, 8-15% of polyethylene wax, 0.5-1% of turpentine, 1-5% of azodicarbonamide, 2-6% of pentaerythritol ester, 2-6% of calcium stearate and 0.5-1% of n-butyl stearate. The invention also discloses a preparation method of the polystyrene transparent color master batch. The adopted raw material polystyrene resin and the colorizing agent have high transparency, the polyethylene wax can improve the internal fluidity of the color master batch, the calcium stearate and turpentine are used in cooperation to increase the gelatinization speed of the color master batch, the n-butyl stearate can improve the plasticizing efficiency of the color master batch, azodicarbonamide is arranged to make the prepared color master batch good in elasticity, uniform in foam hole diameter and good in strength, and the pentaerythritol ester is nontoxic and harmless, and improves the oxidation resistance of the color master batch, so that the high-strength color master batch is prepared.

Owner:安徽缤飞塑胶科技有限公司

Residual glue-free peelable blue glue after peeling and preparation method therefor

The invention discloses residual glue-free peelable blue glue after peeling and a preparation method therefor. The blue glue comprises the following components in parts by weight: 25-35 parts of inyl chloride-vinyl acetate resin, 20-30 parts of modified epoxy resin, 8-18 parts of n-butyl stearate, 5-12 parts of silicon dioxide, 2-8 parts of a plasticizer, 3-9 parts of a thixotropic agent, 1-5 parts of a pigment, 5-15 parts of nano filler and 4-10 parts of a defoaming agent. According to the residual glue-free peelable blue glue after peeling prepared by the preparation method disclosed by the invention, the tensile strength of a film after curing is high; the film is not worn if being peeled; the blue glue can be easily peeled from the surface of an adherend; and the peeled adherend is free of residual glue on the surface. The blue glue disclosed by the invention is free of organic solvents and free of solvent volatilization during curing, is environmental-friendly, and is simple in preparation process, low in production cost and easy to produce in a large scale.

Owner:ZHONGSHAN BRK SPECIAL CHEM PROD

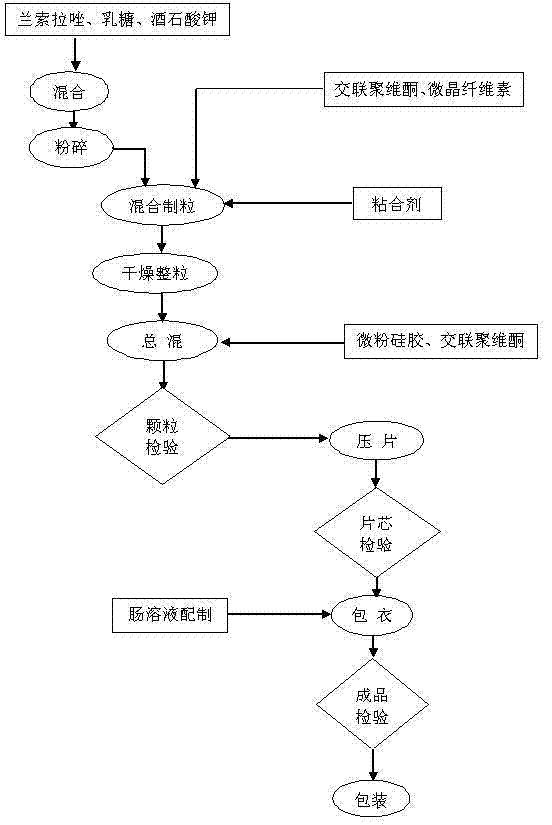

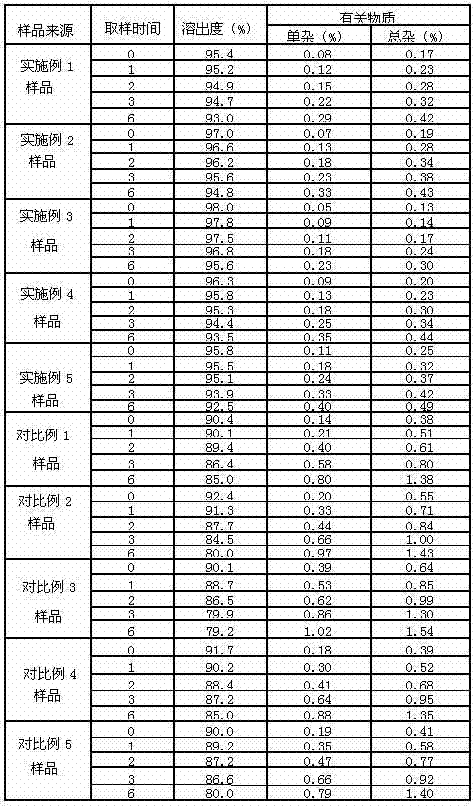

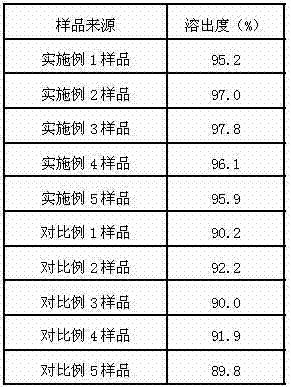

Preparation method of pharmaceutical composition for treating digestive system disease

