Heat tracing cable sheath material capable of preventing growth of mildew and preparation method of heat tracing cable sheath material

A technology of heat tracing cable and sheath material, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of affecting the performance of heat tracing cables, poor anti-fungal properties, etc., and achieve excellent weather resistance, prolong service life, and avoid losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

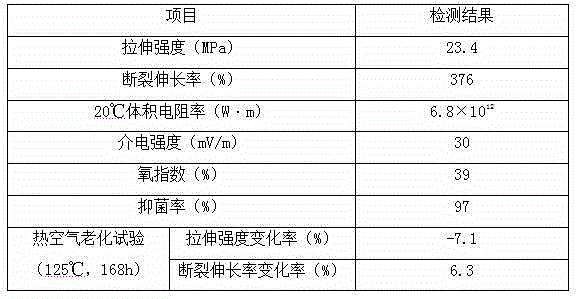

[0013] A kind of anti-mold growth heating cable sheath material, made of the following raw materials (kg): ultra-high molecular weight polyethylene 45, nylon 11 28, cycloolefin copolymer 23, germanium stone powder 12, tourmaline powder 10, Tetrachloroisophthalonitrile 7, dicyclohexyl phthalate 9, zinc undecylenate 3, tris(2,3-dibromopropyl) isocyanurate 4.5, organic bentonite 12, stearin N-Butyl Acetate 6, Neodymium Octanoate 1.5, Cadmium Laurate 2.5, Ammonium Fluoroborate 6, Tris(2-Chloroethyl) Phosphate 8, Dodecyl Dimethyl Benzyl Ammonium Bromide 1.5, Additives 4.5;

[0014] The preparation method of the auxiliary agent is as follows: (1) Take the following raw materials by weight (kg): thiourea dioxide 2.5, calcium sulfite 7, chlorobridge anhydride 4.5, flue ash 13, ethylhexyl palmitate 3, succinic acid Diethyl ester 6, aluminum titanate 8, methacrylic acid chromium chloride complex 2.5, sucrose benzoate 4, dibutyl maleate 8, lanolin 4.5; (2) calcium sulfite, titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com