InactiveCN104739802AEasy to prepareSuitable for mechanized productionOrganic active ingredientsDigestive systemDiseaseHypromellose phthalate

The invention discloses a preparation method of a pharmaceutical composition for treating a digestive system disease. The preparation method comprises the following steps: preparing a tablet core from the medical components, such as lansoprazole, lactose, microcrystalline cellulose, sodium potassium tartrate, polyvinylpolypyrrolidone, povidone K30, 95% ethyl alcohol, polysorbate 80 and superfine silica powder by wet granulation; and then coating the tablet core with hydroxypropyl methylcellulose phthalate, n-butyl stearate, talcum powder and 95% ethanol to prepare an enteric coated tablet. Through screening by a lot of experiments, coating materials hydroxypropyl methylcellulose phthalate and n-butyl stearate are combined; and the sodium potassium tartrate in the tablet core is added, so that an isolating layer does not need to coat between an enteric coat layer and the tablet core; the preparation technology is simplified; the production cost is reduced; and acceleration test and long-term test results show that compared with the prior art, the lansoprazole enteric coated tablet prepared by the preparation method has the advantages of good stability, high dissolution degree and low impurity content.

Owner:崔银方

Flame retardant foaming material with low water absorption

The invention discloses a flame retardant foaming material with low water absorption. The flame retardant foaming material is characterized by comprising the following substances in parts by weight: 3.5-4.9 parts of nano calcium carbonate, 12-25 parts of synthetic plant ester, 10-15 parts of glass beads, 5.5-6.4 parts of ground calcium carbonate, 5-13 parts of brominated epoxy resin, 26-47 parts of expanded graphite, 3-11 parts of butyl octade, 11-24 parts of dicyclopentadienyl iron, 21-35 parts of butyl stearate, 45-64 parts of acrylonitrile-butadiene-styrene copolymer and 25-40 parts of oleic acid. According to the invention, the foaming material has excellent flame retardant effect and also keeps the advantages such as thermal insulation, light weight and low water absorption.

Owner:QINGDAO HUA CHENG TIAN MACHINERY MFG

A kind of high-barrier degradable packaging material and preparation method thereof

InactiveCN106496967BImprove mechanical propertiesImprove barrier propertiesFlexible coversWrappersGlycerolMechanical property

The invention provides a high-barrier degradable packaging material and a preparation method thereof. The preparation method comprises the following steps that 1, 2,6-naphthalic acid glycol ester, polypropylene carbonate, polycaprolactone, petroleum resin, an ethylene-ethenol copolymer, sodium-based montmorillonite, nano titanium dioxide, chitin and hydroxypropyl methyl cellulose are mixed and are stirred with a high-speed mixer; 2, erucyl amide, n-butyl stearate, castor oil and glycerol are added, and stirring continues by using the high-speed mixer; 3, the mixture is charged into a double-screw extruder for extrusion and granulation; 4, blow-molding is performed with a blow-molding machine after cooling. The high-barrier degradable packaging material has good mechanical properties, excellent barrier performance, meanwhile has good degradation performance and is green and environmentally friendly.

Owner:汕头市东发印务有限公司

High weathering flame-retardant decorative coating and preparation method thereof

InactiveCN109294358AHigh limiting oxygen indexImprove flame retardant performanceFireproof paintsEpoxy resin coatingsAcrylic resinAntimony trioxide

The invention provides a high weathering flame-retardant decorative coating and a preparation method thereof. The coating is prepared from the following raw materials in parts by weight: 20-40 parts of hydroxy acrylic resin, 12-20 parts of carboxyl-type vinyl chloride-vinyl acetate resin, 15-30 parts of bisphenol A type epoxy resin, 10-30 parts of glycine, 5-10 parts of isopropylamine sodium dodecyl benzene sulfonate, 7-12 parts of magnesium hydroxide, 4-10 parts of antimony trioxide, 6-13 parts of a nano-enhancer, 3-8 parts of gamma-aminopropyltriethoxysilane, 8-15 parts of tetrabromobisphenol S bis(2,3-dibromopropyl)ether, 2-5 parts of polyoxyethylene polyoxypropylene ether block copolymer, 1-4 parts of polydimethylsiloxane, 3-6 parts of n-butyl stearate, 2-7 parts of microcrystalline paraffin, 10-20 parts of isopropanol, and 20-50 parts of water. The coating prepared by the invention has the dual properties of flame retardation and high weather resistance, so the coating has broad application prospects.

Owner:SUZHOU INST OF TRADE & COMMERCE

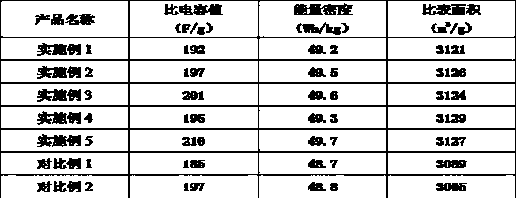

Preparation method for composite material for energy storage elements

The invention provides a preparation method for a composite material for energy storage elements, which includes the following steps: (1) graphene oxide, meso-erythritol, coniferyl alcohol, tea cake meal, lignin, xylan, lactose and distilled water are mixed and stirred; (2) mixture is loaded into a hydrothermal reaction kettle and heated, and temperature is kept; (3) the mixture is cooled to room temperature, filtered, washed to be neutral and dried, so that a product A is obtained; (4) the product A, potassium hydroxide, sodium hydroxide and distilled water are mixed and stirred; (5) sucrose fatty acid ester, quillaic acid, quercetin, paraben, propylgallate, n-butyl stearate and isopropanol are mixed and stirred; (6) the mixtures are mixed, put into a tube furnace and sintered; (7) the sinter is cooled to room temperature, washed to be neutral and dried, so that the composite material is obtained. The specific capacitance value of the material prepared by the method disclosed by the invention is extremely high, the energy density is much higher than the energy density of conventional energy storage elements, the efficiency of discharge is high, moreover, the composite material can show good cycle stability, and the repetition utilization rate is high.

Owner:原晋波

Spandex for paper diapers with improved unwinding and creep properties and production method thereof

ActiveCN107502978BIncrease the constant elongation stressHigh elongation stressMonocomponent synthetic polymer artificial filamentArtifical filament manufactureCarbon monofluorideMagnesium stearate

The invention discloses a spandex with improved backing-off property and creep property for a paper diaper and a production method thereof. Thermoplastic polyurethane which accounts for 3-35% of the spandex by weight percent and cellulose acetate butyrate or cellulose acetate propionate which accounts for 0.5-2.0% of the spandex by weight percent or a mixture of the two, as well as an internal lubricant and external lubricant composition which accounts for 0.3-5.0% of the spandex by weight percent, are added into a polyurethane-urea stock solution, and drying spinning is performed to prepare a polyurethane elastic fiber, wherein an internal lubricant is one or more of n-butyl stearate, oleamide, ethylene bis stearamide and amino silicon oil; and an external lubricant is one or more of talcum powder, carbon monofluoride and magnesium stearate. The prepared spandex has favorable backing-off property and creep property, can be effectively applied to the field of elastic materials of paper diapers, and meanwhile, is suitable for two modes of rotary backing off and axial backing-off.

Owner:ZHEJIANG HUAFENG SPANDEX

A kind of capacitor element composite material and preparation method thereof

ActiveCN105632782BHigh specific capacitanceImprove discharge efficiencyHybrid capacitor electrodesHybrid/EDL manufactureDischarge efficiencyCapacitance

The invention provides a capacitor element composite material and a preparation method thereof. Its preparation method is as follows: (1) Mix and stir graphene oxide, xylitol, lignin, sucrose and distilled water; (2) Put it in a hydrothermal reaction kettle and keep it warm; (3) Cool to room temperature, filter, and wash with distilled water to neutrality; (4) dry in an oven to obtain product A; (5) mix and stir product A, potassium hydroxide, sodium hydroxide and remaining distilled water; (6) mix tea saponin, sorbic acid, butylated hydroxyl Mix and stir anisole, 2,6-di-tert-butyl-p-cresol, n-butyl stearate and isopropanol; (7) Mix the above mixture and sinter in a tube furnace; (8) Cool to room temperature , washed with concentrated hydrochloric acid and distilled water successively until neutral; (9) put it in an oven and dry it. The capacitor element composite material of the invention has very high specific capacitance value and energy density, high discharge efficiency and excellent cycle stability.

Owner:东莞怡德电子有限公司

A kind of foam ceiling and preparation method thereof

The invention discloses a foamed ceiling and a preparation method thereof. The preparation method comprises the following steps: in parts by weight, weighing LDPE (low-density polyethylene), stearic acid, DOP (dioctyl phthalate), barium stearate, calcium carbonate, dibutyl tin dialurate, a flame retardant, n-butyl stearate, zinc stearate, dihydroxyl tetramethoxy diphenyl ketone, an antioxidant, triphenyl phosphate, an AC (azodicarbonamide) foaming agent, MBS (methyl methacrylate) and chlorinated paraffin, plastifying, discharging, foaming and performing mould pressing to obtain the foamed ceiling. According to the foamed ceiling, the relative density is 0.1-0.5, the bending strength is 8-12Mpa, the tensile strength is 1.8-2.2Mpa, the gap impact strength at 80 DEG C is 20-25kJ / m<2>, the break elongation rate is 240%-260%, the shore hardness is 45-65, and the vicat softening point is 90-110 DEG C.

Owner:湖北德居沃家新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com